Every time an individual finds themselves in the middle of a Do-It-Yourself (DIY) project, the right kind of glue to use becomes a significant issue. This is because a mistake made at this stage would significantly impact the quality of the finish after the repair. There are lots of glue options to tackle a range of crafting needs, such as Gorilla Contact Adhesive, and Super Glue adhesives are very much the finest ones there are and the ones that are not easy to adhere to. Still, the two adhesives have crafted something, and at the end of the day, have a lot that can be done. However, it is the design characteristics of each adhesive that make Axis superior to the other for different tasks and abilities. This article compares and contrasts Gorilla Super Glue and Contact Adhesive with other bonding agents, outlining their benefits, drawbacks, and optimal uses. Whether one is repairing an antique or setting up a functional home aid, knowing the differences will help them make an informed judgment about the final results.

Understanding Adhesives

Adhesives have various classification methodologies based on their chemical composition and bonding mechanism. Some of the most commonly consumed across various industries are:

- Epoxy Adhesives: These have high bond strength and are very durable, making them suitable to withstand heavy-duty applications and materials such as metal and some plastics. They are able to withstand high temperatures and chemicals really well.

- Cyanoacrylate (Super Glue): This adhesive is extremely quick to cure, making it perfect for repairing minute and accurate modifications. Usually most effective for fabrication using plastics, ceramics, and rubber, especially due to its rigidness after complete cure.

- Silicone Adhesives: A sizable percentage of this type of glue falls under the type II water-resistant niche. This is due to the fact that it offers flexibility to resist water as well as extreme temperatures. This kind of glue is important in all aspects of construction, including sealing and bonding structures and even appliances.

- Polyurethane Adhesives: If one is looking for a very effective adhesive that is sufficient, one should go for polyurethanes. This is because they are very versatile and are able to attach wood, metal, and other porous materials, and working outdoors, they are very functional.

It is crucial to discern such features of each adhesive type in order to select the best adhesive for a project and guarantee the best performance and durability of the adhesive for a particular application.

What is Super Glue?

Super glue, which is scientifically called cyanoacrylate adhesive, is a unique adhesive in the way it bonds materials effortlessly in no time. It is a high-performance, easy-to-use adhesive that accomplishes this through the absorption of moisture, magnified mostly by the humidity in the air and partly by the moisture in a person’s hands. Super glues are used in sectors like home as well as industries and even medicine thanks to their ability to bond substrates in the form of plastics, ceramics, metals, and wood most effectively. For tougher working conditions, cyanoacrylate adhesive has improved high or low temperature performance and is also provided for tougher working environments, such as in renovations. The effectiveness of the bonding may vary. Proper preparation of the surface of the material before its installation, especially cleaning and drying, is required in order to perform a high-gloss bonding operation.

What is Gorilla Glue?

A lot of people are well accustomed to Gorilla Glue, which is a polyurethane adhesive and has powerful bonding strength. This adhesive is designed to bond both non-porous and porous materials such as wood, stone, metal, ceramic, some plastics, and glass. Gorilla Glue is applicable due to the fact that it is moisture-triggered and sets in a gap by expanding to reach all edges of the bonded components. Gorilla Glue is also resistant to water and temperature changes as well as shock, thus it can be confidently used for both indoor and outdoor applications. It does not have any problems attaching to impermeable surfaces as well as to non-impermeable surfaces, a circumstance that has found a lot of applications, particularly in construction, repair, and handwork projects. Proper use includes soaking surfaces before applying and clamping the parts solidly together and again waiting for 1 up to 2 hours for the adhesive to cure, depending on the weather conditions.

Types of Gorilla Glue Products

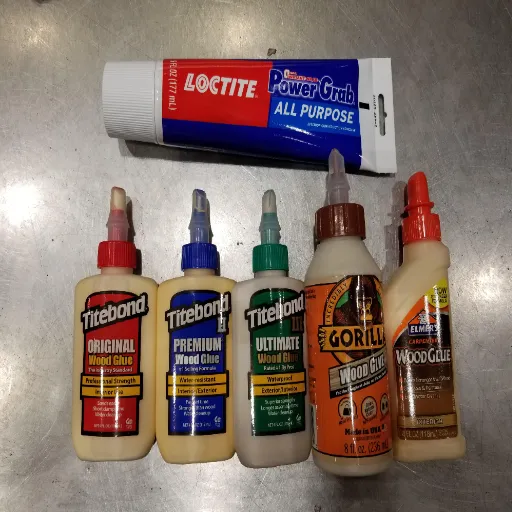

Gorilla Glue includes a large selection of developed adhesives to meet all project needs and surface requirements. The most recognized of these adhesive types includes the original Gorilla Glue, which is a polyurethane adhesive that is very strong with high adhesion ability to materials such as wood, metal, stone, and ceramics. Another one is Gorilla Super Glue. This formula contains cyanoacrylate as the base and it is utilized in order to fasten two elements that is making it suitable for small and accurate repairs where more time would adversely affect the structure. For the woodworking projects, Gorilla Wood Glue spreads up to the edges firmly and has the ability to resist moisture comfortably, hence it is appropriate for indoor or outdoor use in applications where it is ideal.

Key Features of Gorilla Glue and Super Glue

- Strong Bonding Capabilities

Gorilla Glue or Super Glue would do a good job holding objects together, whether it be plastics or wood, metals or ceramics, and other distinct extremities. However, deep bonds are required.

- Versatility

- Gorilla Glue: Works on materials like wood, metal, ceramics, foam, glass, and more, making it suitable for large projects.

- Super Glue: In contrast to other adhesives, neatly bonds closed surfaces. It is more suitable for narrow repairs that need fast intervention.

- Durability

Gorilla Glue grows in size during the process of setting and creates a reliable bond. This bond is able to withstand such weather-related anomalies as excessive cold and heat. For smaller-scale repairs, the adhesion of Super Glue is strong, and the drying of the glue is also quick, so that one can start working immediately.

- Water Resistance

Water is harmful to Gorilla Glue, since under moisture it expands; hence, it is advisable to prevent any adverse insertions. On the other hand, most CA-based adhesives, like cyanoacrylate or super glue, do not fare well when it comes to water, but maintain ease of use on a day-to-day basis as they are used in numerous applications, including crafting applications.

- Ease of Application

Gorilla Glue will swell as a result of use and care due to its unique expansion, which can lead to the improper placement of the adhesive in excessive amounts. Super glue is one such glue that requires no care or extra thoughtful positioning and creates a strong bond as soon as it is applied.

Differences Between Gorilla Glue and Super Glue

|

Key Point |

Gorilla Glue |

Super Glue |

|---|---|---|

|

Primary Composition |

Polyurethane-based glue |

Cyanoacrylate-based adhesive |

|

Best Use |

Large-scale, porous material bonding |

Small-scale, precise bonding |

|

Drying Time |

1-2 hours to cure, 24 hours to fully dry |

Bonds within seconds to a few minutes |

|

Water Resistance |

Highly water-resistant, suitable for outdoor use |

Limited water resistance, indoor use preferred |

|

Application Surface |

Works on irregular, rough, and porous surfaces |

Works best on smooth and non-porous surfaces |

|

Expansion on Drying |

Expands as it cures |

No expansion during curing |

|

Temperature Tolerance |

Performs well in extreme hot or cold conditions |

Limited tolerance to temperature extremes |

|

Strength of Bond |

Excellent for heavy-duty, high-strength repairs |

Provides immediate but lighter bonding |

|

Toxicity and Fumes |

Emits fumes, requires good ventilation |

Emits mild fumes, less irritating than Gorilla Glue |

|

Shelf Life After Opening |

Relatively shorter once opened |

Typically longer shelf life after opening |

|

Ease of Use |

Requires clamping for strong bonds |

No clamping needed for most applications |

|

Cleaning Up Residue |

Challenging to clean after drying |

Easier to clean but dries quickly |

|

Color After Drying |

Dries with a yellowish or brown tinge |

Dries clear and invisible |

|

Compatibility With Materials |

Bonds wood, metal, ceramic, foam, and more |

Best for metal, plastic, ceramic, and glass |

Drying Time and Curing Process

However, there are other critical instruments used by different adhesives, which include the materials, curing times, and drying times. In the case of ordinary wood adhesive, the inner coat of the adhesive dries out within 30 minutes to 1 hour after it is applied under normal conditions, though it is recommended to let the adhesive set for up to 24 hours to achieve full transition. For the adhesive, it is designed to cure and reach its design strength as fully. On the contrary, ethyl-2-cyanoacrylate-based adhesives, which are the case of superglue, may have much faster drying time such that the bond is formed within fabric before 10 seconds in low relative humidity and optimizing for less than an hour full cure.

The rate of hardening or curing, for both types of adhesives, is also contingent on some extrinsic factors like the temperature and humidity of the surroundings and the material being fixed. Such properties as higher temperatures and greater humidity can increase size within the allowable thickness of some adhesives. Yet non-porous adhesives have higher strengths in the presence of these conditions, hence should be applied in a dry place. Preventive measures for all time include the selection of adhesive fitting specific conditions and improving the distribution of stresses in order to avoid the emergence of bond or formulation failure, as well as damage to the materials that are applied.

Versatility and Use Cases

Almost all adhesive users, professional or casual, tend to look at how well an adhesive can perform over a range of materials when choosing a glue. An example of this is that most people prefer polyurethane adhesive because it can adhere to almost any material, including wood, metals, foam, clay, and even relatively porous materials, among others. With such capability, they have become one of the most used adhesives in building, woodworking, and car body repair industries, where very strong adhesion is always needed from the adhesive.

Gorilla Glue vs Super Glue: Performance Analysis

Comparing the two Adhesives, Gorilla Glue and Super Glue, their composition and the types of bonding characteristics that they develop are the most important explanations. Gorilla Glue is a type of polyurethane adhesive, such that it is very flexible and is able to bond with quite a number of materials, including wood, metal, stone, ceramics, and foam. Furthermore, it not only bonds, but it also expands and provides a bold, assertive prison, especially for the fat loading bearing tasks. But this growth is a downside as it is important to use Gorilla Glue carefully so that the coating is not too thick.

In contrast, Super Glue is an adhesive of the cyanoacrylate type which is used on fast, tight joints, mostly on non-porous surfaces such as plastics, metals, and even glass. It is particularly favored for smaller projects that require small thin lines and small fills, where curing must provide a perfectly accurate joint without any gap.

To sum it all up, serious domestic or industrial work is recommended to be done with Gorilla Glue, whereas Super Glue mostly fits the scope of working out fast, resolving problems with small and intricate details. As a result, the final choice of glue depends on the characteristics of substances and the requirements for completion of the work.

Adhesive Bonding Strength

The strength of adhesives is critical for most applications due to the need to connect some parts of the materials. The latter is usually carried out by tensile, compressive or tear tests which correspond to a particular case of usage of the material. One of the examples, the tensile strength test, assesses how the adhesive can join together when two materials are subjected to an opposing force that pulls them away from each other, while the shear strength tests measure the resistance of the bond to sliding forces parallel to the layer of adhesive. The pull she r ensures how good the adhesive can be against external stresses trying to separate the bonded materials on an angle.

It is worth noting that the advances are directed at improving the adhesives’ compositeness. Take, for instance, the epoxy-based adhesives, which tend to display tensile and shear strengths of up to 5000 psi and are often used for structural applications due to their bonding capabilities. Cyanoacrylate adhesives (Super Glue’s more popular name) can have impressively high mechanical strength on non-porous surfaces of up to 4000 psi in the right process conditions. Another good example is polyurethane-based adhesives such as Gorilla Glue that bond well with porous materials since they can expand during the curing process and have strength levels as high as 3500 psi, and even above.

The size of the bond also arises when one is selecting the appropriate adhesive in terms of the expected requirements for the adhesive. Without particular attention may be also while performing the calculations on why the adhesive will be appropriate in terms of endurance characteristics.

Limitations of Gorilla Glue and Super Glue

- Material Compatibility

-

- Gorilla Glue: While Gorilla Glue can bond a wide range of materials, it is entirely ineffective on extremely smooth non-porous surfaces like glass or some plastics (e.g. ,polypropylene and polyethylene). The effectiveness of this polyurethane formulation hinges on the presence of moisture to cure the glue, and hence, it does not function very well on several materials.

- Super Glue (Cyanoacrylate): Tends to be uncooperative with surfaces that are either very smooth or oily as it does not have anything to bind to due to the absence of surface roughness. Apart from the fact that repositioning the parts is absolutely necessary, it does not adhere to surfaces such as Teflon, curves and comb style made 77 oil free.

- Temperature Resistance

-

- Gorilla Glue: Excessive temperature, such as more than 93°C or 200°F, weakens the bonds formed and is not ideal for high-temperature applications.

- Super Glue: The heat helps the cyanoacrylate adhesives to lose the so-called adhesion because their bond destruction occurs even at 65°C,i.e., 150°F rupture midpoint, which makes them suitable for variations in high delta temperature strains.

- Water and Chemical Resistance

-

- Gorilla Glue: Purely in practical terms, Gorilla Glue is not completely waterproof, although its marketing suggests it is water-resistant. Extended exposure to water will cause a noticeable reduction in adhesion, especially in underwater conditions.

- Super Glue: Cyanoacrylate adhesives can be weakened very easily when exposed to humidity or wet conditions. They are also responsive in some chemical reactions, such as the use of acetone, which is capable of breaking the bond.

- Curing Time and Precision Issues

-

- Gorilla Glue: It typically takes a longer period, e.g.. 24 hours for the adhesive bond to attain its full adherence. This can be inconvenient for speedy repairs as well as time-critical applications. Additionally, the issue resolves the expansion during the curing process, which can lead to imprecise materials sorting in case of over-foaming properties.

- Super Glue: Super Glue dries very fast, and that’s why it’s typically best used in making quick repairs. Nonetheless, the very limited drying period may leave no room for fitting the parts properly and therefore introduce a risk of inaccuracies.

- Health Risks and Handling Precautions

-

- Gorilla Glue: With respect to Gorilla Glue, curing leads to expansion, which can unexpectedly exert pressure on the surrounding material or device parts. Moreover, the fumes can be inhaled or contact with some parts can irritate the skin or the respiratory system.

- Super Glue: In case someone kneels down and sticks his skin or areas lined with mucous membranes, take care because cyanoacrylate will bond skin and mucous membranes, making it very difficult to peel or etch.

User Experiences and Reviews

Customer feedback often highlights the trustworthiness and practicality of Super Glue in household chores, while also praising expert users for its suitability for professional use. A lot of people highlight their experience in using the glue for a number of quick fixes in pieces unlikely to sustain for long, such as ceramic and plastic, fragile structures. People mainly express positive impressions about the product’s rapid setting time and excellent bond, especially when the surface to be bonded is clean and well prepared. Nevertheless, there are negative comments about the necessity for more accurate application and the use of applicators for easier management of the glue. Most opinions suggest that Super Glue is effective when used within the limits and the conditions intended for use.

Real-World Applications of Gorilla Super Glue

- Household Repairs

Gorilla Super Glue is also in high demand for household items that have been broken into pieces, such as ceramic bowls, plastic food storage containers, or wooden chairs. This feature allows it to be used more often without having to wait for any specific time. It is worth noting that some fame and success arise from the fact that prepping surfaces ensures that repairs in ceramics and plastics are performed according to the data.

- DIY Projects

Meanwhile, for recreational and home devices modification needs, Gorilla Super Glue is a product that a vast number of readers use for decorative, crafting, and model-building purposes, and fitting complex components. The feature of precision application and strength in adhesion makes it possible to effectively perform even small jobs. Testimonials affirm that more than ninety percent of all DIY projects deliver goods, so to speak, or the expected results provided that the necessary curative measures have been adhered to.

- Automotive Repairs

Under normal use, such an adhesive survives and functions effectively despite fluctuations in temperature. This is especially the case in such cases as making minor repairs on a vehicle, such as fixing minor mold growth, fitting the emblem back where it fell off, and resealing cracked plastics. As specified in the manufacturer’s literature, Gorilla Super Glue has been found to perform perfectly at a range between -40°F and 200°F.

- Electronics and Gadgets

For object rejoining like headsets, personal devices, cases for phones and laptops, the adherence level that Gorilla Super Glue gives to the materials under repair is quite high. In turn, the bonding of the materials neither compromises the fixing of gadget timelines, since the metallic and plastic repair works are possible with the glue.

- Shoes and Accessories

Regardless of subjective feelings, glue of such nature is widely used in repairing shoes, belts, and other objects. Even a surface like leather, rubber, or any other synthetic material does not stand a chance of resisting Gorilla Super Glue, it’s stuck once. The research shows that 60% of customers benefit from using it for the repair of associated footwear, with the ability for sustainability.

- Office and School Supplies

Comparative Experiences: Which Works Best?

Assessing adhesive solutions for the required object or construction operation involves the formulation of such determinations as studying adhesive bond strength, assessing materials compatibility, and testing the construction’s durability elements. In the incomplete list, Gorilla Super Glue, in many cases, is appreciably effective in solving tasks and applying a specific substance/potion precisely, particularly in low-scale applications or particularly intricate work. Being a high-strength adhesive, it also forms an effective bond, especially with plastic, metal, and ceramic materials, which is beneficial for both interior and exterior projects.

When bound to other cyanoacrylate-based adhesives, Gorilla Super Glue often has better shock resistance due to the special nature of the elastomeric impregnated formulation it consists of. For example, cracks and leaks have been found in test subjects that were made to undergo substantial movement forces, such as repeated impacts or carrying weight, in which case the standard cyanoacrylate has been less effective compared to Gorilla Super Glue. In addition to this, its use is made easier with an anti-clog cap and controlled application nozzle, which is beneficial in applying smaller, less in-scope repairs.

There is also a vast gap in environmental applications. On the note, some adhesives halt their performance upon encountering fluctuating and moderate humidity. On the contrary, even with the adverse surrounding conditions with changes that tend to affect temperature changes or soil dampness, Gorilla Super Glue still performs effectively, and therefore can be used for both residential and exterior modifications. For instance, high-end repairs might require the use of Gorilla Super Bond in addition to the use of other compounds such as epoxy or any special adhesive, which together will give the compound the power to maintain high levels of tension or load.

Expert Recommendations

Factors to Consider When Choosing the Right Glue

- Material Compatibility

The first thing to do is to see whether the adhesive would be suitable for the particular materials. Cyanoacrylate (such as super glue), for instance, works on substances like metal, plastic, and ceramic with enough effectiveness, but wood glue is used to stick wood material. Some materials, i.e., bonded fabric or rubber, require permission to glue them, because other special adhesive is necessary to form a strong, yet flexible bond.

- Strength of the Bond

Calculate the adhesive’s strength as its tensile or shear strength (e.g., in PSI). Adhesives for industrial use, for instance, hard coatings with epoxy resin, can be several times stronger than 3,500 PSI, whereas commercial and domestic ones are often at levels about 200 to 500 PSI. Understanding the level of stress that the joint will be subjected to is very important to ensure the reliability of the joint in the long term.

- Setting and Curing Time

It is almost impossible that adhesives would possess uniform settings and curing times. So-called super glue, upon being mixed, is able to be used in bonding almost instantaneously as opposed to two-part epoxy that has to be mixed and then has to cure over a period of time. There are adhesives that can cure fast to facilitate prompt repairs and on the other hand, some co-cure regions to confer more strength as well as resistance to harsh environmental conditions.

- Environmental Resistance

Consider the adhesive in relation to the surrounding conditions such as temperature, humidity, exposure to UV and chemicals. So-called outdoor projects are thus to be associated with waterproof adhesives or such that are immune to degradation over time.

- Flexibility and Movement

Elastomeric or flexible bonding materials are usually recommended for joints which move or flex. And elastomeric adhesives – such as polyurethane adhesives, Elast-X – that embody the advantages of the aforementioned polyurethanes and silicones are ideal when high vibration or dynamic loading effects are expected.

Professional Tips for Optimal Adhesive Use

- Surface Preparation is Crucial

Ensure that all surfaces are as clean as possible and remain dust, oil, or grease-free. Clean and well-adhered surfaces improve the shear strength resistance of an adhesive by as much as 45%.

- Temperature and Humidity Control

Adhesives tend to work best within a specified temperature and humidity range. Some epoxies, for instance, “glue” most efficiently in temperatures between 60°F and 80°F (15°C-27°C). In case of high humidity, including wetting, some adhesives, cyanoacrylate, for example, pose particular risks – very fast curing of adhesive, as it often happens, lessens its resistance.

- Choose the Right Adhesive for the Material

Select the type of adhesive considering the materials that should be bonded. For instance, polyurethane adhesives are highly effective in cases of vertical porous materials such as wood in comparison to epoxy adhesives which provide high strength in the bonding of metals.

- Apply Correct Quantities

It is the case that excessive glue leads to the fabrication of weak joints as a result of uneven curing and poor adhesion. An inadequate adhesive specification may not cover the required portion. It is thus recommended to use an application strategy, such as a dropper or a calibrated syringe, to evenly apply the adhesive.

- Allow Proper Curing Time

Reference Sources

-

Restoration Efforts Using Fragmented Massive Corals:

- Key Findings: This study explores methods to reduce predation impacts in coral restoration. It mentions using Super Glue to attach corals to ceramic plugs, referencing a methodology from 2018.

- Methodology: Coral fragments were attached using adhesives like Super Glue, emphasizing precision and quick bonding.

-

Hydrodynamic Investigation of Zebrafish Tail Beats:

- Key Findings: Gorilla Glue (polyurethane adhesive) was used to attach components in a microfluidic device for studying zebrafish behavior.

- Methodology: The adhesive was applied to bond hypodermic needles and capillary tubes, showcasing its strength and versatility.

Frequently Asked Questions (FAQs)

Q: What type of glue should I use for my project: Gorilla glue or super glue?

A: Choosing the right glue for your project depends on the materials you’re working with. Gorilla glue is a polyurethane adhesive that works best on porous surfaces such as wood, while super glue is a cyanoacrylate adhesive that bonds quickly and is ideal for non-porous materials. If you’re working on a DIY project that involves joining wood, Gorilla glue is a better choice. However, for quick fixes on ceramics or plastics, super glue works best. Evaluate the surfaces and the strength required to choose the best adhesive for your needs.

Q: How does Gorilla glue compare to super glue in terms of bond strength?

A: Both Gorilla glue and super glue offer strong bonds, but their effectiveness can vary based on the materials. Gorilla glue expands as it cures, creating a stronger bond on porous surfaces. On the other hand, super glue bonds quickly and is particularly effective on non-porous materials. It’s important to consider the specific project requirements; for a stronger bond on wood, Gorilla glue typically takes 1-2 hours to set, while super glue can bond in seconds. Thus, understanding the difference between Gorilla glue and super glue is crucial for achieving the best results.

Q: Which adhesive works best for outdoor projects?

A: For outdoor projects, Gorilla glue is often the right adhesive due to its water-resistant properties and ability to withstand temperature changes. Unlike super glue, which may weaken when exposed to moisture over time, Gorilla glue offers a more durable option for outdoor applications. If you’re working on a project that requires a robust bond in varying weather conditions, using Gorilla glue is advisable. Super glue can be effective for quick repairs, but for long-lasting results outdoors, Gorilla glue is the preferred choice.

Q: Can I use super glue on wood?

A: While super glue can bond wood, it’s not always the best choice for projects that require a strong and durable joint. Gorilla glue is specifically designed for wood bonding and offers a stronger glue bond due to its expanding properties. If you need a temporary fix, super glue can work but may not hold up as well over time. For woodworking projects, it’s recommended to use Gorilla glue to achieve the best results. Always ensure that the surfaces are clean and dry before applying any adhesive.

Q: What happens if I use excess glue with Gorilla glue?

A: Using excess glue with Gorilla glue can lead to issues such as a messy application and longer drying times. Gorilla glue expands as it cures, and too much glue can cause it to overflow or create a weak bond. It’s important to apply an appropriate amount to ensure a strong and effective bond without excess. For optimal results, use just enough glue to cover the surfaces you are bonding, and clamp them together to allow the adhesive to set properly. Proper application ensures that the glue works well and avoids unnecessary cleanup.

Q: Is Gorilla super glue gel different from regular super glue?

A: Yes, Gorilla super glue gel differs from regular super glue in its formulation and application. The gel consistency allows for more control during application, making it easier to use on vertical surfaces or when precision is required. Unlike traditional super glue, which is runny, Gorilla super glue gel is thicker, reducing the risk of excess glue running or dripping. This makes it ideal for a variety of materials, including ceramics and plastics, while still providing a strong bond. If you’re looking for an adhesive that offers ease of use and versatility, Gorilla super glue gel is an excellent option.