Selecting an adhesive is often the final, decisive step in any repair or construction job, one that can seal or unravel the entire undertaking. A quality concrete glue sits at the center of that choice, proving itself again and again in settings as modest as a home basement and as ambitious as a bridge deck sequence. Turn the aisle of any hardware store, and the sheer range of bottles, tubes, and cans quickly becomes bewildering. Good, cheap, quick-every label offers an answer but leaves the user with more questions than confidence. This overview trims the clutter and focuses on concrete adhesives, outlining their formulation, practical scope, and proven application methods. Chapters to follow will cover everything from patching aesthetic cracks to bonding heavy rebar, giving makers the information they need to produce work indistinguishable from a professional’s field repairs. The material itself will be set beside a short discussion of bond chemistry, workmanship standards in the industry, and field-tested reminders that help keep the repair or pour stout for the long run.

What’s Concrete Glue and How Does It Work?

Concrete glue, called concrete adhesive in many catalogs, begins life as a resinous compound specifically tuned to bond cured Portland-cement surfaces. The liquid enters voids and microfissures, afterward solidifying to form either a tenacious mechanical grip or, in some advanced formulas, a genuine chemical weld, depending on temperature and relative moisture during cure. That dual action physical lock plus hard-setting matrix is why engineers will reach for the product long after casual DIYers have put their tubes back on the shelf. Modern concrete glues typically blend advanced polymers epoxy, polyurethane, acrylic and each chemistry targets a specific professional need. The cured bond resists moisture, shrinks minimally with heat cycles, and holds strong under compressive stress.

Understanding the Composition of Concrete Adhesive

Manufacturers now engineer concrete adhesives around polymers like epoxy, polyurethane, and acrylic so the bond performs better under real-world stress. Chemists fine-tune each formula to resist moisture, heat, and even the odd splash of chemicals common on a job site. An epoxy base typically offers the highest compressive strength and locks down almost permanently once cured. Polyurethane variants, by contrast, stay noticeably flexible and can grip together materials that expand and contract at different rates. Fast-curing acrylics work well on both porous concrete and smooth, sealed surfaces, making them the go-to choice when repairs cannot wait.

Most modern adhesives borrow from the toolbox of high-performance chemistry by hiding specialized additives inside the mix. Fillers-think finely milled powders-boost viscosity and turn a watery slurry into something that won’t simply slump away from a wide gap. Nanomaterials, sprinkled in at the nanometer scale, bulk up resistance to wear and extend overall lifespan. The weighty task of hardening is delegated to curing agents that kick-start the necessary chemical dance, setting the body of the glue solid so the bond can flex without breaking. When everything works in concert, the end product stands up to the jerks of construction life: high tensile strength, stubborn resistance to weathering, and the grit to keep going long after the job is done.

How Concrete Glue Bonds with Various Surfaces

Concrete glue forms a durable bond by mixing chemical attraction, mechanical fit, and careful surface-energy management. On porous substrates wood or rough concrete the liquid seeps into tiny voids, locks in place, and sharply boosts adhesion. Smooth materials, such as glass or polished metal, demand a different tactic: the formulation is designed to produce a nearly uniform molecular pull across the entire joint. Recent epoxy blends take this further, building a web of cross-linked polymers that can withstand heavy pull, heat spikes, and steady vibration. Still, the strongest bond begins long before any glue touches a surface; scrub the substrate, grind it if needed, and you’ll raise its energy, expand the contact area, and give the adhesive something solid to grasp.

Types of Concrete Adhesives Available

|

Type |

Key Features |

Best Uses |

Bond Strength |

Curing Time |

Application Method |

|---|---|---|---|---|---|

|

Epoxy-Based Adhesive |

High durability, water-resistant |

Structural bonding, industrial |

Very high |

24-48 hours |

Dual-component mixing |

|

Polyurethane Adhesive |

Flexible, weather-resistant |

Outdoor projects, damp areas |

High |

4-6 hours |

Direct application |

|

Acrylic Adhesive |

Quick bonding, UV-resistant |

Small repairs, lightweight use |

Moderate |

5-15 minutes |

Single-component tube |

|

Silicone-Based Adhesive |

Elastic, resistant to temperature |

Sealing joints, waterproofing |

Low to moderate |

24 hours |

Caulking gun |

|

Latex-Based Adhesive |

Easy cleanup, non-toxic |

Indoor projects, décor |

Low |

2-8 hours |

Brush or roller |

|

Cyanoacrylate Adhesive |

Instant bonding, small-scale use |

Minor and precise repairs |

Moderate |

Seconds to minutes |

Base application |

|

Cementitious Adhesive |

Traditional, cement-like compound |

Large-scale masonry work |

High |

12-24 hours |

Trowel |

When Should You Use Concrete Adhesive for Repairs?

Field experience shows that adhesive is the right call for cracks, spalling spots, or when fresh concrete must be glued to older slabs. Unlike mortar mixes, which weaken as moisture moves through, a good adhesive bond lasts because the polymer fills every tiny void. Vertical walls and overhead patches pose special challenges, yet the shear strength of modern adhesives keeps the patch in place long after the drum of cement would have sagged. Clean, dust-free surfaces are non-negotiable; oils, laitance, or loose particles will make even the strongest formula fail.

Identifying the Need for Concrete Repair

Concrete repair estimates begin with a careful inspection of both the material and the surrounding structure. Obvious signs cracks spidering across a slab, pocked surfaces that chip away under foot traffic, color patches that hint at moisture raise the first alarm. Winter freeze thaws and hidden water leaks are often to blame, though heavy, repeated loads can also push the concrete past its limits. More serious trouble appears when reinforcing steel stands exposed or corners crumble as soon as they are brushed. Tapping the surface sometimes reveals a hollow tone, and white, powdery efflorescence sits like chalk in the joints or on the curb. Relying on sight alone is guesswork: strength cores or non-destructive tools such as ultrasonic pulse velocity scanners convert suspicion into measurable numbers and guide repair strategy.

How to Choose the Right Concrete Glue for Your Project

Choosing the right adhesive for concrete is not a minor detail; it is, in fact, the hinge on which the entire project turns. Select an epoxy glue if the job demands a bond stout enough to resist impact, compression, and sheer wear; the hardened layer will act almost like another slab of concrete. Use polyurethane if sun, rain, or wide temperature swings are part of your world, because that formula stays elastic and adheres stubbornly even when the surface is damp. In lighter repairs, an acrylic or polymer-modified adhesive can save time and reduce mess without bankrupting the strength the patch requires.

Gelled formulations shine when the repair is vertical or overhead; the thicker consistency stays put while you work rather than dribbling into unintended corners. Always scan the package for an estimate of set time; some products clutch the aggregate within minutes, while others demand hours or even days before they reach peak toughness. Pick the timing that matches the pace and demands of the build.

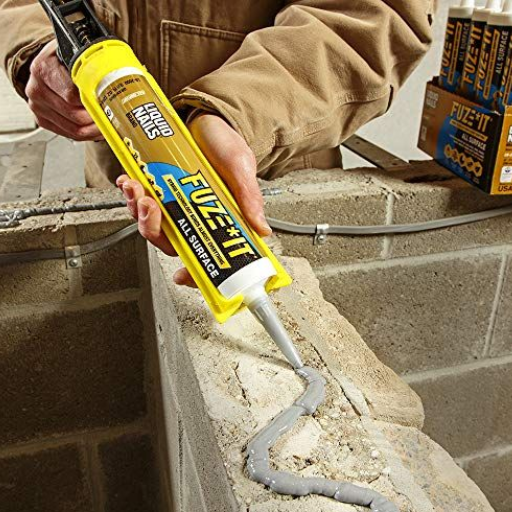

How to Apply Concrete Glue Effectively?

- Surface Preparation: The bonding surface must be inspected and rid of any loose particulates, moisture, or oily residues. A good scrubbing with a wire brush or light sanding usually suffices to restore a sound substrate.

- Adhesive Selection: Not every concrete glue works for every pairing, so consult the technical data sheet to confirm compatibility with the specific substances being joined.

- Application Method: Depending on manufacturer directions, a trowel, spatula, or even a coarse brush may be recommended for distributing the adhesive. Coverage should remain even to avoid weak spots after curing.

- Positioning Components: Once the glue is laid, the two pieces should be brought together and aligned without delay. Moderate pressure locks them in place until the bond begins to set.

- Curing Duration: True bond strength develops only after the chemical curing period specified on the product label. Movement or shock to the joint before this time can compromise performance.

Following these procedural checkpoints usually leads to a joint that withstands both load and time.

Tools Needed for Concrete Glue Application

- Trowel or Spatula: A wide drywall knife or small masonry trowel works well for thicker adhesives, allowing the user to spread a substantial film quickly.

- Brush or Roller: For thinner formulations, a stiff-bristle brush or foam roller lays down the resin smoothly, accommodating both flat and textured substrates.

- Mixing Container: When the product at hand is a two-part epoxy or similar paste that insists on being blended, a tough plastic bucket or a metal pot becomes the stage where both halves meet and marry as the label directs.

- Protective Gloves: Heavy, chemical-proof gloves stand between your skin and the stew of irritants that many adhesives harbor, so slipping them on first is never a gamble.

- Safety Goggles: One stray drop or an airborne fleck can ruin an afternoon, which is precisely why both lenses stay clear and intact behind a proper pair of safety glasses.

- Clamps or Weights: Only a firm, unyielding grip keeps two bonded faces from drifting apart while the glue thickens; whether you’re using quick-release clamps or a stack of concrete blocks, something must press steadily until the cure is finished.

- Measuring Tools: A tape or a machinists rule makes certain that joints stay straight and overlaps stop where they should; rough eyeballing usually awards the blame once the bond is set.

- Cleaning Supplies: Rags drenched in solvent, or the citrus cleaner that pretends to be less toxic, wipe dust first and then leap in to tame any runaway bead before it hardens.

Handling these items in turn allows the messy craft of gluing concrete to yield an edge-quality bond while protecting sight, skin, and even sanity.

Tips for Ensuring a Strong Bond with Concrete

- Surface Preparation and Cleaning:

Before any glue goes on, give the bonding surfaces a quick once-over. Research warns that dust, oil, or stray fragments hide in plain sight and can trim bond strength by nearly 40%. A rag soaked in a recommended solvent or cleaner clears away those hidden culprits.

- Achieve Proper Surface Texture:

Flat, glossy finishes may refuse to hold even the strongest adhesive. Roughening the surface with sandpaper or a wire brush opens new pathways for the glue to squeeze into. More texture means more microscopic cradles for the material to cling to.

- Control Environmental Conditions:

Temperature and moisture play their own tricks on bonding power. Most manufacturers peg the sweet spot between 50°F and 86°F (10°C to 30°C); stray outside that window and shear strength can slip by a quarter. Pay attention to the printed range, not just the calendar date.

- Apply Adhesive Uniformly:

Sloppy glue lines create voids or cavities where nothing sticks. A steady hand with a trowel, spreader, or dispensing gun lays down a uniform coat that fills every nook. Some pros cross-hatch the adhesive in stripes to double-check even coverage.

Stick to these practices and respect the product instructions, and the bond you form today should still be trustworthy years from now. A little care at the start often saves a much bigger headache down the road.

What Are the Benefits of Using Epoxy Glue for Concrete?

Many repair specialists reach for epoxy when bonding concrete because, quite simply, the glue is uncommonly tough. An epoxy joint typically shrugs off the kind of shearing and compressive forces that can split weaker bonds in seconds. Engineers routinely cite those remarkable numbers, yet the real-world takeaway is less technical: when the patch is done, you can walk away trusting it won’t fail under a passing truck.

Advantages of Epoxy Over Traditional Concrete Adhesives

- Superior Strength and Bonding

Bonding strength tells only part of the story. Most ordinary construction adhesives top out around 3,000 pounds per square inch of pull and buckle well before that mark. A good epoxy, by contrast, struts past 5,000 psi on the same test and often climbs even higher once cured.

- Resistance to Environmental Factors

Longevity matters even where the initial bond is solid. Standard glues turn brittle in sunlight and dissolve after months of rain; epoxies withstand moisture, ultraviolet light and a chemical soup that leaves typical products wrecked. The temperature range is equally broad, holding strong through a frigid -20°F to 200°F. Put those traits together and you have a repair that lasts, not just until the next season but across years of punishing service.

- Adhesion to a Wide Range of Surfaces

Epoxy sticks to nearly anything: metal, wood, plastic, glass, and of course concrete. That kind of cross-material grip means an epoxy bond can swing between very different surfaces without breaking a sweat. Standard glues usually phone in a one-or-two-material rule, so they tap out when a job gets complicated.

- Quick Curing Time with Adjustable Settings

A single epoxy blend can cure in five minutes or stretch its set time to eight hours, depending on what the user picks off the shelf. The adjustable clock gives craftsmen room to fiddle with alignment and still finish the job before the glue thickens. Most off-the-shelf adhesives dont even pretend to offer that range.

Those performance quirks explain why concrete pros reach for epoxy when sidewalks crack and warehouse floors need patching. The bond holds up to moisture, grit, and temperature swings that would shred weaker products. In short, the chemistry makes epoxy the quiet workhorse behind both DIY repairs and heavy-duty industrial fixes.

Best Practices for Using Epoxy in Construction

- Surface Preparation

Achieving a durable bond with epoxy begins long before the material touches the surface. The substrate must be cleaned of every trace of dust, oil, and moisture. Concrete owners should grind, scarify, or blast the floor until it feels roughly sandpaper-like under the hand, because a coarse texture grips the cured resin. After roughing, a final vacuum or blow-off removes any loose grit that could otherwise interrupt the bond.

- Mixing Ratios and Techniques

Epoxy chemistry hinges on precise proportions, so strict adherence to the manufacturers mixing ratio is non-negotiable. Most formulations consist of a resin component paired with a hardener; variations in weighting them tilt performance toward weakness or incomplete cure. Clean, dedicated containers prevent cross-contamination, and careful stirring until a uniform color appears ensures the curing agent disperses throughout the mixture.

- Temperature and Environmental Conditions

Application conditions, particularly temperature and humidity, further govern the outcome. Most products cure reliably between 60°F and 85°F (15°C to 30°C), although colder environments sluggish the reaction, and excessive heat can trigger premature gelation. Elevated humidity invites amine blush, a greasy film that appears on the surface once the epoxy hardens, and this must be stripped mechanically or chemically before applying any topcoat.

- Application Techniques

Thin, consistent coats of epoxy perform best, so reach for a brush, roller, or trowel and avoid the temptation to lay it on heavy. On big jobs, automated pumps and injection rigs deliver the material with surgical precision and keep production moving. Respect the pot life listed on the data sheet; once that clock runs out, the mixture hardens in the can.

Following those simple routines can transform an ordinary application into a durable, trouble-free bond that withstands the rigors of modern construction.

How to Ensure the Concrete Adhesive Cures Properly?

- Prepare the Surface: Clean the surfaces until dust, grease, and moisture are gone; even a thin film can halt adhesion in its tracks. The time spent prepping the substrate almost always pays dividends later.

- Maintain Recommended Conditions: Apply the adhesive within the temperature and humidity window set by the manufacturer; ignore those limits at your own risk. Data sheets usually spell out the sweet spots for optimal curing.

- Use the Right Mix Ratio: Mix the two parts by weight or volume exactly as specified; a careless guess or a slight excess of hardener can turn a strong bond brittle. Good chemistry demands discipline.

- Avoid Movement During Curing: Keep the joint still until the product fully cures; shifting the pieces too soon invites a weak link that defies repair. Patience at this stage is faster than redoing the work.

- Follow the Manufacturer’s Guidelines: Obey the manufacturers specifications for curing time and technique; respect the intervals the label demands for the bonding agent to develop full strength.

Following these directions normally yields a secure, long-lasting bond.

Understanding the Curing Process of Concrete Glue

Curing concrete glue is not a simple waiting game; it is a genuine chemical choreography, usually involving polymerization or cross-linking exchanges. These exchanges give the bond its characteristic toughness and gripping power. Whatever the brand printed on the container, the reaction still leans heavily on three capricious partners: moisture, air speed, and the temperature itself. The sweet center of that temperature ballpark sits roughly between 50°F and 80°F; drift too far in either direction, and the glue either stalls out or dries up like old chewing gum. Most manufacturers steer clear of saying that number out loud, yet engineers tend to whisper the same upper and lower bounds to one another in the field.

One cartridge may call it a fast set and shrug after four hours, while another drum, aimed at heavy traffic, insists on a full day or even seventy-two ticks of the clock. Put another way, not all adhesives wear the same wristwatch. Recent chemistry has even given formulators the nerve to promise grip in soggy basements or under real-world loads that keep stiffening long after the contractor leaves the site. If the crew ignores that promise and shortcuts the right conditions, odds are the bond breaks long before the concrete does.

Environmental Factors Affecting Concrete Adhesive Drying

Environmental variables such as temperature, relative humidity, and air movement govern how quickly and thoroughly a concrete adhesive forms a durable bond. Temperatures hovering between 50°F and 90°F generally yield the most reliable cure; anything colder drags out the schedule, yet heat above that range can bake the surface before the interior has set properly. Bond strength and overall longevity may both pay the price for that uneven hardening.

Humidity matters, too: wetter air slows evaporation from water-based adhesives, leaving them gummy, while a shallow atmosphere sucks moisture away so fast that shrinkage cracks appear almost on cue. Spiraling breezes thin that boundary layer and hasten drying, but still air wraps the adhesive in a stagnant pocket, adding yet another delay.

Reference Sources

-

Adhesive Bond Performance of CFRP-Patched Concrete: This article evaluates the effectiveness of adhesively bonded CFRP patches in reinforcing and rehabilitating concrete.

-

Strategic Strengthening of Interfacial Bonding Between Old and New Concrete: This study explores interfacial bonding issues in repair projects and proposes using carbonized recycled aggregates (CRA).

-

Interface Bonding Properties of New and Old Concrete: This paper examines the effects of repair materials, interface agents, environmental factors, and test methods on bonding properties.

Frequently Asked Questions (FAQs)

Q: What is the best product for gap filling in concrete?

A: For gap filling in concrete, a concrete crack filler or a premium adhesive glue like Loctite PL Premium Max is highly recommended due to its strong adhesion and long-lasting properties.

Q: Can I use construction adhesive on wood and stone?

A: Yes, many construction adhesives are versatile and can be used on wood, stone, and other materials. Make sure to choose a heavy duty adhesive specifically designed for the materials you are working with.

Q: How much adhesive do I need for my project measured in oz?

A: The amount of adhesive needed will depend on the size of the project and the specific usage. Always refer to the manufacturer’s instructions for coverage per oz and calculate based on the area you are working on.

Q: Is there a waterproof adhesive suitable for outdoor use?

A: Yes, there are waterproof adhesives designed for exterior use, such as Gorilla Glue or other polyurethane-based options, which provide strong adhesion even in wet conditions.

Q: What is the difference between super glue and construction adhesive?

A: Super glue is typically used for small, quick fixes and has a fast drying time, while construction adhesive is designed for larger projects and offers more strength and versatility for various materials.

Q: Can I use clear glue for filling gaps in my indoor flooring?

A: Clear glue can be suitable for filling small gaps in indoor flooring, but for larger cracks or gaps, it is advisable to use a specific concrete crack filler or a premium construction adhesive for better results.

Q: How fast does fast drying adhesive set?

A: Fast drying adhesives can set in as little as 10 to 30 minutes, depending on the product and environmental conditions. Always check the product specifications for exact setting times.

Q: Are there any adhesives that are specifically designed for heavy duty applications?

A: Yes, there are heavy duty adhesives available, like Loctite PL Premium Max, which are engineered to provide strong bonds for demanding construction applications.

Q: What type of sealant should I use for exterior concrete projects?

A: For exterior concrete projects, a waterproof sealant that is resistant to weather conditions is ideal. Look for products specifically labeled for outdoor use and capable of handling temperature variations.

Q: Can I use construction adhesive for patching concrete?

A: Yes, construction adhesive can be used for patching concrete, especially those that are designed for filling and repairing concrete surfaces, providing a durable and long-lasting fix.