Strong, enduring bonding between parts can often be the greatest hurdle that creators have to overcome when working with PLA 3D prints. If assembling a multipiece project, repairing a dented print, or bonding complicated parts, knowing which glue to go for will make or break your success. The list of adhesives is enormous, with the most widely heard name being CA glue due to its simple application and availability. But how good is superglue in bonding PLA as a thermoplastic with its own idiosyncrasies? The present article attempts to go into the compatibility of superglue with PLA, explore the chemistry of their interaction, and provide useful tips on producing strong and lasting bonds. Continue to learn the tips and tricks of gluing PLA prints and where superglue stands as far as the best adhesives for your next 3D printing job is concerned.

Understanding PLA and Its Properties

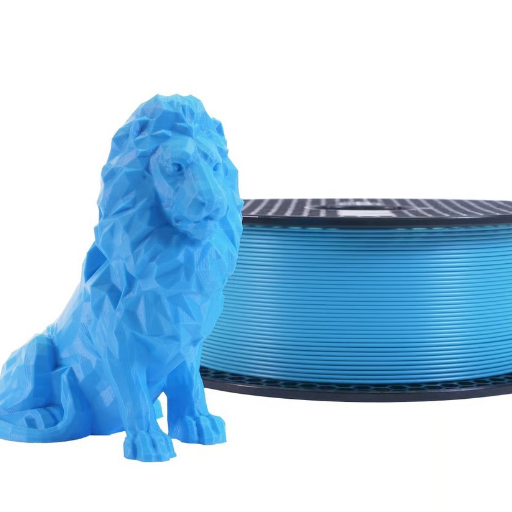

PLA is Polylactic Acid, a biodegradable thermoplastic that derives from renewable resources like corn starch or sugarcane. It is common in 3D printing mostly due to its ease of printing procedure, low printing temperature, and less warping when compared to other plastics. PLA allows a smooth surface finish with high dimensional accuracy, therefore perfect for detailed printing applications. On the other hand, it lacks heat resistance and softens considerably at 60°C (140°F). PLA also has relatively low flexibility and impact strength, and, therefore, is not a good alternative to ABS or PETG. While still a very workable factor in limitations, PLA styling has been accepted in the crafts industry and even in colleges for greater affordability, easy availability, and beautiful sustainability.

What is PLA and why is it Popular?

PLA is the name for a biodegradable thermoplastic derived from renewable resources such as corn starch or sugarcane, most generally used in a general 3D printing environment because of its low melting point and easy handling, with probable environmental considerations. PLA filament is most commonly used in FFF printers, as the material 3D prints well at moderate temperatures from 190°C to 220°C and without the need for a heated bed.

PLA is so widely used because it warps much less during printing, giving much more consistent results even with very complex or intricate models. Moreover, as it is compatible with lots of 3D printers and easily available in various colors and blends, the choice becomes an affordable one for users across various competencies. It doesn’t do so well withstanding heat or mechanical stresses, but ongoing development in PLA formulas, such as high-heat PLA and toughened PLA, is clearly addressing this very issue, ensuring its sustainability. Thus, PLA continues to gather sustainability, a very low price, and extreme versatility behind it for additive manufacturing applications.

Characteristics of PLA

- Biodegradability

With the emergence of PLA, firms are looking into resins suitable for composting. PLA is prepared from starch or sugarcane, making it biodegradable under industrial composting conditions. It decomposes by water, carbon dioxide, and organic matter under certain conditions, thus lessening the hydrological footprint.

- Thermal Properties

PLA has a rather low glass transition temperature of around 60°C (140°F) with a melting point between 150°C and 160°C. Although these properties enable easy processing of the material, the use of PLA in high-temperature applications is limited unless some modified formulations are applied.

- Ease of Printing

PLA is considered an excellent print medium due to its low tendency to warp and require minimal heating. It does not require a heated build plate for most applications and adheres well to various print bed surfaces.

- Mechanical Properties

It is a material that offers tensile strength and stiffness with a Young’s modulus generally in the range of 2.7-16 GPa, but it’s comparatively brittle when equally loaded with other thermoplastics like ABS or PETG, thus impacting its applications that require load-bearing.

- Aesthetic Versatility

With a color palette that covers everything imaginable and finishes like matte or glossy, PLA is flashy enough to adorn any function or artistically oriented application.

- Density

PLA weighs approximately 1.25 g/cm³, which is a little heavier than ABS but light enough for almost all 3D print applications.

Factors Influencing Adhesive Performance

- Surface Preparation

Surface preparation brings about a large effect on adhesive performance. Contaminants such as grease, oils, or dust have to be removed from the surface. Then there is the surface roughness or smoothness to consider: sometimes smooth surfaces need to be mechanically abraded or chemically etched to improve adhesion by providing more surface area or producing a substrate that bonds more easily.

- Environmental Conditions

While there are environmental factors that may play against the longevity and integrity of the adhesive bond-those being the high temperature, heavy humidity, exposure to chemicals, and UV radiation-high humidity works against adhesion by bringing in moisture; extremes in temperature work against it by causing thermal expansion or contraction-many times effects of the extreme might be seen long after the structural properties have been compromised.

- Adhesive Type and Composition

- Load Distribution

The Nd mechanical loads under which the adhesive is subjected in service, tensile, compression, or shear stresses, will affect its performance. Ideally, load on the orthopedic should be evenly distributed across the bond line to maximize strength. An uneven load will maximize the chance of adhesive failure, especially in structural applications.

- Curing Process

Best Adhesives for PLA

For PLA (Polylactic Acid) work, adhesives that bond well are crucial to the achievement of strong, lasting results. Below is a list of the best options for PLA:

- Cyanoacrylate Adhesives (Super Glue)

Cyanoacrylate glues bond well with PLA because they are quick to set and offer good adhesion. They are used mostly in small repairs and fairly precise applications.

- Epoxy Adhesives

Two-part epoxies provide the strongest bond and are the best for joining larger PLA parts where a degree of gap-filling is necessary. Good strength and durability can be achieved, but also consider the relatively long times needed for curing.

- PLA-Specific Adhesives

There are also some PLA adhesives or plastic cements designed for chemically bonding PLA surfaces. These options provide a strong molecular bond and are easy to use in other applications.

- Hot Glue

Not as strong or permanent as any other, hot glue is somewhat useful for quick bonding tasks on PLA.

Compare Common Types of Adhesives for PLA

|

Adhesive Type |

Strength |

Application Ease |

Temperature Resistance |

Durability |

Key Features |

|---|---|---|---|---|---|

|

Cyanoacrylate (Super Glue) |

High |

Easy to apply |

Moderate to low |

Strong, semi-permanent |

Quick drying, clean bond |

|

Epoxy Resin |

Very high |

Moderate |

High |

Very durable |

Excellent for structural strength |

|

Hot Glue |

Moderate |

Very easy |

Low |

Temporary |

Ideal for quick fixes |

|

Plastic Weld |

Very high |

Challenging |

High |

Very durable |

Provides chemical bond |

|

UV-curing Adhesive |

High |

Requires UV light |

Moderate |

Durable |

Precise application, low mess |

|

Acetone-Based Adhesive |

Moderate to high |

Moderate |

Low |

Semi-permanent |

Works by softening material |

Specialized Adhesives for PLA

When working with PLA, it is crucial to employ adhesives designed to address the specific properties of this material, such as its rigidity and relatively low melting point. Cyanoacrylate (CA) glue–better known as superglue–is one of the best choices, allowing fast bonding with minimal surface prep and working well for small or precise joins. For stronger bonds or those needing some flexibility, for instance, when you want to bind things that might otherwise separate under stress, an epoxy goes a bit farther with filling gaps and providing resistance.

Further, polyurethane adhesives are a worthy consideration in each application that demands its own flexibility and tensile strength. The properties of polyurethane-based adhesives will remain unchanged at various temperatures, which is beneficial if adhesives are used in a dynamic environment. Furthermore, professional PLA solvent adhesives can also fuse PLA pieces on their own: The surface of the halves to be joined is softened with an acetone-based solution or with dichloromethane that proves effective in welding even large parts, leaving few traces. It is best to use this type of glue with great care since they are quite aggressive.

Step-by-Step Guide: How to Use Superglue on PLA

- Prepare the Surfaces

Ensure that PLA parts are clean and dry. No dust or grease is permitted. Assure sticking by wiping with isopropyl alcohol using a lint-free cloth.

- Sand for Better Bonding (Optional)

- Apply the Superglue

Apply a bit of superglue based on cyanoacrylate onto one of the surfaces. Using precision applicators will help avoid excessive use, keeping control in hand.

- Press and Hold the Pieces Together

- Allow Full Curing Time

Even though the adhesive sets in advance, wait the full expertise time according to the operations of the products, typically 24 hours, to ensure optimal gluing strength.

- Inspect the Bond

Preparing the Surface for Bonding

Surface cleaning will have to be prepared before giving a good adhesive bonding. Keep surfaces clean and dry from contaminating material such as dust, dirt, grease, or oil. Prepare the surface with isopropyl alcohol (IPA) applied with a lint-free cloth, removing residues from the surface. IPA will quickly evaporate and will not leave any film behind. If the surface has a finish or is coated, the area should be lightly sanded with fine sandpaper (120-220 grit). This light sanding will help the adhesive bond by making the surface slightly roughened. After sanding, wipe all the dust away so no dust will impede the bonding.

Different surfaces might require treatment prior to bonding to ensure the best adhesive setting. Sometimes woods and concretes may absorb adhesives; hence, a primer may be applied to reduce absorption and increase adhesion. For metals or plastics, having surface preparation that consists of using an adhesive promoter or generating some surface roughness will increase bonding strength by counteracting some inherent smoothness and slick finish of these materials. Always check the recommendations of the adhesive manufacturer on the particular surfaces to be joined for compatibility and best performance.

Applying the Superglue Effectively

For an essentially perfect adhesion using superglue, exactness and preparation are the essentials. First, clean the surfaces to be joined thoroughly using isopropyl alcohol or any good cleaning agent to remove grease, dirt, and other contaminants. After this washing, allow them to dry completely. On porous materials or uneven surfaces, lightly sanding the area to create a suitable texture means better adhesion. Use a very thin layer of glue, either it’s superglue or another one; thicker glue will weaken the adhesion or slow down the curing.

After applying the glue, bring the surfaces together with uniform pressure and ensure that the surfaces are aligned well. Such pressure causes any entrapped air to escape before the glue solidifies into a bond. If a significant amount of stress is to be borne by the surface, it is easy to clamp the surfaces or place a weight for a while. Next up is to wait for the glue to cure, as stated by the glue manufacturer; this period varies from a few minutes to several hours, depending on the conditions of your environment and the surface to be glued. Low-humidity room conditions will ensure the best outcome, for high-moisture levels can hamper cyanoacrylate glue staining.

Joining and Curing PLA Parts Together

Tips for Strong and Long-Lasting Bonds

- Prepare Surfaces Thoroughly

Clean all surfaces to remove dust, dirt, oil, or grease. Proper surface preparation ensures maximum adhesion and prevents weak points in the bond.

- Use the Right Adhesive

Choosing an adhesive that performs efficiently with the materials being joined and under the surrounding conditions, e.g., temperature and humidity.

- Ensure Proper Application

Apply glue evenly and is required in amounts suggested for use. Do not apply glue excessively, as excess glue can weaken the bond over time.

- Allow for Adequate Curing Time

The adhesive should not be disturbed during the bonding and curing process as prescribed by the manufacturer.

- Consider Environmental Factors

Maintaining Pressure During Curing

Applying pressure during cure is critical to bonding an adhesive with strong reliability. Pressure forcibly makes great contact between all surfaces, allowing the adhesive to distribute evenly. It also helps fill in spaces that are microscopic in level. Clamps, weights, or mechanical means that can uphold this pressure are preferable. This should remain for the curing time that is set by the adhesive manufacturer. It is also proven that if there is not enough pressure, then there will be weak bonding and decreased performance under stress. It is also good to check your force applied so as not to over-compress, in which most of the glue is pushed away and destroying the integrity of the joint. If these rules are applied, we will now follow the directions of the pressure for the type of glue we are using and for the materials that are to be bonded. Such care will definitely reward one with the strongest joint ever and one that will last forever.

Working Safely in a Well-Ventilated Space

Ensuring adequate ventilation is a critical safety measure, particularly when handling adhesives, coatings, solvents, or other materials that release volatile organic compounds (VOCs). Proper airflow prevents the accumulation of potentially harmful fumes, thereby reducing the risk of respiratory irritation, dizziness, or other health complications. As outlined in the standards of the construction industry, there has to be continuous interchange of air. This condition can be based on either mechanical systems for ventilation, such as an exhaust fan, or natural ways, such as an open window. In addition, air filtering units equipped with HEPA filters can serve to enhance the air quality by removing particulate and airborne contaminants. In another metric of applications that deal with high-VOC materials, one can benefit from the LEV system, e.g., fume hoods, to capture their emissions at the source. This can be combined with the proper application of PPE, e.g., respirators, that have been rated for working in chemical environments to comply with occupational safety standards and ensure worker welfare.

Using High-Quality Superglue

Good superglue bonds slowly and solidly, yet it has now been said to be amongst the glue types widely used in different industrial fields for its speedy curing time and great versatility in bonding. It forms a sneering bond for metal, plastic, rubber, ceramics, and wood pretty fast. As it is applied to the surface, cyanoacrylate is polymerized by the moisture present on surfaces to give a very secure bond within seconds.

Alternative Solutions for Bonding PLA

- Epoxy Adhesives

An epoxy works best for bonding PLA due to its high-strength bonding capacity and compatibility with various surfaces. It offers superior durability when the application calls for a long-lasting hold.

- Polyurethane Adhesives

Polyurethane adhesives are elastic and form a strong bond with PLA. These adhesives are recommended in instances in which some level of flexibility or resistance to impact is desired.

- PLA Filament Welding

Bonding by filament welding allows PLA parts to be melted together using the filament of a 3D printing pen or a soldering iron. When performed well, these processes create strong and permanent bonds.

- Hot Glue

Though hot glue would not be as strong as other solutions, it can be utilized for temporary bonding or non-load-bearing applications. It sets quickly, so it is very much suitable for quick and easy fixes.

- Acetone Treatment

Not quite good with pure PLA, acetone can probably work with PLA blends with ABS-type polymers for bonding. Pre-testing is necessary since results may be hit or miss.

PLA Welding Techniques

Friction welding realizes bonding via high-speed rotational friction of a PLA filament against the joint. The technique involves using a rotary tool or a custom electric drill to spin the filament at high speed. The heat created through friction melts the PLA at the interface and, upon cooling, forms a strong bond. This technique is very well suited to small, precise repairs, as it affords detailed control to the operator over the application of the bond.

Chemical Bonding Agents for PLA

Chemical adhesives are an effective and trusted method of joining PLA parts, using solvent or adhesive properties to form an invisible bond. Cyanoacrylate glue, commonly referred to as superglue, is widely preferred for its ease of use, fast setting time, and high strength in adhering PLA parts. Alternatively, solvent glues containing dichloromethane or chloroform dissolve the PLA chemically at the bonding interface. The molecular-level fusion resulting from this causes the cured bond to be almost indistinguishable from the original material in structural integrity.

Reference Sources

1. Testing the Best Glue for PLA 3D Printed Parts

- Source: Instructables

- Summary: This article tests various adhesives for PLA, including Weld-On 16, super glue (cyanoacrylate), epoxy, and contact cement. Weld-On 16 was found to be the most effective, creating a bond that mimics PLA-to-PLA welding. Super glue also performed well, offering a strong and fast-setting bond.

2. Which is the Best Glue to Joint PLA Parts Together?

- Source: Prusa Forum

- Summary: Forum users discuss their experiences with different adhesives for PLA. Super glue (cyanoacrylate) is widely recommended for its ease of use and strong bond. Loctite 4062 and SCIGRIP 16 are highlighted as effective options, with SCIGRIP acting more like a solvent that welds the PLA. Users also suggest using activators to speed up curing and improve adhesion.

3. How to Glue PLA: Tips and Tricks for Your 3D Projects

- Source: Loctite Consumer

- Summary: This guide explains how to glue PLA effectively using super glue or epoxy. Super glue is recommended for its strong hold, quick drying, and transparent finish. The article provides step-by-step instructions, including sanding the surfaces, applying glue, and clamping the parts.

Frequently Asked Questions (FAQs)

Q: What is the best way to glue PLA together?

A: The best way to glue PLA together is to use super glue or a specialized adhesive designed for plastics. Super glue, particularly Loctite super glue gel, is known for its quick bonding capabilities. When using super glue, ensure the surfaces are clean and dry for optimal adhesion. You may want to use a toothpick to apply a little glue precisely where needed. For larger 3D printed parts, consider using model cement for a stronger bond. Always work in a well-ventilated area to avoid inhaling fumes.

Q: Can you use super glue on 3D printed parts?

A: Yes, you can use super glue on 3D printed parts made of PLA. Super glue is compatible with PLA and works effectively to bond these materials together. For enhanced results, using super glue gel can prevent excess adhesive from running and allow for better control during application. If you encounter gaps, you can fill them with baking powder to create a stronger bond. Always press the parts together immediately after applying the glue to ensure a secure hold.

Q: How to learn how to glue PLA correctly?

A: To learn how to glue PLA correctly, start by researching different types of adhesives suitable for PLA. Super glue and Loctite products are popular choices and provide strong bonds. Watching video tutorials on 3D printing projects can also provide practical insights into gluing techniques. Experiment with different methods, such as using activators or combining super glue with baking powder for better adhesion. Practicing on scrap pieces can help you master the technique before working on your final prints.

Q: What is the right adhesive for PLA?

A: The right adhesive for PLA includes super glue, model cement, and specific plastic-based glues. Super glue offers a quick bond, while model cement can provide a more substantial hold for larger or load-bearing structures. If you need to remove parts later, using super glue may complicate the process, so consider alternatives if disassembly is required. Always ensure that the adhesive you choose is compatible with PLA to achieve the best results.

Q: Can you superglue PLA and expect it to hold?

A: Yes, you can superglue PLA and expect it to hold well if done correctly. Super glue creates a strong bond with PLA, especially when the surfaces are clean and fit closely together. For added strength, you can use activators that speed up the drying process and enhance adhesion. If you experience any gaps in the bond, using a mixture of super glue and baking powder can fill those gaps effectively. Just be sure to allow adequate time for the glue to harden fully for the best results.