Styrofoam crafting will let your creativity go wild, giving you a wide range of options such as DIY decorations, school projects, and many others. But, the most suitable glue for Styrofoam is hard to find. The application of the wrong adhesive may lead to disastrous outcomes and even the destruction of the fragile foam surface. Thus, we have created this article in advance, to assist you in selecting the glue that is at its best for your Styrofoam crafts and also to teach you how to apply it effectively. Whether a professional or a beginner in crafting, you are bound to get all the tips and insights provided in this article that will help your projects hold together perfectly and pass the test. Stay tuned for the most trustworthy adhesives and the techniques that would give a lift to your Styrofoam crafting game!

Introduction

Common Frustrations with Gluing Styrofoam

One of the main problems that users run into with Styrofoam is getting a strong and durable adhesive. This is because not every glue is compatible with Styrofoam, and in some cases, the adhesive can either make the material weak or there will be no adherence. Furthermore, some glues with strong chemicals or solvents may, in fact, dissolve the Styrofoam, thus resulting in frustrations and loss of materials.

Another common issue is the difficulty in making a clean and uniform application. Most adhesives have an annoying nature of being messy, leading to dripping, the surface being uneven, or the residue being visible, which then reduces the overall appearance of the project. This becomes most problematic where intricate or delicate crafts are concerned since it is almost impossible to clean up without damaging the Styrofoam.

Finally, drying time is also a major cause of frustration. Some adhesives need a lot of time for setting, which in turn slows down the work progress, while others may not be strong enough to hold the pieces securely in place. This is especially true when it comes to making sure that the projects are structurally sound, particularly for larger or more complex designs. It all boils down to the right adhesive and preparation method to win these battles.

The Significance of Selecting the Correct Adhesive

Choosing an adhesive that fits the project is a prerequisite for getting strong, durable, and trusted results. Material forces and their respective requirements are the major factors that define the selection. There are different types of adhesives depending on the bonding of wood, metal, plastic, or glass, and the kid one ensures a secure and lasting hold. Knowing the properties of the materials and to the adhesive prevents failures or complications from happening later in the process.

Another factor which is just as critical is the working and drying time of the adhesive. Some projects require fast-setting adhesives for efficiency, while others benefit from slower-drying options that allow for repositioning or adjustments. Evaluating the time frame and flexibility needed for the project goes a long way in narrowing down the best choice. Additionally, the environment where the adhesive will be applied also matters, as some adhesives are specifically formulated to withstand heat, moisture, or outdoor conditions.

Taking the right action during preparation is as crucial as selecting the proper adhesive. Cleaning, drying, and eliminating dust and grease from surfaces are crucial to the effectiveness of the adhesive bond. Neglecting this procedure could result in weak joints and unstable structures. Considering all the above factors, one may be able to give the adhesive maximum performance and thus the success of the project in the long run.

What This Guide Will Cover

The adhesive selection process will be thoroughly explained, including preparatory work and application tips. The guide will provide detailed instructions on how to distinguish between various adhesive types. The choice will depend on a few factors such as the materials, their environment, and the use of the product, thus making sure you choose the best one for the project.

Moreover, the guide will address the very significant preparatory processes such as cleaning and treating the surface, so the bond will be strong and last long. Paying attention to these steps is very important in order to prevent the most common errors that can lead to the weakening of the bond or the failure of the adhesive to work as intended.

Not least, this guide will highlight the safety issues and the correct handling of adhesives. It is hoped that once these measures are put in place, projects will be completed efficiently with no or little risks and will be of professional quality.

Criteria for Selecting the Best Glue for Styrofoam

Drying Time: Quick-Set vs. Longer Working Time

If you are picking out the perfect glue for Styrofoam, it is a must to take the drying time into account in order to properly match the adhesive to your project’s needs. The quick-set glues suit the operations that are in need of immediate bonding or less waiting time the most. This kind of adhesive is nicest for small projects, repairs, and situations where time is of the essence. On the other hand, the rapid drying might not give enough time for making adjustments or repositioning during the application, which could be a difficult scenario especially when accuracy is required.

The reverse holds for the longer working time adhesives as they are more flexible than the others and they are, therefore, suitable for the larger or more intricate projects. The users of these adhesives will have the benefit of being able to align the materials, correct if there is an error and apply the glue evenly before it sets. The long drying time is a plus but it also has the downside of requiring very careful handling in order not to displace the bonded parts accidentally or risk the bond being compromised during the curing of the glue.

At last, the drying time should be the one determined by the task’s complexity and size. A fast-drying adhesive is enough for quick repairs or simple applications. On the contrary, when dealing with intricate or large-scale projects, using the glue with a longer working time will boost the accuracy and provide the strong, reliable bond. Weighing these factors will certainly lead to the best results for your Styrofoam project.

Safety: Non-Toxic and Low-Fumes Options

⚠ Safety First: Prioritizing safety is a must when dealing with adhesives for Styrofoam. Non-toxic and low-fume adhesives are the best choice as they will not only ensure a cleaner but also a healthier working environment, especially if the place is closed or poorly ventilated. Such adhesives also greatly reduce the chances of breathing in toxic chemicals that might cause irritation of the respiratory system or other health issues.

To check the safety of an adhesive, seek certification labels or product descriptions that indicate non-toxic and low-emission standards. Often water-based adhesives are the ones that are preferred since they usually generate fewer fumes and are easier to work with. Always read and follow the manufacturer’s safety instructions to avoid misuse.

Moreover, keep the working area well-ventilated and think about wearing protective equipment like gloves or safety goggles to further minimize the chances of exposure. By choosing adhesives with safety as the priority, you are not only securing the durability of your project but also the health of the people involved.

Adhesive Power: Light versus Heavy Attachments

Determining the strength of adhesive for your project application should first depend on an understanding of the difference between light and heavy attachments. Light attachments are usually involved with the smaller and less demanding tasks like crafting, assembling, and materials repair or making very minor renovations. Moderate-strength adhesives such as PVA (polyvinyl acetate) or some craft glues are the most common applications for these. The mount is strong and at the same time the complexity introduced is minimal.

In the case of heavy attachments, the need for stronger adhesive arises when the materials involved are wood, metal, or stone. Epoxies, construction adhesives, or polyurethane-based glues are the better options for such applications. These adhesives are developed specifically to bear the stress and weight of heavy materials thus, their durability and reliability during the more demanding conditions will last much longer.

When picking the right adhesive, think about the materials that will be bonded, the surroundings where the adhesive will be used, and the load or stress that the bond will face. Light adhesives are good for everyday tasks that are not very demanding, while heavy-duty adhesives provide strength for more robust projects. This difference not only guarantees the success and planned life of your work but also reduces the risks of bond failure.

Top Recommended Glues for Styrofoam Crafts

Glue Options for Light Attachments

If you are making light and small Styrofoam crafts, using glues that are specially made for Styrofoam is very important to get a clean and secure finish. Water-based adhesives like white glue or craft glue are suitable for small projects that do not need a lot of strength. The reason why these materials work well is that they do not ruin the Styrofoam and keep a safe and permanent bond.

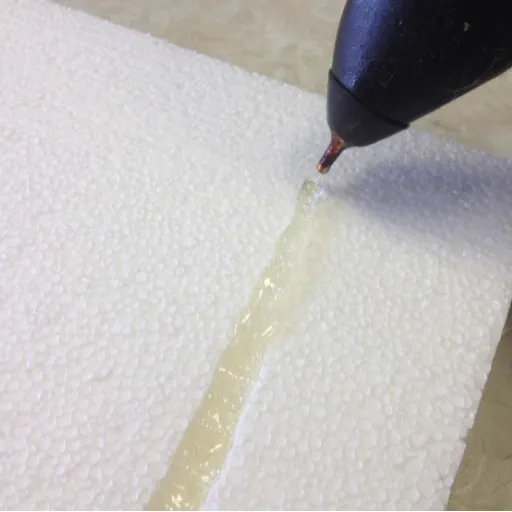

Another option that is good in terms of reliability is hot glue when applying light and small attachments. However, this is not a do-it-yourself process as Styrofoam can be affected by high heat. The best tools for this type of work are low-temperature hot glue guns which give fast and strong adhesive solutions without the fear of damaging the material in any way.

Double-sided tape can be an efficient choice for quick setups or temporary adhesion as well. It is a no-mess way of attaching and it is perfect for projects that might need taking apart or moved around. No matter what glue you decide on, always try it on a small and hidden part of the Styrofoam first before going on with your crafting.

Glue Options for Heavy Attachments

The selection of adhesive is important for heavy-duty attachments with Styrofoam. One of the glue types that stand out is epoxy, which forms an unbreakable bond and is the best choice for long-lasting bonding situations. Epoxy creates a good bond while attaching Styrofoam to non-porous materials like plastic, metal, or wood. Before applying, ensure that you mix resin and hardener thoroughly and give ample curing time for the best results.

Polyurethane glue is another great option that works by expanding as it dries and thus perfectly gripping the surfaces. This quality makes it a very good adhesive for cases of irregular surfaces or when Styrofoam is being glued to other materials with a groove, because the glue will fill the groove. On the other hand, it is important to use the glue in a small quantity because too much expansion may alter the look of your project at the end.

Finally, construction adhesive is a flexible and heavy-duty option for sticking Styrofoam to different surfaces. Always choose the one that is marked safe for Styrofoam to avoid damaging the material. Construction adhesives bear moisture and can be used outdoors, which is why they are perfect for projects that are not indoors. Always adhere to the manufacturer’s instructions for application and curing to guarantee a firm attachment.

Comparative Breakdown of Pros and Cons

To gain a better understanding of the different types of adhesives available for Styrofoam, as per the latest industry revelations, a thorough analysis of their pros and cons is given below:

| Adhesive Type | Pros | Cons |

|---|---|---|

| White Glue (PVA Glue) |

|

|

| Spray Adhesive |

|

|

| Hot Glue |

|

|

| Construction Adhesive |

|

|

Practical Application Tips for Gluing Styrofoam

Applying Thin Layers for Best Results

When gluing Styrofoam, using thin and even layers is the main thing for the best adhesion. A thin layer of adhesive guarantees that the spreading of adhesive across the surface is done uniformly, thus no uneven sticking or weak spots will appear. The use of glue that is more than required can result in messiness, slower drying times, and even damage of the Styrofoam material through chemical interaction or heat.

First of all, make sure that the surfaces to be glued are clean and dust and dirt free. Then, apply a little bit of glue to one side and then spread it gently using a tool like a popsicle stick or a piece of cardboard. The layer should be uniform but not too thick because thinner applications usually lead to a stronger bond.

After glue application, press the Styrofoam parts together lightly but with enough pressure so that the adhesive gets hold. Do not shift the parts after placing them to make sure they get set right. It is important to wait for a long time for curing according to the drying instructions of the adhesive because hurrying up the process can weaken the bond. These steps will guarantee that the connection between the Styrofoam parts is strong and durable.

Proper Clamping Techniques

Appropriate clamping methods are the foremost factor that assures secure and durable bond between Styrofoam parts. Light, even pressure has to be applied while clamping Styrofoam so that no dent the material or deform it. Special clamps with soft padded jaws are perfect as they spread the force over the surface evenly and do not let the surface of the foam suffer.

Key Steps for Effective Clamping:

- Select the Right Clamp Type: For Styrofoam, lightweight clamps like spring clamps and bar clamps with soft pads are the appropriate ones. Keep away from the traditional heavy clamps as they would simply squish the fragile material.

- Protect the Contact Surface: Soft materials like felt, foam pads, or a layer of wax paper can be used to protect the Styrofoam from indentations or surface damage by putting them between the clamp jaws and the Styrofoam.

- Apply Uniform Pressure: Set the clamps in such a way that pressure is applied uniformly all over the bonded area. Non-uniform pressure may result in gaps or weak places in the bond, which would ultimately reduce the longevity of the bond.

- Consider Clamp Placement: Clamps should be put very close to the edges of the adhesive joint without interfering with the drying area. In addition to that, proper airflow which is essential for curing must be taken into account while leaving the space for drying.

Working in Well-Ventilated Areas

When you are dealing with Styrofoam and adhesives, proper ventilation is not merely a safety measure but a necessity. A lot of the adhesives are such that they emit fumes which can cause toxicity if inhaled over a long period. Hence, always do your work in a place that has good airflow to reduce the vapors’ concentration.

To make ventilation better, work outside whenever it is possible or in a room that has windows and fans, so that cross-ventilation is generated. If you position yourself close to the airflow path, you will be sure that you are not breathing in fumes right away. If the natural ventilation does not meet the requirement, then consider using exhaust fans or air purifiers that specifically target the removal of airborne particles.

Finally, safety equipment for personal use such as masks that are made for fume filtration, can add to your protection. By taking these measures, the likelihood of respiratory irritation or other health effects will be considerably reduced, thus allowing you to work safely and efficiently. Always prioritize the ventilation factor as a vital part of your workspace configuration.

Safety Precautions When Using Adhesives

Wearing Gloves and Protective Gear

Wearing gloves and protective gear while using adhesives is extremely important as a means to limit the chance of direct contact with the chemicals that are not safe. Skin irritation, allergic reaction, and some health problems through the skin can occur along with the substances in many adhesives that are raw. In this case, disposable nitrile or latex gloves are mostly recommended due to the fact that they give the user a very strong barrier against the chemicals while maintaining, at the same time, flexibility and comfort during use.

Safety goggles or glasses should be part of the protective gear that you wear. This will prevent your eyes from coming in contact with adhesives, either through splashes or accidentally. The most secure eye protection is provided when fast-curing adhesives are being used. If they accidentally get into the eyes, they can quickly bond and become very hard to remove. Also, if you wear a chemical-resistant apron or long-sleeved clothing, you add more protection to your skin against accidental drips or spills.

Using the right gloves and protective equipment consistently not only ensures a safer working area but also significantly reduces the risks that come with adhesives. Always verify the safety instructions of the adhesive manufacturer for their specific recommendations regarding gear and do inspect your protective equipment before use for any signs of wear or damage. Proper preparation is the best way to get rid of unnecessary exposure and work confidently with potentially harmful substances.

Ensuring Adequate Ventilation

When handling adhesives, It is very important to ensure proper ventilation since this will help reduce inhalation of fumes from the adhesive and thus keep the environment safe. Always work in a well-ventilated area for the circulation of fresh air. Whenever possible, open windows and doors, and if necessary, use fans to help with the airflow. If you are working indoors without any access to natural ventilation, consider installing or using mechanical ventilation systems, such as exhaust fans, to effectively draw fumes out of the workspace.

Also, refer to the adhesive product’s safety instructions to determine if specialized ventilation measures are required. Some adhesives can emit volatile organic compounds (VOCs) that can be a health hazard by causing headaches, dizziness, or respiratory irritation when inhaled. These health hazards can be greatly reduced with proper ventilation, so closely monitor and follow the manufacturer’s instructions to achieve both compliance and safety.

Moreover, in areas where air cannot flow in or out, the use of respiratory protective equipment may be necessary. Yet, this should be a last resort and not a replacement for proper ventilation. With the adoption of airflow as the primary means and safety measures, a safer working environment will be created where health hazards related to adhesive use are reduced.

Proper Storage of Adhesives

Adhesives need to be stored in a cool, dry, and well-ventilated space to maintain their quality and avoid risks. When exposed to high or low temperatures, humidity, or direct sunlight, adhesives will lose their properties and hence, their effectiveness will decrease. It is very important to keep containers well-sealed when not in use so as to avoid contamination and also keep the volatile components from evaporating.

Always observe the manufacturer’s storage instructions because different adhesives might have special requirements. To illustrate, some glue may need to be kept at a certain temperature, while others may need to be kept away from materials that are not compatible. Additionally, proper labeling of containers is very important to avoid confusion and prevent misuse.

To ensure safety at the place of work, it is necessary to keep adhesives away from open flames, heat sources, or places where sparks might occur, as most adhesives are flammable. If necessary, use storage cabinets or areas that are specifically designated for hazardous materials. Regularly check storage conditions, and replace old or damaged products to keep safe and effective use. One can significantly minimize the risks associated with adhesive storage by following these guidelines.

Frequently Asked Questions (FAQ)

Q: What is the best glue for styrofoam crafts?

Generally, the strongest glue for styrofoam crafts includes the likes of tacky glue, gorilla glue, and hot melt glue. The glues have the property of being foam-friendly and can efficiently keep styrofoam together without causing it to melt.

Q: Is it possible to use super glue on styrofoam?

The use of super glue on styrofoam is highly discouraged, as it could melt the foam due to the chemical nature of the super glue. Preferably, foam-safe glues that are compatible with porous materials like styrofoam should be used.

Q: What is the method of joining styrofoam and polystyrene foam?

For the combination of styrofoam and polystyrene foam, it is recommended to work with an adhesive that caters specifically to foam materials. Tacky glue or a foam-safe adhesive will offer a solid connection without compromising the foam.

Q: What is the proper method to adhere styrofoam and avoid its melting?

The proper method to adhere styrofoam and avoid its melting is to apply the glues that are specially designed for foam melting like hot melt glues or 3M Super 77 spray. Always confirm that the glue dries clear so that the final look is neat.

Q: Is it permissible to use wood glue on styrofoam crafts?

While wood glue can be effective on some surfaces, it is not the preferred adhesive for styrofoam crafts. It might not be strong enough, and foamplied adhesives are always the better choice.

Q: How should I apply the adhesive to foam board surfaces?

A caulking gun can be used to apply the adhesive to the foam board surfaces if they are large, while a glue stick is enough for the small areas. Once the glue has dried press the surfaces together tightly to make a bond that is strong.

Q: What are the expert tips for gluing styrofoam together?

The expert tips for gluing styrofoam together are using a utility knife for shaping the foam, making sure the surfaces are clean before applying glue, and holding the board in place until the glue dries to get the proper secure hold.

Q: Can I use contact glue for making crafts with Styrofoam?

Absolutely, contact glue is very much suitable for Styrofoam crafts since it gives a strong union. But just to be on the safer side check if the contact glue is foam-safe so that it doesn’t melt the Styrofoam.

Q: Is there a specific adhesive for the large styrofoam surfaces?

For large styrofoam surfaces, strong adhesive like gorilla glue or foam-safe construction adhesive works great. These options are not only suitable for expanded polystyrene foam boards but also provide a strong bond.

References

-

Loctite Products: How to glue Styrofoam – Tips for Styrofoam and polystyrene

This guide provides insights into using Loctite Spray Adhesive Multi Purpose for Styrofoam projects. -

Loctite Consumer Australia: How to glue Styrofoam – Best methods for strong bonds

Discusses Loctite Extreme Gel for quick repairs and strong bonds on porous surfaces. -

Hobby Foam Supplies: Top 11 Glues & Adhesives suitable for Styrofoam crafts

A comprehensive list of adhesives, including UHU Por, Foam Safe CA Glue, and 3M Super 77 Spray Adhesive.