Bonding PLA, one of the most utilized materials in 3D printing, is very important for making sure the strength and reliability of the bonds. Be it a broken part which needs to be repaired or a model which needs detailing, preserving the integrity of your prints with the right adhesive is key. This guide aims to equip you with the right information regarding the best glue and bonding methods for PLA. From providing a different types of adhesives, to offering application tips, this article aims to serve every need you have for PLA bonding tips. Get ready to achieve boundless possibilities in your projects with tips from professionals and tested methods.

What’s the Best Glue for PLA?

When it comes to bonding PLA plastics, cyanoacrylate glue, commonly referred to as super glue, tends to work the best. Its PLA super glue bond is effective, strong, and sets incredibly fast. For an even stronger hold, epoxy adhesives are also readily available and are extremely durable as well as gap-filling, so they work great on bigger and more irregular surfaces. If there is a need for a temporary bond or longer working time, Methylene Chloride, a solvent-based glue specifically designed for plastics, can also do the trick. Like with all adhesives, make sure to remove any grease or dirt on the surfaces for the best contact.

Understanding PLA and Its Properties

PLA stands for Polylactic Acid, which is among the most popular thermoplastic polymers as it can be manufactured from renewable sources like corn, sugar cane, or other plant material, making it a sustainable and environmentally friendly material. Biodegradability and printability are two important factors that can drive the use in almost any industry, especially in 3D printing and other environmentally driven industries. PLA has a glass transition temperature of around 50°C to 60°C, the temperature range in which the material performs well is known as the softening zone for heat. This feature makes PLA suitable for applications requiring high precision and attention to detail, however, it becomes problematic in strong heat conditions.

Moreover, PLA shows a fair amount of tensile strength and modulus, which give strength and structural support to the printed objects. Nevertheless, its impact strength and brittleness may render some uses more challenging due to these mechanical shortcomings. Progress in material science has spun new blends and composites of PLA to improve its durability and thermal stability, broadening its scope of applicability. Also, it is important to mention that PLA can only be considered biodegradable under conditions of industrial composting processes where precise temperature, humidity, and microbial activity are necessary to support effective decomposition. These properties make PLA straddle the divide between functional performance and environmental responsibility.

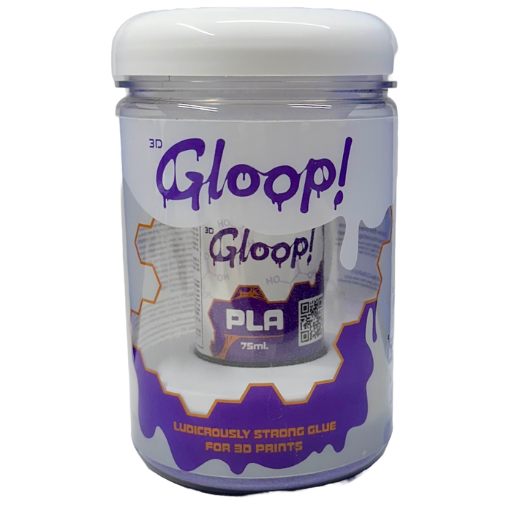

Top Adhesives for 3D Printed Parts

When choosing the appropriate adhesives for a 3D printed part, material compatibility with the glue and the application must be considerations. Websites and literature of PLA 3D prints frequently recommend using cyanoacrylate glue or super glue since it is easy to use and forms strong bonds. Apart from this, epoxy adhesive systems especially two part systems have a strong bond and are good for joining large or highly structured components. For ABS parts, acetone can be used as an adhesive solvent. Acetone can chemically weld the parts together by dissolving a portion of the material. Adhesives that work well with these filaments include those based on polyurethane, since they need to bond flexible filaments such as TPU, and must be flexible themselves without losing resiliency, when dealing with multi-material components, hybrid solutions where cyanoacrylate is combined with activator spray work best with bonding adhesives. Cleaning and light sanding improves adhesive bonds, ensuring enduring outcomes.

How to Choose the Right Adhesive for PLA 3D Printing?

It is critical to determine whether there is a need for bonding an object that is meant to have thermoplastic features, as with PLA. PLA is a rigid thermoplastic, meaning cyanoacrylate (super glue) and epoxy provide the best adhesives generally plastic as they withstand bonding thermoplastics. For optimal performance, cleaning and light sanding of the surfaces is advisable prior to applying glue. Moreover, gel-form cyanoacrylate glues are best suited for the filling of parts with small gaps, while structural bonds are effectively provided by two-part epoxies. Besides, perform a compatibility test on a small area first before using the adhesive to confirm suitability.

Factors to Consider When Selecting Glue

1. Material Compatibility

Attempts to select suitable adhesives should be based on the proper understanding of the components being joined. A case in point concerns adhesives based on polyurethane. They are designed for materials which are porous in nature, wood for instance. They would work very efficiently on foam, wood or even porous rubbers, however adhesion would not be as effective with glass where no permeability is present. Silicone, on the other hand, bonds firmly to bendable materials and is also high-temperature. This means that it can effectively seal glass, metal, and ceramics.

2. Environmental Conditions

Factors such as temperature, humidity, and UV light exposure have an impact on the effectiveness of an adhesive. Consider anaerobic sealants: some of them are specially designed for high-temperature uses and can withstand thermal resistance of up to 500°F (260°C). Also, unprotected projects that are meant to be worked on professionally should have exposed to enhancer binding and UV-stabilizers because prolonged sunlight exposure leads to degradation and eventual bond failure.

3. Cure Time and Application Process

Depending on the kind of adhesive, the curing time will differ significantly, and this time can take from seconds for cyanoacrylate to multiple hours or even days for some resins or epoxies. In construction works, fast curing adhesives are beneficial, but they are not recommended for enduring works that are more likely to require stronger, high-grade, slow curing. A more favorable option is to constantly monitor viscosity and tooling requirements while applying the product in order to yield a clean as well as efficient results.

4. Load-Bearing and Flexibility Requirements

The degree to which an adhesive is flexible and strong should be appropriate for the mechanical stresses the joint will face. Take, for instance, epoxy adhesives; they are phenomenal in enduring tensile stress due to their rigidity and are not easily damaged, making them superb for high-load environments. On the other hand, rubber-based adhesives which exhibit elastic properties are better for dynamic loads where the materials can shift unexpectedly.

Meeting all of these considers provide maximum effectiveness of the adhesive used regardless if it is for repairs at home or engineering endeavors. Also, when thinking of what adhesive to purchase, manufacturer data sheets should always be consulted for fabrics like fiber reinforced polymer composites.

Expert Tips for Selecting the Best Glue for PLA

- Consider the Surface Energy of PLA

For bonding purposes, PLA (Polylactic Acid) is a good choice considering the component needing to be bonded to; however, due to its low surface energy, PLA can be troublesome since its surface adhesion energy effort is approximately 40 mN/m. This means it can be troublesome for many adhesives since PLA is a low-surface-energy thermoplastic. Thus it needs to be chosen to have high surface energy materials. Super glue excels PLA’s unique properties, including low surface energy, because they are designed especially for surface with a 40 mN/m lower range.

- Use Adhesives Designed for Thermoplastics

Thermoplastic adhesives like epoxy resins and two-part acrylic adhesives bond strongly to PLA because they can fill gaps and use surface chemistry. A high-strength shear epoxy bond is especially effective due to the tensile weight of 3,000–4,500 PSI.

- Mechanical Surface Preparation Enhances Bonding

P la has Smooth surfaces that inhibit the performance of adhesive PLA. Sanding with fine-grit sanders like 220 to 320 grit improves adhesion through surface roughness. To optimize cleaning, soak abrasive surfaces blast with isopropyl alcohol 70% to 99% to clean oils and debris post washing.

- Match Adhesive Properties to Application Conditions

Determine the operating environment of the bonded PLA parts. If the bonded structure undergoes thermal exposure, moisture or chemical weathering, select permeable adhesives. For instance, high-temperature epoxies are able to endure exposure to heat up to 120°C (248°F), making the epoxy suitable for high-temperature applications.

Following the implementation of these tips provides reliable and simple bonding with PLA while improving its durability alongside tailoring specific needs of the project.

What is the Best Way to Glue PLA Together?

Super glue and cyanoacrylate adhesive are ideal for gluing PLA. The strong and quick bond offered makes them perfect for all PLA applications. In more challenging cases, two-part epoxy can be used since its other properties make it stronger and more enduring. Such epoxies require greater curing time. To maximize adhesion, cleaning and lightly sanding the areas to be joined affording improved contour to increase clawing and remove objectionable matter.

Step-by-Step Guide to Applying the Glue

- Prepare the Surface

Begin with the cleaning of surfaces with isopropyl alcohol to wipe off mud, grease, and oil. For great adhesion clean the surface thoroughly and sand lightly using grade 220-320 sandpaper. This will increase adhesion by generating friction.

- Dry Fit the Pieces

Before the adhesive is applied, perform a dry fit aligning the pieces to see if they match properly. This minimizes the alignment problem post-gluing.

- Apply the Adhesive

For cyanoacrylate adhesive (superglue): Apply a thin layer of glue to one of the surfaces. Be sparing with the amount used, as too much can cause uneven adhesion, wedged surfaces elsewhere, or extended cure times.

For two-part epoxy: Mix the resin and hardener together as per the instructions of the manufacturer. It is advisable to first apply a thin, uniform layer to one of the surfaces.

- Join the Pieces

If needed, the two surfaces should be pressed down with uniform force. With super glue, the adhesive bond needs to be held for anywhere within the range 10-30 seconds based on the amount of time it takes the particular adhesive to set. With epoxy glue, the bond should be held mechanically with clamps during the long set time to prevent displacement and aid alignment.

- Allow for Full Curing

Most cyanoacrylate adhesives reach a level of stress handling strength within a minute but might need 24 hours for the maximum strength bond. Most epoxy adhesives will take several hours to complete curing, it will differ based on the adhesive found in the product as well as the datasheet for specific curing schedule timings.

- Inspect the Bond

After all mortises have been set and the final post application curing check is complete, the joint should be inspected and any arbitrary misalignment checked for precise alignment. Any other unwanted features should be brought as close to the correct dimensions as possible through finishing with a sanding block or guide hand.

With these methods, a robust and enduring bond with PLA, which withstands both light and intense stress, can be achieved. Correct surface cleaning, along with a regulated working procedure, guarantees the best results.

Best Techniques for Joining PLA Parts

- Mechanical Fasteners

Mechanical fasteners like screws or bolts are one of the most effective methods for joining PLA parts. Make note that PLA is brittle and stiff, therefore mechanical fasteners should not be overtightened as they can cause PLA components to crack. Heat-set threaded inserts are very efficient as they form an embedded durable thread which is greatly bonded to the material. These inserts are put in place by heating them with a soldering iron, PLA is then melted slightly enabling it to surround the insert. This method provides a strong mechanical bond as well as repeated assembly and disassembly without the risk of damaging the part.

- Solvent Welding

Solvent welding employs a different approach where a chemical binder is used to PLA with an intersecting bond by partially dissolving it where the two parts meet. As is the case with most bonds, add solvents like methylene chloride that can dissolve PLA and work as bonding agents. Utilize as little as possible during this stage, as your goal is not excessive melting and deformation. An effective bonding technique where the two parts need to be precisely aligned after which one needs to be still until the solvent evaporates completely for strength and bond integrity which allows for a connection similar to seamless.

- Thermal Bonding

Using thermal bonding means using heat to permanently fuse different components of PLA. A soldering iron or a 3D pen can be used to melt the parts that will be assembled, and thereafter, the parts can be pressed together to get a cohesive bond. Proper control of the applied heating is essential because overheating can warp and weaken the material. For all types of joint repairs, reinforcing weak areas, modifying joints, and other custom work, thermal bonding is the best method.

- Adhesives

For rapid bonding of surfaces with low requirements of precision, super glue can work, as well as other specialized adhesives made for PLA. Each surface adhesive bond needs to be clean, which means no dust, oil, or dirt needs to be present. Lightly sanding the surfaces increases the chances of adhesion since the glue would have more surface to latch on to.

Utilizing these methodologies permits tailoring of PLA assembly procedures while optimally balancing structural integrity, durability, and surface finish.

Can You Use Super Glue on PLA Plastic?

Indeed, PLA can be glued. PLA can indeed be glued with super glue, as super glue PLA bindings can be performed with Cyanoacrylate-based glues as they bond firmly and cut timeously to PLA. To ensure maximum results, the surfaces must be clean and dry, as well as lightly sanded to provide texture for the glue. Therefore, super glue works well in meeting the need for speed and efficiency when PLA needs to be repaired or bound mechanically.

Benefits of Using Super Glue for PLA

- Fast Curing Time

When using super glue, the suggested set time is instantaneous to a few minutes, but this varies from product to product. This speedy getting is a great asset for those looking to quickly assemble or carry out repairs on a project. Based on the manufacturer’s information, the bond formed by these adhesives is cured fully in 24 hours but only if the bond is left undisturbed under room temperature conditions.

- Strong Adhesion

Due to their cyanoacrylate mixtures, cyanoacrylate glues form potent bonds with PLA. This type of adhesive works by polymerizing in the presence of moisture and forming strong connections on the molecular level. Research indicates that cyanoacrylate bonds can withstand tensile forces of 20-25 MPa on some thermoplastic PLA parts, firmly cementing mechanical integrity of the stored PLA components.

- Ease of Application

The application of super glue does not require any prior surface preparation although washing the surfaces may be recommended. Super glue works best when only a tiny amount of the adhesive is used which makes the application of super glue very efficient in PLA models with complex geometries and small joints.

- No Need for Specialized Equipment

Not requiring tools such as heat guns or clamps makes super glue different from other techniques plastic welding and epoxy. This simplifies the procedure and broadens the audience using this technique from the casual DIY user to specialists working with PLA.

With no extensive preparation required, super glue bonds PLA parts in a matter of seconds, making the process efficient hands down.

How to Apply Super Glue for Best Results

- Prepare the Surfaces

Before binding surfaces, ensure the prospective surfaces are well dried, cleaned and free of dust, oils or any other industrial contamination. Such contamination would greatly impede the bond that can be formed by adhesion. Wash the area with isopropyl alcohol or any other cleaner with similar qualities.

- Apply the Glue Sparingly

Spread a thin, consistent layer of super glue to one of the constituent parts. Overapplication must be avoided, as excess Superglue may lengthen both the curing duration as well as degrade the bond.

- Align the Parts Carefully

Super glue unites surfaces almost instantaneously, thus for optimum results align properly before gluing the pieces together, as poor snug alignment makes readjustments nearly impossible.

- Hold in Place to Cure

Depending on the brand and type of adhesive, hold the surfaces tightly together for 10–30 seconds. Most super glue brands require a waiting period after setting for maximum bond strength but allow some additional curing time.

- Allow Full Cure Time

Even if the bond looks to be strong right away, permits the adhesive to fully cure for the timeframe suggested by the manufacturer. This ensures the bond attains full strength.

These steps can be particularly useful while working with PLA and other types of plastics to improve the durability and performance of the bond. Using the right technique is key to achieving strong and permanent adhesion.

How to Repair Broken PLA Parts?

Follow the list of steps given below for effective methods of repairing broken PLA parts:

- Clean the Surfaces

The bond will be stronger if both broken parts are free from dust, grease, debris or any sort of unwanted particulates.

- Choose the Right Adhesive

The bond would work nicely with PLA components so long as the adhesive is a high strength cyanoacrylate or epoxy resin which are meant specifically for plastics.

- Apply Adhesive Evenly

One surface should have a thin, uniform layer of adhesive. Overapplication should be avoided to the point where there is no opportunity of excess glue spilling out.

- Align and Hold

Precise alignment of the broken parts will make it easier to keep them in place until the manufacturer’s suggested time, usually set within minutes.

- Allow Full Curing

Adhered parts should not be moved until the manufacturer’s guidelines on curing time are followed exactly. While these instructions may vary, everything hinges on the time spent for maximum strength.

The right choice of materials combined with the proper steps will allow you to PLA parts easily and with very little effort.

Using Epoxy for Strong Repairs

Epoxy adhesive achieves permanent bonds that are robust and durable because it is an excellent choice for repairs requiring high strength. An epoxy consists of 2 parts, which includes the resin and hardener. It is crucial to prepare the surfaces as epoxy is not an as adhesive. Be sure your parts are cleaned, dried, and free from any debris and oils. Initial scuffing lightly with fine grit paper will increase roughness which will increase adhesion and improve bonding.

Follow the manufacturer’s instructions on plastering epoxy, being sure the ratio of resin and hardener is maintained to ensure optimal performance. The mixture also needs to cover all surfaces through application. The fully covered components need somewhere to be placed securely to stand still in order to prevent any movement until the epoxy cures. Parts usually take several hours to one day to cure fully without being disturbed. Parts should not be used immediately after so they must endure at least a month of slow curing. For industrial uses, higher curing temperatures improve rate of curing while increasing mechanical strength, shear strength, and external resistance.

Reference Sources

-

Testing the Best Glue for PLA 3D Printed Parts – This article discusses various adhesives for PLA, including Weld-On 16, which is highlighted as a top choice.

-

Best Glue for PLA: A Comprehensive Guide – This guide covers different types of glue, such as cyanoacrylate (super glue), known for its quick-drying and strong bonding properties.

Frequently Asked Questions (FAQs)

Q: What are the best products used for gluing PLA parts together?

A: Some of the best products used for gluing PLA parts together include Loctite Super Glue, Gorilla Glue, and CA glue. These adhesives are known for their strong bonding capabilities with PLA surfaces.

Q: How can I glue PLA like a pro?

A: To glue PLA like a pro, use products that are compatible with PLA, such as Loctite Ultra Gel or Gorilla Super Glue Gel. Make sure to clean the surfaces with soapy water and some acetone before applying the adhesive for better adhesion.

Q: Does Loctite work well with PLA surfaces?

A: Yes, Loctite products, particularly Loctite 401 and Loctite Super Glue, are highly effective for bonding PLA surfaces. These adhesives set quickly and create a strong bond.

Q: What is the best method to learn how to glue PLA effectively?

A: To learn how to glue PLA effectively, consider researching tips and techniques specific to gluing plastics. Experimenting with different products, such as super glue gel or model cement, can also help you understand what works best for your projects.

Q: Can I use Gorilla Glue on PLA prints?

A: Yes, using Gorilla Glue on PLA prints can work, but it is important to note that it expands as it dries, which may not be ideal for all projects. For a cleaner bond, consider using Gorilla Super Glue Gel instead.

Q: What is the role of an accelerator when gluing PLA?

A: An accelerator can be used to speed up the curing time of cyanoacrylate (CA) glues when bonding PLA parts. This can be particularly useful when you want the bond to harden immediately for quick assembly.

Q: What should I do if my PLA parts do not bond well?

A: If your PLA parts do not bond well, ensure that the surfaces are clean and free of dust. Consider using a stronger adhesive like Weld-On 16 or applying baking powder to the adhesive to help it harden and bond better.

Q: Are glue sticks effective for bonding PLA?

A: Glue sticks are generally not the best option for bonding PLA. While they may work for temporary holds or lightweight applications, stronger adhesives like Loctite or Gorilla are recommended for a durable bond.