It is often difficult to bond 3D printed objects that are made out of Poly Lactic Acid (PLA) securely and reliably. And yet, it is absolutely essential – be it their assembly in small and sophisticated parts, replacement of broken hardware, or their improvement in terms of their usefulness – the issue of the appropriate adhesive cannot be left out when it comes to these elements. But, given the number of glues in the market, it is a common question: how does one determine the right type of glue for their PLA projects, which will be effective? This article answers how to glue PLA in a cohesive way that allows for the application of the best adhesives, the science of how they work, and some practical advice for creating strong, effective joints. At the end, you will be ready to glue any PLA work that you have to undertake or fix with proper perspective.

Understanding PLA Material and Its Properties

PLA, or polylactic acid, is a biodegradable thermoplastic polymer that is commonly formed from either corn starch or sugarcane. PLA is in demand in 3D printing as it fuses very easily and has a minimal tendency to deform while in the 3D printer. It is a material that is usually hard and brittle in nature, but performs better under less stressful applications. On the other hand, PLA cannot resist exposure to high ambient temperatures or moisture that significantly weakens the material’s composition. Moreover, the mixing material also has a limit on one side, and that side is its slick surface that bonds very well. Therefore, the chemical makeup in the polymer blend consumed shows, as an alternative, how safe bonds are obtained without any issues, and thereby, the effectiveness of the adhesive is improved. Handling these constraints becomes critically necessary in devising appropriate gluing agents and methods for handling PLA project work.

What is PLA?

Polylactic Acid or PLA is by description a biodegradable thermoplastic material which is produced by the use of renewable resources like corn starch, and sugarcane among others. The material is the most commonly used one in 3D printing and other manufacturing industries only because it is simple to handle, exhibits a low melting point, and is overall pollution-free in terms. It has a moderate rigidity in terms of longitudinal elasticity, which is suitable for its purpose, making it competitive in terms of compliance strength, but not to the point of being destructive.

Key PLA Specifications:

- Glass transition temperature: approximately 60°C

- Melting point: 150°C to 160°C

- Processing methods: injection molding, extrusion, and 3D printing

Why Choose PLA for 3D Printing?

Pleasantly, it is quite interesting for me to observe how poly-lactic acid material intrinsically became important for 3D printing, with some of the outstanding qualities it adopted most recently, and as regards it. For example, if since the bioplastic is a polymer also called as thermoplastic, in which case, it can be produced from materials accessible like corn as well as sugar cane, how in modified sense poly-lactic acid were created from the ancient hydrocarbon is biodegradable, how strong and tough and yet tough polymers exist is how one does not have to use petrochemicals for strength as tough alternatives are now readily available.

Technical advantages include:

- Relatively low melting temperature (typically around 190-220°C)

- Excellent adhesion to build plates

- Reduced risk of warping or print failure

- Low shrinkage rate during cooling

- Compatible with most 3D printers

- No strong or harmful odors during printing

Nowadays, due to new developments in the domain of PLA, the use of the material is not limited to lamination only. Enhanced grades are designed such that there is greater improvement in the thermal resistance and mechanical properties of such materials, so that they can be used in the manufacture of parts that require higher toughness. Furthermore, PLA includes a most valuable feature that allows the surface of the cosmetic parts to be treated with all types of painting, sanding, or annealing, just like the post-processing of the filament.

Common Uses of PLA in Printed Parts

| Application | Description | Key Benefits |

|---|---|---|

| Prototyping and Product Development | Creating detailed models for form and fit testing | Low cost, rapid iteration capability |

| Educational Models | Anatomical models, geometric shapes, mechanical structures | Safety, ease of handling, sustainability |

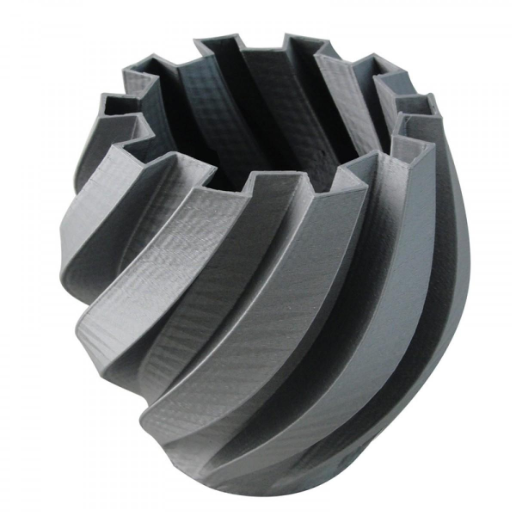

| Decorative Items and Art | Figurines, vases, artwork | Vibrant colors, post-processing compatibility |

| Custom Tools and Fixtures | Lightweight jigs and fixtures | Precision, moderate strength |

| Medical Device Prototypes | Surgical tool and device component prototypes | High detail accuracy, design validation |

| Consumer Products | Phone cases, holders, household accessories | Low toxicity, smooth finish, warp resistance |

Choosing the Right Glue for PLA

One of the most effective gluing methods when working with PLA is superglue (cyanoacrylate) and epoxy. Superglue is very suitable for making accurate and fine bonds, where in certain cases, it is not only the most effective but also the only glue that can be used to achieve successful bonding of smaller parts. On the other hand, epoxy wins the palm collection of the best plastic by providing more adhesive and durable bonds, which are suitable for tougher components like large or load-bearing loads.

Types of Adhesives Suitable for PLA

| Adhesive Type | Key Points | Suitable Applications | Strength Level | Notes |

|---|---|---|---|---|

| Cyanoacrylate (CA) | Quick drying, precise application | Small parts, minimal stress points | Medium | Requires clean, dry surfaces |

| Epoxy | Strong, durable, gap-filling | Large or load-bearing parts | High | Two-part mixture, longer curing time |

| Polyurethane Glue | Expands for better bonding, water-resistant | Irregular surfaces, outdoor applications | High | Can expand excessively, apply sparingly |

| Hot Glue | Flexible bond, quick application | Temporary bonds, low-stress areas | Low to Medium | Best for lightweight attachments |

| Acrylic Adhesive | Durable, good for high-impact scenarios | Structural components | High | Requires clean surfaces for optimal bond |

| PLA-Specific Adhesive | Designed specifically for PLA bonding | All-purpose bonding | Medium to High | Formulated for maximum compatibility |

Best Glue Recommendations for PLA

1. Cyanoacrylate Glue (Super Glue)

Cyanoacrylate glue has been observed to have good performance when it comes to PLA material due to the fast curing rate, the strength of the bond formed, and the seal formed between the materials. Anthese adhesives are activated by the presence of moisture in the air. When moistened, they bond far better and end up even harder and rigid than most materials, which makes them fit for precision joints or small parts that require an even closer margin of inaccuracy. However, excessive caution must be exercised when using this adhesive in situations where corrosive forces are likely to occur, as constructive interfacial and bonds will be weak, or material begins to accumulate a glue film.

2. Epoxy Resin

For a combination of sturdiness and ability to fight off any mechanical soiling, Epoxy adhesives can be exceedingly efficient. These adhesives come as two components, that is, the resin and hardener, which must be mixed correctly before use. In terms of curing timing, it takes more time to cure compared to cyanoacrylate; however, the bond formed is relatively tougher and can be used for the strong bone support structures or even if parts experience a lot of external loads in the PLA solid components.

3. PLA-Specific Adhesives

Among various other types of adhesives that exist in the market, adhesives fitting PLA specifically were in existence, which were the most effective. These enabled the attachments to merge by actually interacting with the chemical properties of PLA and so decreasing the probability of errors. All these developments are helpful, especially when dealing with large projects that contain many parts of PLA that require uniform adhesion.

4. Acrylic Adhesives

Acrylic adhesive is utilized where high tensile strength is a major requirement. This adhesive is also recommended for bonding PLA in applications where impact or mechanical wear is anticipated. Within the process, the proper bonding adhesives are applied to the surface, which is covered in a cloth that includes any foreign material. A cloth with isopropyl alcohol is rubbed on the surface to clean and remove any adhesives before sticking the bond which exposed contaminants might damage. In this regard, it is the bond line breakdown or a phenomenon when more than one material is mixed over essentially high tensile fibers.

5. Hot Glue (Low-Temperature)

Low temperature hot melt glue, also referred to as craft or fabric glue, can suffice for bonds that are temporary or non-structural. This adhesive has several good properties including being user friendly because it is not hot and so does not have danger of being soiled or burned and it is also fast to cool down after seconds of application, but on the negative note it is not as durable as other kinds of adhesives. It is also useful in cases where full operational PLA assemblies require only decorations, or for prototyping purposes, where assemblies of different parts are expected to fail.

Comparing Acrylic Cement and Other Options

| Adhesive Type | Strength | Application | Durability | Ease of Use | Cost |

|---|---|---|---|---|---|

| Acrylic Cement | High | Precision industrial applications | Long-term | Moderate | Moderate |

| Epoxy Resin | Very High | Structural bonds and repairs | Long-term | Moderate | High |

| Cyanoacrylate (Super Glue) | Medium to High | Quick small-scale fixes | Short to Medium-term | High | Low |

| Hot Glue (Low-Temperature) | Low | Temporary lightweight or decorative tasks | Short-term | Very High | Low |

| Polyurethane Adhesive | High | Flexible and strong bonds (wood/plastic) | Long-term | Moderate | Moderate |

| Silicone Adhesive | Medium | Sealing and flexible bonding | Medium to Long-term | Moderate | Moderate |

Techniques for Gluing PLA Parts Together

When bonding PLA components, the AIC must make certain that an appropriate adhesive and such an adhesive application method are employed, because strong and long-lasting bonds are what are being sought. The following actions are recommended:

Super Glue (Cyanoacrylate) Method

- Place a thin application of adhesive on the surface using a brush or spatula

- Use a clamp or press to squeeze the parts together

- Hold for a short period to let the adhesive cure or until it is permanently set

- Here for the jobs that need fine attention or with a few residues of the adhesive

Epoxy Adhesive Method

- Apply resin and hardener in the set proportions controlled by the manufacturer

- Use a brush or a spatula to spread the mixture over both surfaces

- Waiting for the curing of the epoxy, fix both parts with a clamp

- Another thing, designed for such high-stress areas and the large-sized parts.

Polyurethane Adhesive Method

- Place a thin application of the Adhesive on the Puzzle

- Lightly splash the not-yet-dried PLA surface with water in order to activate it

- Leave it for some hours to fully cure.

- This works perfectly when bonding PLA to other substrates

Hot Glue Method

- Place adhesive modestly

- Quickly and gently put the stuff together the moment before the glue colds

- Recommended to be used with PLA in only temporary or light loading structures.

Surface Preparation for Strong Bonds

When working with PLA in order to achieve good adhesion, you need to be very careful in preparing the surface. Here are some basic steps:

Cleaning Process

- Clean thoroughly: The first step is to clean, and clean using <90% isopropyl alcohol.

- Remove contaminants: Next step is eliminate all types of contamination (oils, grease, residues and so on) to promote bonding.

- Allow to dry: Along with the previous two steps, the surfaces must be allowed to dry out completely prior to starting the bonding procedure.

Surface Texturing

- Sand lightly: Use 200 to 400-grit sandpaper

- Create micro-abrasions: This enhances mechanical interlocking for stronger bonds

- Remove dust: Clean away all particulate dust after sanding

Environmental Considerations

- A working temperature range of 60°F to 75°F is proper.

- It depends as well on the moisture content of the substrate, the adhesive, and the primer that will cure submerged in these conditions.

- Consider using specialized adhesion promoters for professional applications

Step-by-Step Instructions to Glue PLA

Step 1: Select an Appropriate Adhesive

Plastic being the target material, select an adhesive that is specially made for sticking various types of plastic materials, such as the most common ones, epoxies, or even the PLAs. If you choose cyanoacrylate, it’s good for immediate joining of thin members or small areas in water, while using the two-component, then it’s ideal when handling bulk areas.

Step 2: Prepare the PLA Surfaces

Make sure that the surface texture of the two adjoining surfaces is uniform and contacting to the extent that there is no deposited dirt or oil on them. Clean the surface using isopropyl alcohol (IPA) and let it dry completely, and abrade it if needed by using lightly fine-grit sandpaper in the range 220-400 around the glue edges to enhance the stickiness of the material.

Step 3: Primer Application (Optional)

In order to make the best out of the resin coating process, provisions such as appropriate adhesion enhancer products are necessary. This is particularly true of many adhesion promoters that work well with PLA, which assists in enhancing the chemical bond between the adhesive and the substrate. Allow the primer to cure per the manufacturer’s instructions and criteria before any further action.

Step 4: Apply the Adhesive

Evenly apply the adhesive on one of the surfaces fully. It is suggested to make use of rollers or syringes for more limited and accurate control over the amount of the adhesive used. This concern could affect the fulfillment of the bond on the one list and ethical issues with the application of excessive amounts of adhesive.

Step 5: Join the Surfaces

Close adhesion between the aforementioned two parts of polylactide fits so well. Pressure should be kept constant through clamps, rubbers or other devices to aid in adhesion of the final composite. Keep the devices in one position so that the structures of the two parts do not shift or attach with weak strength during this curing stage in vitro and avoid destructive malfunction of tools or fixtures.

Step 6: Allow Adequate Curing Time

Consult the instructions provided by the manufacturer on how long the bonded surfaces should set and the air hardness that is appropriate. In most cases, cyanoacrylate adhesives usually heal within minutes, contrary to epoxies, which can take as long as several hours to manifest their efficiency characteristics. Ambient temperature and relative humidity need to be strictly maintained in the interests of precipitation.

Step 7: Test the Bond

Common Challenges and Troubleshooting

Bond Failure or Weak Adhesion

Cause: Impurities present on the surface (e.g. oil, dirt), use of an inappropriate adhesive, and cure time was not long enough.

Solution:It instructs those to whom it may concern to use a solvent to thoroughly clean the surfaces to enable bonding to occur. Select the right adhesive according to the given materials and process, and understand what the cure involves, including the requirements for the environment, such as temperature plus humidity.

Excess Adhesive Causing Messy Application

Cause: Putting much of the adhesion material or rather the absence of tools enabling precision of application.

Solution: When using adhesive work in tight spaces necessitating high accuracy, it is proper to apply adhesive only in the areas of intended use i.e. use glove syringes or precision applicators. Because excess spread adhesive will reduce the effectiveness of the bond.

Curing Delays

Cause: Low temperature, high humidity, or the absence of required activators.

Solution: Ensure the working environment meets the adhesive’s specified curing conditions. For certain adhesives, apply an accelerator to expedite curing.

Joint Failure Under Stress

Cause: Adherents are subjected to a lower stress than the joints can bear or joints lack engineering competence to withstand the stress.

Solution: Ascertain the resistance of the adhesive, and identify the alternatives if such resistance appears to be inadequate. Retune the form of the joint by increasing the area of adhesion and by introducing interlocks, for example.

Adhesive Degradation Over Time

Cause: Active agents cause deterioration of the adhesives under certain conditions — high temperature, UV, or specific aggressive media.

Solution: Select adhesives resistant to factors influencing their properties in the assembly itself. Use frost glues or cover laminates for UV applications.

Tips to Avoid Messy Applications

Professional Application Tips

- Use Proper Dispensing Equipment: Dispensing systems decrease the weight percent of the waste, resulting up to 30% in manual operating costs

- Control the Environment: Applicator should be directed at a clean, dry, and air-temperature environment

- Apply the Correct Amount: Have wasted guide bars, measure and store dispensing amounts effectively

- Prep Surfaces Properly: Over 50% adhesion failure can be prevented if the cleaning process does not comply to the recommendations.

- Allow Adequate Curing Time: Failure by adhesion loss will be more than 20% when applied than when properly cured.

Final Thoughts on Gluing PLA

Every single crafter, especially those in 3D printing, can attest to the fact that one of the most important exercises in the creative process is to possess a compatible adhesive that is able to bond rigid materials in appearance and structure, such as the polylactic acid (PLA). While in use, one is supposed to work on plastic industry-grade superglues – cyanoacrylate or epoxies to be precise, since they are bound to give an efficient adherent for PLA. It’s essential to lightly sand the surface before sticking so as to bond better. Minimizing the sunscreen in its adhesion to jot down the Adhesive seal, although in issue, does help with increasing the adhesive char. For maximum medical bonding, ensure core placement is clean amd no presence of dust or oil or any other residue. Furthermore, while the joining is setting, retaining nose bleeds, it should be facilitated as well. Extra caution must be taken to check everyone’s medical bond because, as well as the adhesive cure, any decrease of the subtler components in the adhesive would increase its tendency to degrade.

Recap of Best Practices

- Select appropriate adhesives (cyanoacrylate or epoxy for best results)

- Prepare surfaces by light sanding to enhance contact area

- Clean thoroughly to remove dust, oils, or debris

- Maintain consistent pressure during curing process

- Follow manufacturer guidelines for curing times and handling

- Test bonds under minimal stress before full application

Encouragement for Experimentation

As the pace of technology keeps changing, it becomes necessary to practice and improve the results as everyday pragmatic skills. For instance, there are tools and technologies that rely on the newest strategies, and hence they have to be tested and improved in response to the changing environment. By use of experiments that are well aligned and the right resources focused only on one affecting parameter, for example, heated to a temperature, the experiments are undertaken and appropriate solutions are identified for a particular application. Through this repeat of the same process, new ideas are created in the new building, and the practical factors that are active in it are perfected, as their ability to understand the concepts at work in new techniques and processes.

Resources for Further Learning

Professional Resources

- Peer-Reviewed Journals: Nature, ScienceDirect, IEEE Xplore for advanced methodologies and recent breakthroughs

- Technical Databases: European Space Agency Archives, PubMed, industry-specific portals

- Professional Organizations: American Society of Mechanical Engineers (ASME), Institute of Electrical and Electronics Engineers (IEEE)

- Government Research:

The study at the level of government is interesting. NASA’s Technical Research Server and the NIST data source are the examples.

Reference Studies

- “The studies on the production of polylactide’s paper adhesive” – Explored PLA as a component in paper adhesives, highlighting effectiveness in creating strong bonds in carton-glued joints

- “The Influence of Cardboard Dust on Structural, Morphological and Mechanical Properties of Biocomposite PLA and HDPE Filaments for 3D Printing” – Examined integration of cardboard dust into PLA filaments and gluing processes

- “On-chip fabrication and in-flow 3D-printing of cell-laden microgel constructs” – Involved PLA in fabricating 3D-printed encasings with specific mention of gluing PLA encasings with other materials

Frequently Asked Questions (FAQs)

Q: What is the best glue for PLA 3D printed parts?

A: The best glue for PLA 3D printed parts often depends on the application and the desired strength of the bond. Popular options include CA glue, super glue gel, and Loctite, which can create strong adhesive bonds. For a more flexible joint, wood glue or glue sticks may be appropriate. If you need a quick-setting solution, consider using Gorilla glue or Weld-On 16, which is excellent for bonding PLA pieces together. Always ensure that the surfaces are clean and dry before applying the adhesive for optimal results.

Q: How do I use acetone for gluing PLA pieces together?

A: Acetone is not effective for gluing PLA pieces together since PLA is not soluble in acetone like ABS. However, for some PLA blends, you might find that using a solvent welding method with MEK (Methyl Ethyl Ketone) can provide a strong bond. To use this method, apply a small amount of MEK to the surfaces of the PLA pieces you wish to bond, allowing it to soften slightly before pressing them together. This creates a glued joint as the materials fuse. Always work in a well-ventilated area and wear appropriate safety gear when handling solvents.

Q: What is a good way to glue PLA 3D prints?

A: A good way to glue PLA 3D prints is to use super glue or CA glue, which can bond quickly and effectively. For larger prints or those requiring more strength, consider using epoxy or a specialized adhesive designed for plastics. Ensure that the surfaces are flat and clean for the best adhesion. You can also use a glue joint technique where you apply the adhesive evenly across the surfaces before pressing them together firmly. The bond will harden as the glue sets, resulting in a strong connection between the pieces of plastic.

Q: Can I use wood glue for gluing PLA together?

A: Yes, wood glue can be used for gluing PLA together, especially when working on models that require a less rigid joint. While it may not be as strong as CA glue or epoxy, it can still provide sufficient adhesion for many applications. Wood glue tends to set quickly, making it a convenient option for PLA pieces. Just apply it evenly on the surfaces you wish to bond, align them properly, and clamp them if necessary until the glue has cured. Keep in mind that wood glue is best suited for indoor use and may not hold up well in wet conditions.

Q: How can I ensure that my PLA pieces are glued together securely?

A: To ensure your PLA pieces are glued together securely, start by selecting the right adhesive for your project. Clean the surfaces thoroughly to remove any dust or grease, as this can interfere with the bond. When applying the glue, make sure to cover the surfaces evenly without excessive amounts, which could weaken the joint. For stronger bonds, consider using techniques such as solvent welding with MEK for specific PLA blends. Allow sufficient curing time for the glue to harden fully before subjecting the bond to stress. Additionally, using clamps or weights can help maintain pressure while the adhesive sets, promoting a better bond.