When working with Styrofoam, finding the right adhesive can make all the difference in achieving a seamless and durable finish. Whether you’re crafting intricate designs, securing insulation panels, or bonding polystyrene foam for larger projects, using an appropriate glue ensures precision and strength without damaging the material. This guide dives into the top adhesives suited for Styrofoam, highlighting their unique properties, applications, and benefits. From versatile craft glues to heavy-duty industrial adhesives, we’ll break down the best options for various projects and provide tips for achieving optimal results. By the end of this post, you’ll have the knowledge you need to make informed decisions and tackle your Styrofoam-related tasks with confidence.

What is the best glue for styrofoam projects?

The best glue for Styrofoam projects depends on the type of project and its specific requirements. For general crafting, white craft glue (PVA) is an excellent, non-toxic option that dries clear and offers a strong bond. For quicker drying times and stronger adhesion, hot glue works well, but it must be applied carefully with low-temperature glue guns to avoid melting the Styrofoam. If you’re working on large surfaces or intricate designs, spray adhesives provide even coverage, while specialized foam glues, like urethane-based adhesives, ensure maximum durability.

Top adhesives for polystyrene foam crafts

When crafting with polystyrene foam, choosing the right adhesive can make all the difference. Here are the top recommended adhesives for various Styrofoam applications:

Low-Temperature Hot Glue

Ideal for quick bonds, low-temperature hot glue is a convenient option. It works well for both small and medium projects but must be used cautiously to prevent melting the foam. Opt for a glue gun explicitly designed for low-heat use.

Spray Adhesives

Perfect for large surfaces and even coverage, spray adhesives ensure smooth application without clumps or uneven spots. Look for a product labeled safe for Styrofoam to avoid corrosion or surface damage.

Urethane-Based Foam Glue

Urethane adhesives provide a strong, durable bond, especially for intricate designs or structural projects. They are long-lasting and offer excellent compatibility with polystyrene foam, making them a go-to choice for professional or heavy-duty applications.

By selecting the adhesive suited to your specific needs, you can ensure your Styrofoam crafts are both durable and visually appealing. Always follow the manufacturer’s instructions to maximize performance and project success.

Comparing different types of glue for styrofoam

When working with Styrofoam, choosing the right glue is essential for a successful project. Here’s a concise comparison of the most commonly used adhesives for Styrofoam:

Hot Glue

While hot glue can be convenient, it requires caution as excessive heat may melt Styrofoam. Look for low-temperature glue guns designed for safe application on foam materials. Hot glue provides a strong hold but may not be ideal for precise or delicate projects.

Foam-Safe Spray Adhesives

Spray adhesives specifically labeled as “foam-safe” are excellent for evenly covering large surfaces. These adhesives dry quickly, offer a smooth finish, and are less likely to damage the Styrofoam. However, their strength may be less robust for heavier objects.

White Glue

PVA glue is a versatile and affordable option that works well for lightweight foam bonding. It is non-toxic, dries clear, and is suitable for arts and crafts projects. However, it requires longer drying times and may not bond as strongly as other adhesives for heavier applications.

Specialized Foam Glues

Adhesives formulated explicitly for Styrofoam, such as urethane or epoxy-based glues, offer a durable and long-lasting bond. These are well-suited for intricate or structural projects, providing superior strength and resistance to wear.

Each glue type has its strengths and weaknesses, and the best choice depends on your project’s specific requirements. For larger or structural applications, opt for specialized foam glues. For lightweight crafts or general use, PVA or foam-safe sprays will meet your needs effectively.

How to choose the right glue for your styrofoam project

Selecting the right glue for your styrofoam project involves considering factors like the material being bonded, the type of styrofoam, and the intended use.

Type of Glue: For basic arts and crafts, PVA glue is a reliable choice as it’s easy to use and dries clear. However, it may not be suitable for heavy-duty bonds. For stronger applications, urethane-based glues or construction adhesives labeled foam-safe are ideal since they provide robust bonds without dissolving the material.

Spray Adhesives: When you need fast and seamless application, foam-safe spray adhesives work well, especially for attaching thin styrofoam layers or lightweight materials like paper and fabric. These sprays create an even coat, avoiding uneven adhesion.

Epoxy for Strength: If you need a long-lasting and durable bond, two-part epoxy adhesives can bond styrofoam to non-porous surfaces like metal or plastic. Be cautious not to use adhesives containing solvents like acetone, which can dissolve styrofoam.

Specialty Glues: Use hot glue guns with low-temperature settings for rapid assembly of styrofoam to other surfaces. Always ensure the glue is foam-compatible to prevent damage.

Ultimately, the best glue depends on your project’s scale, materials, and demands. Combine practicality with the specific requirements of your styrofoam project for the best results.

How to glue styrofoam together effectively?

To effectively bind Styrofoam pieces, consider taking the following steps:

Selecting the Correct Glue: Use an adhesive that is safe for foam materials, such as white glue, spray adhesives for foam, or hot glue guns set to low heat.

Surface Preparation: Clean the surfaces of the Styrofoam to remove any dust or residues to increase adhesion.

Evenly Apply Glue: Place an even coating of glue on one or both surfaces; this reduces the likelihood of making a mess and maximizes even bonding.

Press Together and Maintain Position: Integrate the components precisely slide them together and maintain a position for the indicated curing time.

Once the glue is applied, adhere to the recommended curing guidelines stated within the product’s instructions, to allow the glue to set without interference.

By observing these procedures, the styrofoam pieces will successfully adhere together securely and permanently.

Step-by-step guide to applying glue on styrofoam

Select the Right Kind of Adhesive: Styrofoam does not suit all types of adhesives, so select specialty products designed for foam such as foam safe glue, craft glue, or low temperature hot glue.

Preparing a Surface: Styrofoam surfaces should be cleaned of any dust or dirt that prevents effective bonding as a preliminary step. If required, light sanding can be performed to make adhesion more effective.

Use a Small Amount of Glue: Apply a thin layer of glue so there is an even distribution of the adhesive. For liquid glues, do small amounts of work to avoid filling up spaces too much, which might be detrimental to foam.

Foam Pieces Require Gentle Handling: Ensure pieces are correctly lined up prior to the final press since adjustments will be nearly impossible after you adhere the foam.

Add Light Pressures: Still maintain the same pieces in a position where they are gently held in place without applying too much pressure. Soft foam can easily be squished and damaged.

Hold Until Set: Addition of light tape or clamps on parts before the glue hardens increases the bond strength.

Tips for creating a strong bond between styrofoam pieces

Use the Correct Styrofoam Glue: Be certain to select glue designed for styrofoam, including: foam safe adhesives, polyurethane glue, or a low-temperature hot glue. Do not use solvent-based adhesives as they will eat away at the foam.

Pre-Bond Surface Treatment: Wash the styrofoam surfaces in order to get rid of dust or particles which create a clean area for bond. For enhanced adhesion, also the surface with fine-grade sand paper.

Balance glue application: Apply adhesive in a thin film to both surfaces to be bonded as this ensures contact will happen. Too much glue will result in poor bonding as this causes irregular adhesive coverage.

Exert Appropriate Pressure: Put the pieces together after applying glue and press down firmly. If needed, clamp or tape them so they do not come apart during the adhesive drying period.

Do not Dry Less Than the Time Recommended: Do not rush to reduce the time taken for curing, adhere to the glue manufacturer’s recommendations for time limits, because removing this aid reduces bond strength.

Keep the Workplace Air Fresh: Improve the air quality in the area or room before using glues so that glue smells can be avoided.

Common mistakes to avoid when gluing styrofoam

Using the Wrong Adhesive: Not all adhesives are suitable for styrofoam. Some glues, such as those containing solvents, can dissolve or damage the material. Always opt for styrofoam-specific or solvent-free adhesives for the best results.

Skipping Surface Preparation: Applying adhesive directly to dirty or uneven surfaces can weaken the bond. Ensure all surfaces are clean, dry, and smooth before starting.

Applying Excessive Adhesive: Using too much adhesive can lead to uneven bonding, mess, or extended drying times. Apply an even, thin layer for optimal adherence.

Ignoring Drying and Curing Times: Rushing the process by not allowing sufficient drying or curing time can result in weak bonds. Follow the manufacturer’s instructions precisely.

Failing to Secure Pieces During Drying: Not securing styrofoam pieces together as the adhesive dries can cause misalignment or an ineffective bond. Use clamps or weights as needed to hold the pieces firmly in place.

By avoiding these common mistakes, you can ensure strong, lasting bonds in your styrofoam projects.

Can you use hot glue on styrofoam?

Yes, you can use hot glue on styrofoam, but caution is required. Standard hot glue guns can produce high temperatures that may melt or damage the styrofoam. To avoid this, use a low-temperature glue gun specifically designed for delicate materials. Additionally, test the glue on a small, inconspicuous area beforehand to ensure it bonds well without causing harm.

Pros and cons of using hot glue guns with styrofoam

Pros:

Strong Adhesion: Hot glue can create a secure bond between styrofoam and other materials such as cardboard, paper, or wood.

Quick Drying Time: Hot glue sets rapidly, making it efficient for projects that require immediate handling.

Versatile Application: With proper use of a low-temperature glue gun, hot glue can be applied to delicate or irregular surfaces without significant difficulty.

Cons:

Risk of Melting: High-temperature glue guns may cause the styrofoam to melt, deform, or release harmful fumes.

Limited Flexibility: Once dried, hot glue becomes rigid, which might not be suitable for projects requiring flexibility.

Surface Damage: Attempting to remove dried hot glue can damage the styrofoam’s surface, leaving dents or tears.

Choosing the right type of glue gun and applying it carefully can help mitigate the risks while taking full advantage of its benefits.

Alternatives to hot glue for styrofoam crafts

When working with styrofoam, selecting the right adhesive is crucial to ensure both durability and safety while avoiding damage to the material. Here are some top alternatives to hot glue:

White Craft Glue: An affordable and widely available adhesive, white craft glue is ideal for lightweight styrofoam projects. It dries clear and is easy to use, although it may require longer drying times compared to other options.

Spray Adhesive: Designed for even application, spray adhesives bond styrofoam effectively without melting or causing surface damage. They work well for covering large areas and are perfect for mounting or attaching sheets of styrofoam.

Foam-Safe Glue: Specifically formulated for foam materials, these adhesives provide a strong bond without triggering any melting or deformation. They are available in both liquid and gel forms, offering versatility for different project requirements.

Silicone Adhesive: Known for its flexibility, silicone adhesive works well for styrofoam crafts that might experience movement or slight strain. It waterproofs and adheres strongly, making it suitable for outdoor projects.

Double-Sided Tape: For simple and temporary applications, double-sided tape can quickly attach styrofoam pieces without requiring drying time. It’s a mess-free option for lightweight assemblies.

Each adhesive has unique strengths and is suited for specific types of styrofoam crafts. Proper surface preparation and testing adhesives on a small area prior to full application can help ensure optimal results.

What are the best waterproof adhesives for styrofoam?

As far as Styrofoam Projects are concerned, styrofoam when used in damp conditions requires special waterproof adhesives for projects that will last for a long time. The main types of waterproof adhesives relevant to Styrofoam are:

Epoxy Resin: Water-resistant epoxy bonds are effective with epoxy reinforced styrofoam projects, both indoors and outdoors.

Silicone Sealant: Stays waterproof and pliable under varying humidity and temperature ranges.

Polyurethane Adhesive: Dry polyurethane suits best where high strength bonds to styrofoam is required due to its waterproofing strength.

Marine Adhesives: Specific to water exposure from extreme exposed conditions, marine adhesives offer a violent waterproof seal.

Marine conditions, required bond strength, and exposure particulars are major factors to carefully consider before choosing adhesives for Styrofoam. However, be certain to always check for compatibility and read the instruction labels carefully if they were provided for testing on non-visible areas.

Top waterproof glues for outdoor styrofoam projects

For outdoor styrofoam projects, choosing a suitable waterproof glue is critical for the project’s longevity and performance.Here are the best options:

Gorilla Original Waterproof Polyurethane Glue: This glue is versatile as well as the known best waterproof polyurethane glue. Its bond strength is unmatched as it withstands water and harsh weather. styrofoam, this glue is versatile. Also, during curing, this glue expands slightly providing a secure seal.

3M Super 77 Spray Adhesive: This spray glue works best for lightweight styrofoam applications as it dries quickly. It provides exceptional moisture resistance as well. Its spray application ensures precise coverage and makes this glue ideal for intricate or large-scale projects.

Loctite PL 300 Foamboard Adhesive: An excellent choice for beginners and professionals, this glue is crafted specifically for foamboard and styrofoam, yielding waterproof adhesive results for outdoor use. This adhesive is water-resistant and easy to apply, making it an excellent choice for both DIY and professional use.

It is crucial for each of these projects to have a balance between strength, water resistance, and ease of use. Remember to consider your project’s requirements before making your final selection.

How to seal and protect glued styrofoam from moisture

To effectively seal and protect glued styrofoam from moisture, start by applying a waterproof sealant such as epoxy resin. This provides a durable, moisture-resistant coating that adheres well to styrofoam. For additional reinforcement, consider using a combination of a protective primer and a polyurethane or acrylic-based clear coat. These layers add extra protection against humidity and water exposure.

Before sealing, ensure the surface is clean, dry, and free of dust for optimal adhesion. Apply the sealant evenly across all surfaces, including edges and seams, with a brush or spray, depending on the product. Allow sufficient drying time as recommended by the manufacturer. For outdoor applications, using a UV-resistant sealant is recommended to prevent degradation under sunlight. These steps will not only protect your glued styrofoam from moisture but also extend its lifespan.

Is spray adhesive suitable for styrofoam insulation?

Yes, spray adhesive is suitable for styrofoam insulation, provided you choose a product specifically designed for use with styrofoam. Regular spray adhesives may contain solvents that can dissolve or damage the material. Look for solvent-free or foam-safe adhesives, as these will bond effectively without compromising the integrity of the styrofoam.

Benefits of using spray adhesives on styrofoam insulation

Using spray adhesives on styrofoam insulation offers several advantages, making it a preferred option for many applications:

Strong and Reliable Bonding

Spray adhesives designed for styrofoam provide a secure and durable bond, ensuring that insulation panels stay firmly in place. This helps maintain the integrity and effectiveness of the insulation over time.

Ease of Application

Spray adhesives are simple to apply and cover large areas quickly. Their even distribution reduces mess and ensures a uniform application, improving efficiency during installation.

Compatibility with Styrofoam

Foam-safe spray adhesives are specifically formulated without harmful solvents, preventing damage or degradation to styrofoam insulation while allowing for a long-lasting and safe connection.

Versatility

Many spray adhesives can bond styrofoam to various surfaces, including wood, metal, and plastic, increasing their utility in diverse insulation projects.

Reduced Waste

With precise application and minimal dripping, spray adhesives help reduce material waste compared to traditional adhesives, making them a cleaner and more cost-effective option.

How to apply spray adhesive to styrofoam safely

Prepare the Surface

Ensure both the styrofoam and the surface it will adhere to are clean and dry. Remove dust, grease, or debris to promote a strong bond.

Choose the Right Adhesive

Use a foam-safe spray adhesive specifically labeled for use with styrofoam to prevent melting or degradation. Check the product instructions for compatibility.

Apply in a Well-Ventilated Area

Work in an open or well-ventilated space to avoid inhaling fumes. Wearing a mask and gloves is recommended for added safety.

Spray Consistently

Hold the adhesive can 6–8 inches away from the styrofoam and apply a thin, even layer. Avoid oversaturating the foam to prevent dripping or uneven bonding.

Wait for Tackiness

Allow the adhesive to become tacky according to the manufacturer’s drying time, usually a few seconds to a minute. Avoid immediate pressing, as the bond forms better when slightly tacky.

Press Together Firmly

Carefully align and press the styrofoam to the other surface with steady, even pressure to ensure a secure bond. Avoid shifting the materials during this process.

By following these steps, you can achieve a durable and safe connection while protecting the integrity of the styrofoam.

What glue works best for styrofoam and other materials?

When working with styrofoam, it is essential to choose a glue designed to provide a strong bond without damaging the material. For styrofoam-to-styrofoam applications, contact cement or foam-safe adhesives like spray adhesive or white craft glue work effectively. To bond styrofoam to other surfaces, such as wood, metal, or plastic, epoxy glue, hot glue, or polyurethane glue are excellent choices. Always check the product label to ensure compatibility with styrofoam and avoid solvent-based adhesives, as they can dissolve or weaken the material.

Adhesives for bonding styrofoam to wood, cardboard, and plastic

When bonding styrofoam to wood, cardboard, or plastic, selecting the right adhesive ensures a sturdy and reliable connection. For styrofoam-to-wood applications, polyurethane glue or construction adhesive works well due to their strong bonding properties. If attaching styrofoam to cardboard, white craft glue or spray adhesive provides an easy and effective solution, as these adhesives are gentle and ideal for lightweight materials. When working with plastic, epoxy glue is a top choice as it creates a durable bond and adheres well to non-porous surfaces. Ensure the chosen adhesive is labeled as safe for styrofoam to prevent material damage or weakening. For best results, clean and dry all surfaces before applying the glue, and allow adequate curing time as specified by the product instructions.

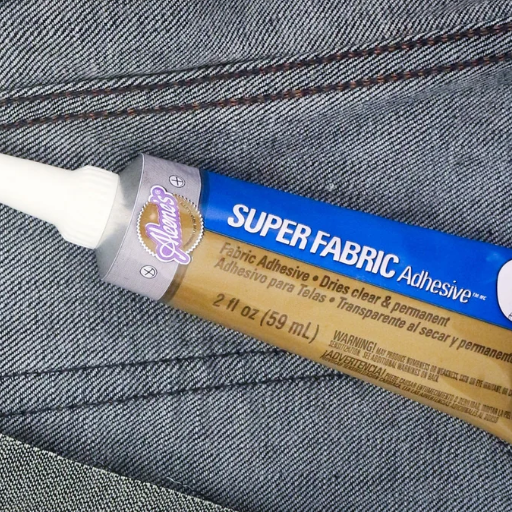

Specialized glues for styrofoam and mixed-material projects

When selecting specialized glues for styrofoam and mixed-material projects, the choice depends on the materials being bonded and the project’s requirements. E6000 Craft Adhesive is highly versatile, offering industrial strength and flexibility suitable for styrofoam and materials like wood, glass, and metal. For fast-drying and precise application, Loctite Spray Adhesive is an excellent option, working well with styrofoam and porous surfaces like paper or fabric. Another reliable choice is Aleene’s Tacky Glue, known for its strong hold and compatibility with lightweight materials such as cardboard, ensuring a secure and lasting bond. Always test the adhesive on a small area first, ensure proper ventilation, and follow manufacturer instructions for optimal results.

How to remove or dissolve glue from styrofoam?

Removing or dissolving glue from styrofoam requires care to avoid damaging the material. Start by gently peeling off as much glue as possible using your fingers or a blunt tool. For residual glue, apply a small amount of isopropyl alcohol or acetone to a cotton swab and dab it carefully on the glue without saturating the styrofoam, as strong solvents can melt it. Alternatively, a mild soapy solution can help loosen water-based glues. Always test any substance on a hidden area first, and proceed with patience to protect the styrofoam’s integrity.

Safe methods for removing adhesive residue from styrofoam

The glue left on Styrofoam can be removed best by applying heat to the edges so it can be pulled away from the middle using fingers or a plastic scraper. The remaining residue may be removed with a gentle touch of isopropyl alcohol, but not too much so it becomes saturated. In the event that alcohol does not do the trick, water-based adhesives can be wiped off with a soft cloth soaked in mild soap and water. Stubborn wipeable adhesives can be removed with the help of petroleum jelly and vegetable oil. To use, apply to the residue and leave for several minutes before wiping them off. With these methods, care must be exercised in applying any solution so that no structural damage is inflicted on the material.

What solvents can be used on styrofoam without damaging it?

Styrofoam is a sensitive material that can easily degrade when exposed to harsh chemicals, so only a limited range of solvents can be used safely. Isopropyl alcohol is generally considered a safe option, as it evaporates quickly and does not break down the styrofoam structure. Mild soapy water is another effective solution for removing residues without causing harm. Additionally, vegetable oil or specific adhesive removers labeled as “styrofoam-safe” can be used cautiously. Always test any solvent on a small, inconspicuous area to ensure compatibility and prevent potential damage to the styrofoam.

References

Frequently Asked Questions (FAQ)

Q: What is the best way to glue styrofoam?

A: The best way to glue styrofoam is to use adhesive glue specifically designed for foam. Options like UHU, 3M spray adhesive, or a styrofoam glue ensure a strong bond without damaging the material.

Q: Can super glue be used on styrofoam?

A: Super glue is generally not recommended for styrofoam as it can cause the foam to melt. Instead, use a glue gel or other adhesive specifically designed for foam materials.

Q: Is Gorilla Glue effective for styrofoam projects?

A: Gorilla Glue can be used for styrofoam, especially their specific formula for foam materials. However, it is essential to ensure the glue is foam-safe to prevent any damage.

Q: What type of glue is best for foam board?

A: For foam board, UHU adhesive or a tacky craft glue works great. These options provide a strong bond and dry clear, making them suitable for various projects.

Q: Can wood glue be used on styrofoam?

A: Wood glue is not ideal for styrofoam as it doesn’t adhere well to non-porous surfaces. It’s better to use an adhesive glue specifically designed for foam.

Q: How does glue gel work with styrofoam?

A: Glue gel is a thicker adhesive that works well with styrofoam because it doesn’t run or drip, allowing for precise application. It forms a strong bond without melting the foam.

Q: What is the best adhesive for foam insulation?

A: For foam insulation, construction adhesive or a product like Great Stuff is ideal. These adhesives are formulated to bond well with foam and other construction materials.

Q: Are there specific considerations when using hot melt glue on styrofoam?

A: When using hot melt glue on styrofoam, ensure the temperature is low to prevent melting the foam. Hot melt glue works great for quick projects where a fast bond is needed.

Q: What is the role of silicone in gluing styrofoam?

A: Silicone adhesive can be used with styrofoam, providing a flexible and waterproof bond. It is suitable for applications where long-term durability and resistance to moisture are required.

Q: Can epoxy be used for styrofoam model building?

A: Epoxy can be used for styrofoam model building, but it requires careful application to avoid melting the foam. It’s best for projects that need a strong and durable bond, like urban design projects.