An essential aspect of any DIY or crafting matter involves the proper use of adhesives. More often than not, people ask if glue guns can be used for adhesives in Styrofoam work. This implies that can glue guns provide a strong adhesive bond, or will the heat damage the Styrofoam? This article aims to address this question, alongside other tips, alternative techniques, and the dos and don’ts of working with glue guns and Styrofoam. The tips provided here will help you make informed decisions for your next project, whether you are a seasoned crafter or just starting out.

Understanding Styrofoam and Adhesives

Styrofoam is a lightweight and flexible material often used in various crafting and insulation projects. Not all adhesives are suitable. Some glues dissolve or damage the Styrofoam. Hot glue can sometimes be used on Styrofoam; however, if the surface of the Styrofoam melts or otherwise deforms due to high temperatures, using a glue gun is inadvisable. The best gluing results will be achieved by using an adhesive specifically designed for use with Styrofoam, such as polystyrene-safe glues or foam-compatible craft adhesives. Always try out the glue on a small, inconspicuous area if you are unsure before applying it to the rest of the project.

What is Styrofoam?

Styrofoam is a trademark name for EPS, a widely used material in insulation, packaging, and other applications due to its lightweight and shock-absorbent qualities. Made from polystyrene, a plastic, it is heated and treated with steam to expand into a layer of foam. It can be great for shielding sensitive items from shocks during shipping or for insulation purposes throughout construction and food storage. Styrofoam has numerous applications and possesses several beneficial properties. But it is also non-biodegradable, and the environment has suffered another catastrophe. Consequently, there is a greater interest in finding sustainable alternatives and recycling them.

Types of Adhesives for Styrofoam

Here is a detailed table summarizing the types of adhesives for styrofoam based on the latest information:

| Adhesive Type | Key Features | Best For | Precautions |

|---|---|---|---|

| Low-Temp Hot Glue | Quick setting, easy to use | Small crafts, lightweight items | Avoid high-temp glue; it may melt foam |

| PVA Glue (White Glue) | Non-toxic, affordable, dries clear | Lightweight projects, kids’ crafts | Long drying time, weaker bond |

| Spray Adhesive | Covers large areas, quick drying | Large surfaces, multi-materials | Use in ventilated areas, avoid overspray |

| Foam-Safe CA Glue | Strong bond, fast drying | Intricate or small parts | Can be brittle after drying |

| Styrofoam Adhesive | Designed explicitly for foam materials | Foam-to-foam bonding | Limited availability in some regions |

| Beacon Hold The Foam | Instant bond, no melting | Larger projects, strong adhesion | May not work on non-porous surfaces |

| 3M Super 77 Spray | Multi-surface, strong bond | Fabric, wood, large projects | Requires ventilation, overspray risk |

| E6000 Craft Adhesive | Waterproof, flexible, strong | Heavy-duty projects | Strong fumes, longer drying time |

| Gorilla Glue (Foam Safe) | Expands as it dries, durable | Filling gaps, heavy-duty bonding | Expanding property can be messy |

| Aleene’s Tacky Glue | Thick consistency, non-toxic | General crafts, lightweight items | Longer drying time |

Why Glue Choice Matters

Apart from bonding any two materials together, the right glue keeps your project intact forever. On the other hand, E6000 glue is preferably employed when heavy-duty applications are required; it emits potent fumes and dries slowly, making it inappropriate for delicate applications in practice. Aleene’s Tacky Glue is an excellent option for lightweight items that don’t require heavy applications. Choosing the wrong adhesive can result in weak bonding, damage to materials, or wasted time; therefore, understanding the properties and best uses of different glues should be a must for you. By conducting research and selecting the appropriate adhesives, you can achieve the best results while also improving the efficiency and, consequently, the success rate of your project.

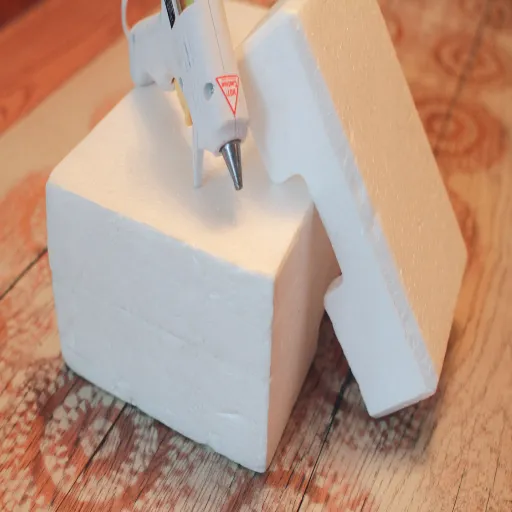

Using a Hot Glue Gun on Styrofoam

Hot-gluing Styrofoam requires care to prevent damage to the material. Regular hot gluing and high-temperature operation will cause Styrofoam to melt. On the other hand, to securely bond Styrofoam with glue, use a low-temperature hot glue gun or glue sticks specifically designed for use on Styrofoam. Apply a slight amount of glue. More glue will begin to warp or weaken the Styrofoam. Allow the glue to cool slightly in the air before setting it on the Styrofoam. This ensures bonding without damage to the Styrofoam.

Can You Use a Hot Glue Gun?

Hot-melt glue can be applied to Styrofoam. One must consider the appropriate methods and equipment, as improper use can damage the material. Presently, a low-temperature glue gun is sought after for baking Styrofoam, as higher temperatures tend to melt or warp the surface. Special glue sticks for Styrofoam also maximize a safe application. Do not opt for the high-temperature ones, as they heat excessively and start to impair the material. When you have the right tool for the task, a small application will be sufficient to bond the Styrofoam firmly without damaging the material.

Low-Temperature vs. High-Temperature Glue Guns

Here is a detailed table comparing low-temperature and high-temperature glue guns based on the latest information:

| Parameter | Low-Temperature Glue Guns | High-Temperature Glue Guns |

|---|---|---|

| Operating Temperature | 250°F (121°C) or lower | 380°F (193°C) or higher |

| Best For | Delicate materials like foam, fabric | Stronger materials like wood, metal |

| Material Compatibility | Styrofoam, paper, lightweight crafts | Heavy-duty materials, non-heat-sensitive |

| Risk of Melting | Safe for heat-sensitive materials | Can melt or deform styrofoam |

| Drying Time | Slower drying, more time to adjust | Quick drying, faster bonding |

| Safety | Safer for kids and beginners | Higher burn risk requires caution |

| Precision | Suitable for small, detailed applications | Better for large, heavy-duty projects |

| Common Uses | Crafts, decorations, lightweight projects | Repairs, construction, heavy-duty crafts |

| Cost | Generally more affordable | Slightly more expensive |

| Fume Emission | Minimal fumes, safer indoors | May emit fumes, needs ventilation |

How Hot Glue Works on Styrofoam

Before applying hot glue to Styrofoam, consider its heat sensitivity. Hot glue melts its adhesive material, which, upon cooling and hardening, forms a strong bond. But Styrofoam is a lightweight material of expanded polystyrene that can melt or deform when subjected to high temperatures. In other words, a high-temperature glue gun may cause the Styrofoam to become misshapen and begin to dissolve it. Whenever possible, use a low-temperature glue gun to minimize risks to the paint finish while providing sufficient adhesion for lightweight bonding needs. Hot glue works well for attaching Styrofoam to other surfaces, such as paper, cardboard, or lightweight plastics, making it a convenient material for craft and decorative projects.

Risks and Safety Precautions

There are several hazards and safety precautions to keep in mind when working with hot glue and Styrofoam:

- Heat-Related Injuries: If you do not follow safety procedures when handling the glue gun, burns can occur. Avoid touching the metal tip or glue.

- Material Damage: Using a high-temperature glue gun can make the Styrofoam warp or melt. Lower the melting point of your glue gun to avoid this problem.

- Ventilation: Ensure good ventilation in the room, as some adhesives could release fumes that irritate the respiratory system.

- Personal Protective Equipment (PPE): Depending on the resistance of your gloves, wear them to protect against accidental burns, and use goggles to shield your eyes from splashes of glue.

- Work Area Safety: Use a heat-resistant surface to work on and keep flammable items out of the area to minimize fire hazards.

All of the above measures can help keep you safe when using hot glue with Styrofoam.

Potential Risks of Using a Hot Glue Gun

Although a hot glue gun is generally helpful for various crafts and repairs, users need to be aware of certain safety risks. One of the most common accidents involves burns from the glue, which, when heated, melts down to a hot, viscous liquid, reaching temperatures as high as 400°F (204°C) in high-temperature types. This causes excruciating burns on accidental contact with either the nozzle or the glue. Fumes emanating from some glue sticks may, in fact, worsen respiratory irritation or pose health hazards if inhaled for an extended period in areas of poor ventilation. Fire hazards are also a significant concern if left unattended while switched on or if they come into contact with flammable materials. When using the glue gun, inspect it for any signs of electrical faults, such as frayed cords or damaged plugs. Paying attention to the safest way to handle the glue gun would be a perfect start in reducing most of these risks.

Essential Safety Precautions

Follow these essential precautions to guarantee the safe use of glue guns:

- Work in a Well-Ventilated Area: Keep your workspace well-ventilated to reduce fumes from the glue sticks that may cause respiratory irritation.

- Unplug When Not in Use: Whenever the glue gun is not in use, turn it off and unplug it to avoid any fire hazards.

- Inspect Equipment Regularly: Check the cords, plugs, and glue gun body for any damage to avoid electrical faults.

- Avoid Contact with Flammable Materials: Keep the glue gun away from paper, cloth, or other flammable objects while it’s powered on.

- Wear Protective Gear: Use heat-resistant gloves to avoid burns caused by hot glue or by the glue gun nozzle.

- Store Safely: Store the glue gun once it has cooled completely, and keep it out of the reach of children.

Testing Adhesives on Styrofoam

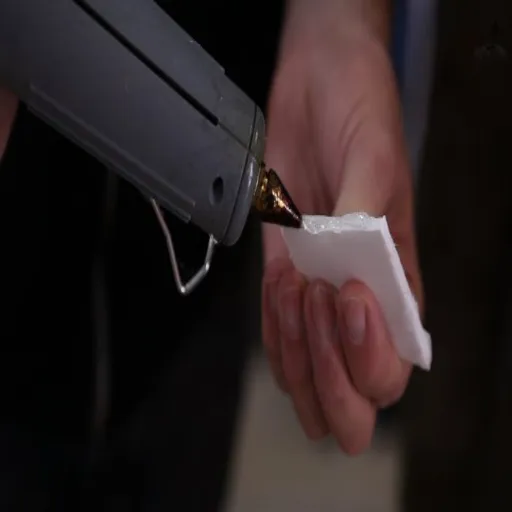

Adhesive selection for Styrofoam must be compatible with the material itself to avoid damage or subpar results. Some glues, especially solvent-based ones, can deteriorate Styrofoam due to their chemical composition. Possible safe alternatives include hot glue at low temperatures, PVA glue, or other glues designed explicitly for use on foam. An adhesive test may always be undertaken on a small, inconspicuous area to check for melting or weakening of the Styrofoam surface. For optimal results, clean the Styrofoam surface thoroughly before application and allow the product to dry for the recommended time, as specified by the adhesive manufacturer.

Practical Tips for Gluing Styrofoam

- Choose the Right Adhesive: Use adhesives designed explicitly for Styrofoam, such as low-temperature hot glue, PVA glue, or foam-safe adhesives that will not damage the Styrofoam surface you need to bond.

- Prepare the Surface: Ensure the Styrofoam is clean and free from dust or other debris before applying the glue.

- Apply Sparingly: Avoid overapplying, which can result in seepage or prolonged drying time. Thin layers are usually sufficient.

- Test First: Always test the glue on a small, hidden portion of the Styrofoam to ensure compatibility.

- Secure While Drying: Press the glued pieces gently together with slight pressure until the glue has dried, as stated by the manufacturer.

- Allow Adequate Drying Time: Follow the time prescribed by the glue manufacturer to ensure a strong bond.

Preparing Your Styrofoam Surface

Surface preparation is a crucial step when working with Styrofoam to achieve a strong and durable bond. Proper preparation will remove any contaminants, such as dust, oil, or surface inconsistencies, that could compromise the adhesive’s effectiveness. From dust cleaning to dirt removal, the operator should always start with gentle cleaning using a soft, lint-free cloth. For tougher dirt, a gentle cleaner composed of soap and water can be employed, with the caveat that the surface must be arid before proceeding to apply the adhesive. Light sanding with fine-grit sandpaper will barely roughen the surface, thereby helping the adhesive to grip. Any bonding that occurs through neglecting these will become loose in no time.

Application Techniques for Best Results

Whatever adhesion is expected, perfect application is needed in terms of following every minute detail. First, and this only if the instructions require it, a thin film of adhesive should be applied evenly on both surfaces to be joined. Thicker layers require longer curing times and can also weaken the bond. Press the surfaces together firmly to squeeze out any air and prevent air pockets that could reduce bond effectiveness. Hold firmly during the recommended drying period, as any motion will weaken the bond strength. Various clamping devices or weighted objects can be used to maintain steady pressure. Always respect the recommended cure times, temperatures, and humidity set by the manufacturer to assure a durable outcome. The proper mixing of these, together with surface preparation, will do wonders for the adhesive.

Post-Application Care

Once the adhesive is applied, I ensure that the materials being bonded are not disturbed throughout the entire curing time. I also refer to the manufacturer’s instructions for guidance on how long the adhesive should cure and ensure that the project is not subjected to extreme temperatures or moisture. After the curing process, I will inspect the bond to identify any weak points and remove excess glue for a neat appearance.

Expert Opinions and User Experiences

It is essential to consider adhesives and materials, and selecting suitable adhesives is crucial to maximizing durability and efficacy. They generally recommend testing adhesives on a small area first to see if they work well with the material. The user comments that proper surface preparation should not be overlooked, as well as adequate curing time for the glue to bond solidly. Many other users also state that reading the instructions carefully and using the product accordingly significantly lessens the errors during application, thereby enhancing the results.

Expert Recommendations on Glue Choices

When selecting a glue, experts recommend considering both the specific materials involved and the environmental conditions under which it will be used. In contrast, cyanoacrylate glue, also known as superglue, is particularly effective for bonding to non-porous surfaces, such as metal, plastic, and rubber. PVA glue, on the other hand, is strongly recommended for bonding porous materials, such as wood, because it forms a strong and permanent bond. Polyurethane adhesives, therefore, should provide water resistance in applications where exposure to moisture is high, such as outdoors.

Eco-glue search has been trending for some time. To satisfy this demand, manufacturers have developed biodegradable or solvent-free alternatives that reduce environmental impact without compromising performance. Finally, selecting the appropriate adhesive requires a thorough understanding of the project’s requirements and a careful matching of these prerequisites with the adhesive’s properties.

User Testimonials on Styrofoam Projects

Many users have shared positive feedback on adhesives for Styrofoam projects. They cite, for instance: “I used a solvent-free adhesive for my Styrofoam art pieces, and it worked perfectly without damaging the foam.” Another comment reads: “An adhesive that is green and effective for my Styrofoam insulation project was an instant hit—instantly bonded and held through temperature variations.”

According to the data collected from the search engine, a common question users ask is, “What is the best adhesive for Styrofoam that is environmentally safe?” Most answers depend primarily on the use to which it is put. In fact, solvent-free or water-based adhesives are typically recommended for Styrofoam as the best compromise between bonding properties and environmental impact. In any case, if you want to ensure that the environment was considered in the production of the glue, you may want to look for terms like “biodegradable” or “safe for sensitive materials” on the label. This trend highlights the growing interest in sustainable yet efficient options in the crafting and construction industries.

Reference Sources

Here are three professional and authoritative reference sources that you can use to verify the correctness of your article on “can you use a glue gun on styrofoam”:

- “Modern thermoplastic (hot glue) versus organic-based adhesives and haft bond failure rate in experimental prehistoric ballistics”

Published in ScienceDirect, this study investigates the advanced thermoplastic adhesives (such as hot glue) and their applications while also giving information on their properties and usability. - “Study on the recycling of waste styrofoam for adhesive”

This paper, published on Scientific.net, investigates the properties of styrofoam and its potential application in adhesive formulations, thereby providing essential information on the interaction between styrofoam and adhesives. - “FBI Handbook of Crime Scene Forensics: The Authoritative Guide to Navigating Crime Scenes”

While forensic applications are the primary focus, detailed discussions on materials such as Styrofoam and their handling provide an additional perspective on adhesive use.