Styrofoam is one of the most widely used materials across various industries, including packaging, insulation, crafts, and do-it-yourself projects, among others. However, the problem of adhesion arises when working with Styrofoam. Making the right choice and following the correct method with adhesive is both an art and a science, ensuring a strong yet lasting bond is created without harming the material as a whole. This piece of writing clarifies the most suitable types of adhesives when working with styrofoam and informs about the state of the art in their application. Especially when working on a work-related project or on a decorative endeavor, knowing these basics will help save the day and work without mistakes.

Understanding Styrofoam and Its Properties

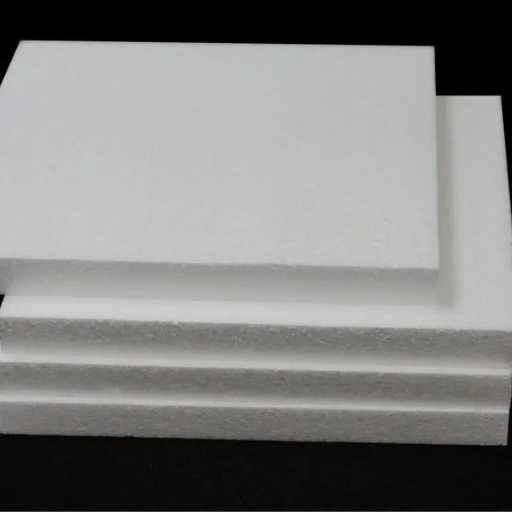

Styrofoam or expanded polystyrene, EPS, is a light material packed with mostly air and containing about 5-10% styrene. Insulation is enhanced due to the microporous nature of the foam structure, with polystyrene offering the advantage of very low weight. It is cost-effective and easy to shape, making it the ideal insulation material for construction, storage material for packaging purposes, and art, among other uses. Moreover, it is not advisable to use certain materials when working with this material, such as solvents and adhesives, as they may dissolve or damage it. The foundation of understanding these properties is instrumental when considering materials and techniques that involve using Styrofoam.

What is Styrofoam?

Among other names, Styrofoam is polystyrene foam, which is prepared by polymerizing styrene, a substance derived from oil. The majority of Styrofoam, ranging from 95-98%, is made up of air, which contributes to its ease of handling and heat retention capacity. The aptness of Styrofoam as an insulating material and water-resistant closed-cell foam can achieve a thermal conductivity of around 0.033 W/(m·K). Such qualities establish Styrofoam as the ideal material for insulating construction, where heat preservation is a crucial factor. Besides insulation, the pads are also preferred in the packaging industry, particularly for protecting fragile equipment and other objects during transit.

Despite this, it is clear that the same material has certain limitations, which, to some extent, affect its adoption. Styrofoam, for instance, has a moderate ability to burn unless it is treated with various flame retardants, because the temperature at which it starts to melt is not too high, around 240°F (115°C). Moreover, it is not the type of material one wants to put into the soil, as it does not decompose and, therefore, creates pollution problems. To address sustainability issues related to Styrofoam, current advocates have explored human-friendly or biodegradable materials and focused more on the ingenuity of waste management methods that emphasize the recycling of the product. Additionally, while powerful and efficient in its application, Styrofoam requires some responsibility and care regarding environmental degradation.

Types of Styrofoam

|

Type of Styrofoam |

Key Characteristics |

Common Applications |

|---|---|---|

|

Expanded Polystyrene (EPS) |

Lightweight, strong insulator |

Packaging, construction, disposable cups |

|

Extruded Polystyrene (XPS) |

Higher density, water-resistant |

Insulation boards, architectural models |

|

Polystyrene Foam Core |

Flexible, lightweight core material |

Signage, crafting, prototyping |

|

Molded Polystyrene Forms |

Pre-shaped molds, structural stability |

Appliance packaging, product protection |

|

High-Impact Polystyrene (HIPS) |

Durable, shock-resistant |

Electronics casing, toys, trays |

Common Uses of Styrofoam

- Packaging

When it comes to packaging, Styrofoam has established a significant presence. The material is excellent at absorbing energy and, therefore, provides good protection for delicate items during transportation and storage. Such products are generally provided in a variety of molded foam types for the appliance’s protective packaging or for the electronics and glassware packaging containing such items. There are also Styrofoam peanuts which are used for packing in Abbey boxes in order to prevent rattling of items.

- Insulation

Advancements in thermal insulation have been made thanks to Styrofoam since the material exhibits excellent properties in this regard. Since energy inefficiency has always been a problem, especially in older buildings, Extruded Polystyrene (XPS) boards are present in many walls for insulation purposes. At the same time, Styrofoam is built inside refrigerators and cold stores for the purposes of fabrication.

- Food and Beverage Containers

Styrofoam takeaway containers, disposable cups and plates are to be found everywhere mainly because they are convenient to use, they can maintain heat or cold for a reasonable period of time and yet they are very light in weight since all of it is not used part of it also provides packaging since the entire cup is not occupied. For instance, when a consumer orders coffee from a cafe in an insulated Styrofoam cup, the beverage will remain hot for much longer.

- Construction Materials

Professional architects use Styrofoam to construct models and molds for concrete. It allows the creation of flat or curved designs without adding a great deal of extra weight.

- Signage and Display

When it comes to creating signs, displays, or even simple craft projects, foam core boards are very popular. They require little or no modification and can be effectively and beautifully concluded with paint for both temporary and permanent setups.

- Model Making and Prototyping

Choosing the Right Adhesive for Styrofoam

- Compatibility with Styrofoam

Ensure the adhesive is explicitly a Styrofoam-safe adhesive or has been tested with and on Styrofoam. Some adhesives have dangerous solvents as they tend to melt the material or ‘eat’ the material away significantly.

- Bonding Strength

You can use a weaker adhesive in mild, less-stressful situations, whereas suitable bonding adhesives are required for heavy-duty work, such as polyurethane-based adhesives.

- Application Surface

It is essential to be cautious and verify the material you are working with. Some adhesives work better for bonding Styrofoam to other Styrofoam, while others are more suitable for bonding Styrofoam to other materials, such as wood, metal, or plastic.

- Drying Time

Consider the viscosity; it is the time the glue takes to set up or harden. Quick-drying, by the way, comes in handy for specific projects that require some glues to dry up quickly. For example, slow drying may result in weak or low bond strength.

- Environmental Conditions

Look at what elements the adhesive will face, such as heat, moisture, and even the outside. Choose adhesives engineered for external application if the project is going to be carried out outside.

Best Glue Options for Styrofoam

- Epoxy Adhesives

Additionally, the impressive strength and long-lasting bond nature of epoxy make it a suitable choice for styrofoam, as it can withstand pressure. These two-part adhesives are composed of resin and catalyst that cure together to form a hard material. Epoxy can stick to styrofoam without also damaging other surfaces, such as metal or wood, thus affording a user the choice of such material for intricate projects. Yet it is resilient enough to humidity and changes in temperature, and thus could be used either inside or outside.

- Foam-Safe Cyanoacrylate Glue

Standard cyanoacrylate, or super glue, is extremely fast-acting but requires caution when used with styrofoam, as it can be harmful to the surface. But ‘foam-safe’ cyanoacrylate glue specifically targets the foam’s natural tendency to erode its surface upon brushing. Such adhesives are designed to meet the needs of applications that require meticulous care and are performed in a very short period, such as the joining of small details or restoration work.

- Spray Adhesives

For attachment of adhesives, spray adhesive with nozzles, rather than a spray nozzle, is also a good choice for bonded structures of Styrofoam to avoid a case where the bonding is slightly children or Styrofoam gets damaged. There is also light-stick glue in the form of high-strength spray adhesive that helps create a bond between foam materials without excessive mass accumulation. They prove to be quite helpful in situations where the adhesive is to be provided over exposed areas or large adhesive layers are required for project assembly.

- Silicone-Based Adhesives

Silicone-based adhesives are also very good for bonding when dealing with Styrofoam materials, as they are flexible and have very high wet and dry strength. These adhesives do not prevent the combination of spring and movement of materials as they expand and contract while bonding. They are ideal for applications where there are vibrations or movement of the material in place.

Spray Adhesives vs. Liquid Adhesives

Needless to say, there are many differences between spray adhesives and liquid adhesives in Styrofoam applications, particularly in view of their distinct properties, and users must assess these differences in order to apply the most appropriate adhesive for the specific requirements. The great advantage of spray adhesives is not only that they are easy to use but also that they blanket a large area uniformly within a very short time. This quality functions as a time-saving measure, allowing for the swift application of adhesive in projects where efficient results require rapid application. However, in certain applications, aerosol adhesives may not provide the same adhesion strength as liquid types, particularly when a concentrated adhesive is required.

Step-by-Step Guide to Gluing Styrofoam Parts Together

- Prepare the Workspace

Ensure that the workplace is kept tidy, quiet, and well-ventilated, which will prevent contamination of the adhesive and encourage proper curing. Place newspaper or starch fabrics on the surfaces to prevent gluing them.

- Select the Appropriate Adhesive

Select a special glue for compatibility with Styrofoam, such as spray foam-compatible adhesives, epoxy, or certain polyurethane-based materials. Do avoid using glues that include a composition that contains harmful solvents – it is dangerous for expanded polystyrene foam.

- Clean the Styrofoam Surface

Softly rub the Styrofoam parts to clean them of dirt and trash. A smooth and dry surface ensures the best paste bond.

- Apply the Adhesive

Spread the glue evenly on the surface of any one part. In case of spray adhesive, maintain the recommended specified distance on the container for effective use. Avoid applying more than the needed amount of adhesive as it can break the bond in case of later use.

- Combine the Pieces

Squish the surfaces gently but firmly without undue force on the Styrofoam to avoid breakage. Hold the position for a few seconds until the desired effect is attained.

- Secure and Allow to Cure

In the case when, the pieces may need to be bound with string, clamps, or weights until the glue hardens. Ascertain the curing time through referencing the guidelines provided by the adhesive supplier.

- Inspect the Bond

You can only check the strength of the bond once the adhesive has thoroughly hardened. Be prepared to remove any extra glue from the area if necessary.

Preparing Your Workspace

When working with adhesive and this Styrofoam-like material, it is essential to have a well-equipped work area to maximize the project’s potential. It is essential to begin by selecting the most appropriate layered surface that is positioned vertically. It should be a dusty plug-in in grease or any other material that might interfere with the process of adhesion. Make sure the working environment is well-prepare,d particularly if the adhesive used in the task produces noxious materials that affect the user’s health when inhaled for a prolonged time. Prepare all the necessary equipment, including the bonding adhesive, an application device or its substitutes, edged instruments for cutting, and any clamps or weights that may be used to secure the material during its curing process. Also, it is required to keep a stock of gloves, goggles, and other prevention devices for accidental spills and contact of dangerous chemicals with the skin and the respiratory system. Install a thermometer and a hygrometer for accurate temperature and humidity control, as these factors significantly impact the performance of the adhesives. Sound preparation of the work area significantly increases efficiency as well as the value of the adhesive bond created.

Applying the Adhesive

It is also important that when you introduce an adhesive, the surfaces are prepared with an undercoat that is clean, solid, dry, free from moisture and pollutants. The adhesive application is typically carried out by evenly applying the adhesive to one or two surfaces, as recommended in the technical documentation for the respective adhesive, and using the applicable applicator, such as a brush, roller, or notched trowel. It should be considered to make a layer of adhesive with appropriate thickness as recommended by the manufacturer so as to provide the desired bond strength. It is also noted that it would be best to know the open time of the adhesive, which is the total time allowed to elapse after applying adhesive before two surfaces are brought into contact; extending beyond this period greatly affects adhesion.

Expert Tips for Successful Styrofoam Projects

- Choose the Right Adhesive

Prevent further distortions and trimmings of Styrofoam by using adhesives for Styrofoam such as either polystyrene adhesives or epoxy quick-setting resins. Do not use solvent-based glues as these melt the foam.

- Work in a Controlled Environment

Obviously, one wants to work in a clean and organized area, free from any traces of dust or debris associated with building restoration. Appropriate humidity and temperatures in the assembly area are important as often imbalances can lead to bowing and warping issues.

- Use Precision Cutting Tools

Hot wire cutters or utility knives are the preferred tools for cutting Styrofoam as they easily create sharp, straight edges as needed. The blade cuts or sharpens if the man-made fiber starts straining when cutting.

- Apply Even Pressure When Bonding

Evenly exert force on the surfaces joined using clamps or weights. This enhances the adhesive’s performance and extends its bonds.

- Paint with Care

No time for a full sandwich, or chomp off the ears of those bunnies! Water-based or Styrofoam-safe surfaces both drain less of the paint and preserve the surface satisfactorily.

Recommended Products for Gluing Styrofoam

- 3M Super 77 Multipurpose Adhesive

This is a superior spray adhesive that dries quickly, ideal for bonding expanded polystyrene and a wide variety of other materials. Other applications include art projects or projects where members are to be bonded.

- Loctite PL 300 Foamboard Adhesive

Appropriate for use on foam boards, this adhesive also has a high bond strength while preventing the dissolution or weakening of the Styrofoam. It is effective in DIY and professional work applications.

- Gorilla Original Glue

Polyurethane adhesive, Gorilla Glue, is known for its exceptional bond with the materials, and it lends well with the use of small amounts on Styrofoam. The cure is slightly expanded filling gaps making any joint more durable.

- UHU POR Styrofoam Glue

Adhesives designed to adhere to Styrofoam are crucial to the success of both basic and artistic efforts, and these can often be expensive, potentially affecting the material’s characteristic properties if they are effective. Do make sure also to follow the right procedures and wait for an adequate duration to let the glue bond the surfaces together for attaching the surfaces.

Compare Different Types of Adhesive for Styrofoam

|

Adhesive Type |

Strength |

Drying Time |

Flexibility |

Application Suitability |

Temperature Resistance |

Notes |

|---|---|---|---|---|---|---|

|

Polystyrene Glue |

High |

5-10 minutes |

Moderate |

Small repairs, crafts |

Low to moderate |

Designed specifically for Styrofoam use |

|

Spray Adhesive |

Medium |

Immediate tack |

Flexible |

Crafts, large surface bonding |

Moderate |

Even coverage, use in ventilated area |

|

Epoxy |

Very high |

5-20 minutes |

Rigid |

Heavy-duty applications |

High |

Mix liquid components before application |

|

Hot Glue (Low Temp) |

Medium |

Instant |

Semi-flexible |

Temporary bonds, crafts |

Low |

Avoid high-temp glue guns for Styrofoam |

|

Silicone Adhesive |

Medium |

24-48 hours |

Flexible |

Indoor/outdoor projects |

High |

Moisture-resistant, excellent for gaps |

|

Construction Adhesive |

Very high |

15-30 minutes |

Rigid |

Permanent installations |

High |

Can be overkill for lightweight tasks |

|

Double-Sided Tape |

Low to medium |

Instant |

Flexible |

Lightweight Styrofoam bonding |

Low |

Suitable for non-permanent applications |

Avoiding Common Mistakes When Gluing Styrofoam

Please avoid the following errors while using adhesive on Styrofoam so as to have the bond last long and be successful:

- Using the Wrong Adhesive

Most adhesives do not pair well with or work with Styrofoam. Substances such as high-temperature glue guns, solvent-based adhesives, and petroleum-based adhesives can cause the material to melt or weaken. These and many other examples are why it is recommended that materials safe for use with styrofoam be used at all times when carrying out such applications. These include silicone adhesive, adhesives suitable for construction applications (where applicable), double-face acrylic foam tape for light applications, and others.

- Ignoring Drying or Curing Times

Every adhesive requires a specific timetable for drying and curing to achieve desirable adhesion. In case the steps are skipped, it is possible to experience adhesion that is too weak or even none at all.

- Applying Excess Adhesive

It can result in poor adhesion if too much heat-sensitive adhesive is used or if adhesive seeps through the edges without it beads up. Hence, a thin even layer is to be used for improved performance.

- Skipping Surface Preparation

Before applying adhesive, Styrofoam surfaces have to be free from any contaminants and also dry. An adhesive bond may not form properly if dust, original joins to the Styrofoam, or moisture are present.

If you follow these pieces of advice, you can avoid many problems and create a guaranteed clean joint with the Styrofoam you use.

Mistakes That Can Melt Styrofoam

- Using Solvent-Based Adhesives

When using adhesives that contain solvents like acetone, toluene, or benzene, a chemical reaction can take place between these solvents and Styrofoam. These solvents attack the styrene chains present in the polystyrene and therefore destroy the structure of the material. Before adhering anything, it is advisable to check that the package of the particular adhesive being used indicates the adhesive’s suitability for the use of Styrofoam.

- Exposing Styrofoam to High Temperatures

Proper care should also be taken to ensure that exposure to heat is kept at a minimum due to the sensitivity of the Styrofoam and that it starts to shift or melt when it reaches temperatures above the softening temperature, which is usually around 200°F (93°C). Heat guns, hair dryers, or any other form of heating, as well as the use of fire, can cause structural problems that can only be tempered by the abolishment and reconstruction of Styrofoam.

- Applying Strong Chemical Cleaners

Unless the labels of the chemicals and cleaners that will be used indicate the presence of harsh chemicals, other detergents are not expected to harm Styrofoam. Therefore, one should use gentle, non-abrasive detergents to clean such material so as to prevent chemical damage.

- Improper Use of Spray Paints

Many paints contain solvents that are known to dissolve Styrofoam when used. Therefore, when painting Wteroj, it is better to use acrylic spray paint or water-based spray paints that are designed to be used specifically on styrofoam.

Using the Wrong Kind of Glue

Ensuring Proper Adhesion

Several factors must be considered when seeking optimal bonding between Styrofoam substrates. These include surface preparation, where the first step typically is to ensure the Styrofoam base is clean and devoid of any foreign particles like oil or dust, which might compromise the bonding strength. Applying adhesives in spaces where temperatures and humidity comply with those specified by the adhesive manufacturers significantly improves adhesion strength. For example, numerous adhesives work best in temperatures ranging from 60°F to 80°F and with relative humidity levels below 60%.

Reference Sources

-

Loctite: How to glue Styrofoam

This guide highlights the use of spray adhesives, such as Loctite Spray Adhesive Multi-Purpose, as one of the best methods for gluing Styrofoam. It provides step-by-step instructions for application, emphasizing the importance of clean surfaces and proper ventilation. The article also discusses the compatibility of adhesives with Styrofoam to avoid damage. -

LePage: How to glue Styrofoam together

This resource explores various adhesive options for Styrofoam, including super glue for quick fixes and flexible adhesives for more durable bonds. It offers professional tips on selecting the right adhesive based on the project type and provides advice on achieving strong, lasting bonds. -

Quora: What glue works the best on Styrofoam?

This Quora discussion features user recommendations for the best adhesives for Styrofoam, such as UHU Styrofoam glue, Weldbond, and 3M 77. It includes practical insights from users about their experiences with these products and their effectiveness for different applications.

Frequently Asked Questions (FAQs)

Q: Best Way to Glue Styrofoam Together

A: Finding the best way to glue styrofoam can be crucial for various crafting and construction projects. The ideal adhesive depends on the specific application and the materials involved. For instance, using a foam board adhesive or a spray adhesive like 3M Super 77 works great for bonding styrofoam to other porous surfaces. If you’re looking for a strong bond, consider using hot glue or contact cement, as they adhere well to styrofoam. However, ensure the glue is foam-safe to prevent melting the material. Always work in a well-ventilated area when using strong adhesives.

Q: What Kind of Glue Works Well for Styrofoam?

A: When it comes to choosing a kind of glue for styrofoam, you have several options. White glue or PVA glue is often recommended for lightweight projects, while hot glue is favored for a stronger hold. Contact glue and vinyl adhesive caulk are also effective, particularly for larger surfaces or when bonding styrofoam to polystyrene foam. It’s essential to use an adhesive designed for foam to avoid damage, and be sure to apply the glue evenly for the best results. Always test the glue on a small area first to ensure compatibility.

Q: How to Apply Glue to Styrofoam?

A: Knowing how to apply glue to styrofoam properly can make all the difference in the success of your project. Start by ensuring that the surfaces are clean and free of dust, which can affect adhesion. Use a sharp blade to cut the styrofoam if necessary, as clean edges help create a stronger bond. When applying glue, whether it’s craft glue or contact cement, spread it evenly across the surface. For larger areas, using a foam brush can help achieve a uniform application. Allow the adhesive to set according to the manufacturer’s instructions for optimal results.

Q: Is Spray Adhesive Effective for Gluing Styrofoam?

A: Spray adhesive can be an effective method for gluing styrofoam, especially for projects requiring a broad coverage area. Products like 3M Super 77 spray adhesive are designed for foam and offer a strong bond while being easy to apply. Ensure that you are in a well-ventilated area when using spray adhesives, as the fumes can be strong. Additionally, it’s important to follow the directions carefully, applying the adhesive in a consistent, even layer to avoid excess drips. Test the adhesive on a small piece of styrofoam first to ensure compatibility.

Q: Can I Use Hot Glue on Styrofoam?

A: Hot glue is a popular choice for many crafters, and it works really well for styrofoam applications. It creates a strong bond and is quick to set, making it ideal for projects that require immediate holding. However, be cautious, as excessive heat can melt the styrofoam if the glue is applied too thickly. It’s best to use a low-temperature hot glue gun to minimize this risk. Additionally, ensure that the surfaces are clean and dry before applying the hot glue for the best adhesion. Always wear safety glasses when working with hot glue to protect your eyes from any splatters.