Putting up drywall is one of the most important stages in every building or renovation project, and making sure that it is done correctly can determine the life and the look of your walls. Screws and nails have been the traditional methods for attaching drywall but now construction adhesive is being accepted as either a supplementary or even a completely independent solution. But the question is when exactly should one use the adhesive in drywall installation? The current article uncovers the pros of drywall adhesive, the occasions and the reasons to use it, and lastly how it stands against the classic fastening methods. At the end of the day, you will clearly see if this revolutionary method is the best fit for your upcoming project or not.

Understanding Drywall Adhesive

What is Drywall Adhesive?

To get it on the dot, drywall adhesive is a kind of vegetation that lets the drywall panels bond securely to the surface, whether it be wood, metal assembly or anything, without relying on the use of screws and nails only. Usually, it is used in conjunction with mechanical fasteners on hand, ensuring that the installations are strong and stable in the end. The purpose of this adhesive is to let the whole process of installing drywall become more productive and to keep the quality of the work done, i.e. by creating a firm and lasting bond between surfaces.

Another thing that drywall adhesive does is a major plus, and that is it prevents or at least reduces the occurrence of pops coming from nails or screws, which can ruin the smooth and perfect appearance of painted or plastered walls or ceilings. To make it clearer, the adhesive plays the role of a stress reducer which leads to creating fewer imperfections as time goes by. Besides, this technique can eventually become a very effective way of improving the soundproofing and insulating properties of a drywall installation by virtually merging the two spaces.

Drywall adhesive is indispensable for big projects or situations with materials that need extra support. It will also make using mechanical fasteners more economical and the number of spots where the wall surface has to be treated will be less. Thus, painting or plastering would be quicker and more efficient among all of its many practical uses. This versatile and multifunctional product is no less than a blessing for all those engaged in the effort of creating sturdy and aesthetically pleasing results, whether they are professionals or amateurs.

Types of Adhesives for Drywall

Choosing the appropriate adhesive is crucial to getting a strong, durable, and seamless result when installing drywall. There are various kinds of adhesives specifically made for drywall applications, each advantageous for specific needs and surroundings. The primary types of drywall adhesives, their particulars, and situations for use are given below:

1 Construction Adhesives

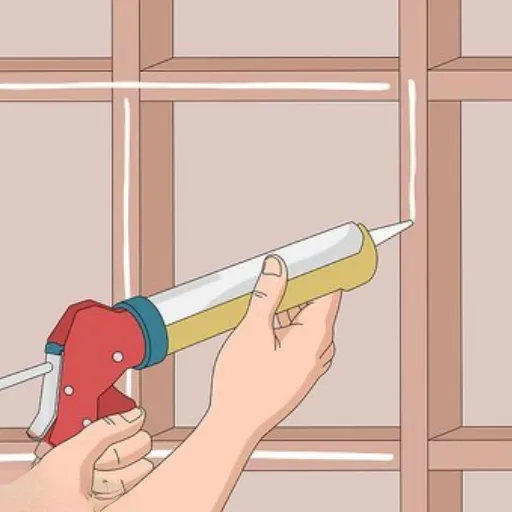

Construction adhesives are commonly used for drywall due to their versatility and high bonding strength. These adhesives are designed to adhere to a variety of materials, including wood, metal, and plasterboard, making them ideal for drywall installation. They often come in cartridges that can be used with a caulking gun for precise application.

- Strength: High-strength bonding, capable of supporting heavy panels.

- Dry Time: Typically cures within 24 hours.

- Best Use: Applications requiring strong and long-lasting bonds or in combination with mechanical fasteners for added security.

2 Acrylic or Latex-Based Adhesives

Acrylic and latex-based adhesives are popular choices for drywall due to their easy application and water-based nature. These adhesives are low in volatile organic compounds (VOCs), making them an eco-friendly option.

- Environmentally Friendly: Low VOC emissions make them safer for indoor usage.

- Flexibility: Perfect for adhering drywall in areas with temperature fluctuations.

- Dry Time: Fast drying, which can accelerate project timelines.

3 Polyurethane Adhesives

Polyurethane adhesives are known for their exceptional bonding properties and durability. These adhesives work well in both indoor and outdoor settings and can withstand moisture and temperature changes.

- Durability: Resistant to both heat and moisture exposure.

- Applications: Ideal for areas prone to humidity, such as bathrooms and basements.

- Dry Time: Generally sets in a few hours, but full curing may take up to 24 hours.

4 Spray Adhesives

Spray adhesives are a newer option gaining popularity in drywall applications. They are ideal for quick and large-scale projects because of their ease of use and even application.

- Convenience: Spray-on application makes for improved efficiency during installation.

- Best Use: Temporary or light-duty adherence, often used in conjunction with screws or nails.

- Considerations: Not as strong as other types of adhesives for long-term use.

5 Epoxy Adhesives

Epoxy adhesives are highly effective for heavy-duty drywall installations and repairs. They offer excellent strength and are resistant to a variety of environmental conditions.

- Strength: Very strong and durable, suitable for structural drywall needs.

- Applications: Often used in industrial settings or for patching damaged drywall.

- Dry Time: Slower to cure, typically taking 24-48 hours for full adherence.

Benefits of Using Drywall Adhesive

Incorporating drywall adhesive for building and repairing activities gives rise to many merits, compared to the traditional methods of using screws or nails. Here are some of the main advantages, supported by the latest research and industry statistics:

✓ Stronger Bond and Long-Lasting Results: The bond created by the drywall adhesives is stronger and more uniform than that of the drywall and the framing materials, thus reducing the likelihood of cracking and sagging with time. As per the construction industry studies, the durability of adhesive-bonded drywall is up to 25% greater than that of the nail-fixed drywall.

✓ Minimized Risk of Nail Pops: A major problem faced in drywall installation is nail pops which are formed when the nails or screws get loose over the period, causing bumps to develop on the surface. One of the solutions that drywall adhesives offer is to tackle this issue from the root by cutting down the stress on fasteners which in turn allows producing to have a smoother and more stable finish.

✓ Improved Efficiency: The use of adhesives can make the installation process faster as there will be fewer fasteners needed. Contractors claim that adhesive application results in less finishing work and touch-ups, thus saving time and labor costs. In recent surveys it has been reported that on average the use of adhesives can lead to a reduction in total installation time of 15-20%.

✓ Soundproofing and Vibration Resistance: Besides giving additional sound attenuation, adhesives contribute to the acoustic performance of a room. Moreover, they serve as a buffer for vibrations, thus making drywall installations less likely to be damaged, especially in busy areas or buildings experiencing movement.

✓ Suitable for Various Environmental Conditions: Certain drywall adhesives can endure temperature variations, moisture, and humidity; such adhesives would be reliable for construction in different climates, as they are designed to prevent screw pops. For instance, moisture-resistant adhesives are indicated for bathrooms or basements, hence are the ones to use in such places to avoid damage due to the wet conditions.

✓ Cost-Effectiveness: While adhesives appear to be an extra cost at the beginning, they are likely to yield savings in the long run. They will, and lessen the need for repairs and maintenance as well as installation time; therefore, the adhesive is a cost-efficient solution for both residential and commercial projects.

The modern drywall adhesives, which are supported by the newest findings in material science, have not only increased these profits but have also made them indispensable for quality and durable building practices. It is important to take the specific job requirements like environmental conditions and load-bearing capacity into consideration while selecting an adhesive in order to pick the correct product.

Construction Adhesive: An Overview

What is Construction Adhesive?

Construction adhesive is a super-strong and multi-purpose bonding agent that is widely used to join together materials in construction and renovation. It is capable of holding together the most disparate of materials like wood, metal, concrete, ceramic, or drywall. This adhesive is not limited to structural applications but it is also used in non-structural applications where it provides strength and at the same time makes the installation process easier.

The chief benefit of construction adhesive lies in its ability to provide a robust and durable bond between the materials without the need for mechanical fasteners, such as screws or nails, in each case. It can also fill the gaps efficiently, and thus, it will be very helpful in providing a tight seal between the surfaces, which will in turn enhance the stability as well as the aesthetic appeal of the finished work. Furthermore, a lot of the construction adhesives are made resistant to the environmental factors such as moisture, extreme temperature changes, and chemical exposure.

Construction adhesives come in a wide variety of formulations, including both water-based and solvent-based options. Each of them is suitable for a particular type of project. It is very important that you take into account the materials to be bonded, the environmental conditions, and the weight or load the bond is likely to bear when choosing a construction adhesive. The selection of the right adhesive will help not only the construction professionals but also the DIY enthusiasts in increasing the efficiency and quality of their work.

Comparing Construction Adhesive to Other Types

Construction adhesive typically offers stronger bonding for a wider range of materials compared to other adhesives like wood glue or epoxy.

| Key Point | Construction Adhesive | Wood Glue | Epoxy Glue |

|---|---|---|---|

| Material Bonding | Versatile | Wood Only | Limited Types |

| Drying Time | Moderate | Fast | Variable |

| Strength | Very Strong | Moderate | High |

| Flexibility | High | Low | Moderate |

| Application Area | Indoor/Outdoor | Indoor Only | Mostly Indoor |

| Environmental | Durable | Low Durability | Moderate |

| Ease of Use | Simple | Easy | Complex |

| Load Capacity | Heavy Load | Light Load | Medium Load |

Best Practices for Using Construction Adhesive

Using construction adhesive in the right way will give you a strong and long-lasting bond for different materials. To get the best possible result, observe these best practices:

Surface Preparation: Before the application of construction adhesive, it is necessary to check that the surfaces are clean, dry, and completely free of debris, grease, or dust. Cleaning the surfaces properly increases the adhesive’s bonding capacity and keeps it from getting weaker as time passes. If the materials are porous, try to lightly sand the surface to promote bonding.

Application Method: Depending on the requirements of the project, apply the adhesive in a consistent pattern, for example, a straight line or beads. On larger areas, spreading the adhesive evenly is recommended in order to avoid gaps and to make sure that full coverage is achieved. Be careful not to apply too much, as the excess will ooze during pressing and may also lead to a weakened bond.

Curing and Bonding: Once the adhesive is applied, quickly bring the materials together and apply the same amount of pressure through the bond to make it strong. If needed, use clamps or weights to keep the pieces stationary during the curing process. Consult the adhesive instructions for the suggested curing time since improper curing can deteriorate the adhesive’s strength and durability.

By adhering to these simple steps, you will not only get the most out of construction adhesive but also make strong and durable bonds for your projects.

When to Use Drywall Adhesive

Drywall Adhesive – A Must-Have for Specific Situations

Drywall adhesive finds its applications mostly in such situations where the drywall has to be bonded strongly with different surfaces and the use of screws or nails is greatly reduced. It gives an extremely good adhesion when used for attaching drywall to wood, metal studs or masonry, thus making it an important instrument for the different construction and refurbishment projects.

One frequently encountered situation is the installation of drywall over an irregular or non-standard surface. Here, the use of adhesive will certainly result in better flexibility, as it will allow the surface to overlap with the drywall and thus create a connection that minimizes differences. Besides, the use of adhesive will greatly reduce the chance of cracks or other damage occurring over time through the equal distribution of stress over the entire bonded area.

The use of drywall adhesive can also be suggested when sound or vibration reduction is a priority. Adhesive produces a bond that is much less affected by mechanical fasteners used alone and is therefore more effective in damping sound transmission and increasing the overall stability of the construction. Moreover, it can further improve the efficiency of the installation process by cutting down on the number of fixings needed, thus making the process faster and allowing to achieve a durable and professional finish without sacrificing the quality.

Considerations for Attaching Drywall

Attaching drywall is effective when it is well-planned and done accordingly so that the result is stable and long-lasting. First of all, it is necessary to use the appropriate materials like either drywall screws or nails to fasten the panels to the framework in a manner that is correct. Screws are the choice most of the time due to their holding power being excellent and not easily losing strength over time. Furthermore, the united fasteners must be placed in the right manner, which means putting screws or nails about 12 inches apart on the edges and 16 inches apart in the center of the panel will keep it tight.

Another important thing to pay attention to is the alignment of the drywall panels and the evenness of the wall surfaces during the installation process. If the framing is uneven or the panels misaligned, it can result in visible gaps, cracks, or spots that are weak. To counter this, check the wall studs or framework thoroughly for irregularities before starting. If necessary, use a level to adjust and place shims on the framing to create a smooth surface for the drywall to rest upon.

Lastly, do not forget to consider humidity and moisture control, particularly in the high-risk areas like kitchens, bathrooms, or basements. Moisture-resistant drywall will serve as a protective barrier against mold as well as the degradation that comes with prolonged exposure to wet conditions. Proper ventilation and sealing techniques in these areas will also help in making your installation last longer. It is the environmental factors that are to be managed properly that will yield a professional and durable drywall finish.

Environmental Factors Affecting Adhesive Choice

Environmental factors are very important in selecting the adhesive type for a drywall project. The main points to consider are heat, moisture, and the likelihood of chemicals or moisture coming in contact with the adhesion layer. In case of a high moisture area, it is a must to pick out the adhesive that is water-resistant and capable of keeping its grip under such conditions. On the contrary, dry areas require the use of adhesives that will not lose their strength due to the development of brittleness over the years.

The oscillation of temperatures also has an effect on the adhesives’ performance. When it comes to drywall installation in places with extreme temperature differences like garages without heating or outside walls, kindly pick an adhesive that is powerful and efficient in both hot and cold situations. A lot of adhesive products are made ineffective when applied in a temperature that is beyond their range hence it is vital to use the one that is rated for that particular environment.

Another issue to deal with is the availability of chemicals or contaminants in the environment. For instance, spaces like industrial facilities may have exposure to solvents or acidic elements, which can weaken standard adhesives. Opt for adhesives that are chemically resistant if working in such environments. Carefully assessing these environmental factors ensures the drywall installation remains secure and long-lasting.

Application Techniques for Drywall Adhesive

Preparing the Surface for Adhesive

The surface preparation done right is an important factor to ensure that the drywall adhesive sticks, and there will be a strong, lasting bond. Dust, debris, grease, or loose particles should be the first things to be found through the inspection of the surface. Cleaning the area very much, as wiping with a damp cloth or lightly sanding if necessary, are some of the good ways to do cleaning. An adhesive can have direct and uniform contact with a clean surface.

The next step is to check the surface for any unevenness or imperfections. Such surfaces may lead to poor adhesion with resultant gaps or weak spots. Crack or hole filling can be done with the appropriate filler and then left to dry. The area can then be sanded to a smooth finish so that the uneven base is created and the adhesive has the best conditions to bond.

Lastly, ensure that the surface is completely dry before the application of adhesive. The surface moisture can hurt the adhesive’s integrity leading to the formation of a weak bond. Therefore, drying time after cleaning or filler application must be adequate. If these steps are followed, it will result in a successful and long-lasting drywall installation.

Applying Adhesive for Optimal Results

In order to apply adhesive in a proper manner, first of all, you need to check that the adhesive is distributed uniformly all over the area where the bonding will take place. Depending on the adhesive type use the appropriate tool like a notched trowel or applicator to achieve the desired coverage. Do not overdo the adhesive application as this would result in uneven bonding or oozing out from the surface during application.

Once the adhesive is applied, carefully place the drywall or other material on the surface prepared with adhesive. Apply pressure so that the material sticks and holds the position giving a strong bond. Use a leveling tool to check if the alignment is correct and if not, then do the necessary adjustments while the adhesive is still in the tacky stage. It is very important to apply proper pressure and do the right alignment as these are the two main things that determine if the hold will be secure and last long.

The curing time indicated in the adhesive instructions should be allowed to pass. This step guarantees that the bond reaches its maximum strength. The area where the bonding has been done should not be subjected to any stress or weight until the adhesive has completely set. Adhering to these recommendations leads to the best results and the drywall installation lasting longer.

Tips for Installing Drywall with Adhesive

Prepare the Surface: Before you go ahead and apply the adhesive, first make sure that all surfaces are clean, dry and free of any dust or debris. A clean surface for bonding provides not only a better bond but also a more durable installation. Lightly sand down uneven areas if necessary to create a smooth surface for the best adhesion.

Apply Adhesive Evenly: The use of an appropriate tool like a caulking gun or a trowel for the application will allow you to spread the adhesive evenly. The adhesive should be applied in a uniform pattern which is usually in beads or dabs depending on the size and material of the drywall. Overuse of adhesive is to be avoided, as the excess will cause messy results or improper positioning.

Position and Secure the Drywall: Apply pressure to the drywall and quickly make changes to the position of the panels, as most adhesives will start to set within a couple of minutes. After adjusting, fix the drywall with temporary fasteners or clamps while the glue sets up. Adhere to the adhesive’s instructions for cure times to make sure that the bond is completely set before taking down any supports.

If these steps are followed, the result would be smooth and durable drywall installation, thus minimizing the chances of problems over time.

Choosing the Right Adhesive for Your Project

Factors to Consider When Selecting Adhesive

Among the factors to be weighed when choosing an adhesive for your project is the kind of materials to be bonded, which is the most important one. Each adhesive is specifically made to be used effectively with certain surfaces, such as wood, metal, plastic, or drywall. By selecting the adhesive that is compatible with your materials you get a stronger, more reliable bond plus reduced risk of failure.

Another factor that plays a vital role is the adhesive’s application and usage in environmental conditions. Take into account the temperature, humidity, and the elements like water or UV light that will be the adhesive’s stress factors. For example, outdoor projects may necessitate the use of waterproof or weather-resistant adhesives while the high-temperature areas need the heat-resistant types. Evaluating these conditions assists you in selecting an adhesive that will last and maintain its quality throughout very long periods.

Finally, determine the curing time, strength, and flexibility required for your application. In case you want a quick fix or are doing a task that is time-sensitive, then go for an adhesive with a fast curing time. For building applications, the use of high-strength adhesives is a must. If the materials to be bonded are going to move or get stressed then the use of flexible adhesives may be necessary. Considering these factors helps you to get the right adhesive that would be appropriate for your project.

Surface Material Compatibility

It is essential to know the compatibility of the adhesive with the surface material before making a choice, as this will not only secure the bond but also save time and effort afterward. Adhesive manufacturers usually indicate the materials, along with plastic, wood, glass, or fabric, that each adhesive would work best with. For example, the adhesive for bonding glass and metal surfaces might have the property of strong chemical bonding due to the smooth surface, while adhesive for wood or fabric, which are porous materials, needs to be penetrating and gripping.

It is wise to conduct a small test with the adhesive first on a non-visible area of the material to check its compatibility and performance. Factors like temperature and humidity can also influence the quality of adhesion. For instance, some adhesives lose their effectiveness at very high or low temperatures, while others work well under such conditions because they are actually designed for that.

Moreover, surface preparation greatly influences the adhesion achieved. Oil, dust, and debris on the material’s surface can hinder the bond, hence the need to clean it beforehand. In the case of materials with glossy finishes, lightly sanding the surface could actually result in the adhesive gripping better, as a rougher area for bonding has been created. All these combined actions will bring the most trustworthy and long-lasting results for your project.

Load-Bearing Needs and Adhesive Performance

The comprehension of the interplay between load-bearing requirements and adhesive performance is of utmost importance in the process of selecting the most suitable adhesive for the specific project. Adhesives have to endure both static and dynamic loads depending on the application. Static loads are characterized by constant pressure over a period, e.g. holding two materials together without movement, whereas dynamic loads are composed of fluctuating or moving forces, like vibrations or impacts.

In the first place, the direction of forces plays an important role in determining the adhesive’s suitability for the load-bearing application and thus both shear strength and tensile strength must be taken into account. Shear strength is used to describe the resistance of the adhesive to the forces that are applied parallel to the bonded surface while tensile strength is the measure of the adhesive’s resistance to the forces pulling perpendicular to the bond. It is always a wise move to be aware of the kind of forces that the adhesive has to tolerate since it marks a better product selection meeting the mechanical specifications of the task. Moreover, environmental factors such as temperature, humidity, and chemical exposure should be thoroughly discussed, since these conditions can make the adhesive less durable and less reliable.

As a last point, the testing of the adhesive under actual conditions is very important to prove the acceptance of the application. For high-stress or safety-critical projects, consulting the adhesive manufacturer’s performance specifications and performing trial runs can support the confirmation that the selected product will indeed perform as expected. Weighing up these factors assures that the adhesive will be capable of providing a strong and durable bond meeting all load-bearing requirements.

Frequently Asked Questions (FAQ)

Q Which glue is the best for drywall?

A: Generally speaking, Loctite PL Premium is the first choice when it comes to the best glue for drywall. This glue of high quality is made especially for trimming, which means it can offer very good bonds that can even fill some gaps and thus in many cases eliminate using additional fasteners.

Q Is it okay if I use adhesive foam instead of regular glue for drywall installation?

A: Certainly, foam adhesive can be efficiently used in drywall construction. It is not heavy, and combined with its ease of application, also creates a strong bond. This adhesive type is particularly good for faster jobs where there is no need to use screws, which in turn helps to lower the need for rebroadcasting.

Q What are the comparisons between Loctite PL Premium and other types of adhesive?

A: Loctite PL Premium is a premium-grade adhesive that is superior to PVA or white glue in many ways. Its high-performance features as an adhesive and the like wood or metal bonding possibilities make it a versatile choice for drywall and other construction work.

Q What are the issues that can happen if the wrong glue is used for drywall?

A: Using an unsuitable adhesive (like a cut-price one that shrinks or fails to cure) could lead to pops of screws being pushed to the surface and the weakening of the joints. Then, it is really important to select a heavy-duty adhesive that will not only overcome but also come up with a bond that lasts.

Q Is it ever permitted to use liquid nails on drywall?

A: Liquid Nails has a wide range of applications, and drywall is one of them. Liquid Nails will make a strong hold on the drywall and can be used for joining drywall to different types of surfaces, making it a great option for minor repairs and big installations alike.

Q Gaps during drywall installation can be filled how?

A: For filling gaps between panels, a foam adhesive or a jointer compound can be used. The above-mentioned materials will not only provide the need for a smooth surface but also overall appearance while ensuring a strong bond.

Q What are the downsides of the use of polyurethane construction adhesive in drywall?

A: Polyurethane construction adhesive is a double-edged sword as it is great for dry application but not a must-have in the indoor areas. It cured hard but inflexible while shrinking the bond area thus stronger heating and moisture issues arise, thus making it tough for various drywall applications.

Q Do they sell a glue for drywall with low VOC content?

A: Of course, there are low VOC glues told first any one LOCTITE PL or any other premium-grade adhesives among them strong-hold glues. These alternatives provide high adhesion with reduced harmful emissions, thus making them safer for interior use.

Q What are your considerations when you choose an adhesive for drywall?

A: You must take into account the curing duration, holding strength, and compatibility with the materials you are using when making the final decision about the adhesive. Using the specific type of adhesive that is meant for your application, whether it be a foam adhesive or a polyurethane construction adhesive, will give you the best results.

References

- •Loctite Products: Adhesive for Drywall – A guide on using Loctite PL 200 Projects Construction Adhesive for drywall applications.

- •Home Depot: Drywall – Construction Adhesive – A selection of construction adhesives for drywall, featuring product ratings and key details.

- •Green Building Canada: Best Construction Adhesive for Wood to Drywall – A detailed article on less toxic adhesive options for drywall applications.

- •Hot Melt: Glue Guns for Drywall & Plasterboard Assembly – A Guide to Choosing the Right Hot Melt Adhesives and Glue Guns for Drywall and Plasterboard Assembly.