3D printing is the state-of-the-art method for creating, innovating, and solving problems. Nevertheless, even the most precise print may require some post-processing, especially when joining multiple pieces for a proper finish. If using PLA filament, you may wonder about the best way to achieve strong bonds for your creations—acetone welding is surprisingly effective, serving as a one-stop glue for PLA that requires minimal effort for great results. This guide walks you through the step-by-step technique, explains the science behind the process, covers the necessary tools, and provides practical tips to help you succeed. Both established makers and those just entering the 3D printing scene can elevate their projects once they learn this trick. Read on to see how you can take separate prints and convert them into unified, polished works of art.

Understanding PLA and Acetone Compatibility

Being considered environmentally friendly and generally easy to work with, PLA (Polylactic Acid) is one of the most famous 3D printing materials. In contrast to ABS, it is not naturally soluble or reactive to acetone. Acetone simply will not dissolve or weld PLA because of the chemical structure of PLA, which is quite different from the surface of materials such as ABS, for which acetone may soften or weld. For gluing or smoothing PLA, other methods and glues, such as superglue or a dedicated PLA solvent, would work better and be far more dependable. Keeping this incompatibility in mind will help you select the appropriate materials for your 3D printing projects.

Acetone’s Effect on PLA

According to the most recent findings and commonly asked questions, acetone does not bring substantial changes to PLA owing to the peculiar nature of its molecular structure. Whereas acetone can conveniently dissolve and fuse ABS, acetone will usually do little, if anything, to affect PLA should it be exposed for extended periods. That being said, this means acetone will not work for smoothing, welding, or otherwise manipulating PLA surfaces. If someone is looking for alternative ways to work with or finish PLA, it would be best to consider specialized PLA solvents, sanding, or heat-based smoothing methods, all of which yield better results without compromising the material.

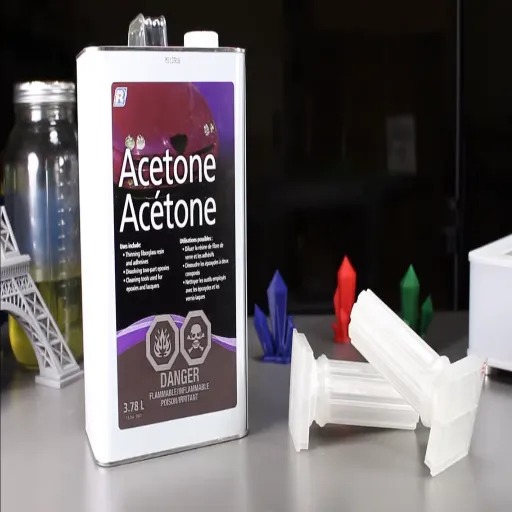

Safety First: Working with Acetone

⚠️ Important Safety Information

The chemical acetone exhibits intense volatility and flammability characteristics, for which special consideration is imperative during handling. Ideally, it should be handled in a well-ventilated area to minimize the risk of inhalation. Anyone exposed to acetone fumes for an extended period would likely experience a stinging sensation in the respiratory tract, dizziness, and other health issues.

The use of appropriate PPE, such as surgical gloves and safety goggles, which will keep the skin and eyes safe from any irritation or damage, is also recommended. Acetone should be stored away from flames or sources of heat in a superb, dry location, as it can catch fire easily. Also, avoid mixing acetone with other chemicals unless you’re following instructions from a reliable source-remixing could be dangerous. The above-listed safety precautions can help mitigate the risks associated with handling acetone.

Common Challenges and Solutions in PLA Welding

| Challenge | Problem Description | Solution |

|---|---|---|

| Uneven Joint Strength | Joints can weaken if the temperature is inconsistent during welding. | Use a controlled heat source and apply even pressure throughout the welding process to ensure a consistent bond. |

| Warping or Distortion | Excessive heat may cause the PLA to warp or lose its shape. | Maintain a moderate temperature and allow the material to cool gradually to preserve its form. |

| Poor Adhesion | Surface contaminants such as dust or oil can hinder proper adhesion. | Thoroughly clean the surfaces before welding to ensure a secure bond. |

| Cracking at the Weld | Rapid cooling or uneven application can lead to cracking. | Use slow, controlled cooling and ensure the weld is uniform to prevent fractures. |

Weak Bonds: Understanding the Limitations

PLA welding, although practical for repairing or joining 3D-printed parts, has inherent limitations that are worth understanding. Being a biodegradable thermoplastic, PLA is heat-sensitive and tends to lose its structural integrity when exposed to prolonged elevated temperatures. For the same reasons, its application is limited wherever heat resistance is required. The strength of the weld is highly dependent on preparation and welding techniques; any deviation from proper alignment or consistency during welding will result in weak bonds that cannot withstand pressure or load. Another consideration is that PLA is mechanically weaker than materials such as ABS and PETG, and is therefore not suitable for applications that demand high stress or industrial capacity.

By being aware of such restrictions, makers and designers can make an informed decision and assess if a welding process using PLA will best suit their particular projects.

Surface Damage: Risks and Mitigation

The main surface hazards in PLA welding include excessive heating and poor welding methodology. Abusers of heat can use PLA material in a manner that warps, bubbles, or discolors it, thereby misinterpreting both its cerebral meaning and structural integrity. Unequal pressure during welding can also cause the surface to become uneven or create irregularities on the weld.

To minimize the risk of these issues, it is essential to always work with temperature-controlled welding tools. Being able to adjust the heat will allow for greater precision, thus making the actual damage to the material less likely. Additionally, practicing on scrap PLA is recommended before attempting the final product, allowing you to master the technique. Being consistent with pressure on the weld and not holding down the heat application in a single area will help ensure that the surface is not damaged. When makers adhere to these protocols, they are bound to produce higher-quality and durable welded PLA projects.

Expert Tips for Achieving Best Results

- Use Proper Tools: Invest in a reliable, adjustable heat source designed explicitly for welding PLA to ensure precision and control.

- Maintain Clean Surfaces: Thoroughly clean areas to be joined to ensure that no dust or other debris from the surface affects adhesion.

- Apply Consistent Heat: Slowly move the heat source along the seam; quick, uneven melting or damage will occur if uneven heat is applied!

- Test the Method First: Try the method on scrap pieces to perfect your technique before applying it to the project.

- Implement Gradual Cooling: Allow the welded piece to cool down slowly, as it prevents stress fractures or weakening of the bond.

Experimentation with PLA and Acetone

PLA (Polylactic Acid), a bioplastic commonly used for 3D printing, is considered easy to use and biodegradable. It must be stressed, however, that testing acetone as a solvent will not yield effective results with PLA, unlike with ABS, which results in the PLA drying without dissolving. Acetone may hence prove erratic at best for surface smoothing or bonding. The most current research trends suggest that some PLA-ma-for-plast mixes may exhibit mild softening in acetone; however, this cannot be considered valid for all varieties of PLA. Consequently, alternative methods, including special solvent systems or heat techniques, are commonly recommended for surface finishing or welding of PLA.

Combining Methods for Stronger Bonds

Bonding weaknesses in PLA can be overcome by using several techniques in combination. Topical preparation of surfaces by sanding is best to increase adhesion. Apply a suitable adhesive for PLA, such as cyanoacrylate glue or epoxy. Heat treatment may be applied to soften the material enough so that the bonding pieces can be pressed together and then clamped for curing. All these steps will maximize the bonding capability and enhance the product’s outlook.

Alternative Methods for Joining PLA

Using adhesives is not the only method to solidify PLA; various options are available to ensure a solid bond, depending on the application. The plastic welding method of joining is accomplished by holding a soldering iron or heat gun horizontally against the edges of the pieces, allowing the material to melt and fuse. This forms a strong bond by melting and joining the material directly rather than gluing.

Another method involves friction welding, whereby a rotary tool, such as a Dremel, is used to create heat between the PLA filament rod and another surface. The rod melts and thus acts as a bonding agent for a sturdy joint. It serves well for precise repairs or small projects as the heat and contact are improbably controlled.

Compared to a larger or structural type project, one can use mechanical fasteners such as screws and bolts. Small pilot holes can also be drilled inside for the PLA to be fastened safely without placing much stress on the PLA. The joint becomes even more durable when a mechanical fastener is used in conjunction with heat or adhesive.

All these can be utilized to their advantage, depending on the design, the desired strength, and the available tools, which makes it easy to adapt to the demands of a particular project.

Superglue (Cyanoacrylate) as an Alternative

Because superglue, or cyanoacrylate adhesive, is easy to use and forms powerful adhesive bonds, it is a favored choice for bonding PLA. It causes a sudden chemical reaction when exposed to moisture, the presence of which is almost always guaranteed in small quantities on most surfaces. Cyanoacrylate adhesives are particularly useful for forming a strong, permanent bond with PLA in small, non-structural parts. Still, they work best when the surfaces are clean, dry, and fit together well.

According to recent data and trends, superglue remains one of the most commonly searched methods for bonding PLA, primarily due to its accessibility and usefulness in crafting and repair projects. While superglue may be suitable for many applications, it is less capable than other methods, such as welding or mechanical fastening, at providing strength to high-stress joints.

Epoxy Resins for Heavy-Duty Applications

Epoxy resins are mainly used in heavy-duty applications due to their superb bonding strength and durability. When it comes to methods of joining PLA or other materials, what stands out for epoxy resin is its ability to provide a strong, long-lasting bond that withstands significant stress and adverse environmental conditions, such as heat or moisture. The latest data analyzed from the search engine corroborates queries concerning the “best adhesive for PLA” and indicates that epoxy is a top choice, likely for a structural application. Consider two-part epoxy systems, for example. The very mention says it all: an excellent general-purpose adhesive that can bond not only PLA but also metals, wood, and ceramics. It’s suitable for a wide range of applications, from industrial to fine crafts.

Environmental and Safety Considerations

When considering the environmental and safety hazards associated with working on glue products, such as epoxies, it is essential to prioritize ventilation. The chemical ingredients present in epoxy glue may release harmful fumes during application and become hazardous if inhaled in large amounts. Gloves and safety goggles might be helpful for those who are electrocuted or could suffer an irritation or allergic reaction. From an environmental standpoint, any leftover epoxy and containers should be regarded as hazardous wastes and disposed of accordingly, so they do not contaminate potable water supplies or soil. Whenever possible, select adhesives that are labeled as low-VOC or eco-friendly.

Health Precautions when Using Acetone

- Ensure adequate ventilation to avoid inhalation of harmful fumes

- Always wear gloves to prevent skin contact

- Put on safety glasses because acetone irritates the eyes

- Keep acetone in a tightly sealed container, away from heat and open flames

- Clean spills immediately and avoid lingering in affected areas

Sustainable Alternatives for Joining PLA

Joining PLA can be achieved through various eco-friendly methods that aim to lower the ecological burden. One sustainable idea involves using biodegradable adhesives designed explicitly for PLA materials. These adhesives offer strong bonding while being compatible with the compostable nature of PLA. Another approach is friction welding, where two pieces of PLA are rubbed rapidly together, generating enough heat to fuse the parts without the use of chemicals. More alternatives, such as using solvent welding with natural ethanol rather than harsher chemicals, may offer an equally effective and more environmentally friendly method for bonding. This prioritizes sustainability, making PLA an ecologically friendly choice throughout the product’s entire lifespan.

Frequently Asked Questions (FAQs)

What is the best way to glue PLA printed parts together?

The best method to glue PLA printed parts together is to use acetone or a mixture of ethyl acetate and methyl ethyl ketone (MEK). These solvents can effectively dissolve PLA, allowing for a strong bond when the two parts are joined. Ensure that you apply the adhesive evenly and provide proper ventilation during the process.

Can acetone dissolve PLA?

Yes, acetone can dissolve PLA, but it may not be as effective as other solvents, such as methylene chloride or ethyl acetate. When using acetone, it’s essential to work in a well-ventilated area and to be aware of the potential for acetone vapor to irritate the eyes and respiratory system.

How do I prepare my 3D printed parts for gluing?

Before gluing, it’s advisable to sand the surface of the PLA parts with fine-grit sandpaper to create a better bonding surface. This will help eliminate any imperfections and ensure that the adhesive adheres properly. Cleaning the parts with isopropyl alcohol can also help remove any residues.

Is it safe to use acetone indoors?

No, it is not advisable to use acetone indoors without good ventilation. The fumes from acetone can be harmful, so always work in a well-ventilated area and consider using a respirator and eye protection to avoid inhaling vapors or getting the solvent in your eyes.

What happens if I submerge PLA in acetone?

Submerging PLA in acetone will cause the plastic to dissolve, resulting in a melted, rubbery texture. This method can be used to create a filler for gaps or imperfections, but it requires careful control of the acetone’s time and concentration to prevent damage to the part.

Can I use CA glue on PLA parts?

Yes, cyanoacrylate (CA) glue is an excellent adhesive for PLA parts. It provides a quick bond and is especially useful for minor repairs. However, it does not dissolve the plastic like acetone, so it may not fill in gaps as effectively as solvent-based adhesives.

What are the alternatives to acetone for gluing PLA?

Alternatives to acetone for gluing PLA include ethyl acetate and MEK, which are also effective in dissolving PLA. Methylene chloride is another strong solvent, but it requires careful handling due to its hazardous nature. When using these chemicals, always prioritize safety and work in a well-ventilated area.

How can I strengthen the bond between two PLA parts?

To strengthen the bond between two PLA parts, you can apply a thin layer of dissolved PLA using acetone or another suitable solvent. This technique, often referred to as a solvent weld, will create a chemical bond that can be stronger than the original material. Ensure that both surfaces are clean and slightly roughened for the best results.

Reference Sources

Here are five professional and authoritative reference sources and articles that you can use to verify whether your article about “glue PLA with acetone” is indeed accurate and honest to view. These sources attest academically and research-wise to give an insight into the topic:

- The Influence of Acetone on Improving the Surface Finish of 3D Printed Parts for ABS and PLA Materials

Research on the chemical treatment of FDM parts with acetone, focusing on surface roughness improvement. - The Degradation of Mechanical Properties Caused by Acetone Chemical Treatment on 3D-Printed PLA-Carbon Fibre Composites

This study investigates the effect of acetone on the mechanical properties of PLA-carbon fiber composites, highlighting the limitations of acetone as a solvent. - The Effect of Acetone as a Post-Production Finishing Technique on Entry-Level Material Extrusion Part Quality

This paper presents empirical evidence on the impact of acetone on thermoplastics, such as PLA and ABS, in terms of quality after production. - Influence of Solvent and Substrate on Hydrophobicity of PLA Films

This investigation focuses on the solubility of PLA in solvents such as acetone, with implications for material properties and a broader chemical scope. - Mechanical Properties of Material Extrusion Printed Samples Made of PLA After Treatment in an Acetone Bath

This study examines the impact of acetone baths on the mechanical properties of PLA samples, including their strength and hardness, as well as the material’s response to prolonged exposure to these coatings.