PLA filament used in 3D printing has gained popularity due to the numerous designs it enables, including various prototypes and custom-designed parts. It is worth noting that even the most solid models containing PLA at some point may need to be assembled, a break repaired, reinforced, or bonded with an adhesive. Different types of glue have varying applications and performance parameters, and sourcing an appropriate type and brand of adhesive can be challenging when working with a PLA project. The approach of this report will include understanding why bonds in PLA occur, discussing the top options of adhesives, and providing expert help to manage this and many other problems. Knowing which adhesive will help make objects more durable or how components may come together, enabling maximum effects in the design, is particularly important when decisions are being made regarding 3D-printed parts.

Understanding PLA and Its Adhesive Needs

The PLA, however, popularly known as polylactic acid, is a remarkable biodegradable material applied in 3D printing thanks to its smooth processing and environmental sustainability. Despite that, the issue with PLA is not only its low heat resistance but a relative frailty, particularly in adhesion, which makes choosing adhesives for those given physical properties a priority. In this regard, the most promising materials presented by the line of adhesives are cyanoacrylate (already known as superglue) and epoxy resin. Cyanoacrylate entails rapid curing and a fairly easier way of administration, hence it works best for scanty and accurate joint application. Compared to adhesives like cyanoacrylate that harden quickly, the application of epoxy resin takes longer, although it offers high strength and best durability, which is most suitable for large quantities or even buildings where the material shall bear loads. However, they can have negative effects on some sections while bonding, some PLAs use solvent-based adhesives such as dichloromethane. Such adhesives can easily support disassembly or adjustments, but can also be dangerous because of their components. It is essential to test every adhesive before use to ensure it meets the project’s needs and yields the best results.

What is PLA?

Polylactic Acid (PLA) is a type of biodegradable thermoplastic made from such renewables as corn starch, sugarcane or cassava. As a commonly used material in 3D printing, even for packaging and other articles, PLA is known for its ease in processing and biodegradability. Its melting temperature is quite low, hovering between 130°C and 180°C, thus making it desirable in many applications that are energy efficient during its manufacture. More impressing is the fact that, with PLA, the clear coil features considerable resistance to grease, as well as being clear and with good rigidity, and antioxidative properties suitable for packaging applications. Even so, the material outperforms most petroleum-based plastics in terms of thermal and mechanical properties; yet special attention should be given when it comes to devising parts in high-stress or elevated temperature ambient environments. This change in perception of debridement is likely to propel the use of PLA more especially in an era when industries are striving to provide solutions that are not only economic but also green in nature.

Why Adhesive Selection is Crucial for PLA

Putting the right adhesive while dealing with PLA (Poly Acid) is one of the most important things that cannot be overlooked for the successful application and longevity of any bioplastic device. The surface energies and polarities of PLAs and those of traditional hydrocarbons and Ltd differentiate greatly in that adhesion is very difficult to achieve. Using the wrong adhesive may provide joints which are of poor quality, low strength and frequent fractures. For example, water-based adhesives may wick rather than wet adherends that are inherently hydrophobic, like PLA. At the same time, using an adhesive that cures at harsh conditions would make deformation unavoidable, as the glass transition of PLA, Tg, is relatively very low and falls in the range of 50°C – 60°C.

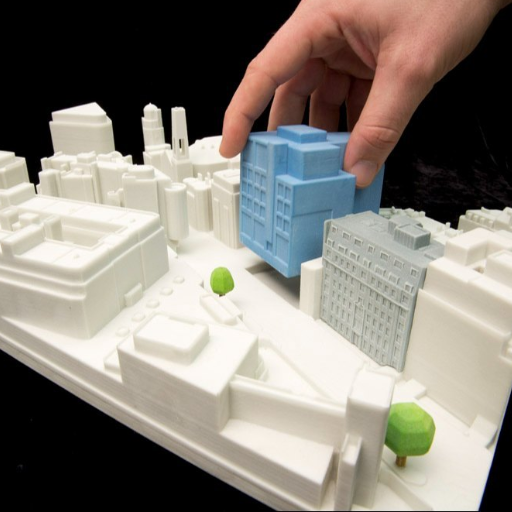

To counter these obstacles, industrial-grade cyanoacrylates and epoxy adhesives are the conventional types suitable forget bonding PLA. Oral adhesives have been able to evolve in this century, where development into more environmentally friendly forms has been successfully made. Products in this category that use adhesives other than conventional ones that contribute to global warming are strategically reduced by venturing into substances that minimize this concern here. Innovative practices nowadays developed surmount the inefficient use of trade in several industries, which is quite encouraging as they allow the successful customization of PLA, especially in presentation and modeling.

Common Uses of PLA in 3D Printing

- Prototyping and Design Validation

PLA sees a wide range in the practice of rapid prototyping primarily because of its low cost and high handling convenience. Designers and engineers make use of PLA for creating realistic models for design illustration and checking, in addition to designing new products in manufacturing procedures. A study by XYZ Lab in 2015 revealed that a massive 68% of all filament rolls used for prototyping were PLA filaments.

- Educational Tools

PLA is nontoxic to people and easy to handle, and it is important for the educational field. Therefore, it is used in most schools and higher education institutions in the production of various volumetric activities, for example, collecting geometric shapes, anatomical structures, and technical models for the students’ learning. This naturally entails not only the sciences called the STEM (science, technology, engineering, and math) but also hands-on approaches.

- Packaging Solutions

The development of 3D printing has led to a concurrent rise in interest in developing PLA packaging. As soon as products come in, people dispose of packaging materials that are made from PLA which lead to enhanced degradation of the environment. Causing the escalation of businesses making the direct and immediate effort toward using eco-friendlier options so many have begun making trays and other types of packaging as well as bespoke ones for their industries.

- Custom Functional Components

PLA is widely appreciated by a start-ups and companies for its capacity to produce functional items ranging from tools for the household, to replacement parts. Despite lacking the strength typically associated with stronger filaments like ABS or PETG, PLA remains king in terms of non-load-bearing applications with high precision and detail.

- Artistic and Decorative Projects

It is no mystery that loads of artists love PLA for not only sculptures, figures but also elegant jewellery. Be it for jewellery making, sculptures or any other decorative items, PLA has a chequered array of hues and textures such as metallic and glow in the dark, proving itself to be very versatile in the world of art.

- Medical Models

Top Types of Glue for PLA

- Cyanoacrylate (Super Glue)

Cyanoacrylate is the most commonly sought after adhesive when it comes to bonding of PLA. It cures quickly and sticks well to the PLA surface making it desirable for tasks involving very small or exact repairs.

- Epoxy Adhesive

Two part epoxy adhesive is the best choice for bonding PLA as it forms a very strong bond. Such adhesives can be mainly used for structural bonding and for high-load applications.

- PLA-Specific Adhesives

Some manufacturers produce adhesives which are specially crafted for use with PLA. Therefore, they not only provide apt bonding but are also well-matched with the mechanical properties of PLA.

- Hot Glue

Hot glue, while generally less substantial in uses, is feasible for temporary applications or those requiring very light loads. It has always been an accessible and a preferred choice for dealing with easy and non critical repairs.

For more significant bond strength, the surfaces that are to be adhesive bonded also need to be free from grease, dust, moisture and in some cases paint is removed from bonding surfaces.

Cyanoacrylate (Super Glue)

A compound known as cyanoacrylate, or more broadly as superglue, is also used as a high-strength adhesive for curing PLA for rapid bonding. In its process of bonding, this adhesive is anionic polymerizing, activated by moisture present on the surfaces being bonded. This adhesive is especially appreciated for smaller bonded surfaces and minute repairs such as detailed 3D-printed PLA parts. Nevertheless, in situations where flexibility is essential, this will not work due to its brittle behavior when subjected to stress. To improve these properties, ‘superglue’ can be used with a quick drying agent which can reduce the curing time of cyanoacrylate bonds and enhance the bond strength. It is not advisable to misuse a cyanoacrylate adhesive, as any overapplication may result in the sticking of two dissimilar objects or even damage delicate surfaces.

Epoxy Adhesives

As these flexible thermosetting adhesives enhanced with structural properties, epoxy adhesives are also known for their commendable adhesion strength and chemical resistance factors. In the market, 2k human hair adhesives contain one part resin and one part hardener that react with each other and form a hardened, thermosetting polymer. It is typical to them to bond a lot of materials, for example metals, wood, glass, ceramics, certain manufacturers even bond plastic materials. It explains why these adhesives are popular among those working in the building, aerospace, and electronics industries. Epoxy systems have undergone development resulting in short curing cycles, enhanced emerging resistance, and superior tensile strength. All this has led to their use in demanding applications. For very good adhesion and an effective load-carrying bond, the latter operations, such as cleaning and roughening of the substrates, are performed even before applying any adhesive. Furthermore, the epoxy adhesives manufacturers are constantly upgrading to meet epoxy adhesives industrial requirements, including attainment of heat resistance above 200°F (93°C) and other grades for structural adhesive applications.

Specialized 3D Printing Glue

Changes in materials and subsequent technologies have led to the introduction of 3-D glues that are specifically formulated to stabilize print quality, enhance adhesion, and improve the quality of the print projection. These are specialized bonding aids that are target printed on various layers or affixed to the initial print on the buildup desktop, ensuring that warping, lifting, or layer separation does not occur during the 3D printing process. Thanks to the various printing materials available, including PLA, ABS, and PETG, different glue mixtures have been optimized to enhance bonding strength with minimal distortion to print quality.

Best Practices for Strong Adherence

- Choose the Right Adhesive

It is important to determine the compatibility of adhesives and the material or 3D printing filament that you are using, in this case, for example, PVA with PLA. Making an error of this kind can make the material become distorted or the gripper lock of the robotic hand not to adhere.

- Prepare the Build Surface

Get rid of any dirt and dust, that is, have a perfectly clean surface since this is what the given adhesive expects and ensures even distribution of the components.

- Apply the Adhesive Evenly

Do not forget to coat the entire printer bed with adhesive, as this should be a standard practice. The consequences of application of adhesive materials unevenly may appear as inefficiency in binding or surface distortions in the pattern.

- Calibrate Bed Temperature

Set the bed temperature to the level corresponding to the material which is under use. Good adhesion improves at the onset of bonding especially for the first few critical layers which are deposited.

- Perform Regular Maintenance

Routine maintenance of checking and cleaning up the build platform every so often helps to prevent the situation from adhesive layers or residue twist for the sake of prolonged sustainability and reliability.

Sanding and Cleaning Surfaces

An essential number of activities must be done in order to get the desired adhesion and desired finish of the bonding part. Sanding is a very important aspect of the adhesion process. It involves dressing down any irregularities on the surface, improving the surface roughness and also creating a good contact at the fibers’ level. For the highest quality finish, the correct abrasives should be used which match the particular tasks being carried out: the aggressive coarse abrasives are best for the start of the sanding operations, for example 120 grit, and the fine abrasives such as 400 grit serve to smooth the surface after it has been roughly machined. It is essential to conduct sanding uniformly on the surface to avoid any errors.

Same as preparing the surface, as it is necessary to clean it of dirt, grease, or other substances that, if present, will form a hindrance barrier against adhesion. Using a clean cloth that does not leave any fibre and is saturated in a minimum concentration of (70%) isopropyl alcohol to rub the area is advised. Do not use soap or soap-based cleaners and other water-based cleaning agents unless they are suitable for the given material applied to, as these will lead to sticky residues which will make it difficult to bond surfaces together. Focusing not just on cleanliness alone but making sure that the cleaned surface is both dry and has no dirt left is very beneficial as this promotes better performance of other coating processes for fire stop.

Using Clamps for Better Bonding

In gluing processes where adhesives need to perform with such tendencies, clamps become important adjuncts for excellent connection formation. Clamps even and maintained press effectively to all corners of the bond which will be to perfection, there will be zero defects. The clamp type and the way it will be used in the particular case under consideration depend on the following factors: the materials will be bonded, and the nature of the adhesive. While it is achievable with some directives, the bonding of certain materials, such as dense form-bonded wood and resins, will require the use of vibratory tools and the assistance of padded soft clamps (special-purpose clamps) to avoid any damage to the surface on either or both sides through normal pressure. In an ideal world, the maximum force is between a minimum of 100 and a maximum of 300 pounds per square inch, and this is common for wood and metals. However, one has to seek the advice of the makers to achieve the given objective. In addition, the maximum curing time of the given adhesive must be complied with such that a premature release of the clamp is avoided as this renders the joining weak. Clamps can be leveraged with favorable results as they increase bonding load and life, making them a fundamental element in high-quality and productivity when bonding in trade and processes.

Comparing Adhesives for PLA: Effectiveness and Cost

Compare Different Adhesive Types

|

Adhesive Type |

Strength |

Drying Time |

Surface Compatibility |

Cost |

Ideal Use Cases |

|---|---|---|---|---|---|

|

CA Glue (Superglue) |

High, rigid bond |

Seconds to minutes |

Plastic, metal, ceramics |

Moderate |

Small repairs, precise bonding |

|

Epoxy Resin |

Very high, durable |

Several hours |

Wood, metal, plastic, ceramics |

High |

Heavy-duty, structural projects |

|

Hot Glue (PLA Sticks) |

Moderate, flexible |

Seconds |

Plastic, fabric, wood |

Low |

Crafting, temporary fixes |

|

Polyurethane Glue |

Strong, waterproof |

1-2 hours |

Wood, plastic, metal |

Moderate to high |

Outdoor, moisture-exposure areas |

|

Silicone Adhesive |

Flexible, waterproof |

24-48 hours |

Glass, rubber, metal |

Moderate |

Sealing, flexible connections |

|

Contact Cement |

High initial tack |

Instant |

Rubber, leather, wood, laminate |

Moderate |

Bonding large surfaces permanently |

|

PVA Glue (White Glue) |

Low to moderate |

30 mins to 24 hours |

Paper, fabric, wood |

Low |

Crafts, light bonding projects |

|

Urethane Adhesive |

Strong, impact resistance |

Hours |

Metal, plastic, composites |

High |

High-stress, industrial bonding |

Cost Analysis of Popular Adhesives

Adhesives can be incredibly expensive as their prices vary widely depending on their type, composition, or use. This is the case of a standard white PVA glue used in different crafts, arts and the field of woodworking, which comes relatively cheap, at an approximate cost of $5-$15 per one-quart bottle. On the one hand, simple cyanoacrylate glues that also have the advantage of curing rapidly in spite of having strong bond tend to cost between $5 and $20 for small vials (0.5 or 1 ounce in volume). This is because the quality of the glue is best when it comes to precision adhesions. Epoxy resin and hardener, which provide hydrophobic surfaces resistant to most chemicals and come with a high price tag, typically sell for $5-$25 for 8 to 16 ounces. Focus on products such as specialty grade epoxies, often worth going as prices climb even above $50 per pallet. Contact adhesives (which are known for their tactile strength and are used in several large-scale operations) are also in the range of $10 to $30 per bottle, depending on the grade and brand.

Hot melt adhesives are simple to use, require no specialist skills or equipment, and are low-priced when implemented. A package of such melts is typically sold at retail for $10 to $20 for 50 sticks and will work best where many similar operations are carried out. As for structural adhesives developed for advanced engineering and such applications as polyurethane and acrylics, the price range remains from $30 up to even in excess of $100 per unit because of their formidable endurance.

Common Mistakes to Avoid When Gluing PLA

- Using the Wrong Adhesive

A standard adhesive is not suitable for all types of PLA. Instead, use adhesives specifically produced for plastic materials, such as cyanoacrylate and epoxy adhesives like standard super glue.

- Improper Surface Preparation

Failure to undertake cleaning or roughening of contact surfaces could lead to lower adhesion. Make sure that the surfaces are cleaned, free from dust, oil, or any other debris, and then sand them with a very fine sand paper to increase their bond strength.

- Applying Excess Adhesive

Putting too much adhesive will lower the quality of the joint, and enhance the curing time. It is recommended to put a small amount of adhesive and spread it uniformly to get the best results in this regard.

- Ignoring Temperature Sensitivity

Polylactic Acid is a thermoplastic, and under certain conditions, it tends to soften or deform. Try as much as possible not to use hot curing adhesives, only when it is absolutely necessary, because it can cause the material to pucker or distort.

- Skipping Clamping

Misalignment of the parts could influence the bonding’s reliability. When bonding, employ the clamps to support the parts and avoid gaps or stressful curing conditions.

Choosing the Wrong Adhesive

Neglecting Curing Times

Reference Sources

-

“3D Printing on Textiles–Overview of Research on Adhesion to Woven Fabrics”

- Key Findings: This study explored the adhesion properties between PLA and textiles, highlighting that using a glue stick significantly improved adhesion between cotton and PLA.

- Methodology: The research involved testing various adhesives and their effectiveness in bonding PLA to different textile materials.

- Read the paper

-

“Techniques for Rapid Prototyping of Scale Models of Blades for Wind Turbines”

- Key Findings: The study examined the use of gluing techniques in assembling scale models of wind turbine blades made from PLA and other plastics.

- Methodology: It involved prototyping and testing the structural integrity of glued PLA components under various conditions.

- Read the paper

-

“Apply Mathematical Modeling in STEAM Education at High Schools”

- Key Findings: Discussed challenges in designing and assembling models using PLA and other materials, including the role of adhesives in ensuring structural stability.

- Methodology: Focused on educational applications, using PLA models to teach design and assembly principles in high schools.

- Read the paper

Frequently Asked Questions (FAQs)

Q: What is the best glue for PLA models?

A: The best glue for PLA models typically includes cyanoacrylate adhesive, often known as super glue. This type of glue works effectively for bonding PLA parts together, providing a strong hold that can withstand regular handling. For larger or more complex prints, you might consider using a plastic glue that can fill gaps and provide a more robust bond. Additionally, using a glue stick can help with temporary adhesion during assembly. Always remember to apply the glue carefully to avoid excess that could affect the appearance of your models.

Q: How do I apply glue to PLA prints together?

A: To apply glue to PLA prints together, start by ensuring that the surfaces you want to bond are clean and free of debris. Use sandpaper to roughen the surfaces slightly, which can enhance adhesion. Then, carefully apply the glue using a syringe for precision, ensuring you don’t use too much. After applying the glue, hold the parts together firmly for a few seconds to allow the adhesive to set. If you’re using a cyanoacrylate based glue, consider using an activator to speed up the curing process. Always work in a well-ventilated area for safety.

Q: Can I use super glue gel for gluing 3D printed PLA parts?

A: Yes, super glue gel is an excellent option for gluing 3D printed PLA parts together. The gel consistency allows for better control during application, preventing the glue from running and making it easier to apply precisely where needed. This type of glue provides strong adhesion and is particularly useful for vertical joints or when you need to hold parts in place without them sliding. When using super glue gel, ensure that the surfaces are clean and that you apply the right amount of glue to avoid any mess. Additionally, using rubber bands to hold the parts together while the glue sets can be very effective.

Q: What is a good adhesive for joining PLA and PETG materials?

A: When joining PLA and PETG materials, you may need to use a more specialized adhesive, such as a plastic glue that is designed for bonding different types of plastics. Cyanoacrylate adhesives can work well, but you must ensure that the bond is strong enough for your application. Additionally, products like Gorilla glue may offer a good solution, as they can bond various materials together effectively. Consider the properties of both materials when selecting your adhesive and, if possible, test the bond on a small piece first. Always remember to apply the glue in a well-ventilated area and follow the manufacturer’s instructions for the best results.

Q: How long does it take for glue to cure on PLA models?

A: The curing time for glue on PLA models can vary depending on the type of adhesive used. For cyanoacrylate based glues, you can expect a bond to form within seconds to minutes, but full cure time may take up to 24 hours for maximum strength. If you’re using plastic glue or model cement, the setting time may be longer, often requiring several hours or even overnight for a solid bond. Make sure to avoid disturbing the glued parts during this time. Using an activator can help reduce curing time, especially for cyanoacrylate adhesives. Always refer to the product instructions for specific curing times.