Finding the right glue for PLA filament can make or break your 3D printing projects. Whether you’re repairing a print, joining complex parts, or increasing the durability of your designs, selecting an adhesive for PLA is a critical yet often overlooked step for achieving professional results. With the many varieties available, ranging from specialty adhesives to the average household glue, it would undoubtedly make your head spin trying to figure out which one works best for PLA. This booklet will discuss the considerations for selecting an adhesive, including the best options available, as well as some tips for achieving the cleanest and strongest bond. Now, let’s set the foundation for 3D printing skills with PLA adhesive!

Understanding PLA Filament

PLA (Polylactic Acid) is one of the most widely used materials in the 3D printing arena because of its ease of use, minimal warping, and environmentally friendly characteristics. Made from renewable raw materials like cornstarch or sugarcane extracts, PLA is fully biodegradable and non-toxic, making it a top choice for beginners and hobbyists.

Key PLA Characteristics:

- Optimal printing temperature: 190-220°C

- Biodegradable and non-toxic

- Made from renewable resources

- Minimal warping during printing

- Less heat-resistant than other filaments

It prints optimally at medium temperatures, typically 190-220°C. Although it does not require a heated bed, using one is beneficial for improved adhesion. This filament has another set of distinctions that make PLA less heat-resistant and brittle when compared to other filaments, which limits its use in high-stress or outdoor applications. Knowing the properties of PLA would help users maximize the applications of this material for their various 3D printing projects.

Benefits of Using PLA in 3D Printing

🌱 Environmentally Friendly

Produced from renewable sources like cornstarch or sugarcane, and can be degraded under specific conditions

🏠 User-Friendly

Prints at lower temperatures with minimal odor, suitable for home and educational settings

🎨 Excellent Detail

Allows for fine printing with smooth finishes and numerous colors and blends

🔧 Universal Compatibility

Works with almost every 3D printer, reducing access complexity for users

This set of advantages ensures that PLA remains a consistent and versatile choice for a wide range of 3D printing requirements.

Common Applications of PLA

🏭 Prototyping

Detailed mockups and product models for designers and engineers

🛍️ Consumer Goods

Phone cases, home décor items, and customized accessories

🏥 Medical Applications

Custom prosthetics and biodegradable surgical implants

🎓 Education

Learning tools for students, educators, and hobbyists

Its diversity has ensured that it remains the preferred material across sectors that need innovative yet eco-friendly solutions.

Why Choosing the Right Glue Matters

Choosing the right glue is essential for ensuring an effective and lasting bond between materials. Different adhesives are designed for specific purposes. Using the wrong glue can result in weak joints, damage to either one or both materials, or the project’s outright failure.

⚠️ Critical Considerations:

- Types of materials involved

- Surface finishes and preparation

- Intended use and stress requirements

- Environmental conditions

- Desired final appearance

It also enhances the strength, performance, and quality of the final product, making glue an indispensable part of any task.

Importance of Strong Bonds in 3D Prints

Achieving strong bonds is pivotal if durable 3D prints have to be considered. Were it not for such adhesion between layers, 3D-printed objects would exhibit structural weaknesses, thus causing flecking and failure upon application of force. In functional applications, this is particularly crucial, where strength and reliability are essential.

Conditions, including print temperature, material compatibility, and surface preparation, enable adequate adhesion between the layers. Other new methods of adhesion or print settings optimizations can be considered to enhance the strength and, consequently, the lifespan of the product.

Enhancing Project Outcomes with the Right Adhesive

The proper adhesive can make or break a process in demanding applications. The latest data suggest that knowing what your materials and environment require for the appropriate adhesive selection is crucial.

Pro Tip: Where powerful bonds and durability are required, an epoxy or polyurethane-based adhesive may be the ideal choice due to its high bonding strength and ability to withstand environmental stressors.

On the other hand, newer technologies have introduced materials with formulations that can withstand extremes in temperature, chemical attacks, or flexible surfaces. Thus, utilizing these technologies for your own application will provide you with the best solution, completed in the fastest and most reliable manner possible.

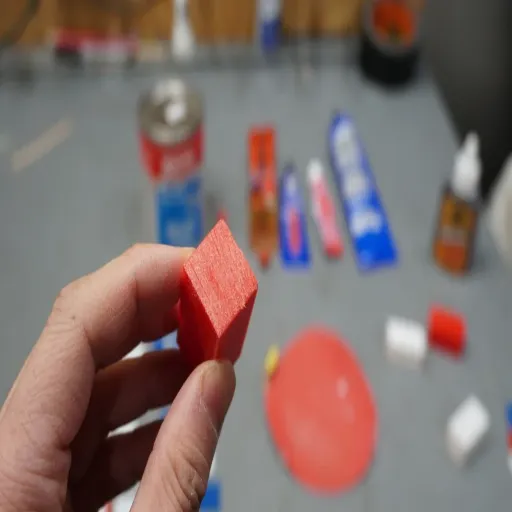

Comparison of Popular Glue Products for PLA

| Product | Type | Best For | Cure Time | Durability |

|---|---|---|---|---|

| Loctite 4062 | Cyanoacrylate | Quick assembly, small parts | Seconds | Moderate |

| Epoxy | Two-part system | Heavy-duty, gap-filling | Hours | High |

Loctite 4062

It is a cyanoacrylate adhesive, and this glue is handy for bonding PLA, as it is fast-drying and strong with a short cure time. It shall be used for gluing smaller parts and for applications where the parts need to be handled and assembled quickly.

Note: It may not offer sufficient flexibility or durability in cases where joints are subjected to considerable stress and vibration.

Epoxy

Epoxy glue is highly versatile and offers an excellent, durable bond for PLA. There may be situations where gaps need to be filled in projects, and the parts must be subjected to high stress.

Advantage: Can withstand high temperature variations and environmental conditions, making them more suited for heavy-duty applications.

Loctite 4062: Specialized Performance for Plastics

Loctite 4062 is a specialized cyanoacrylate that bonds almost anything, especially plastics that are typically very difficult to work with, such as PLA or ABS. Being rapid-curing means it forms safe, precise bonds within seconds, making it the preferred adhesion for high-speed assembly. Its low viscosity allows easy application and penetration in tight gaps, leaving a perfectly smooth finish.

✨ Enhanced Performance:

When combined with a primer such as Loctite 770, Loctite 4062 can attain better adhesion on plastic surfaces that are generally hard to bond.

It’s a quick and lasting solution that requires minimal preparation. Moreover, it’s also resistant to humidity and aggressive environmental factors, making it a premium choice for both indoor and outdoor use. Whenever it comes to a strong, efficient, and highly specialized application for plastics, Loctite 4062 can certainly qualify as the adhesive of choice.

Epoxy: Ideal for Rigid Bonds and Gap Filling

The primary benefit of epoxy glue is that it creates rigid bonds with exceptional strength while filling gaps between surfaces. Epoxy glue exhibits greater durability and chemical resistance compared to other adhesive varieties, along with a wide range of applications: these adhesives bond metals, ceramics, wood, and certain types of plastics.

🔬 How It Works:

Being a two-part system, the resin is currently one part, with the other part being the hardener. Epoxy resin adhesives formed from these associate with each other during curing to create the strongest possible bond.

Epoxies can withstand environmental changes and variations in moisture, and perform well both indoors and outdoors. Any project, construction, or repair that is considered a “hard task” cannot go wrong with this glue.

Factors to Consider When Selecting Glue for PLA

When selecting glue for PLA, consider the following factors:

🔗 Adhesion Strength

Select a glue specifically designed for plastics to achieve adequate bonding of PLA. Super glue and epoxy would be your most reliable options.

⏰ Drying Time

Choose a glue that will not dry instantly, allowing for fine adjustments to the pieces being glued.

💪 Durability

Ensure the glue withstands the use the PLA item will undergo, including stress, temperature changes, or moisture, all of which are relevant.

🎯 Ease of Application

Choose a glue that can be applied and cleaned up easily, especially for detailed or intricate parts.

🛡️ Safety

Ensure the glue is safe to use and emits minimal fumes, allowing for safe work in confined spaces.

Surface Preparation for Better Adhesion

Proper surface preparation is one of the most critical procedures for strong and reliable adhesion when working with PLA materials. The surface should be clean, smooth, and free of any dust, oils, or other contaminants before the adhesive is applied.

📋 Step-by-Step Preparation Process:

- Clean the surface: Wipe down surfaces with isopropyl alcohol to eliminate any pollutants that may weaken the bond

- Create texture: Lightly sand the PLA surface with fine-grit sandpaper to add texture for better adhesive grip

- Ensure dryness: Make sure both surfaces are dehydrated before applying the adhesive

- Remove debris: Check for any remaining dust or particles and clean if necessary

Following this procedure will significantly enhance your bonding and the overall durability of the project.

Setting Time and Environmental Factors

The setting time of an adhesive is very much dependent on the type in question. Almost all glues require a minimum curing time, which can range from several minutes to hours, depending on the manufacturer’s instructions.

🌡️ Temperature Effects

Cold temperatures may slow down the curing process, while an optimal room temperature (around 70°F) ensures proper curing.

💧 Humidity Impact

Excess moisture may prevent the glue from achieving its full strength and should be controlled during the application process.

💡 Best Practice:

Following instructions on curing is imperative, and having some control over the working environment is even better. These factors must be understood to establish a solid and enduring bond.

Troubleshooting Common Issues with PLA Glue

❌ Poor Adhesion

Cause:

Surfaces are not adequately cleaned or prepared.

Solution:

Ensure surfaces are free of dust, oil, or debris before applying the glue.

⏳ Slow Curing Time

Cause:

Low temperatures or high humidity.

Solution:

Use the glue in a room with moderate temperature (around 70°F) and low humidity, or follow recommended curing conditions.

🔧 Glue Weakens After Curing

Cause:

Excessive exposure to moisture or improper mixing of glue components.

Solution:

Ensure an optimal environment during curing and follow the mixing instructions exactly.

📏 Uneven Application

Cause:

Using too much or too little glue on the surface.

Solution:

Apply an even, thin layer of glue across the surface for a better bond.

Weak Bonds: Causes and Solutions

When the bonds appear weak with PLA glue, several factors may be considered. Common causes include surface preparation issues, insufficient curing time, or incorrect gluing for the specific application. According to recent search data, users often neglect to have a clean surface that is entirely free of dust, grease, or any other residues before applying glue.

⚠️ Common Mistake:

Getting caught up in the fun of hurrying the curing process is the fact that PLA glue usually demands set time frames to build strength optimally.

To mitigate such scenarios, it is advisable to emphasize surface preparation, strict adherence to the curing period, and, ultimately, selecting glue tailored to the project’s specific goals. Considering the above points would undoubtedly aid in decreasing instances of weak bonds and would tend to offer good adhesion.

Glue Not Setting: Factors to Consider

When glue does not set, several factors should be considered:

🔍 Checklist for Non-Setting Glue:

- Verify temperature and humidity are within stated ranges

- Check the expiration date – expired products lose effectiveness

- Ensure surfaces are clean, dry, and well-prepared

- Confirm the glue is appropriate for the material or application

- Review mixing ratios for two-part adhesives

Reference Sources

Here are five professional and authoritative reference sources to check the underlying of your article on “glue for PLA filament.” All are attached to academic and research-type sites:

Emerald Insight

This article describes PLA filament and adhesion promoters, including glue-stick, in the technology of 3D printing.

SpringerLink

An overview of fused filament fabrication technology and the advancement in PLA-biocomposites

The paper discusses the use of PLA filament and technological advances in 3D printing.

ScienceDirect

This study examines PLA-based composites for 3D printing, with a focus on their adhesion properties.

MDPI (Multidisciplinary Digital Publishing Institute)

Extrusion-based 3D printing applications of PLA composites: a review

This review paper explores the practical applications of PLA composites in 3D printing and examines their adhesive properties.

SpringerLink

This systematic review goes through adhesives and their role in 3D printing techniques.

Frequently Asked Questions (FAQs)

❓ What is the best glue for PLA filament?

The best glue for PLA filament often depends on the specific application. Standard options include cyanoacrylate (CA) glue, also known as superglue, and specialized plastic adhesives, such as Weld-On 16. These adhesives create strong bonds that can withstand mechanical stress, making them ideal for gluing PLA parts together.

🦍 Can I use Gorilla Glue on PLA?

While Gorilla Glue can be used on PLA, it is generally not the best choice. Gorilla Glue expands as it cures, which can lead to unwanted mess and loss of detail in your prints. For more precise applications, CA glue or a gel adhesive is recommended for better control and a stronger bond.

🔗 How do I glue PLA parts together?

To glue PLA parts together, first, clean the surfaces to ensure a strong bond. Apply your chosen adhesive, such as superglue or CA glue, and hold the parts together for a few seconds. For added strength, a sprinkling of baking soda can be used on the glue to create an instant bonding accelerator. Allow the glue to cure for at least 24 hours for optimal results.

🧪 Is there a combination of adhesives that works best for PLA?

A combination of CA glue and baking soda can be an effective method for gluing PLA. The baking soda acts as an accelerator, creating a stronger bond in seconds. This method is beneficial for filling seams or rough edges in your prints, resulting in a smooth finish.

⚖️ What is the difference between CA glue and model cement for PLA?

CA glue is a fast-drying adhesive that creates a strong bond quickly, whereas model cement is specifically designed for plastic models and typically requires a longer drying time. Model cement works by melting the plastic slightly to create a welded bond, making it suitable for specific applications. Still, CA glue is generally faster and easier to use for PLA.

💨 Can I use spray adhesive on PLA?

Yes, spray adhesive can be used on PLA, especially for large surface areas. However, it is essential to ensure that the spray adhesive is compatible with plastics. Look for an acrylic-based spray that provides a strong bond without damaging your print.

💪 How can I strengthen the bond between my PLA and the surrounding material?

To improve the strength of your PLA bond, consider using an accelerator with your adhesive, such as a CA glue activator. Additionally, using rough-grit sandpaper to texture the surfaces before applying glue can help create a better mechanical lock between the materials.

🏪 Where can I find the best glue for PLA at a hardware store?

Many hardware stores carry a variety of adhesives suitable for PLA, including CA glue and specialized plastic adhesives. Look for products labeled as ideal for plastics or specifically for 3D printing applications to ensure you are getting the best glue for PLA filament.

🎯 What should I consider when choosing glue for PLA 3D prints?

When choosing glue for PLA 3D prints, consider factors such as drying time, bond strength, and whether the adhesive is suitable for the specific application. Additionally, consider the environmental conditions your print will face, as some glues may not withstand moisture or extreme temperatures well.