Choosing between Super Glue and Gorilla Glue offers two prime voters in decision-making factors for picking the right glue for an occasional DIY project or quick fixes around the house. But how does one know which to trust for his specific set of requirements? Both were infamous for being strong and very versatile, yet they shine in different circumstances. This article goes through the main differences regarding use cases and benefits of the glue. From fixing broken ceramics and gluing wood to craft projects, we’ll make sure you know which glue is worthy of being on your tool shelf.

Understanding Adhesives: Glue Types

What Is Super Glue?

Super glue, otherwise known as cyanoacrylate adhesive, is a strong and fast-setting bonding material. Commonly used to bond a wide range of substances, something in the moisture of the air or on the surfaces where the glue is applied reacts with it to make a chemical bond holding the materials together. These very rapid curing properties give it the aptness to quick repairs and precision applications.

Super glue is quite good in many respects, mainly being highly versatile. It can bond plastic, metal, wood, ceramic, and rubber. The glue works very well when bonding small areas of non-porous surfaces, creating a strong bond. Hence, it may not be the best option for flexible materials or places that are subjected to high temperatures since the bond tends to go brittle over time.

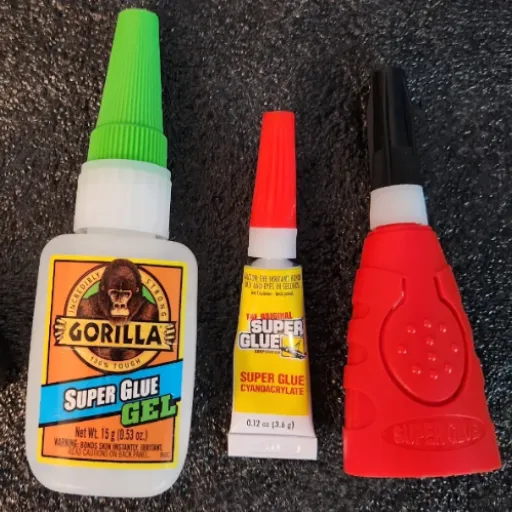

Super glue is a product used in household repairs, craft projects, and industrial processes due to its strength and simplicity. A glue packaging normally looks like a tube; it allows pinpoint application to just the area worthy of gluing. Yet it ought to be handled with care because it glues skin or anything else quite quickly. Follow safety guidelines for safe working results and to avoid accidents.

What is Gorilla Glue?

One of those glues that is so flexible and broad-spectrum that it is equally insured from failure: Gorilla Glue is a polyurethane adhesive of supreme bonding strength and durability. It is used for a wide array of applications, from woodworking to repairs and from craft activities to assembly. It bonds well with materials like wood, metal, ceramics, glass, foam, and stones, making it suitable for any house or industry.

The powerful effectiveness of Gorilla Glue comes from it expanding while curing, thus filling any gaps and making a very secure surface bond even in the presence of uneven surfaces. From a high range of temperatures to being water-resistant, it provides a suitable ‘job-fit’ for use in outdoor projects or in places that would be exposed to moisture. Though it is very important to ensure surfaces are well prepared and that the application of the glue is done properly to reap the best rewards.

The glue must be handled with care due to its very strong adhesive properties. It can get stuck on the skin in seconds and is very hard to get off once cured. Always wear gloves when working with Gorilla Glue, and ensure adequate airflow in the working space. Following the instructions of the manufacturer will not only ensure a proper use of this glue but will also prevent accidents with this powerful adhesive.

Comparative Overview of Adhesive Types

Adhesives are classified based on chemical composition and the purpose for which they are intended. Here come some types of adhesives like those in the epoxy, cyanoacrylate, polyurethane, and water-based. Each type has certain advantages and disadvantages depending upon the application and substrate materials being bonded.

Epoxy Adhesives

Very durable and versatile, meant for heavy bonding. Resist heat and moisture but require precise mixing and longer curing time.

Cyanoacrylates

Work fast and are suitable for small repairs requiring immediate bonding. Perfect for glass, plastics, and metals.

Polyurethane

Flexible yet strong bonds with many materials. Resist water and temperature fluctuations, but may require surface pre-moistening.

Water-based

Used in lighter applications like bonding paper and fabric. Non-toxic and easy to clean but not suitable for heavy industrial use.

Knowing what is needed in a project will help in selecting the adhesive that will work best for your particular need.

Chemical Composition and Bonding Strength

Chemical Makeup of Super Glue

Super glue is a cyanoacrylate adhesive: a fast-acting adhesive, binding strongly and setting through polymerization. Trace amounts of moisture either in the ambient air or on the surface initiate this reaction, during which cyanoacrylates rapidly bond together to form a hard, rigid structure. Hence, it serves the quick, precision bonding of small surfaces.

Super glue bonds a good variety of materials: metal, plastic, ceramics, glass, wood, etc. Its effectiveness often depends, however, on the texture and porosity of the materials involved. Non-porous material makes for the best surface because it absorbs very little, thereby keeping the adhesive concentrated on the surface. On the other hand, highly porous materials could badly diminish the bond as they take the glue into themselves before the glue has set.

Though super glue has a waterproof characteristic after it has set, it is best utilized for many home and light industrial applications in a fairly controlled environment. Nevertheless, it does not suit flexible materials because the bonds are rigid, and with stress or movement, they will crack. One should spare no effort in preparation of the surfaces, like using cleaning and ensuring they remain dry just before applying the glue for perfect and reliable adhesion.

Gorilla Glue: Chemical Composition

Gorilla Glue is basically made of polyurethane: a polymer versatile in nature and able to create strong adhesive bonds in the works. So the solution is able to act like a glue on materials like wood, metal, ceramic, glass, and plastic. With air moisture, the glue reacts chemically in a polymerization reaction where the glue expands while curing to form solid and water-resistant adhesion.

Isocyanates in the polyurethane formulation are important for the greatest bonding effect. They react with water to form carbon dioxide gas. This causes the glue to foam and expand, filling materials and creating a tight bond that will last for ages. The only drawback to this expanding property is that it’s easy to get some on your hands or surfaces if you’re not careful.

Polyurethane adhesives, like that of Gorilla Glue, are made to survive under extreme situations, such as under water or with temperature fluctuations. However, the glue meanders into a rigid bond and hence would be less apt with materials that require any form of flexibility. The chemical makeup of the glue is a key factor in building resistance to static wear and tear, which guarantees a superb feature for any standard that requires adhesion that is durable and waterproof.

Bonding Strength Comparison

Polyurethane (Gorilla Glue)

- Excellent strength and durability

- Large-scale, heavy-duty projects

- Resists moisture and temperature changes

- Suitable for outdoor/industrial use

Cyanoacrylate (Super Glue)

- Fast-drying precision bonding

- Best for small-scale applications

- Bonds smooth, non-porous surfaces

- Ideal for quick repairs

In summary, depending on the specific needs of your project, the decision between those adhesives vary: Consider polyurethane adhesive for strength, flexibility, and durability under harsh conditions; use super glue for applications requiring immediate fixes or requiring precision application.

Drying Times and Shelf Life

Super Glue Drying Times

⏱️ Typical Drying Time: 10-30 seconds

The fixative dries roughly in 10 to 30 seconds, depending on the amount of glue used, the materials being bonded, and the environmental conditions. Thin layers are drying quicker than thick ones.

Environmental Factors:

- Humidity: Higher humidity enhances drying as moisture activates the glue

- Temperature: Lower temperatures slow down the drying process

- Surface type: Porous surfaces absorb glue, affecting drying time

Always allow extra time to develop full bond strength, ordinarily 24 hours, for maximum durability.

Gorilla Glue Shelf Life

📅 Shelf Life: ~12 months after opening

Gorilla Glue Shelf Life-The shelf life depends mostly on storage conditions. Gorilla glue in the original and well-sealed container, stored in a cool, dry place, will generally maintain its quality for about 12 months after being opened.

Storage Tips:

- Tightly close the cap after every use

- Store in cool, dry place

- Avoid exposure to heat, cold, or direct sunlight

- Check for thickness, discoloration, or hardening before use

Factors Affecting Shelf Life of Adhesives

There are numerous factors that can influence the shelf life of adhesives. A good understanding of these factors will help ensure their peak performance for a longer duration.

🌡️ Storage Conditions

Cool, dry places away from sunlight, heat, or freezing temperatures prevent chemical changes.

📦 Packaging Integrity

Tight sealing prevents air and moisture penetration that can cause degradation.

🧪 Formulation Type

Different compositions react differently to environmental changes affecting shelf life.

It, therefore, becomes paramount to check on storage instructions given by the manufacturer, and also note the expiry date of the adhesive to ensure that it functions as it is supposed to. In addition, the product should be periodically checked for signs of thickening or discoloration, so as to avoid using an adhesive that has degraded and, therefore, does not give reliable adhesion all the time.

Best Uses for Each Adhesive

Using Super Glue for Quick Repairs

⚡ Best For: Instant adhesion and quick fixes

Super glue provides instant adhesion and that sustains quickly in a bond; hence, it has an edge in fast repairs. It works best with tiny articles: ceramics, plastics, glass, or metals-making precision and the speed needed by day. Because of the instant bonding time, it becomes a popular choice for day-to-day minor fixations such as broken pieces of ornaments or other little parts that may be glued back together.

Application Tips:

- Ensure surfaces are clean and dry

- Remove all dirt or grease

- Use small amount on one surface

- Press firmly and hold until set

- Allow hours for full-strength cure

⚠️ Note: Not suitable for flexible surfaces, high-stress joints, or long-term water exposure.

Gorilla Glue for Heavy-Duty Applications

💪 Best For: Strong, lasting bonds under extreme conditions

The choice of Gorilla Glue for heavy-duty applications is famous only because of its strength and versatility. Unlike common adhesives, it creates a strong bond that lasts forever with materials such as wood, metal, stone, glass, ceramic, clay, and many others. It is waterproof and can stand severe temperatures, making it appropriate for indoor and outdoor work.

Key Benefits:

- Gap-filling: Expands during cure to fill uneven surfaces

- Waterproof: Suitable for outdoor applications

- Temperature resistant: Works in extreme conditions

- Multi-material: Bonds various surface types

⚠️ Application Note: Apply sparingly, clamp surfaces, and allow proper curing time. Expansion requires careful handling.

Crafting Projects: Choosing the Right Glue

When comparing Gorilla Glue with superglue, it is important to take into consideration the type of material that is being glued, as well as the purpose of the project.

| Criteria | Gorilla Glue | Super Glue |

|---|---|---|

| Best Materials | Wood, metal, ceramic, porous surfaces | Plastic, ceramic, rubber, small surfaces |

| Curing Time | 24 hours, requires clamping | 10-30 seconds, instant bonding |

| Best Applications | Outdoor projects, heavy-duty repairs | Quick fixes, precision work |

| Water Resistance | Excellent, fully waterproof | Good when cured, not for long exposure |

In the end, the choice of Gorilla Glue or super glue really depends on the particular requirements of your project. If a strong, long-lasting bond is needed for larger or more porous materials, Gorilla Glue may be a better option to consider. If small, intricate repairs that need a great deal of precision or speed are on hand, super glue will probably be the best choice. The right glue will suit the need of your particular craft project.

Removing Adhesives: Super Glue vs. Gorilla Glue

How to Remove Super Glue

🔧 Primary Method: Acetone/Nail Polish Remover

Step-by-Step Process:

- Initial softening: Soak the area with warm water and soap to soften the glue

- Acetone application: Apply nail polish remover with acetone using a cotton ball

- Gentle removal: Let it work for a few minutes, then gently scrape with plastic tool

- Final cleaning: Wash thoroughly with soap and water to remove residue

⚠️ Safety: Test acetone on inconspicuous area first. Use in well-ventilated space and avoid skin contact.

It’s a case where patience is needed against the really stubborn glue residue. Softened glue can be gently scraped off by a plastic tool or the edge of a spoon-just try to avoid harsh scraping that can burn the material beneath.

Removing Gorilla Glue Effectively

🔧 Primary Method: Warm Soapy Water + Acetone

Removal Process:

- Fresh spills: Immediately soak with soapy warm water for 15-30 minutes

- Softening: Place damp cloth on glue to allow penetration

- Gentle scraping: Use plastic scraper or spoon edge, avoid metal tools

- Acetone treatment: A pply acetone for stubborn residue with cotton swab

- Final wash: Clean with soap and water, allow to dry completely

⚠️ Important: Test acetone on a hidden area first. Work in a ventilated space with protective gloves.

Having been accidentally spilled onto a surface, Gorilla Glue can have removal processes that can inflict minor damage to the surface below. However, it may well have set and only been softened slightly; in such a case, employing a dab of acetone could just be the thing to finish the job.

Best Practices for Adhesive Removal

A certain amount of care must be taken to prepare for effective adhesive removal with the correct tools. First, finding out about the type of adhesive and the surface it is on is crucial since some solvents and techniques will damage some materials.

🔍 Pre-Removal Assessment

- Identify adhesive type

- Test removal method in hidden area

- Choose appropriate solvent

🛠️ Method Selection

- Water-based: Warm soapy water

- Oil-based: Rubbing alcohol or vinegar

- Stubborn: Heat application

🔒 Safety Precautions

- Work in ventilated area

- Use protective gloves

- Clean thoroughly after removal

For safety before and after removal, ensure your work area is well-ventilated, preferably outdoors, and you use protective gloves that block the chemical from touching your skin. After removal, wash the area with soap and water to remove any chemical residue, then let it dry thoroughly before putting it back to use. These precautions allow removal to be done more safely.

Frequently Asked Questions (FAQ)

Q: What are the major differences between Gorilla Glue and Super Glue?

A: Major differences between Gorilla Glue and Super Glue lie in their chemistry and use. Gorilla Glue is a polyurethane glue that uses moisture to activate and expand while curing, thus providing a gap-filling quality. Super Glue, on the other hand, being a cyanoacrylate glue, acts very quickly by almost instantaneously bonding but lacks waterproof properties and is best for very precise applications on clean, dry surfaces.

Q: Is Gorilla Super Glue gel anything different from regular Super Glue?

A: Yes, because Gorilla Super Glue gel is thicker than regular Super Glue, it offers a more controlled application. It was formulated to reduce drips and runs, thus, suitable for vertical surfaces and applications that demand a bit more precision.

Q: How can I get Gorilla Super Glue off from my skin?

A: To get Gorilla Super Glue off from your skin, acetone or nail polish remover is the best choice. Soak a cotton ball in acetone, and gently blot on the location until you start seeing the uncured glue dissolve away. Wash the area afterward with soap and warm water.

Q: Can Gorilla glue be used on polyethylene surfaces?

A: Gorilla Glue generally will not bond to polyethylene or polypropylene materials because they have a fairly low surface energy. One is best advised to look for another type of glue, preferably that is a plastic adhesive for these surfaces.

Q: How long does Gorilla Super Glue last?

A: Gorilla Super Glue usually lasts about a year when stored inside a cool and dry place. After you open the glue, always ensure the cap is tightly closed to avoid drying out.

Q: Does the glue expand after it cures?

A: Super glue does not expand after curing. Gorilla Glue requires moisture to activate and thus is termed an expanding glue, whereas Super Glue bonds almost immediately without any change in volume.

Q: Which glue is more applicable for wood projects, Gorilla or Super Glue?

A: Usually, Gorilla Glue is preferred in wood-related projects as it can fill gaps and create a fairly strong bond. Super Glue would be good for quick fixes or precision work if the surfaces are clean and dry.

Q: How can I apply Gorilla Glue for the best results?

A: For the best results with Gorilla Glue, apply a light amount to one surface, then clamp the pieces together. Make sure surfaces are clean and dry for best results. Keep in mind that Gorilla Glue expands while curing, so do not use too much glue.

Q: Is Super Glue safe to be applied on household goods?

A: Super Glue is usually safe to be applied to most household goods as long as the substance does not come into contact with anything related to food. Always follow the proper application instructions indicated by the manufacturer.

Q: What should I do if too much glue is applied?

A: Wipe away any excess glue if you can do so immediately before it cures. With uncured glue, a cloth moist with water should be able to take away any excess. If it has cured, depending on the surface, you may need to scrape the glue off carefully or dissolve it with acetone.