3D printing with PLA (Polylactic Acid) gives 3D creators and enthusiasts the ability to print everything from fully functional prototypes to highly detailed models. On the other hand, joining assembled larger prints or mending broken parts often needs a dependable technique to bond PLA parts together with precision. While there are many adhesives advertising their capability to bond PLA, it can be rather difficult to settle on a one-inch perfect solution. This essay focuses on the entire process of gluing PLA prints together, starting with the most relevant methods, and answers how to pick the right adhesive, which method works best, and what factors must be taken into account for precise and professionally robust results. With an understanding of the document, one is confident in his or her ability to elevate their 3D projects.

What is the Best Glue for PLA?

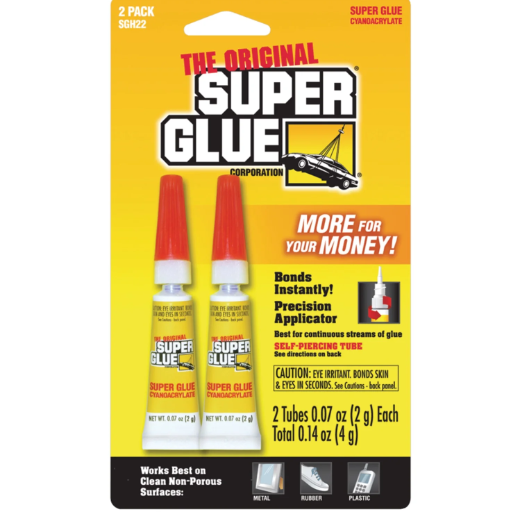

Super glue’s best feature is PLA parts. Because it bonds fast and strongly with PLA surfaces and is easy to find they are most people’s go-to. If high structural integrity is needed, a two-part epoxy can also work, although they require a longer curing time. Polyurethane-based glue can also be very helpful, especially when dealing with bigger and imprecise parts. Remember: to ensure best bonding results the surfaces need to be clean and slightly roughened.

Understanding PLA and Its Properties

Polylactic Acid (PLA) is thermoplastic material which comes from renewable resources such as corn starch and sugarcane. bing PLA sugars An advantage in using starch sugar is its easy acceptance. It has become highly popular for 3D printing due to its easy printing, being friendly to nature, and having a low melting temperature compared to other thermoplastics. It has the great ease in printing when compared to its eco-friendliness and lower melting temperature. PLA has a glass transition temperature of around 60°C and melts between 170°C and 180°C, which makes it suitable for use where temperatures are raised mechanically or during stress are low.

It can absorb moisture from the environment which may reduce its mechanical properties and print quality which may impact its rigidity and tensile strength over time if stored poorly. PLA is hygroscopic or can retain moisture which tends to make it brittle and lose impact strength which greatly limits its utility in components that are expected to bend or flex. Post processing, PLA can be sanded, painted, or coated which makes it useful for different finishes. Its ease of use makes it fit for sustainable manufacturing practices, although it does tend to require industrial conditions for full decomposition.

Comparing Different Types of Glue for PLA

|

Glue Type |

Strength |

Ease of Use |

Surface Preparation Needed |

Drying Time |

Suitable for PLA Parts |

Notes |

|---|---|---|---|---|---|---|

|

Super Glue (CA Glue) |

High |

Easy |

Clean, smooth surface |

Very fast (seconds) |

Yes |

Best for small, precise bonds |

|

Epoxy Resin |

Very High |

Moderate |

Clean, slightly roughened |

Moderate (5-60 mins) |

Yes |

Strongest bond, good for large joints |

|

ABS Slurry |

Medium |

Moderate |

PLA and ABS contact area |

Fast (minutes) |

Limited |

Requires ABS filament for slurry |

|

PVA Glue |

Low |

Easy |

Clean surface |

Slow (hours) |

Yes |

Weak bond, suitable for non-load parts |

|

Plastic Weld |

Medium-High |

Moderate |

Clean, tight fit |

Fast (minutes) |

Yes |

Chemically welds PLA for durability |

|

Hot Glue |

Low-Medium |

Very Easy |

Clean, roughened surface |

Very fast (seconds) |

Limited (low strength) |

Best for temporary or flexible fixes |

Why Choose Super Glue or Epoxy for PLA?

Super glues (cyanoacrylate) and epoxy adhesives are possibly the best recommended options for gluing PLA due to their strength, accuracy, and long-lasting nature. Super glue is exceptionally beneficial for intricate components as it has an extremely fast curing time, frequently fusing surfaces in mere seconds. Pla surfaces, especially those that have undergone light sanding, bond exceptionally well to super glue due to chemical adhesion. Use of super glue is not recommended where gaps need filling or in situations where uneven surfaces need to be joined.

On the other end of the wood based PLA parts, they also need to be joined together with epoxy resin. Epoxy resin is receivable in two forms, a resin and a hardener. Together they form a bond that is durable against both impact and heat which gives epoxy great potential. Its versatile nature, alongside a low curing time, provides ease of use at the cost of waiting while it cures. When compared to super glue, epoxy may take a great deal longer to cure, but it comes out on top in terms of reliability. Combined with its inertial gap-filling properties, it provides an unmatched clean reinforcing bond when compared to super glue.

How to Glue PLA Parts Together?

- Prepare the Surfaces: Apply fine sandpaper to the areas where the parts will be joined to create a rough surface. This is key in increasing try adhesion along with cleaning the joined sections free from grease and dust.

- Choose the Right Adhesive: Epoxy works best for rugged and lasting bonds, especially with load-bearing joints. Smaller and less stressed connections can be made with super glue (cyanoacrylate).

- Apply the Adhesive: Apply a small and even layer of adhesive on one surface. Do not apply too much as this can result in messy joints or weak connections.

- Align the Pieces: Parts should be positioned carefully, and Alignment should be confirmed before the adhesive sets. If epoxy is used, you may have a window to make small adjustments after applying it.

- Clamp or Hold in Place: Apply pressure to the joints and use tape or clamps to hold them while the adhesive sets. Do not forget that epoxy has a curing time of several hours to one full day for best results.

- Allow Full Curing: Jointed PLA sections should not be used immediately after curing. Following the manufacturer’s instructions is a must. Skipping steps in this process can prove detrimental to the bond.

Preparing the PLA Surfaces for Adhesion

Strong adhesion and durability with surfaces made from PLA is enhanced by correct and thorough prep work. Start by cleaning surfaces with isopropyl alcohol (IPA) in concentrations of 90% or above. It will effectively evaporate leaving no residue contaminants behind.

Check the surfaces carefully for any issues after cleaning. For inspection, check if the PLA parts have any edges; if they do, then carefully plaster them with 220 or 320 grit sandpaper. Plastering rough surfaces softens sharp edges, which increases the chances of glue on firmly. Before completing the next step, make sure there is no clean wipe or dust from the previous step left. This step increases the overall performance and makes certain the joint is strong and steady over a long time period.

Steps to Apply the Glue on PLA Pieces

- Select the Appropriate Adhesive

First, buying a tube of PLA Cyanoacrylate glue (super glue) or two-part epoxy adhesives is highly favorable for bonding their chemical and mechanical bonds with thermoplastics like PLA. People have a need for custom-made 3d printed elements to be durable. Depending upon the need, expert alternatives for glues designed with the purpose of 3D printing materials may provide better durability.

- Prepare the Adhesive

Adhesive instructions must be followed exactly as per the guidelines. For two part epoxy adhesives, the resin and hardener components must be measured and mixed according to the recommended ratio. Proper mixing while stirring ensures all parts of the mixture undergo the necessary chemical reaction during the predetermined time, and complete uniformity is achieved, leading to strong and more effective bond.

- Apply the Adhesive

With a precision applicator, apply a thin layer of adhesive on the bonding surfaces, taking care not to over apply as this can cause uneven curing or weak areas in the bond. Focus on complete coverage, paying particular attention to critical edge areas for structural strength.

- Join the Pieces

Prior to pressing the pieces, ensure alignment, as misalignment may weaken bond strength due to repositioning. Apply even pressure to reinforce the bond for the duration specified in the adhesive instructions. Light clamps are sufficient for cyanoacrylate glue, but stronger clamps are necessary for epoxy adhesives during the curing period.

- Allow Adequate Curing Time

Adhesives perform best when the curing duration follows specified recommendations, so consult product guidelines as curing times differ greatly between adhesives. Most cyanoacrylates will bond within minutes, while others such as epoxies will take hours or even a full day to reach peak strength.

- Inspect the Bond

Conduct a post-cure joint inspection to evaluate for uniform adhesion. Where gaps or weak points are identified, consider reinforcing or applying secondary layers as required. Bonds that are effective should demonstrate high tensile strength and resist forces applied to them.

Following these exact procedures will improve the quality and functionality of the final product while guaranteeing strong and long lasting adhesion when working with PLA parts.

Can You Use Super Glue on PLA Material?

Yes, super glue can be used on PLA. PLA parts are often best bonded with cyanoacrylate adhesives as super glues are also known because they cure fast and have strong adhesion. Super glues work best on clean and dry surfaces and are best used for small and detailed PLA parts. For large parts or joints which bear significant load, additional support will be required or other glues used such as epoxies which will guarantee stronger bond.

Benefits of Using Super Glue for PLA Printing

- Strong Bonding Strength

Super glues ( cyanoacrylate adhesives ) work very well, especially for small PLA parts as well as detailed sections, because of their remarkable bonding strength. In moderate mechanical stress situations, superglues will withstand significant attacks and protect the bond due to their composition. Withstanding significant PLA parts that were bonded using Cyanoacrylate, retained a good proportion of tensile strength, proved a strong hold, and therefore maintained stiff and solid joints.

- Quick Curing Time

One of the major benefits of super glue is the speed at which it cures. Super glue generally sets in 10-30 seconds which aids in the fast assembly of parts. The heating and humidweather varies temperature can accelerate or decelerate the custom-made thermoplastics drying process. This aids in Herculean tasks like 3D printing repair.

- Ease of Application

Super glue requires no special equipment, making the application process simple. Super glue’s low viscosity makes it flow easily, enabling it to fill minuscule spaces between PLA rods, ensuring proper contact, letting the geometries be complex without any change to the strength or order of the glue. Use of pinpointable use of applicators with precision tips improves accuracy.

- Compatibility with PLA’s Surface Properties

The super glue’s bond works best with PLA as the raw PLA already has a smooth surface. When the PLA interfaces and The super glue is molecularly bonded to the plastic s, it becomes extremely difficult to separate the two, enhancing durability. In cases when super glues bond plastics is prone to delaminating, lightly sanding the interfaces would significantly improve the strength of the bond resulting in a stronger and more reliable connection.

- Minimal Residue and Clean Finish

Super glue dries clear which means little to no residue is visible after drying which matters windows and plexy glass, projects where a seamless finish is critical. This ensures applying super glue at the correct points makes polish possible without marred areas.

Using the points described above, it is possible to increase the every day blueprints printer users materials reliability regardless if it is a Hector picture, hobby project or prototype.

Potential Drawbacks of Super Glue on PLA

- Brittle Bonding

Super glue sets into a bond that is hard, brittle, and inflexible which is not likely to endure significant axial load or bending moments. PLA by itself is somewhat brittle, and so the combination of brittle PLA and brittle superglue can snap under repetitive bending or impact forces. This can restrict its use in cases where flexibility and resilience under load are needed.

- Limited Heat Resistance

Super glue and PLA both have low resistance to heat. The bond line PLA superglue joint will weaken around 150°F (65°C) and is likely to fail at hotter temperatures. This is an issue for high-temperature environments but does create problems in design considerations for structures or components in open/heat exposed environments as those areas are likely to experience elevated temperatures.

- Uneven Application Risks

Misapplication of super glue can result in pooling or uneven super glue application which leads to weak bonds, visually distinguishable blemishes, defects, or gaps on the glued surface. This is critical for symmetrical components as they require a precise fit.

- Difficulty in Post-Processing

Super glue creates a rigid, cured layer over the joint which is difficult to modify without damaging the adjacent area. This reduces flexibility PLA prints have for post-process adjustment or finishing after they are bonded.

- Health and Safety Concerns

The inhalation of super glue’s vapors can irritate the nose, throat, and eyes. It is best applied in an area that has good ventilation and in limited amounts. Any sort of skin contact to super glue can result in skin bonding which may lead to injuries.

Keeping these cons in mind, a user can decide whether super glue works best for PLA projects or consider other options that provide better results.

What Adhesives Work Best for 3D Printed Parts?

While adhesives for 3D printed parts are based on the material, PLA works best with cyanoacrylate adhesives for their quick setting time and strong bond. For ABS, an acetone-based adhesive works best as it melts and joins the plastic surfaces together. With PETG, the use of epoxy and specialized plastic adhesives is suggested as they strongly bond without damaging the material. For best results, make sure that the surfaces are clean and perfectly placed before any adhesive is applied.

Exploring Epoxy and Cyanoacrylate Adhesives

Customarily, epoxy and cyanoacrylate adhesives are used for bonding materials due to their practicality. Both have their own specific uses. Epoxy adhesives are very strong compared to others. They also have a wide application range because they resist chemicals and can bond metals, plastics, and even ceramics of different forms. This makes them a preferred choice for structural applications and high-stress environments, including aerospace and automotive assembly. From an epoxy’s standpoint, the few cons they do have can be mitigated. A good ratio of resin to hardener and adequate mixing allow for proper curing, increasing strength over time when exposed to moisture or heat.

As for cyanoacrylate adhesives, they are very useful in needing precision as well as very fast bond time. Cyanoacrylate adhesives are very useful for quick bonds and are able to polymerize (bond together) very fast, within minutes, when they are exposed to water. It does, however, only work best when used with very tiny components, like in electronics, as it is only useful for quick, small bonds. Both of them show how diverse adhesives can be when considering their use. Both of them also need armor for protection against moisture for long periods of time along with thermal extremes.

How to Choose Between Solvent and Non-Solvent Adhesives

The choice between solvent and non-solvent adhesives depends most on the details of the application, compatibility of materials involved, and regulatory issues. Metals, plastics, and even glass are often considered non-porous substrates and thus, utilized in industrial manufacturing where high strength bonding flexibility is needed. Such spaces also require the adhesives to withstand high temperatures or harsh chemical exposure. However, these adhesives are not safe for the environment, require proper working conditions, and pose compliance issues since they contain VOCs.

Less-Poluting type of adhesives like water based and reactive non-solvent adhesives have found application due to their lower VOC emissions. They are well suited for use in packaging, woodworking or automotive industries where lower environmental impact is critical. Furthermore, non-solvent immobilization systems have been redesigned to answer unfavorable conditions, thus adopting from traditional solvents systems without losing effectiveness.

Assessing substrate compatibility, curing time, longevity, and considering regulatory compliance and other listed factors provides a holistic approach to guiding the decision-making process. Technical datasheets, pre-application tests, and alignment with industry standards are essential in confirming set performance and sustainability targets.

What to Avoid When Gluing PLA?

Common Mistakes in Gluing PLA Together

An issue that many people have when trying to glue PLA is applying adhesive without surface preparation. A PLA surface’s fine texture often demands sanding or roughening so it is easier for PVA glue to bond. Not doing this step often leads to insufficient adhesion and failure of the joint under load. Another common problem is the misapplication of universal adhesives. While some adhesives are marketed to be universal, not all will work with PLA. Silicone-based adhesives and PVA glue are unsuitable options that lead to poor performance.

Moreover, overuse of adhesives is a common mistake. This not only weakens the bond due to the uneven load transfer, but also creates and even damages surrounding components. Environmental lack of judgment is also an issue, considering that due to high temperatures PLA is known to be sensitive. The application of heat-curing adhesives or those that excessively thermally energize can cause surface distortion or warping of PLA. Careful selection of materials and surfaces to be bonded, as well as preparation of the surfaces, offsets gaps that pose a risk to an effective bond.

How to Ensure Long-Lasting Adhesion

Effective and precise adherence is a multifaceted action that should be approached with level-headed evaluation of materials with risk assessment in mind. Setting out starts with surface preparation—a systematic approach to surface cleaning that focuses on eliminating surface-attached contaminants including grease, oil, or dust by polishing with appropriate solvents. Furthermore, SR achieved by sanding or abrasive blasting extends beyond chemical processes as thorough execution smooths mechanical gripping of adhesives.

Sustaining through factors alongside material criteria smeared range rely heavily on the constituents the bonds will be subjected to, including the working conditions and the temperature. A sound example come through two-part epoxy adhesives. Their use stretches outward to high-strength applications centered around stress and temperature changes. Though in areas where flexibility is crucial, polyurethane-based adhesives certainly offer better performance.

Bond strength is critical in medical device repair, and ensuring optimal conditions for curing is vital. Curing time, temperature, and relative humidity impacts adhesion properties, therefore must be controlled. Also, applying consistent pressure or clamping during curing is beneficial to achieving complete bonds without air gaps.

Reference Sources

-

Improving Interfacial Adhesion of PLA/Lignin Composites: The addition of KH560 improved the bonding between PLA and lignin, forming stable chemical bonds. However, the tensile strength was lower compared to conventional methods due to free radicals from the coupling agents.

-

Key Improvements in PLA Matrix Composites: Enhanced adhesion was achieved through specific surface treatments, which improved the dispersion of fibers and fillers in the PLA matrix.

-

Plywood Composites Using PLA Adhesives: Amorphous PLA adhesives showed superior performance in terms of wetting and substrate penetration, achieving satisfactory strength and water resistance for interior-grade plywood.

Frequently Asked Questions (FAQs)

Q: What is the best glue for PLA 3D prints?

A: The best glue for PLA 3D prints includes options like super glue gel, Loctite 401, and acrylic glue, all of which provide strong bonds for gluing 3D printed pieces together.

Q: Can I use super glue gel for gluing 3D printed PLA?

A: Yes, super glue gel is an excellent choice for gluing PLA 3D prints due to its strong bond and easy-to-use application. Make sure to use super glue gel control to prevent excess spillage.

Q: How does Weld-On 16 work for gluing PLA 3D pieces together?

A: Weld-On 16 is an acrylic solvent that effectively bonds PLA pieces together by melting the surface of the plastic, creating a strong glue joint. It is important to work in a well-ventilated area when using this product.

Q: Is Gorilla Glue suitable for gluing PLA 3D prints?

A: While Gorilla Glue can bond various materials together, it is not typically recommended for PLA 3D prints because it expands as it dries, which may result in a less precise bond. For best results, consider using super glue or acrylic glue.

Q: What should I do if there is a gap left in my glue joint?

A: If there is a gap left in your glue joint, you can use a filler material or a thicker adhesive like super glue gel to fill the space. It is important to ensure that the glue is still wet for proper adhesion.

Q: Can I use acetone to glue PLA pieces together?

A: Acetone is not effective for gluing PLA, as it does not bond well with this type of plastic. Instead, consider using products specifically designed for plastics, like Loctite or acrylic glue.

Q: How can I ensure a strong bond when using super glue and epoxy?

A: To ensure a strong bond when using super glue and epoxy on PLA, make sure the surfaces are clean and free of dust or debris. Additionally, using an activator can help speed up the curing process and enhance the bond strength.

Q: Are there any safety precautions I should take when gluing PLA 3D prints?

A: Yes, it is advisable to wear nitrile gloves when working with adhesives to protect your skin. Always work in a well-ventilated area to avoid inhaling fumes from the glue.

Q: What is the best way to apply acrylic glue to PLA models?

A: The best way to apply acrylic glue to PLA models is to use a fine applicator or brush to control the amount of glue used. This will help avoid excess glue and ensure a clean application.

Q: How long does it take for glue to set when working with PLA 3D prints?

A: The setting time can vary depending on the type of glue used. Super glue typically sets quickly, often within seconds, while epoxy may take longer to cure completely. Always refer to the manufacturer’s instructions for specific set times.