The Consumer’s Manual for Choosing Adhesives for Do It Yourself Projects is Huge in the Evaluation of such Fine Glue Products as Gorilla Super Glue and Gorilla Glue, the Balance Striker. Both of these adhesives are great in that they are strong, reliable and user-friendly. However, it is important to understand what sets them apart for the effective consummation of the project. Gluing is a vital step even when it comes to simple arts and crafts, be it with chipboard or balsa wood. If the right glue is not used, the material may not be able to withstand its much needed appropriate strength or, however, the performance of the structure itself shall be below the minimal standards. The nice thing regarding this review is that we will focus on the features, qualities and differences of the Gorilla Glue and Gorilla Superglue, and clarify what kind of glue is most suitable in each particular case.

What is the Gorilla Glue?

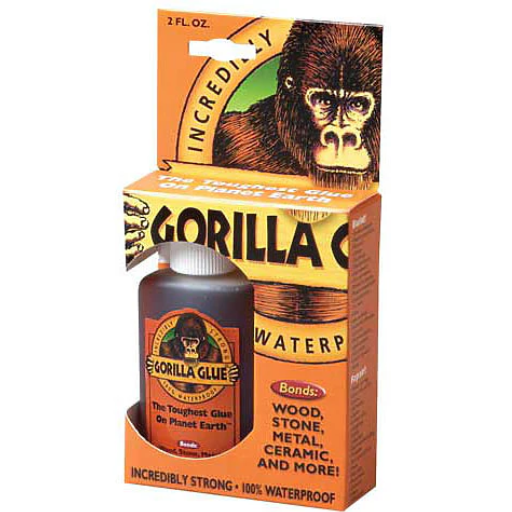

Gorilla Glue, on the other hand, is a polyurethane-based adhesive. It is able to produce strong bonds that are unbeatable by any other type of glue. Ever since it was first introduced to the market. It can be used for repair or connection of various materials, including but not limited to wood, stone, metal, ceramic, foams, etc, without failure. It is also a type of glue that is known to possess the properties of resisting water and weather as it cures and expands, thus filling and providing a closed hold even where it is extremely dry or wet. This in general will allow it to work for indoor and outdoor uses quite effectively which makes it the preferred option for essentially any repair or construction need.

Understanding the Type of Glue

Gorilla glue and all polyurethane-based adhesives in general are perceived to be a valuable asset due to the strength, versatile potential, and good bonding abilities they come equipped with. Being polymers, these adhesives cure through the activity of their water-based macromolecules, depositing on the adhesive surface, which causes polymer growth till pockets are filled and the adhesive turns very hard. While combining these adhesives with these other waterborne macromolecules, it is possible to direct these glues even less disruptive in feel, ins and fillers that perform essential functions in the bonding process. As regadius glue must be non-hydro-regulus, as is typical of all cyanoacrylate esters; this requires curing with a drying or curing agent, generally this is a light-controlled cure. In addition, they adhere to wood, concrete, metal, foam-filled, wood, and metal, also known as mega bond construction materials. Moreover, service appropriateness may vary according to attack rates, load, and environment; hence, modifications are made in relation to structural reinforcement so that masonry behaves satisfactorily under various conditions of usage.

How Gorilla Glue Works?

One of the most fundamental properties that distinguishes Gorilla glue is its unique polyurethane formula, which, when exposed to moisture, causes chemical reactions and the subsequent development of a structure called a polymer. Due to this specific process, as the adhesive bonds cure, there is penetration in the pores of the material to increase the bond strength. The addition of the adhesive is also aided by the fact that it is hydrophilic; hence it reacts with the moisture and also initiates the creation of the foam for increasing the bonding.

This glue in a sealed package straight out of the shelf has a shelf life of fewer than two years. After application, and under ideal conditions, the curing process can last for 24 hours, and this also is dependent on factors such as humidity as well as temperature. Before 24 hours are up, the bond acquires complete strength in such cases making failure of the structure unlikely. A great deal of encasement ensures that the mechanical features of Gorilla glue make it practically immune to environmental impacts such as fluctuations in temperatures, strikes of chemical reagents or mechanical movements that occur. This allows for its longevity in many applications, from construction to delicate repair work.

Common Uses for Gorilla Glue

What is the Gorilla Super Glue?

The Gorilla Super Glue is designed to offer efficient bonding within a very short time. It adopts cyanoacrylate as the adhesive, which enhances its strength and also has a quick set. Generally, intended for small crafts and repairs, the Gorilla Super Glue can bond a metal piece, a wooden board, a ceramic vase, A4 papers, plastic glasses, and many other things. The no-run gel form allows the adhesive to be used on vertical surfaces without it flowing off and provides for a high level of convenience and control during application. It is important to observe that much as this is an adhesive of choice to be used indoors, it can withstand impacts and abrasion quite well.

Properties of Gorilla Super Glue

- Quick Drying Time

Gorilla Super Glue is equipped with an advanced cyanoacrylate formula. Its specific amount of time in which it is completely dry ranges between 10-45 seconds. It is worth mentioning that because of this property there is no need in clamping, which can finally complete the project faster.

- Multi-Material Bonding

Moreover, the adhesive is particularly multipurpose as it bonds many materials easily, for example metal, wood, ceramic, paper, rubber, leather, or most plastic kitchen items. However, it does not bond well to polyethylene nor polypropylene plastics.

- No-Run Formula

The gel form of Gorilla Super Glue is non-dripping which is of big help when fixing objects upside down whereas it also allows an accurate application in hard-to-reach locations. Also, it consists in putting and tightening of components.

- Impact Resistance

In summary, Gorilla Super Glue is a type of glue designed to guarantee perfect results. This is because of its amazing shock-resisting features, which help create bonds that can withstand considerable impacts. Its high-aspect ratio limits ensure that it does not fall short in virtually any challenging situation.

- Temperature and Moisture Resistance

Once Gorilla Super Glue has set, it most certainly dries in a broad temperature range which is typically within -65°F to 180°F (-54°C to 82°C). Moreover, the product does not swell significantly when there is some moisture exposure, thus making it very useful for non-extreme conditions such as glued indoors.

- Shelf Life

Gorilla Super Glue has been desinged for storage up to twelve months any any cool and dark place once has been opened. It remains usabled for twelve months when properly enlosed no after having been opened.

Best Applications for Gorilla Super Glue

- Wood Repairs

Gorilla Super Glue has been tested and proven to function effectively when used in wood-to-wood bonds. Its ease of use, combined with its ability to dry in less than a minute, now adversely affects dismantling restored furniture, mending damaged wooden articles, or dealing with some thin cracks on wooden surfaces. Its quick drying regime eliminates unnecessary clamping, making it highly effective for indoor wooden structure finishes.

- Plastic Bonding

This adhesive is chemically compatible with many plastics, including polystyrene, PVC, and polycarbonate. It creates such hardy bonds that when their tensile strength is fully attained, it goes to 2,600 PSI or more allowing it to withstand any stresses in normal activities. For application note or caution, or indeed, one must understand that it would not be effective for substance like polyethylene (PE) or polypropylene (PP).

- Metal Joining

Gorilla Super Glue was formulated to exclusively for metallic surfaces like aluminum, steel, and brass and possesses promising characteristics for yielding a strong and permanent adhesive bond. The composition of Gorilla Super Glue, which is based on a cyanoacrylate adhesive, is suited for repairing tools, fixing metal decorations, repairing metal-made goods and joints, breaking any metal-made equipment, and so on, in the opinion of users. Based on the results of the laboratory tests the peel adhesion to steel according to the lap-shear measurements can be considered as up to 2900+PSI for the proper thickness of the bond line creation.

- Ceramic and Porcelain Repairs

While using this type of concrete adhesive allows people to repair damage done to fragile objects like porcelains, ceramic wares, and chinaware. It creates a very good bond between two pieces that have been broken as long as one does not let excess adhesive sit because then a clean repair line is maintained. There will be no softening of the repair even during occasional exposure to moisture, thanks to its water—resistant design.

- Rubber Sealing

Flexibility of this glue makes it perfect for adhesion of rubber based components such as gaskets, o-rings and shoes. Gorilla Super Glue is very effective in terms of creation of joints that are not-fragile, and resist destruction while under both tensile and compressive load.

How Do Gorilla Glue and Gorilla Super Glue Compare?

Gorilla Glue and Gorilla Super Glue fulfill different functions because they have different constituent materials and adhesive properties. Gorilla Glue is a polyurethane adhesive which is known for its ability to expand after curing, thus suitable for bonding porous materials such as wood, foam, fabric among others. This has made it also be used in areas like building and construction to bond items that will at any one be exposed to the elements.

Then it comes to Gorilla Super Glue, cyanoacrylate adhesive offers a rapid bond, particularly in nonporous surfaces like metals, porcelain, and plastic. This adhesive is such that it can be simply applied to the broken pieces; it dries fast, and there’s absolutely no need for clamping, but it is not a fit for loose bonds similar to those filled with Gorilla Glue.

It is up to those participating in the project to decide which one to use. Thus individuals will use Gorilla Glue to handle activities that will have it being used for creating more robust stronger longer lasting bonds and in the case of Gorilla Super Glue, it could be more suited to small patch work on top of smooth surfaces.

Gorilla Glue vs Gorilla Super Glue: Key Differences

|

Key Point |

Gorilla Glue |

Gorilla Super Glue |

|---|---|---|

|

Primary Use |

Heavy-duty bonding |

Precision repairs |

|

Material Compatibility |

Wood, stone, metal, ceramics, more |

Metal, ceramics, some plastics |

|

Bond Strength |

Very strong, durable |

Strong, but less than Gorilla Glue |

|

Drying Time |

Takes 1-2 hours to dry |

Dries in 10-45 seconds |

|

Full Cure Time |

24 hours |

Within minutes |

|

Water Resistance |

Fully waterproof |

Water-resistant, not waterproof |

|

Gap-filling Ability |

Excellent, expands as it cures |

Minimal, not suitable for gaps |

|

Temperature Resistance |

High heat resistance |

Moderate heat resistance |

|

Clamping Requirements |

Requires clamping pressure |

Minimal or no clamping needed |

|

Shelf Life |

Long, with proper storage |

Shorter, prone to drying out |

|

Packaging |

Available in larger quantities |

Small tubes for precise applications |

|

Cleanup Ease |

Can be challenging, requires solvents |

Easier, less messy |

Which is Better for Your Project?

Determining the ideal adhesive for your current task is an important factor. If you are embarking on applications that require a high-strength bond that can sustain high stress or heat, usually the best choice is epoxy adhesives. Hence the reason why they are used in certain aspects of industry such as the construction of machines, cars and other structures as well as the making of heavy industrial repairs, including engine blocks.

On the other hand, if the focus is on ease of application, quick setting times and conformability, a classification of cyanoacrylate adhesives as referred to as “super glue” for example, could be suitable. Such adhesives are most efficient at the bonding of smaller parts, specifically in scenarios in which clamping is minimal and quick curing times are required such as in art, domestic minor repairs and the making of electronic devices. Nevertheless, in conditions with high temperature or if there is significant vibration, it is highly unlikely that they will take much wear over wear and tear.

Choosing the Right Glue for Your Projects

Ascertain the products to be bonded — the initial step in product selection. For example, PVA (Polyvinyl Acetate) Glue is often encouraged as a Clear Glue for Most Wood Fabrics and other Porous Instances. Non-porous surfaces such as plastics will therefore require cyanoacrylate adhesives (countless has fast adhesive strength. Epoxy resin is recommended for metals and other materials that are exposed to extreme conditions like heat and chemicals. Keep in mind that you may want to pick glues that can be used with the proposed materials, and also ensure that the working temperature and humidity are within the limits stated by the manufacturer, and do not harm the glue in any way, so that it can perform perfectly.

When to Use Gorilla Super Glue?

Gorilla Super Glue has proven to be one of the best solutions when it comes to bonding which is strong, tough and quick to dissolve. GSG shows up as an excellent option for sticking wooden items as well as metal, ceramic, plastic, and rubber objects among other popular use elements, thus being indispensable in any repair service including household and crafts. The second generation is completely formulated for tasks where the glued fragments of an object (with or without the glue) must resist high shear loads and water splash due to its low-impact properties. Its adhesive is of particular use in general industrial applications and repair of moldings in particular when there are many small parts to put into place and then secure. With no need for clamping, most of these specialized issues are have gone away as one can make it possible in 10-45 seconds by adding a well-directed adhesive amount on the surfaces affected. Equally, the anti-clog cap found in the bottle allows for the continuous application of the glue who prolongs the use of the differentiation between two or three uses. Make sure the surfaces are free of oil and grease prior to applying the adhesive to ensure maximum strength of the bond.

Understanding Adhesive Types for Different Surfaces

To choose a particular adhesive, it is necessary to take into account the requirements of the material and the use for which it is intended. For example, cyanoacrylate adhesives (i.e. superglues) tend to adhere to non-porous surfaces, such as steel, glass, and ceramics, quite well indeed, due to their readiness to cure quickly in the presence of moisture. But epoxies are fitting for such applications where high strength and environmental stress are needed. That is why they are mostly used to join metals and plastics and composites—ideal for structural repairs.

For porous materials such as wood and cloth, Polyvinyl Acetate (PVA) glues are the most common choice. PVA glues penetrate through the medium as they cure, thereby forming an excellent and formidable bond. There is a growing trend for using very-low-modulus, viscoelastic structural adhesives in the current manufacturing processes as these materials are able to physically and chemically absorb some of the strain in the structure. Such construction adhesives, which are usually comprised of polyurethane or silicone for softer bonding capabilities, can be used both for indoor and outdoor applications because they hold on extremely well to non-flat bricks, stones and concrete walls/plane surfaces, while at the same time permitting an amount of bonding and water adhesion in the subsurface which is between the lacrosse and soccer helmets.

Tips for Using Gorilla Glue and Gorilla Super Glue

- Apply Sparingly

When applying Gorilla Glue, it should be noted that it is best to use a small amount on one surface, because the glue swells upon curing. Gorilla Super Glue is considered non-expanding, so a thin line will be fine in most cases.

- Moisture Activation (Gorilla Glue Only)

Any Gorilla Glue is specifically manufactured so that water needs to get into the mix to make the glue effective. Need to wet one side before bonding.

- Clamp or Hold in Place

Both glues make optimal aspects with the materials in the stand-set-up way or when clamped and left until after curing process end. Gorilla Glue is in most instances left for one or two hours after clamping and uses regular clamping, while Gorilla Super Glue sets in much faster even to as low as 10 seconds and sometimes 30 depending on factors.

- Temperature Considerations

Check to see if the place of work is under suitable temperature (40°F -100°F). Both gums are less effective in very low or high temperatures.

- Surface Preparation

Clean all surfaces contributing to the bonding process. Eliminate the remaining grease, dust and other impurities else there would be no adhesion hence failure of attachment.

- Storage Tips

Close the bottle properly after usage and save it in a cool and dry place. This does the job the job of slowing down the hardening process of the glue at an early stage.

How to Apply Gorilla Glue Effectively?

For an effective bond with Gorilla Glue, there is a need to apply the substance in increments and follow a step-by-step method. The adhesive is moisture-activated, meaning that one of the substrates must first be assuaged by water, albeit a little. Do not over-soak the surface because dousing of the area with water may result to formation of gaps in the bond. Proceed to spread the glue with another thin layer. Mechanical application of the adhesive helps to keep the layer created during healing from expanding.

Best Practices for Gorilla Super Glue Application

- Surface Preparation

- Optimal Application Technique

Use Gorilla Super Glue economically — too much adhesive can make the bond brittle, and excessive torque increases the curing time. Around one drop is sufficient for each square inch. Make sure the adhesive covers the bonding surface evenly so as not to leave weak areas. Avoid using too much adhesive since this can result in curing that is less uniform.

- Environmental Considerations

For the application process it is advisable to work in a normal environment with normal humidity, ranging from 65°F and 75°F. Excessive moisture can speed up the curing process whereas very low moisture content could slow down the curing process. Normal controlled conditions also help to manage the performance of the adhesive and ensure consistent results.

- Handling Time

When the bonding surfaces have been positioned and you have exerted pressure on them, keep the assemblies still for not less than 10-45 seconds depending on the materials. During this time do not relocate or change the position of the workpiece as it can weaken the adhesion. For bulky parts, use a clamping tool for additional support.

- Storage and Longevity

After use, ensure that the bottle is sealed properly to preserve the ability of the adhesive be and keep moist and store it upside down. The content of the bottle will deteriorate with exposure to air or moisture. You are advised to keep the Gorilla Super Glue in the vgmpaleitschachterlyed original packing to gain more life span and also from extreme temperatures.

Reference Sources

-

Gorilla Glue vs Super Glue and Variants Strength Test: A video demonstrating the strength differences between Gorilla Glue, Super Glue, and other variants.

-

Is Gorilla Glue stronger than super glue?: A Quora discussion comparing the strength of Gorilla Glue and Super Glue, with user opinions and tips.

-

Which is Stronger: Super Glue or Gorilla Glue? – Fuji Technology: A blog explaining the differences in adhesive properties, curing processes, and applications of Gorilla Glue and Super Glue.

-

Gorilla Glue Vs. Super Glue: Which Is Best For Your Home DIY Projects: An article discussing the formulas, uses, and ideal applications of Gorilla Glue and Super Glue.

Frequently Asked Questions (FAQs)

Q: What is the main difference between Gorilla Super Glue Gel and Gorilla Glue?

A: Gorilla Super Glue Gel is a cyanoacrylate adhesive that provides a strong bond without the need for moisture to activate, making it ideal for quick fixes. In contrast, Gorilla Glue is a polyurethane-based adhesive that requires moisture to activate and expands as it cures, which is effective for porous surfaces.

Q: Can Gorilla Super Glue Gel be used on all types of surfaces?

A: While Gorilla Super Glue Gel works well on a variety of surfaces, it is best suited for non-porous materials. For porous surfaces, Gorilla Glue may be more effective due to its expanding properties that fill gaps.

Q: How long does it take for Gorilla Super Glue to set?

A: Gorilla Super Glue sets in just a few seconds, making it a fast-setting option for your DIY project. However, full curing typically takes about 24 hours.

Q: Is Gorilla Super Glue Gel waterproof?

A: Yes, once cured, Gorilla Super Glue Gel is water-resistant, but it is not recommended for continuous exposure to water. For submerged applications, Gorilla Glue may be a better choice.

Q: How do I properly use Gorilla Super Glue Gel?

A: To use Gorilla Super Glue Gel, ensure the surfaces are clean and dry. Apply a small amount of glue to one surface, press the surfaces together, and hold for 10-30 seconds. The amount of Gorilla Super Glue applied will depend on the project size.

Q: What should I do if I have excess glue on my project?

A: If you have excess glue, allow it to cure fully, then carefully scrape it off with a utility knife or sand it down. Always follow the manufacturer’s instructions for the best results.

Q: Are there any specific materials that Gorilla Glue and Super Glue cannot bond?

A: Gorilla Glue does not adhere well to polyethylene or polypropylene plastics, while Gorilla Super Glue may struggle with certain rubber types. Always check the glue product specifications for compatibility with your materials.

Q: Can I use Gorilla Super Glue Gel for outdoor projects?

A: Gorilla Super Glue Gel can be used for outdoor projects, but it is not as effective as Gorilla Glue in extreme conditions due to its vulnerability to moisture. For outdoor applications, consider using Gorilla Glue for better durability.

Q: How does the drying time differ between Gorilla Glue and Super Glue?

A: Gorilla Super Glue dries quickly, typically within seconds, while Gorilla Glue takes longer to set initially and requires full curing time of about 24 hours due to its moisture-activated properties.