For decades, Babbitt bearings have provided anything from rotary support to reciprocating bushings, making them a fundamental component of any machine. What about the babbitt bearing makes it so particular? Out of their specific makeup, being an integral part of the working of different industrial systems, the Babbitt bearings form the main elements of their operation. Here is an overview of the most essential facts that one does not know about Babbitt bearings and their composition, different examples of their application as well as practical approaches in terms of their servicing. It does not matter whether you work in such industries or would like to learn more about them as a hobby; this resource will give you tips on how to increase your use and service time with this incredible type of bearing.

Understanding Babbitt Bearings

Babbitt bearings are bearings consisting of an alloy of Babbitt, which is made mainly of tin, lead, or a mixture of copper and antimony. Such bearings are known for enabling smoother movement of heavy equipment or machinery by reducing friction. Babbitt bearings wear down over time due to their soft metal surface and do not damage equipment. They are prevalent in electric motors, turbines, compressors, heavy equipment, and similar mechanisms that operate at high speeds. To maximize bearings’ useful life and efficiency, timely replacement and proper operation are essential.

What are Babbitt Bearings?

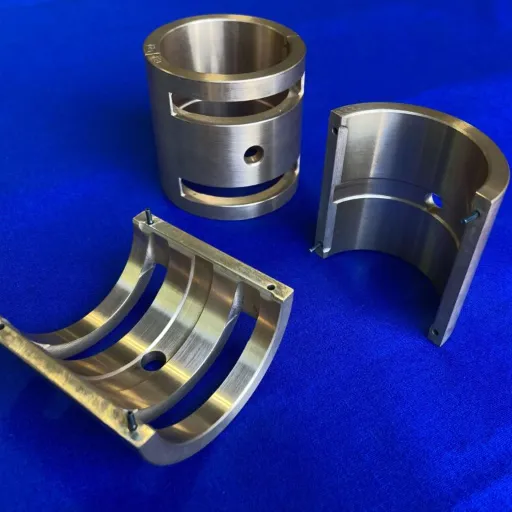

A Babbitt bearing is a type of plain bearing with a lining of Babbitt metal, which is an alloy that is soft, white, and usually composed of mainly tin or lead combined with small quantities of antimony, copper or other metals in some cases. This type of bearing reduces friction between moving parts, making it useful in industrial settings. The soft Babbitt metal serves as a sacrificial layer to protect the larger parts from damage, even at high speeds or under load.

Historical Note: These bearings, which are named after Isaac Babbitt, who in the year 1839 was the inventor of babbitt metal, are extensively applied in electric motors, turbines, compressors, marine engines, and heavy industrial machinery.

Several modern technological developments have refined alloy composition, lubrication systems, and maintenance practices, improving the performance of Babbitt bearings. Featuring properties that enable them to embed particles, fit the shafts, and also absorb small misalignments, these bearings are particularly useful where high performance is an essential requirement. Although several materials can be used as bearings instead of Babbitt, most Babbitt bearings are still preferred because they offer exceptional longevity, are easy to maintain, and have proven their ability to prolong machine service intervals.

Composition of Babbitt Alloys

Babbitt bearing alloy, known as Babbitt Metal, is a term for metals used in bearings, mostly made from tin or lead, with a range of compositional additions, including antimony, copper, and even arsenic or other elements, to improve their properties.

Key Compositional Elements:

- Tin Babbitt: Copper (3-8%) and Antimony (4-8%) to increase hardness and solidity

- Lead Babbitt: Antimony (4-15%) and Tin (5-10%) to increase wear resistance and load-carrying ability

Because, in practice, babbitt alloys are designed to minimize frictional forces and to provide high conformity and embedment during machine operation, the chemical composition is tailored to each application.

Comparison with Other Bearing Types

Babbitt bearings differ from other bearing types such as ball bearings, roller bearings, and plain bearings in terms of material, lubrication, load capacity, friction, and maintenance.

| Key Point | Babbitt Bearing | Ball Bearing | Roller Bearing | Plain Bearing |

|---|---|---|---|---|

| Material | Soft alloy | Steel | Steel | Various |

| Lubrication | Essential | Minimal | Minimal | Depending |

| Load Capacity | Moderate | High | Very High | Moderate |

| Friction | Low | Moderate | Low | Varies |

| Maintenance | Regular | Less frequent | Less frequent | Occasional |

Applications of Babbitt Bearings Across Industries

⚡ Power Generation

Incorporated in turbines and generators quite frequently as they are capable of dynamic load variations and are easy to employ.

🚢 Marine Industry

Installed in the propulsion as well as other support mechanisms in ships, as the performance is long-standing and good operating characteristics do not require weight constraints.

🛢️ Oil and Gas Sector

Found in most compressors and pumps for better load bearing and less friction wear at high pressures.

🚗 Automotive Industry

Constructed in the engines and heavy equipments to prevent damage due to friction and facilitate the rotation of mechanisms.

🏭 Steel and Manufacturing Plants

Incorporated in rolling mills and machinery to make sure that they function efficiently even in harsh weather.

Power Generation: Utilizing Babbitt Bearings for Efficiency

Babbitt bearings are highly relevant in power plants because they enable the reliable operation of rotating machinery such as turbines and electric generators. It has low friction, compacts and adjusts to extreme working conditions, can carry heavy loads, reduces the frequency of service repairs, and assures its operation. This is because Babbitt bearings prevent friction-related wear and tear, facilitating the smooth operation of turbogenerating equipment and increasing output, extending the lifecycle of energy-generating equipment, and helping keep output levels high.

Marine Applications: The Role of Babbitt in Ship Machinery

The efficiency and effectiveness of use, particularly in marine applications, highly depend on the condition and functionality of Babbitt bearings. These robust bearings are used in the propulsion system — propeller shafts and auxiliary engines — and in the pumps, which, while operating under the harshest and most demanding sea conditions, do not compromise on the quality of service delivery.

Babbitt bearings, however, have a unique ability to withstand the varying loads and speeds encountered in these settings without excessive friction. In addition, they incorporate bearing material with properties that allow it to slide, reducing wear and tear, leading to less frequent repairs and maintenance and an extended service life for the machinery. By improving the operation of ship machinery, babbitt bearings help ensure that marine vessels are safe and efficient during their journeys.

Heavy Machinery: Benefits of Babbitt Bearings in Construction Equipment

- Long Life and Wear Removal: Special construction for babbitt bearings is designed to provide long life and withstand heavy loads and long working cycles in construction equipment.

- Self-Emulsifying Features: These self-lubricating properties prevent friction from increasing and machinery parts from wearing out quickly, thereby increasing the useful life of such equipment.

- Anti-Shock Characteristic: Babbitt bearings are designed to easily absorb shocks at high speed and damp vibrations and temporary pulsations, providing smooth action even under extreme operational conditions.

- Maintenance Efficiency: Bearings have been designed to minimize the cost of performance and time since they pay less attention to servicing, such as specific performance, healthy functioning, and uninterrupted work on a construction site.

- Economic Feasibility: Babbitt bearings reduce component wear and repair frequency, making the construction machine more dependable and cost-efficient.

Benefits of Babbitt Bearings

A Babbitt bearing is beneficial in many ways: it has a long service life, can absorb impact and vibrations, and requires little maintenance, thus facilitating operations and cutting costs during equipment standstill. Other than that, they are economical because they reduce the depreciation rate of components, therefore extending their operating time. These features render Babbitt bearings the best devices in enhancing safety during severe construction operations.

Superior Load-Bearing Capacity of Babbitt Alloys

Babbitt alloy bearings can withstand high loads due to their excellent structure and seizure resistance. This helps avoid concentrating stress at a single point on the component and limits wear on the element. These materials also have the advantage of self-lubrication and, consequently, are ideal for operating under heavy loads and for handling heat and friction. All these qualities of babbitt bearing enhance its stability and usability when operating under uncontrolled industrial conditions.

Embeddability: Enhancing Performance and Longevity

Babbitt bearings are popular for their high embeddability, and this significantly contributes to their use and durability. Embeddability is the capacity of a bearing to take foreign materials into itself and encase them in its soft material, without causing much harm to the equipment where it operates.

Key Advantage: In many industries, this feature is critical for preventing contamination, which is challenging to eliminate in such environments, even with filtration. Therefore, embedding these particles into the Babbitt layer provides a solution, as it decreases the chances of shaft or, more importantly, score or scoring the component, leading to substantial component damage. It translates into improved functionality and longer replacement intervals, and eventually these contribute to reliability and financial benefits.

Corrosion Resistance and Durability

Babbitt bearings are commonly used in harsh working conditions due to their excellent corrosion resistance and exceptional durability. These are very special types of bearings because they function well despite exposure to factors such as moisture, chemicals, and abrasives that would otherwise weaken conventional materials.

Babbitt bearings feature corrosion-resistant materials, thereby prolonging equipment service life and minimizing component failures. Not to be outdone, their rigid construction ensures they do not cave in when operating at lower loads and in oil-free applications at higher temperatures in the heavy engineering industries. This integrated approach to corrosion-resistant properties and durability has consistently made babbitt bearings indispensable in industries where system performance and conservation are paramount.

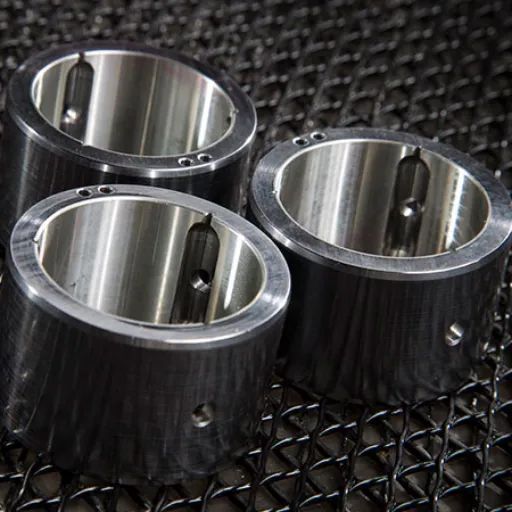

Manufacturing Process of Babbitt Bearings

The manufacturing process for Babbitt bearings can be exemplified in a set of manufacturing procedures to achieve high precision:

- Preparation of Bearing Shell – the steel, and most commonly the bronze casing, is cleaned and prepared for adhesion of the babbitt coating.

- Melting and Application of Babbitt Alloy – The babbitt metal is melted at the appropriate temperature, then poured to form an even layer on the prepared bearing shell.

- Turning and Dressing – The bearing is worked to a final shape with the required dimensions to ensure a smooth fit.

- Examination and Quality Assurance – The manufactured bearing used for measurements and non-destructive methods to check its integrity undergoes several inspections.

Such an approach implies that every single babbitt bearing produced is capable of withstanding the strenuous conditions associated with the industrial service.

Material Selection for Optimal Performance

It is more of a rule than a necessity that, when it comes to babbitt bearings, proper lubrication guarantees efficiency and functional cleanliness. Careful attention is given to selecting high-quality basic materials for Babbitt alloy forgings, which are Babbitt in its enriched form, with metal proportions (tin, lead, antimony, copper) that ensure no slippage. Babbitt, which is made of tin, is used in high-stress, well-oiled elements. On the other hand, babbitt alloy containing lead is appropriately used for mild acceleration and short lengths. Babbitt bearings can be specifically made to meet working conditions, thereby enabling longer, more reliable bearing performance.

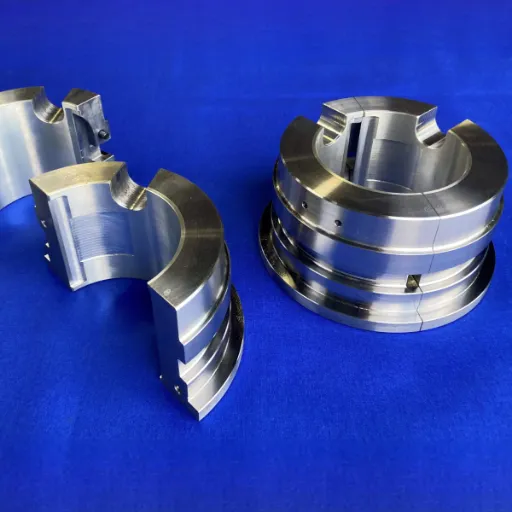

Techniques in Casting Babbitt Bearings

Babbitt bearing. To produce babbitt bearings of a high standard, the casting process must be followed accordingly. Initially, it is necessary to carry out proper cleaning and preparation of the bearing shell, tinning of the shell and heating of the shell before application of the babbitt. Afterward, the babbitt is melted and kept within the pouring range of 370°C to 400°C (700°F to 750°F). Afterward, the metal is poured into the prepared cavity or onto the bearing shell itself, commonly using centrifugal or gravity casting to evenly distribute it.

🌡️ Critical Temperature Range

Melting Temperature: 370°C to 400°C (700°F to 750°F)

The metal usually needs to cool gradually after it is cast in place to reduce shrinkage or prevent internal stress. Once this is achieved, the bearing surfaces are radially finished, then carefully scraped and polished to fit the shaft correctly. Each step in assembling the bearing should include quality control to prevent any workmanship and to make every effort to extend the lifespan of these components. In this way, it is possible to fabricate such elements, such as engines and other machinery, without reliability issues as long as proper techniques are used and a suitable babbitt alloy is selected.

Machining Processes and Quality Control

Babbitt bearings are machined in a way that significantly enhances tolerance and performance targets by using specific variables and methods. The processes used in this situation include turning, milling, and sharpening the most worn-out years in significant activities, and working on the bearing enclosure seams. In production, these new Numerical Control (NC) devices are used to ensure the product has four-and-a-half-dimensional accuracy. Finally, after the completion of machining, the material is subjected to non-destructive testing or NDT such as ultrasonic or liquid penetrant inspections, which reveal defects in the material in the form of cracks and voids.

Another aspect of the machining and finish scope is the extensive quality assurance measures. The issue of quality is handled by a considerable inspection of sizes and surfaces and most importantly, documentation of every parameter’s history is kept. Using the most advanced precision instrumentation, production meets or exceeds bearing requirements.

Provided with techniques for specialized component finishing and control of dimensions and surface quality, ensure that the babbitt bearing will exhibit a long-term service life and outstanding performance even in challenging application areas.

Maintenance and Repair of Babbitt Bearings

It is essential to ensure proper servicing and timely correction of babbitt bearings to enhance their lifespan and achieve their full potential. Necessity to carry out scheduled checks to note any contributing factors leading to wear, such as fracturing, the presence of scores found on the bore, or excessive heat. The lube system should also be kept in efficient condition to avoid the entry of foreign elements, such as dirt, into the oil, or even starvation of the bearings by oil, as this may also cause bearings to fail. Where any repairs are called for following failure of the babbits, methods including resinning, putting back into alignment through machining, or polishing may be applied to ensure there is remediation of the surface of the babbit bearing. Handling such tasks with competent individuals ensures the accuracy of the work and the bearing’s long-term efficiency.

Essential Maintenance Tips for Longevity

✓ Inspection Schedules

Plan for visual and technical checks to spot the initial stages of bearing wear or damage, and misalignments. It is one of the best methods of managing problems before they are out of control.

✓ Wear Endurance

Appropriately utilise the correct lubricant and lubricating method to avoid unnecessary wearing. Check the oil level regularly and change the oil promptly.

✓ Hygiene and Cleanliness

Ensure bearings and the surrounding area are cleaned to remove dirt, dust, and other debris that may lodge in the bearing, reducing its efficiency and lifespan.

✓ Operating Environment Assessment

Measure operating temperature, load, and vibration continuously to detect disturbances. Addressing problems while they are in an aberrant state will reduce additional stress on the machine.

✓ Conforming to Technical Documentation

Perform maintenance and operations in accordance with technical documentation, including timely replacement of components and adjustment of operating loads within the scope to increase bearing life.

Signs of Wear and When to Repair or Replace

Bearings have several significant signs of wear, including increased noise, excessive vibration, unusual heat generation, or visual damage. Protein supporting the bearing surface includes pitting or spalling. Under such circumstances, I would first check the bearing’s condition to determine the extent of damage. If wear is minimal, it can be remedied by lubricating or cleaning. However, if the damage poses a risk to function or increases the risk of the equipment breaking down, I will quickly do the needful to replace the bearing.

⚠️ Warning Signs Checklist:

- Increased noise levels

- Excessive vibration

- Unusual heat generation

- Visual damage (pitting or spalling)

- Bearing surface deterioration

Best Practices for Lubrication of Babbitt Bearings

Indeed, lubrication is necessary for the operation and service life of babbitt bearings. It begins with choosing an appropriate lubricant, considering the manufacturer’s original specifications and the operating conditions, including load, speed, and temperature. Conducting oil analysis regularly to assess the condition of the lubricant will also improve efficiency, as any signs of contamination or wear can be identified early.

Also, proper alignment and maintaining the assumption of not over-lubricating is vital because excess lubricant causes overheating and inefficiency. It is also essential to keep lubrication systems free of contamination and to employ efficient filtration methods to ensure this. With such principles in place, primacy requirements, together with downtime reduction and extension of babbitt bearing service life, are easily kept at bay.

🔧 Lubrication Best Practices:

- Choose lubricant based on manufacturer specifications

- Consider operating conditions (load, speed, temperature)

- Conduct regular oil analysis for contamination detection

- Maintain proper alignment to avoid over-lubrication

- Implement efficient filtration methods

- Monitor for overheating and inefficiency signs

Reference Sources

- Babbitted Bearing Health Assessment

This source discusses the materials used in Babbitt bearings, their applications, and health assessment techniques.Read more here.

- Troubleshooting Bearing And Lube Oil System Problems

This paper explores the causes of bearing failures and effective repair methods, including insights into Babbitt materials.Read more here.

- Design Considerations For Thrust Bearing Applications

This document provides insights into the design and material considerations for thrust bearings, including Babbitt materials.Read more here.

Frequently Asked Questions (FAQs)

Q: What exactly is a Babbitt Bearing?

Also known as a plain or white-metal bearing, a Babbitt Bearing is any plain bearing that uses soft metal layers, such as Babbitt metal, for its wear surfaces. Babbitt metals are generally white metal alloys that contain tin, lead, or copper to improve the properties of the alloy such as the ability to embed particles, prevent frictional welding (galling), and work as a lubricant. In a wide range of applications, including steam engines and automotive systems, Babbitt bearings are commonly used.

Q: Are there any specific contents in a Babbitt Alloy?

The significant component in Babbitt alloy is usually tin, with minimal or no lead, copper, antimony, and, even less so, other elements. Depending on the function and the required properties, the composition also changes. Babbitts made of tin are especially popular because they exhibit low friction, good wear properties, and high dynamic loading capacity.

Q: How are Poured Babbitt Bearings Made?

In the production of poured babbitt bearings, the babbitt alloy is melted and then poured into a mold of the appropriate shape to achieve the desired bearing dimensions. In this technique, the alloy is heated to its melting point, poured with a ladle and allowed to cool. Such casting produces ideal bearing material capable of working at incredible speeds and high loads.

Q: Where are the Babbitt Bearings Used?

Babbitt bearings find their extensive application within heavy machinery, steam engines and automotive applications. Primarily, they are applied in connecting rods, crankshafts and other parts which are subjected to high loads and surface velocities. Most of the modern industries prefer to use these bearings due to their admirable characteristics such as self-lubricating and anti-wear properties.

Q: How Easy Is It To Detect Babbitt Bearing Damages?

One can determine whether the Babbitt bearing has been damaged by checking for wear indicators such as scratches, gouges, gallings, or a bearing gap from the shaft that exceeds the standard nominal size. Regular maintenance, which comprises periodic checks of operational conditions such as vibration levels and heat release, helps pinpoint faults at an early stage. In case of a damaged bearing, repair and/or replacement of the worn Babbitt bearing with a new Babbitt bearing of the exact dimensions may be essential.

Q: What is the Difference Between New Babbitt and Old Babbitt?

The New Babbitt, for instance, is usually made from better material and has a clean, smooth surface, unlike the old Babbitt, which often looks worn and/or dirty. The presence of New Babbitt is advantageous as it carries the promise of enhanced performance and durability which is why it is suggested to exchange the old Babbitt bearings with the new Babbitt in order to maintain proper function and avoid premature failure.

Conclusion

Babbitt bearings remain an essential component in modern industrial machinery due to their exceptional load-bearing capacity, embeddability, corrosion resistance, and longevity. Understanding their composition, proper maintenance practices, and timely repair or replacement strategies ensures optimal performance and extended service life. Whether in power generation, marine applications, or heavy construction equipment, Babbitt bearings continue to prove their reliability and cost-effectiveness in demanding operational environments.