Foam gluing can be difficult if not handled correctly, whether for crafting, custom cushions, or repairing items. Since there are numerous kinds of foams and glues, selecting the best way to glue the foam pieces together can be an overwhelming task. This guide is designed to ease you through the process and help you form a strong and durable bond. No matter whether you are a DIYer or dealing with a professional project at hand, you will be acquainted with the best materials, the right ways of foam preparation for the best glue adhesion, and the most common mistakes to avoid. Prepare yourself to move your foam bonding expertise to a new level!

Understanding Foam Types

Foam is available in a variety of varieties, and each array corresponds to a different application. The most frequently used ones are polyurethane foam, mainly for furniture and upholstery; polystyrene foam, also widely used in packaging and insulation; and polyethylene foam, known for its strength and shock absorption. It is essential to understand their differences because each kind of foam reacts differently to adhesives and environmental factors. To achieve the best results, selecting the most suitable type of foam involves considering its primary use, flexibility, density, and compatibility with bonding materials.

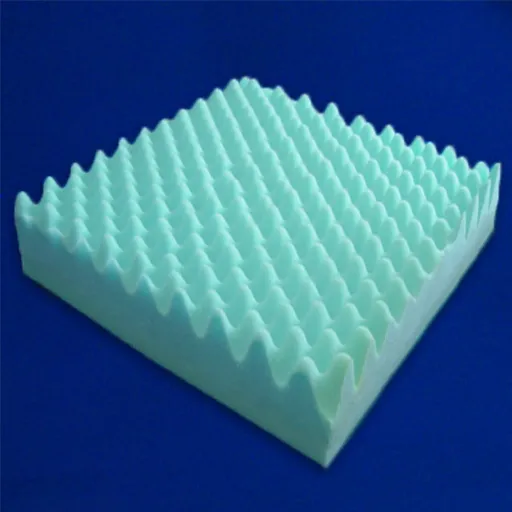

Open-Cell Foam

Open-cell foam is a soft, light, and flexible material best known for its porous structure, which facilitates air and moisture circulation. This kind of foam finds its way into applications where breathability is the main requirement, such as cushioning, sound absorption, and thermal insulation. Being composed of interconnected cells, it is softer and less dense than closed-cell foam, resulting in great demand for it in comfort-oriented items like mattresses and chairs. Knowing its different environment-related properties is very important, as the air permeability can affect its performance in certain conditions.

Closed-Cell Foam

Closed-cell foam is defined by its tightly packed cells that are hermetically sealed from each other. This structure effectively locks out both air and moisture, making the foam ideal for applications where water conservation and high durability are the primary requisites, such as insulation, buoyancy aids, and packing materials. Moreover, it is the intensive material production that usually gives the foam a firmer and more rigid feel as compared to open-cell foam. Also, closed-cell foam offers excellent thermal insulation and is not easily destroyed; thus, it is the material of choice in very tough situations where moisture or heavy impacts could easily ruin other materials. Knowing the particular characteristics of closed-cell foam is a massive help in picking the proper type for industrial, commercial, or private use.

Choosing the Right Glue for Foam

Selecting the proper adhesive for foam requires consideration of both the foam’s nature and the task’s intention. Contact adhesives or spray adhesives are great for most foam materials, like open-cell or closed-cell. They provide strong bonds that don’t harm foam. If water resistance is a requirement, then the adhesive options suitable for foam and explicitly labeled as waterproof should be considered. Make sure the adhesive is non-corrosive to prevent the foam from degrading. Testing the adhesive on a small cutout before applying it is a good practice, as it helps confirm compatibility and secure the best results.

Foam-Specific Adhesives

To get the most out of foam-specific adhesives, proper pre-treatment and application are crucial for achieving a strong and permanent bond. First, make sure that the surfaces are spotless, dry, and free from dust or other materials that might interfere with the adhesion process. Then, using a brush, spray, or applicator specifically designed for the product, apply the adhesive in a thin, even layer, taking care not to use too much, as this could lead to a messy situation or prolonged drying time. Next, let the adhesive become tacky according to the manufacturer’s instructions before pushing the foam pieces together. In case of large foam projects, it might be a good idea to use clamps or weights to hold the bond together while it is drying. It is essential to work in a place with good air circulation, especially when using contact adhesives with strong fumes. If you stick to these best practices, you are guaranteed not only a professional-grade bond but also a longer-lasting project.

Hot Melt Adhesives

Hot melt adhesives come in several different varieties, and their main advantages are flexibility, fast setting time, and strong adhesion. They are thermoplastic adhesives in the form of molten material, solidifying when cooled, allowing them to create an instant bond by simply melting and cooling. These adhesives are great for working on projects with paper, fabric, wood, and some plastics, making them very often used in the packaging, crafts, and woodworking industries.

To get the best results, it is essential to identify the proper hot-melt adhesive formulation that suits your materials and conditions. Furthermore, investing in a quality glue gun will provide you with the precision and safety you need during the application. If you are aware of hot melt adhesives’ properties and their best applications, you can be sure to have a smooth and successful bonding for your project.

Step-by-Step Guide to Gluing Foam Sheets Together

Step 1: Prepare the Foam Sheets

Clean the foam sheets and remove any dust, dirt, or oil. If necessary, use a soft cloth or a mild cleaner, as a clean surface is crucial for achieving good adhesion.

Step 2: Choose the Right Adhesive

A hot melt adhesive, which is meant for foaming or flexible substances, must be your choice. Some adhesives prevent the foam from melting or deforming during the application process.

Step 3: Heat the Glue Gun

Get your glue gun plugged in and wait till the weapon reaches the recommended temperature for the adhesive you are using. Most hot glue guns have an indicator light that indicates when they are ready to use.

Step 4: Apply the Adhesive

Place a thin and even bead of hot melt adhesive with great care along the edge or the surface where the foam sheets will be joined. Do not apply too much glue, as it may ooze out and lead to a messy situation.

Step 5: Press and Hold the Foam Sheets Together

After the adhesive is applied, firmly press the foam sheets together right away. Keep them in position for a few seconds to get a strong bond. Depending on the adhesive, you may have to wait a few more minutes for it to cure completely.

Preparation for Gluing Foam

If you want to achieve the best results when using adhesive on foam, it is crucial to follow the correct preparatory steps. Cleaning the foam surfaces and making sure they are practically free of everything (dust, dirt, and so on) is the first step. If there are any oils from your skin or otherwise present, they can negatively interfere with the adhesive, so clean those off, too. Additionally, by applying very light pressure while sanding the foam with fine-grit sandpaper, you can make the surface a bit rougher, so that it will be easier for the adhesive to stick. Also, ensure there is no wind at your work location, and wear gloves to protect your skin from any possible contact with the adhesive. It is vital to choose the appropriate type of adhesive for your foam—hot melt, spray adhesive, or contact cement are among the standard options, depending on the application and other factors. Proper preparation will form the basis for a strong and durable glued connection.

Gluing Large Foam Pieces

When joining large foam blocks, it is essential to prepare well and use the proper technique to create a strong and seamless bond. First of all, you need to ensure that both surfaces are clean, dry, and free from dust or dirt, as contaminants will weaken the adhesion. If you want to achieve the finest results, apply a layer of glue on both foam surfaces and let it become tacky by following the instructions specific to the type of adhesive being used. Then, push the pieces of foam together with considerable force and ensure that their entire surfaces are in contact. Clamps can be used, or a weighted object can be placed on top to help ensure that there is a constant pressure throughout the curing process. You should have patience, because the curing times will depend on the adhesive and may vary. It is advisable to work section by section when doing the larger projects to keep control and precision. If you follow these steps, you will have a durable bond that will not break easily over time.

Tips for Best Results with Foam Adhesive

- ✓ Clean Surfaces: Before applying the adhesive, ensure the surfaces are clean and dry, as this will help the adhesive create a stronger bond.

- ✓ Uniform Application: To prevent any uneven curing or weak areas, apply adhesive uniformly in a thin layer.

- ✓ Consistent Pressure: Maintain strong and consistent pressure throughout the curing time by using clamps or weights.

- ✓ Good Ventilation: To keep the area safe and the adhesive working well, do your work in a place that has good ventilation.

- ✓ Adequate Curing Time: For a strong bond, the curing time should be allowed as per the adhesive instructions.

Using Foam-Safe Adhesives

Foam-safe adhesives are specially formulated to glue together foam materials without harming or melting them. Selecting the appropriate foam-safe adhesive depends on the kind of foam you are using—rigid foams such as polystyrene or flexible foams like polyurethane might need different adhesive types. Moreover, check if the adhesive is suitable for the other materials and the environmental conditions, such as temperature and humidity. For precision projects, choose adhesives with fast curing times and controlled expansion. It is crucial to comply with the manufacturer’s guidelines for the best results, and it is also advisable to test the adhesive on a small, unnoticed area first to ascertain its effectiveness.

Aligning Edges Precisely

In numerous projects requiring utmost precision, seamless and professional results largely depend on the correct alignment of edges. To start with, using powerful tools like clamps, straight edges, or alignment guides will not only help position the materials correctly but also hold them firmly during the bonding process. Measurement devices such as rulers or digital calipers will play a role in verifying the precise dimensions. Proper cleaning of the edges is necessary to remove any dust, dirt, or residue that might cause irregularities. For extra accuracy, the dry-fitting of the pieces should be done first, before glue is applied, to ensure the edges fit together perfectly. If alterations are needed after the joining, they should be made promptly before the glue sets. The winning factors in accurately aligning edges will be patience and attention to detail.

Common Mistakes to Avoid When Gluing Foam Together

❌ Using the Wrong Adhesive

Foam can not be combined with every type of adhesive. Damaging the foam or creating weak bonding will not happen if you use an adhesive made especially for foam.

❌ Skipping Surface Preparation

Not cleaning and drying the foam surface can be a reason for poor adhesion. Properly cleaning the surface of the foam helps to improve the adhesion.

❌ Applying Too Much or Too Little Adhesive

Applying too much adhesive can cause different drying rates on the sides, while using too little adhesive might result in weak joints. For a strong and consistent bond, use a suitable amount of adhesive.

❌ Rushing the Drying Process

The bond can become weaker if the foam pieces are moved or touched while the adhesive is still drying. It is better to let the glue cure completely according to the manufacturer’s instructions.

❌ Ignoring Proper Alignment

When gluing, misaligned edges may influence the look and stability of the final product. Always dry-fit the foam pieces before applying adhesive to check for correct positioning.

Rushing the Tack Time

One of the most common errors when working with adhesives is accelerating the tack time, which can adversely affect the bond’s strength and longevity. The term tack time refers to the time required for the adhesive to become sticky enough before the surfaces are joined. If the step is neglected or if the surfaces are joined too soon, the result will be a weak and ineffective bond. Manufacturers’ specifications for the tack time should be strictly followed for the best results, according to experts and literature. Being patient during this stage guarantees a strong and durable connection of the materials.

Over-Compressing Foam During Bonding

During the bonding process, the adhesive might become less effective if the foam is over-compressed, as it could either be driven out of the joint or not be covered sufficiently. The manufacturer’s guideline indicates the pressure to be used, and I make sure that it is the pressure I apply so the bond’s strength and integrity are not compromised.

Reference Sources

Five professional and authoritative reference sources relate to the subject matter “can you glue foam together,” and are from academic and research-based sources:

| Title | Source |

|---|---|

| Learning to glue underwater: Inspiration from the decorator worm | Duke University |

| The Gradient Foam Cement of the Sandcastle Worm as a Model for New Materials | Harvard University (NASA/ADS) |

| Bonding wood particle composites with foamed adhesive | Oregon State University |

| Safer Spray Foam Insulation | University of California, Berkeley |

| Foam Wars II | California Polytechnic State University |

Frequently Asked Questions (FAQs)

❓ Can you glue foam together?

Yes, you can glue foam together using various adhesives designed for foam materials. The best glue to use depends on the type of foam you are working with, such as craft foam, EVA foam, or insulation foam. Always check the manufacturer’s recommendations for the best results.

❓ What is the best way to glue foam?

The best way to glue foam involves choosing the right adhesive, applying it evenly, and allowing it to dry correctly. For most foam types, using a glue labeled for foam or a construction adhesive works well. For specific projects, consider using contact cement for a strong bond.

❓ What type of glue should I use on foam insulation panels?

For foam insulation panels, a high-quality construction adhesive or a solvent-based adhesive like Loctite is recommended. These adhesives provide a strong bond and are suitable for the rigid foam types commonly used in insulation.

❓ Can I use super glue on foam?

While super glue can bond foam, it is not always the best choice, as it can sometimes create a brittle bond or dissolve certain types of foam. It’s advisable to use adhesives designed explicitly for foam for better results.

❓ What is the bond strength of the adhesive for foam?

The bond strength of the adhesive for foam varies based on the type of glue and the foam material. For example, contact cement offers a very high bond strength, making it ideal for heavy-duty applications, while craft foam may require lighter adhesives.

❓ What are some tips for gluing foam together?

Some tips for gluing foam together include selecting the right adhesive for the foam type, applying the glue evenly on both sides of the foam, and allowing adequate drying time. Additionally, consider using weights to hold the foam in place while the adhesive cures.

❓ Can I glue foam boards together?

Yes, you can glue foam boards together using adhesives like construction adhesive or barge contact cement. These adhesives provide a strong bond and are ideal for creating stable structures in craft projects or insulation applications.

❓ How do I glue foam sheets together?

To glue foam sheets together, start with the right adhesive designed for foam, apply it to both surfaces, and press them together firmly. Ensure that the glue is spread evenly and allow it to dry completely for the best bond.

❓ Is there a specific way to glue foam cushions?

When gluing foam cushions, it’s essential to use a foam adhesive that is flexible and provides a strong bond. Apply the adhesive evenly to both surfaces and press them together, ensuring there are no air pockets. Allow it to dry thoroughly before using the cushion.