When working with Styrofoam or foam materials, finding a good glue can prove to be a challenge. There really is no better glue-and-wrong-glue-branding answer since the wrong glues will weaken the bond, make a mess of the application, or even damage the foam itself. Whether it is for DIY crafts, repairs, or model construction, knowing the best glue for Styrofoam will make your work easier, less tedious, and more enjoyable. This guide will take you through the best adhesives to use on foam, tips that will help you achieve results worthy of a strong bond, and common goofs to avoid. Get ready to give a new lease on life to your next project using expert-approved gluing techniques!

Understanding Styrofoam and Adhesives

Chemical Composition of Styrofoam

Styrofoam or expanded polystyrene is a light foam of polystyrene. Polystyrene is derived from styrene, a liquid hydrocarbon polymerized into long chains of molecules, rendering it rigid and solid. Treating small polystyrene beads with heat and with a blowing agent such as pentane causes the beads to expand and fuse to form the foam structure referred to as Styrofoam.

Styrofoam has a singular structure; from 95 to 98% of Styrofoam is air, affording it the utmost insulating and cushioning qualities. Because of this closed structure, millions of tiny air pockets are trapped within the foam, making it extremely light yet durable. These properties make it suitable for packaging, insulation, and crafts, but this also explains why it can be incompatible with certain adhesives and solvents that degrade this structure.

Styrofoam remains chemically inert under most conditions: it will not react with water, air, or many mild chemicals. The foam discriminates against solvents: some will break it down, and others, with the help of an intense heat source, will melt it down. It is essential to know such characteristics when choosing adhesives for it: sacrificing the wrong one would mean sacrificing the material itself or impairing the bonding itself. Strong and durable bonds are ensured by opting for glues engineered to bond polystyrene foam.

Properties of Styrofoam and Its Challenges

Styrofoam, also known as expanded polystyrene (EPS), is a lightweight, rigid material made primarily of air-filled polystyrene. Its insulating properties make it a popular choice for packaging, insulation, and craft applications. Styrofoam is resistant to moisture and mild chemicals, which enhances its durability in various environments. However, these same properties can present challenges when attempting to adhere or recycle the material.

One of the main challenges with Styrofoam lies in its chemical structure, which makes it incompatible with many adhesives and solvents. Strong adhesives or harsh chemicals can dissolve, degrade, or melt Styrofoam, rendering it useless or difficult to use further. Additionally, its low-density composition, while beneficial for its lightweight properties, can make it structurally weak under significant pressure or heavy loads.

Another significant challenge is its environmental impact. Styrofoam is non-biodegradable and takes hundreds of years to decompose in landfills. Its lightweight nature makes it prone to being littered, contributing to pollution, especially in marine environments. Addressing these concerns requires careful handling, proper recycling techniques where available, and exploring sustainable alternatives to reduce their long-term ecological footprint.

Examples of Adhesives for Styrofoam

While always considering bonding strength, compatibility, and safety, various adhesives can be chosen for Styrofoam. Some adhesives will chemically react with Styrofoam, damaging or disintegrating it. Thus, it is very important to use adhesives made specifically for foam materials to ensure that the bond will be secure and that the integrity of the Styrofoam will not be compromised.

Water-based glues, such as white glue or wood glue, are safe for lightweight Styrofoam applications and non-load-bearing. These glues are easy to use, have no toxicity, and are great for craft or hobby projects that do not require strong structural support. They generally dry clear, so they look good when used creatively.

For projects that require a stronger bond, polyurethane glues or some variants of silicone-based adhesives work best. These are adhesives for greater strength and durability and can do the job for Styrofoam bonding with a variety of other materials, such as wood, metal, or plastic. One should ensure proper ventilation during the use of these adhesives, as some types emit fumes while curing. Always adhere to the manufacturer’s instructions to obtain optimum results and safety.

Top Rated Glue for Styrofoam

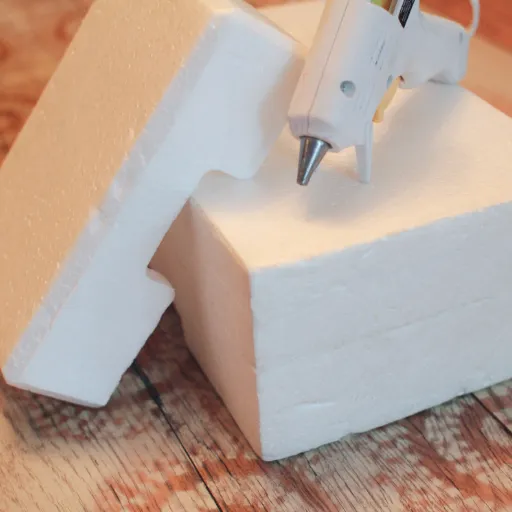

Hot Glue: Pros and Cons

In this respect and others, hot glue would need to hold its own against other varieties of adhesive in the scenario of bonding Styrofoam.

Pros:

- ✓ Quick Bonding Time: Hot glue fast sets and is therefore ideal for kits or projects where immediate set-up is required.

- ✓ Easy to Apply: A glue gun allows for convenient application, which requires little effort or preparation.

- ✓ Compatible with Different Materials: Hot glue binds readily to Styrofoam to several materials, such as cardboard, fabric, or paper.

- ✓ Budget-Friendly: It is pretty cheap and available almost everywhere, therefore enhancing the rating of the glue by various DIYers and professionals.

Against:

- ✗ Potential to Melt Styrofoam: Some hot glue guns operate at a very high temperature level, thereby melting Styrofoam that almost ruin the glue bond.

- ✗ Less Durability: The glue bond might not hold good with heavy loads and working under high stress is more of an experimental bond capable of wearing away over time.

- ✗ Vulnerability to Heat: Once set, hot glue bonds can eventually weaken or fail upon exposure to high temperatures, rendering their use a little iffy in certain environments.

- ✗ Not Waterproof: Unlike putty, normal hot glue is not exactly waterproof, and the moisture can degrade the bond with time.

Super Glue: Best Uses

Super glue or cyanoacrylate adhesive is a fast-acting adhesive with high bond strength. Its bonding nature and durability make it very useful in many situations. Some of the best uses are:

- Repairing Small Items: While it is best for ceramics, it also bonds super glue to plastics and metals. Some things around the house can be fixed fast and well: mugs, small figurines, and jewelry.

- DIY Applications: If you are a crafter, super glue is an essential glue of choice for putting together display pieces and bonding small parts or attaching embellishments with a very firm but sometimes exact grip.

- Medical Applications: Interestingly, the use of medical-grade super glue was developed in closing small skin wounds or surgical incisions as a temporary alternative to stitches with great benefits in first aid.

- Electronics Repairs: Usually, wires or components might be suspended inside small electronic devices for superglue to work under instructions so that it may adhere immediately while not damaging delicate elements.

- Automotive Repair: This can hold together some minor repairs to the car, such as attaching broken trim pieces or small cracks in plastic or rubber components.

Spray Adhesive: When to Use

This is an adhesive to spray where it is needed to blend and quickly bond two surfaces. It would be an advantageous choice in light bonding for materials such as paper, cardboard, fabric, and foam. In other words, this spray glue is extremely helpful for crafts, model making, and other DIY projects in which the glue application has to be precise and easily done.

It is also commonly used in upholstery work and remodeling, where an even layer of glue is necessary so that ridges from the glue become visible. Spray adhesives firmly and evenly bond materials that cover large areas, such as fabric panels, posters, or carpets, without wrinkling or developing excessive adhesive build-up.

In addition, spray adhesives are deemed a temporary fix for application purposes as their varieties provide options for repositioning before cure. This feature comes in handy when adjustment is required in the project, like copying templates, assembling layouts, etc. This characteristic makes it versatile and easy to the prime adhesive for a professional or everyday purpose.

Best Way to Glue Styrofoam Together

Surface Preparation Techniques

Surface preparation is an important consideration in achieving a strong bond between two surfaces of Styrofoam. Begin by making sure that both surfaces are clean and free from dust, dirt, grease, etc. Using a soft cloth or fine brush, remove dust particles that might interfere with binding. Where necessary, a mild soap solution can be used to wash the surfaces, but they should be thoroughly dried before proceeding.

The uneven or rough edges of Styrofoam should be checked next. If there are any, then a thin layer of sanding can be done on the surface. The sanding will ensure the contact area is evenly formed, which will help with the bonding; hence, it should not be overdone since it will make the surface weaker.

Finally, place the pieces to ensure a proper fit before you glue them. It is better to align them before gluing than to have to move them around while the glue dries, especially when using a fast-setting glue. Proper preparation makes this all so much easier while also giving the bond a lot of strength, which should be an important factor in any Styrofoam gluing process.

Application Methods for Different Adhesives

When working with Styrofoam, the choice of an adhesive of great strength will either yield an object of optimum results or an object whose bonding is lacking. Here are application methods for the various kinds of adhesives commonly used with Styrofoam:

White Glue:

White glue, or school glue, is safe and easy to use on Styrofoam. To apply it, first ensure the surface is clean and dry. Using a brush or a small applicator, spread a thin, even layer of glue onto one of the pieces you wish to bond. Press the two surfaces together and hold them in place for a few minutes. Because this type of glue dries slowly, clamping or weighting down the pieces can be done to secure the objects while the adhesive cures.

Hot Glue:

Hot glue is a quick solution for Styrofoam, but it must be handled carefully to avoid melting the Styrofoam. Use a low-temperature glue gun for small amounts of glue because the Styrofoam material can melt if exposed to excess heat. Press the glued area against the other surface immediately since hot glue sets fast. It works well for temporary adhesions or construction projects that require speedy assembly.

Spray Adhesive:

Spray adhesive, while extremely useful for very big areas of Styrofoam, must be shaken thoroughly before use. Evenly spray one or both surfaces of the glue from the distance recommended on the product label. Let the adhesive become tacky before pressing the surfaces together. When done correctly, spray adhesives create strong bonds that are evenly sprayed and perfect for lightweight applications.

Remembering the specific way of using each kind of adhesive ensures really strong and reliable results when working with Styrofoam.

Time of Curing and Drying

The curing and drying times of adhesives that are used on Styrofoam might differ on account of the adhesive type and environmental conditions. Many spray adhesives will become tacky in a matter of minutes to bond very quickly with surfaces. To fully cure, however, the bond may take a full day. During this curing process, the bond gains its strength and durability.

Humidity and temperature are also major factors that affect drying and curing times. Warm air and low moisture expedite drying, whereas a cool, moist atmosphere would be counterproductive. Always check the label for recommended application conditions and give ample curing period for a strong bond.

For best results, do not move or exert any training pressure on the bonded surfaces until full curing is complete. Any interference with the curing process may weaken the bond and its overall effectiveness. By following the above points, you will be able to ensure that the materials are bonded for your Styrofoam works to work reliably and permanently.

Comparative Analysis of Styrofoam Adhesives

Strength and Flexibility of Adhesives

Adhesives used for Styrofoam bonding must be quite strong and flexible. Strength refers to the capacity of the adhesive to retain its bonds when subjected to pressure, whereas flexibility refers to its capability to accommodate slight movements in the bonded materials caused by temperature changes and various forms of stress without breaking. Ideally, to form a lasting bond, both these features must be equally balanced.

Adhesives that exhibit very high tensile strength allow for a good holding strength in applications where the bonded components will be subject to constant tension or weight. Rigid and inflexible adhesives, however, provide for an unsafe bonding under vibrations or thermal expansion, more so under varying temperatures. Hence, flexible adhesives consider such changes by accommodating any movement or deformation undergone by the bonding materials without cracking or separating.

Sometimes, for a work to come up with optimal results, an adhesive must be chosen that meets the specific requirements of the project. For lightweight arts involving Styrofoam structures, a moderately strong and flexible adhesive is sufficiently good. Namely, in the case of heavy applications, it is always better to consider using stronger adhesives that have been tested to hold up in difficult conditions. Environmental demands of your application are thus necessary to be considered in assessing these properties to achieve a result that is both reliable and long-lasting.

Ease of Use and Clean-Up

Ease of use is a critical consideration when choosing an adhesive. If the adhesive is applied with little preparation or tools, it will be a whole lot more efficient and approachable, especially for beginners. Opt for those with a sufficient working time to allow for adjustments before setting. Instructions should be clear and easy to follow so that anyone can adhere correctly, thus obtaining good results.

Equally important in life is the clean-up process and how it will impact your experience of working with the product. If they are water-soluble or easily cleaned with common solvents, then the adhesives would make life easier after the project has been completed. They are a blessing for precision work, as it allows any excess material to be washed out without affecting the surface or, indeed, the ultimate appearance at all.

The ultimate choice of adhesive will depend on the adage of “the operation in balance with practicality.” These non-toxic and green-label products are usually safe for use inside and easy to clean out. Prioritizing the user-friendly features throughout the selection means everything from the beginning to the end of the project goes smoothly.

Cost-Effectiveness of Different Glues

In determining their cost-effectiveness, the price has to be compared with the product performance for the particular project considered. They might seem cheaply cost-effective, but less durability or performance could mean the customer has to repair, redo, or replace the object. These repairs and replacements will then cause a lot of extra expense to the customer. For long-term savings and for better value, one should buy glues that have a better bonding strength and longer lifespan, even with slightly higher purchase prices.

Another factor to measure is their versatility. For example, glues that do the job well on several surfaces, including wood, metal, or plastics, may reduce the need for several solutions, which cuts down on the expense. In addition, if a product is easy to apply, requires minimum cleanup, and does not have long drying times, then labor or project time is saved, again making them cost-effective for both professionals and hobbyists.

Finally, application scale affects cost-efficacy considerations. Adhesives packaged in bulk or at industrial-grade prices are more economical for big projects, while for light usage, small tubes or containers will fit better. Choosing the amount best suited to your project requirements will minimize waste and prevent unnecessary expenses, so treasured funds can be directed for the perfect ratio between cost and performance.

DIY Craft Projects using Styrofoam

Creative Ideas for Using Styrofoam

Styrofoam, being a versatile material, can be used for a plethora of DIY projects. One such idea is making wall hangings out of Styrofoam. This involves cutting Styrofoam into any shape you desire—say a geometric design or an abstract one—and painting it in acrylic colors so you can have lightweight, custom decor pieces that bring some personality into a space. The soft surface of Styrofoam also allows the easy insertion of pins or small objects to create a textured and layered effect in the artwork.

Styrofoam is also highly practical in the making of various containers or organizers. Cut Styrofoam blocks into several small compartments, after which the blocks can be dressed up with fabric, gift paper, or plain paint to create lightweight storage solutions ideal for holding craft supplies, jewellery, or stationery. Durability means these will last a long time and provide for practical use at the same time.

And then there is Styrofoam, which is wonderful to use for seasonal crafts or holiday decorating. Festive ornaments can be made by carving Styrofoam into snowflakes, stars, or spheres and then decorating with glitter, ribbons, or artificial snow. These designs complement wreaths or centerpieces nicely or can be used as cheap, environmentally friendly tree decorations to celebrate the season. Usually, these Styrofoam projects require only simple tools and household items, making them accessible and enjoyable for the whole family.

Tips for Combining Different Materials

While working with Styrofoam, an important factor to keep in mind while choosing the appropriate glue is that it should ensure that the bond is strong and lasts long between Styrofoam and any other materials. The best glue for Styrofoam will depend on the other material being combined. Effective options include those for porous and lightweight surfaces.

| Material Combination | Recommended Glue | Notes |

|---|---|---|

| Styrofoam-to-Styrofoam or Paper | White glue or craft glue | It dries clear and is easy to apply, making it suitable for crafts and decorations. |

| Styrofoam-to-Plastic, Wood, or Fabric | Foam-safe glues, clear all-purpose glue, or low-temperature glue gun | High-temperature glue guns may cause Styrofoam to melt, so always ensure compatibility. |

| Avoid Harsh Adhesives | Super glue and solvent glue | May dissolve or eat into Styrofoam. Always look for glue that explicitly states foam-safe. |

With the right choice of glue, you can ever stick Styrofoam to other materials while maintaining the integrity of the assembly and its finished appearance.

Frequently Asked Questions (FAQ)

Q: What is the best glue for styrofoam?

A: The best glue for styrofoam is one designed for foam, such as theses: UHU, Loctite, and DAP. These adhesives create a strong bond without damaging the material, making them perfect for bonding styrofoam and polystyrene.

Q: Can I use tacky glue on styrofoam?

A: Sure, tacky glue goes great with styrofoam bonding, especially for crafts and DIY projects. It is easy to apply and provides a sturdy hold; this glue is a choice in applications with all types of foam boards.

Q: How do I know how to glue styrofoam properly?

A: Knowing how to glue styrofoam involves first choosing an adhesive made for foams. Apply an even application of glue on one surface of the foam board and press the pieces together firmly; for larger jobs, you may want to use a caulking gun to apply the construction adhesive so you have better control.

Q: Can Gorilla Glue Original be used on styrofoam materials?

A: Gorilla Glue Original was never meant for styrofoam since the glue will expand and damage the foam. Instead, go for any kind of foam board adhesive or an all-clear glue safe to use with expanded polystyrene foam.

Q: Can super-glue gel control be used on styrofoam?

A: Super-glue gel control would glue the styrofoam, but it should be used for small repairs or projects. For larger surfaces, use foam board adhesive for an even stronger bonding.

Q: What glue is good for polystyrene foam boards?

A: Spray adhesives like 3M Super 77 or foam board adhesives are the best for polystyrene foam boards. These two types give a strong hold and bond for foam materials.

Q: How should glue be applied to styrofoam balls in crafting?

A: Applying glue for styrofoam balls in crafting should be done with a glue stick or tacky glue for easy gluing. Spread the glue evenly, and if needed, press the ball firmly in place.

Q: Can I use caulk for bonding styrofoam and polystyrene?

A: Yes, vinyl adhesive caulk can be used for bonding styrofoam and polystyrene boards, especially for insulating boards. It gives a flexible bond that can absorb temperature changes while remaining adhered.

Q: What precautions should I take when using glue on foam boards?

A: When working with glue on foam board, undertake the work in a ventilated environment and wear safety goggles to prevent splashes. Apply the glue carefully so that it is not in excess, as excess glue could cause harm to the foam. Always use a sharp blade to make clean cuts where necessary.

References

- Loctite Products: How to Glue Styrofoam – Recommends Loctite Spray Adhesive Multi-Purpose for bonding Styrofoam.

- LePage: How to Glue Styrofoam Together – Suggests LePage Super Glue Gel Control for quick and strong bonds.

- Amazon: Best Glue for Styrofoam – Lists popular options like Loctite Power Grab Express Heavy Duty Construction Adhesive.

- Quora: What Glue Works Best on Styrofoam? – Highlights UHU Styrofoam glue, Weldbond, and 3M 77 as top choices.

- Walmart: Styrofoam Glue – Offers a variety of non-toxic adhesives suitable for Styrofoam and other porous surfaces.