Trying to glue fabric to plastic can often seem like an illusion, a mismatch of texture, flexibility, and materials. Whether it is for a simple craft project, repairing household items, or a DIY idea, it’s essential to find the proper method for a durable and seamless connection. This guide offers a comprehensive overview of the best strategies for gluing fabric to plastic, enabling you to avoid common issues and focus on the fun, rather than wasting precious time on trial and error.

The process of gluing fabric to plastic involves choosing the right glue, preparing the materials, and applying the correct gluing techniques. Read more to use your newfound knowledge with precision and confidence!

Understanding Material Properties

The materials have different properties. Fabric is porous and absorbent, whereas plastic usually is smooth and non-porous. Because of this difference, the ways adhesives bond to each surface differ. Porous surfaces, such as fabrics, allow liquid adhesives to seep in through them and require sufficient application to develop a strong bond. Non-porous surfaces, such as plastics, may require special adhesives to ensure they are permanently bonded. If you prepare the two materials by cleaning the plastic and ensuring the fabric has no lint, they will likely bond more effectively, resulting in good durability.

Variety of Fabrics and Their Adhesion Properties

Different fabrics have varying adhesion properties depending on their texture, composition, and weave:

- Natural fibers (cotton, wool): Usually very receptive to adhesives due to their porosity, creating stronger bonds when liquid adhesives are applied

- Synthetics (polyester, nylon): Have smoother surfaces and are less porous, requiring special adhesives such as hot glues or spray adhesives

- Stretchy fabrics (spandex): Require adhesives that set flexibly, allowing the fabric to bend without breaking the bond

Types of Plastics and Their Bonding Challenges

| Plastic Type | Characteristics | Bonding Challenges |

|---|---|---|

| Polyethylene (PE) & Polypropylene (PP) | Lightweight and durable, commonly used in packaging | Low surface energy requires pre-treatment or special adhesives |

| Polycarbonate (PC) & Acrylic (PMMA) | Explicit, strong materials are used in various applications | Must resist stress, UV exposure, and temperature changes |

Choosing the Right Adhesive

When selecting the proper adhesive for plastic, the following factors should be taken into consideration:

Material Compatibility

Ensure the adhesive is specifically designed for the type of plastic you are bonding (e.g., ABS, PC, PMMA)

Strength Requirements

Identify the required strength based on the load-bearing or impact resistance expectations.

Environmental Conditions

Consider exposure to heat, moisture, UV light, or chemicals

Application Method

Consider the ease of application, curing time, and the differences between one-part and two-part adhesives.

Recommended Adhesives for Fabric to Plastic

When bonding fabric to plastic surfaces, it is crucial to consider several key factors when selecting an adhesive to achieve a strong and lasting bond. Based on recommendations from the very recent past and verifiable applications, some of the generally accepted options have been considered:

-

Epoxy Adhesives

Among the best options for durable bonding of fabrics to rigid surfaces. They offer high strength and resist heat, moisture, and other environmental effects.

-

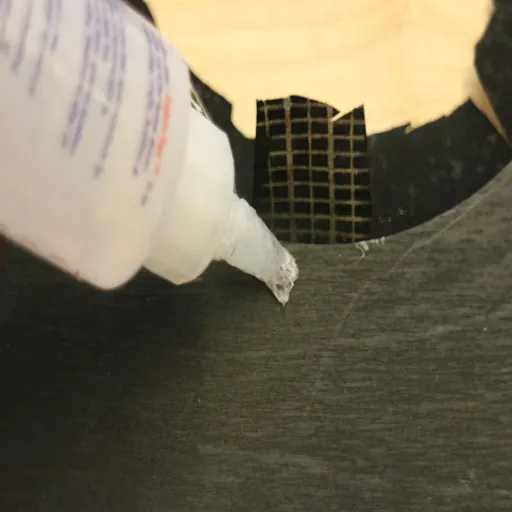

Cyanoacrylate (Super Glue)

Best suited for small projects, it should be used with caution. Bonds quickly and works well with light fabrics and smooth plastic surfaces.

-

Spray Adhesives

Such as 3M Super 77, well-suited for bonding fabric and plastic in larger quantities. Allows even application and works well when flexibility is required.

-

Hot Glue

Offers the benefits of being inexpensive and convenient, suitable for temporarily bonding lightweight items. Works particularly well with certain types of plastics and fabrics.

-

Specialized Fabric and Plastic Adhesives

Adhesives designed explicitly for bonding fabric to plastic, such as E6000 Craft Adhesive. Provides strong bonding yet remains flexible, making it very suitable for projects involving soft materials.

Factors to Consider When Selecting Glue

If you want your project to perform optimally, several factors must be considered before selecting a glue:

- 1

Material Compatibility: Not every glue is compatible with all surfaces. Choose an adhesive made for your specific materials. - 2

Strength Requirements: Determine required strength and durability. Consider structural adhesives for heavy-duty applications. - 3

Environmental Conditions: Consider the environment: temperatures, water, and humidity can affect adhesive performance. - 4

Curing Time: Some adhesives set instantly, others take hours or days. Consider your project timeline. - 5

Flexibility: Some projects require flexible adhesives that can accommodate movement or shifting. - 6

Safety and Toxicity: Assess potential health hazards. Choose non-toxic options when appropriate. - 7

Aesthetics: Consider appearance – clear-drying or paintable adhesives for visible applications.

Common Mistakes to Avoid

Using the Wrong Adhesive Type

Adhesives may impart weak bonds and lead to project failure if selected based on unsuitable materials or purposes. Adhesive should always be matched to the specific materials and conditions.

Ignoring Surface Preparation

Applying adhesive onto surfaces that are dirty, greasy, or uneven compromises adhesion. Surfaces should be clean, dry, and adequately prepared for application.

Overusing Adhesive

Using more adhesive than necessary can result in excessive coverage, prolonged drying times, and weaker bonds. Use only the specified amount as recommended by the manufacturer.

Skipping Manufacturer Instructions

Failing to read instructions regarding application, drying time, and curing can result in poor results or safety hazards.

Rushing the Curing Process

Not waiting enough for the adhesive to set properly hinders curing and weakens the bond. Patience and adherence to the given curing time are essential.

Incorrect Adhesive Selection

Incorrect choices in adhesives can compromise the bond’s integrity. When selecting an adhesive, factors such as the nature of the material being joined, environmental conditions (temperature, humidity), and the types of loads or stresses this bond must withstand should be considered. Thorough research on adhesives and checking guidelines from manufacturers for compatibility becomes essential. If in doubt, conducting compatibility tests is warranted.

Neglecting Surface Preparation

Neglect of surface preparation is one of the primary causes of adhesive failure. Surfaces that are not adequately prepared may contain contaminants, such as dirt, oils, or moisture, which prevent the adhesive from forming a strong bond. The key steps in preparation often include cleaning with the proper solvent, ensuring the surfaces are dry, and occasionally using an adhesive primer.

Tips for Long-lasting Bonds

🧼 Clean the Surfaces Thoroughly

Remove dust, dirt, grease, and other contaminants using an appropriate solvent or cleaner. A clean surface favors adhesion.

💧 Ensure Surfaces are Dry

Any moisture can weaken the bond, so always check that surfaces are dehydrated before applying adhesive.

🎨 Consider Using a Primer

Sometimes, using a primer can enhance the strength and longevity of an adhesive bond.

📏 Apply the Right Amount

Spread adhesive in a consistent, thin layer to avoid weak points or excess mess.

⏰ Allow Proper Curing Time

Follow the manufacturer’s suggested curing time to achieve the best strength and longevity.

🎯 Match Adhesive to Materials

Use an adhesive ideally meant to bond your specific materials for optimal compatibility and effectiveness.

Choosing the Best Glue for Fabric and Plastic

When choosing the perfect glue for bonding fabric to plastic, the glue has to be flexible, have strong adhesion, and be compatible with both materials.

- Two-part epoxy glue: Becomes extremely strong, especially with hard plastics

- Silicone-based or specialty fabric glues: Usually give excellent, flexible bonds with mixed materials

- Cyanoacrylate (superglue): Suitable for smaller applications, but may not be flexible enough long-term

Best recommendation: Always read instructions carefully, thoroughly check the product before use, and test an inconspicuous area first to ensure it meets all requirements.

Safety and Environmental Considerations

Working in a Well-Ventilated Area

Recognizing that adhesives contain volatile chemicals, having proper ventilation is crucial for maintaining good health. Good ventilation reduces the concentration of volatile organic compounds (VOCs) in the air, thereby reducing the risk of inhaling toxic substances.

Ventilation options: Work outdoors, use fans in windows, or utilize exhaust fan systems to improve air quality during adhesive projects significantly.

Proper Adhesive Storage Practices

Adhesives must always be stored in a superb, dry location, away from direct sunlight and heat. The container should never be left loosely closed after use, as it may dry up or become contaminated. Always follow storage instructions printed on labels, taking into account child and pet safety measures.

Eco-Friendly Adhesive Options

The best eco-friendly adhesives balance sustainability with bonding performance:

- Plant-based adhesives derived from natural latex and starch

- Water-based glue labeled as non-toxic

- Soybean adhesive for superior strength and environmental appeal

- Products certified by ecological groups or labeled “Low VOC”

Safety Precautions When Using Adhesives

- Work in well-ventilated areas to prevent dizziness, headaches, or respiratory irritation

- Wear appropriate PPE: gloves for skin protection and safety goggles for eyes

- Keep adhesives away from open flames or heat sources, as many are flammable

- Store adhesives in original containers, tightly closed, away from children and pets

- Follow first aid measures on the manufacturer’s label in case of accidental contact

Reference Sources

Here are five professional and authoritative sources for verifying or augmenting information on gluing fabric to plastic:

- IOP Science: “Preliminary research on the strength of glued connections of plastic elements” – Examines adhesive bond strength between various materials, including plastics and fabrics

- SAGE Journals: “Polyester adhesives in nonwovens and other textile applications” – Reviews polyester adhesive properties and bonding capabilities

- MDPI: “Shear strength of adhesive bonding of plastics intended for high temperature plastic radiators” – Analyzes various plastic-bonding adhesives

- Taylor & Francis Online: “History of adhesives” – Provides historical perspectives on adhesive evolution

- EBSCOhost: “Patch-test reactions to plastic and glue allergens” – Addresses safety concerns about adhesive allergic reactions

Frequently Asked Questions (FAQs)

What is the best adhesive for gluing fabric to plastic?

The best adhesive for bonding fabric to plastic is often a contact adhesive or a specific fabric glue that dries clear. Products like Loctite or specially formulated fabric adhesives are popular choices because they provide strong adhesion while allowing the materials to stay flexible.

How can I effectively attach fabric to plastic?

To attach fabric to plastic effectively, start by ensuring both surfaces are clean and dry. Apply a small amount of adhesive to both surfaces, then press them together firmly. Using masking tape around the area can help keep the materials in place while the glue dries.

Can I use regular glue for fabric to plastic?

Regular glue may not provide the best results when bonding fabric to plastic. It’s recommended to use adhesives specifically formulated for this purpose, such as Loctite super glue or contact cement, to ensure a strong and lasting bond.

What should I consider when applying glue to fabric?

When applying glue to fabric, consider the amount of glue you use. A small amount is often sufficient to avoid bleed-through and ensure a clean seam. Additionally, applying glue to both surfaces can improve adhesion.

How long does it take for glue to dry on fabric and plastic?

The setting time for glue on fabric and plastic can vary depending on the type of glue used. Most fabric adhesives will dry within a few hours, but it’s essential to follow the manufacturer’s instructions for optimal results. Some adhesives may require a longer cure time to achieve maximum strength.

Can I use sandpaper to prepare the plastic surface?

Yes, using sandpaper to roughen the surface of the plastic can improve adhesion. It creates a better bonding surface for the adhesive, allowing it to grip more effectively. Just be sure to clean the surface after sanding to remove any dust.

What are the general guidelines for using fabric adhesives?

General guidelines for using fabric adhesives include applying the glue evenly, wearing gloves to protect your hands, and ensuring the materials are clean and dry before application. Additionally, pressing the edges together until the glue cures is crucial for a strong bond.

What if the fabric rips or tears after it has been glued?

If the fabric experiences rips and tears after being glued, it’s essential to assess the bond. If the adhesive has failed, you may need to remove the old glue and reapply a suitable adhesive, ensuring proper surface preparation and application techniques are followed.

Is it necessary to use a specific type of glue for flexible plastics?

Yes, when working with flexible plastics, it is advisable to use an adhesive that is specifically designed for those materials. This ensures the glue remains flexible after drying and does not become brittle or crack over time.