Bonding materials can be a challenging process for craftspeople, builders, or DIY enthusiasts, especially when it comes to working with Styrofoam and metal. The two materials have almost opposite properties, and so the adhesive and application methods used must be carefully chosen to ensure the best possible bond and a lasting effect. Gluing Styrofoam onto metal can be both a formative project for experimentation or a pragmatic approach in engineering, so it is a valuable skill to have in one’s toolbox. In this article, you will be informed about suitable adhesives and techniques that make the job feasible and effective, while saving you the trouble of overlooking important details.

Understanding Styrofoam and Metal Adhesion

Styrofoam and metal behave very differently, thus presenting a limitation in their adhesion system. Styrofoam, being light and porous, does not behave mechanistically like metal, which is heavy and dense. To establish a strong bond, it is essential to select the right adhesive for the task. Look for adhesives such as epoxy, polyurethane glues, or construction adhesives labeled explicitly for use with plastics and metals. These adhesives can vary surfaces and still yield durable results. Ensure that dust, oils, or any other debris are not present on either the Styrofoam or metal surfaces before applying the adhesive. Additionally, lightly sanding the metal surface can help secure the bond by creating a slightly roughened texture for the adhesive to latch onto. The best approach is always to follow the manufacturer’s instructions for the adhesive when gluing.

Typical Applications for Foam to Metal Bonding

Foam-to-metal bonding finds acceptance in almost every industry, depending on its capability and reliability. Commonly, such methods are used in automobile manufacturing for vibration damping, noise reduction, and thermal insulation, thereby enhancing vehicle performance and passenger comfort to some extent. Another important use is that bonded materials from the construction and HVAC industries serve as insulation panels, soundproofing barriers, and gaskets to conserve energy and enhance noise control. The other major areas would be electronic casing applications for impact resistance for fine internal components. This also demonstrates the suitability and versatility of foam-to-metal bonding in various industrial applications.

Factors Affecting Adhesion Quality

Many factors determine the strength of adhesion. Surface preparation is essential; a surface that contains contaminants, oils, or oxidation will not readily allow adhesion to take place. However, a clean and primed foam and metal surface tends to provide better bonding strength. Another significant factor in adhesion bonds is the adhesives themselves. Some adhesives work better with a particular foam, metal, or are more resistant to heat, moisture, and even chemicals than others. Temperature and humidity are atmospheric conditions during the application that can affect the curing and the longevity of the bonds. Lastly, the approximate application procedure, such as bearing on it, is essential for achieving an even bonding surface. Careful attention to all these factors ensures optimum performance and reliability of the bonded materials in industrial applications.

Top Adhesive Recommendations for Styrofoam

Loctite PL Premium Polyurethane Construction Adhesive

Loctite PL Premium Polyurethane Construction Adhesive provides an excellent bonding solution for Styrofoam, offering a strong, durable hold that works well on various surfaces. It is resistant to moisture, offering everlasting adhesion; it can be used both indoors and outdoors.

Gorilla Epoxy Glue

Another adhesive recommended for Styrofoam is Gorilla Epoxy glue. In its two-part formulation, it ensures a strong and durable bond, yet it remains versatile, compatible with many materials. It sets and dries fast; hence, it offers a clean finish that is perfect for detailed projects.

Loctite PL Premium Polyurethane Construction Adhesive

When it comes to adhesives for bonding Styrofoam surfaces, this is the very best available in the market. It is hence called the best due to its strength and durability, making the waterproofed bond that withstood weather. Therefore, it’s perfect for both indoor and outdoor use. Besides Styrofoam, it is versatile enough to adhere to a wide range of materials, including wood, concrete, and metal. On the other hand, its excellent performance under harsh conditions gives it an edge in delivering permanent results, even in the face of truly challenging situations.

Gorilla Epoxy Glue

For heavy-duty bonding applications, Gorilla Epoxy Glue is a trusted name. The two-part composition, consisting of resin and hardener, imparts great strength and permanence to the bonding process. It is formulated for strong bonding of materials such as metal, wood, ceramic, glass, and plastics, being perfect for all repair and construction jobs. This epoxy glue finishes clear, giving aesthetic appeal to strong holds at a professional level. It is also resistant to water, solvents, and other forthcoming environmental hazards, thus ensuring the endurance and resilience required by heavy-duty applications.

Step-by-Step Instructions for Gluing Styrofoam to Metal

- Prepare the Surfaces: Clean both the styrofoam and metal surfaces thoroughly to remove any dust, grease, or debris. Allow them to dry completely.

- Choose the Right Adhesive: Use a glue that is compatible with both metal and styrofoam, such as epoxy or a polyurethane-based adhesive. Avoid adhesives that contain solvents, as they can damage styrofoam.

- Apply the Adhesive: Spread a thin, even layer of the adhesive on the metal surface. Be careful not to overapply to avoid a messy bond.

- Press the Pieces Together: Gently press the styrofoam onto the metal, ensuring even contact. Hold them firmly for a few seconds.

- Secure and Dry: Use clamps, tape, or a weighted object to hold the pieces in place while the adhesive cures. Refer to the adhesive’s instructions for drying time, which may take several hours.

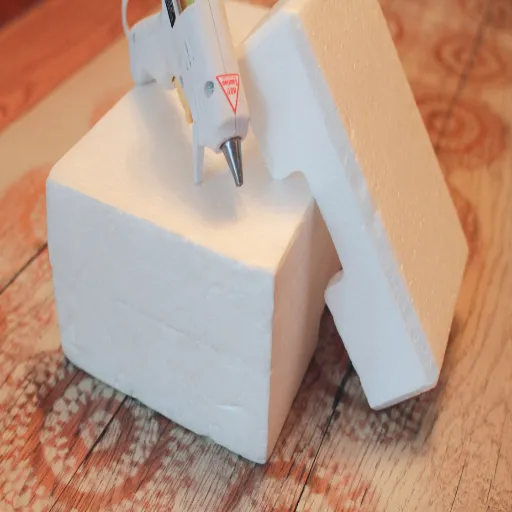

Choose and Apply the Adhesive

When dealing with styrofoam and metal, the best glue is one for mixed materials. Popular choices include epoxy glue, cyanoacrylates (also known as super glue), and certain types of craft glues. In general, epoxy glues are viewed as the strongest, especially when the bond must withstand the test of time and is used in a heavy-duty application. Some recommend using spray adhesives or even hot glue for lighter applications. Consider drying time, tensile strength, and compatibility with both materials. Follow the manufacturer’s instructions to avoid breaking the bond.

Allow Adequate Curing Time

The curing time for adhesives varies depending on the type of glue used and environmental conditions. Epoxies generally require 24 to 72 hours for a complete cure. In contrast, cyanoacrylate glues (also known as superglues) typically bond surfaces in seconds but can take several hours to cure fully under ideal conditions. Other pertinent conditions include humidity and temperature, whereby most glues cure faster in dry, warm climates. Ensure that you range well according to the manufacturer’s specifications regarding the exact curing time and refrain from disturbing the bond during that period. Allowing a bit of time will ensure your glue achieves maximum adhesive strength and durability over time, which prevents failure.

Safety Tips When Working with Adhesives

- ⚠

Work in a Well-Ventilated Area – Many adhesives release fumes that can be harmful if inhaled. Ensure proper airflow to reduce exposure to these fumes. - ⚠

Wear Protective Gear – Use gloves to protect your skin from contact and safety glasses to shield your eyes from splashes. Consider wearing a mask if you work with strong-smelling adhesives. - ⚠

Avoid Open Flames – Some adhesives are flammable. Keep them away from heat sources or open flames during use and storage. - ⚠

Follow the Manufacturer’s Instructions – Always read and follow the instructions on the adhesive label to ensure safe and effective use. - ⚠

Store Properly – Keep adhesives out of reach of children and store them in a cool, dry place, as directed by the manufacturer.

Ventilation and Protective Gear

Proper ventilation is crucial when using adhesives, especially those that emit strong fumes. Ideally, you should work in an open space or arrange for fumes to be sucked out by an exhaust fan to prevent the fumes from making you dizzy or irritating your respiratory tract. The use of these protective measures, which include barrier resins, is paramount to safety. Depending upon the nature of the adhesives being used, you may want to consider wearing gloves to protect your hands from skin exposure, safety goggles to protect your eyes, or, in the case of very high fume levels, a mask or rated respirator to protect against chemical vapors. The more these precautions are followed, the greater the chances are of maintaining a safe and healthy working environment.

Proper Storage of Adhesives

I have this habit of instructing the adhesives to be stored in a cool, dry area with proper ventilation. It should never be kept in direct sunlight or anywhere near a heat source. After every use, I ensure that the containers are tightly sealed against any spills and evaporation. The adhesives are also stored in a location inaccessible to children or pets, as per the provided safety instructions. These measures protect the quality of the adhesive while also safeguarding your environment.

Practical Applications and Use Cases for Foam to Metal Projects

Foam-to-metal projects encompass a wide range of practical applications, showcasing their versatility and uniqueness. Below are some working headlines on everyday operations:

🚗 Automotive Industry

Foam is typically glued onto metal to reduce noise and vibration, enhancing the desirability of the product. The comfort and vibrations in a vehicle also improve performance.

✈️ Aerospace

From reducing weight and structural insulation, foam is affixed to metal.

🏗️ Construction

To manufacture insulated panels and soundproof materials in buildings.

🏥 Medical Equipment

They are used to develop ergonomic supports and hard covers to shield delicate instruments.

🛋️ Consumer Products

Foams bonded to metals provide cushioning, insulation, and aesthetic appeal, ranging from appliances to furniture.

Home Improvement Projects

The mixture of foam and metal in any home improvement project lends itself to both utility and creative possibilities. From insulation upgrades in attics and basements to soundproof walls for a home studio, it makes the whole thing efficient and durable. The foam-to-metal bonded assemblies are ideal for DIY projects, particularly when building custom furniture such as cushioned benches or insulated outdoor seating that combines comfort with style. Simply put, this innovative method offers one of the most reliable balances between modernist style and functionality in any living space.

Crafting and Hobbies

Crafts and arts indeed are witnessing a resurgence in popularity, with people seeking hands-on creative outlets for relaxation, self-expression, and sometimes entrepreneurship. Among the most searched activities are home decor DIY projects, knitting, and woodworking. Data have shown recent trends indicating an increase in interest in resin crafts, with prospective crafters spending time searching for tutorials on resin jewelry, coasters, and keychains. These crafts serve as avenues for creative expression, enabling individuals to decorate their living spaces or give away meaningful, handmade gifts. Additionally, these websites are essential resources for providing people with ideas and offering instructions, allowing them to see their own dreams realized.

Reference Sources

Here are three more professional and authoritative reference sources to verify your article on “glue Styrofoam to metal.” These papers are scientific in nature and offer valuable knowledge with respect to adhesives and their applications:

Experimentation on the reuse of waste Styrofoam as an adhesive material

Published by AIP Publishing, this study employs an experimental approach to the dissolution of Styrofoam waste for creating adhesives that bond various materials, including plastic, metals, and wood.

Development of waste polystyrene (Styrofoam) adhesive as a matrix in composite applications

This paper focuses on the development of adhesives derived from Styrofoam for composite applications, including the bonding of metals.

Polymer composition and substrate influences on the adhesive bonding of a biomimetic, cross-linking polymer

Published by the American Chemical Society, this paper studies the adhesive bonding capabilities of polymers, including polystyrene, and their interaction with metal substrates.

Frequently Asked Questions (FAQs)

What is the best adhesive to glue styrofoam to metal?

The best adhesives for gluing styrofoam to metal include contact cement, Gorilla Glue, and silicone. Each of these options provides strong bonding capabilities while being sensitive to the materials involved, ensuring a secure join without damaging the styrofoam.

Can I use hot glue to attach pieces of foam to steel?

While hot glue can be used to attach pieces of foam to steel, it may not provide a long-lasting bond, especially in high-temperature environments. For a more durable solution, consider using stronger adhesives, such as 3M or contact cement.

Is it safe to use a caulk adhesive for foamboard installation on metal?

Yes, caulk adhesives can be safe for foamboard installation on metal surfaces. However, it’s essential to select a caulk that is compatible with both materials to ensure a strong bond and prevent any melting of the foam.

Will using silicone adhesive melt the foam?

No, silicone adhesive does not melt foam and is a suitable option for bonding styrofoam to metal. It provides flexibility and durability without compromising the integrity of the foam.

How do I ensure an even coat when applying adhesive to foam?

To ensure an even coat when applying adhesive to foam, use a brush or a spatula to spread the adhesive uniformly across the surface. This technique helps prevent gaps and ensures a better bond when attaching the foam to metal.

Can I glue foam to aluminum using regular glue?

Regular glue may not provide the best bond when gluing foam to aluminum. It’s recommended to use specialized adhesives, such as Gorilla Glue or contact cement, designed for bonding various materials, ensuring a strong attachment.

How do I fill gaps when joining foam board to metal?

To fill gaps when joining foam board to metal, consider using a strip of adhesive caulk or a foam filler. This helps create a smooth transition and strengthens the bond between the two materials.

What should I do if the adhesive makes the foam sensitive to damage?

If the adhesive makes the foam sensitive to damage, consider using a less aggressive adhesive or applying a protective coating over the foam before applying the adhesive. This creates a barrier that protects the foam from potential harm during the bonding process.