Working hand in hand with various DIY crafts and creative builds, two differing materials are capable of producing some spectacular results. The downside is that if you don’t find the right way to attach them. One of the common challenges that people face is gluing a piece of PLA onto wood. Both are versatile and often used in craft work, but because of their properties, it becomes difficult to form a strong and lasting bond. This guide discusses the best gluing techniques to achieve a professional-looking result and will make your projects durable. Whether you’re creating a unique design or a working prototype, these actionable tips and insights will simplify the process for you and elevate the standard of your work.

Understanding PLA and Wood Properties

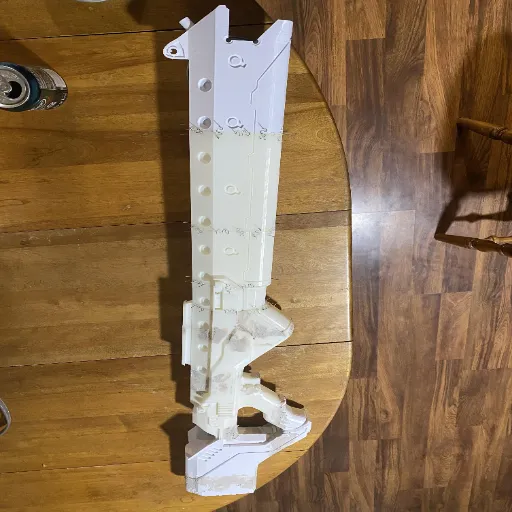

PLA, or polylactic acid, is a biodegradable thermoplastic derived from renewable resources such as cornstarch or sugarcane. It is rigid, lightweight, and has a relatively low melting temperature, and Pakrac sees it as a great 3D printing material. However, prolonged exposure to heat or rough handling renders it somewhat brittle.

Next, we have wood. Wood is a composite natural material composed of cellulose fibers immersed in the lignin matrix. It is durable, solid, and versatile, with an ability to be used both structurally and decoratively. Wood is relatively porous, allowing adhesives to bond well with it.

When bonding PLA to wood, it is essential to consider the differences in texture, surface energy, and porosity to achieve optimal strength and durability. Surface preparation is equally important, as very smooth surfaces of PLA may be slightly abraded for better adhesion, while wood’s natural texture provides a stable surface for bonding.

Properties of Wood

Wood is characterized by a series of closely knit properties that result in its top versatility. It may bear loads without undue weight, making it favourable for construction purposes, thanks to its inherently equal strength-to-weight ratio. Furthermore, as an insulator, it effectively retains heat, thereby contributing to the building’s energy efficiency. Finally, natural wood is not lacking in beauty, given to it by its grains and textures, which can also adorn decorative elements. Being a natural material, wood reacts differently to various environmental factors, such as moisture and pests; therefore, the application of treatments is crucial for its durability. In combination with wood, engineering ensures that applications last, guaranteed across various industries.

Challenges in Bonding PLA to Wood

Bonding PLA (Polylactic Acid) to wood surfaces presents several challenges due to the inherent differences in the properties of the two materials. PLA, being a thermoplastic from renewable resources, generally has a smooth and non-porous surface, whereas wood has a porous, irregularly textured surface. Although such differences sometimes result in limited adhesive performance, others exhibit similar behavior. Additionally, PLA, being relatively low in melting temperature, exacerbates the problem, as overheating merely distorts the plastic and does not produce firm bonding. Another challenge is the adhesive requirement for bonding both materials, as most wood-based adhesives lack the desired properties to bond effectively to PLA. More recent developments attribute adhesion to surface treatments, such as sanding or the application of primer, to PLA. Still, it remains an area in dire need of further innovation to bridge the performance gap in cases where the bonding is larger or load-bearing.

Necessary Adhesives for Joining PLA and Wood

Epoxy adhesives have become revered for their ability to join dissimilar materials, such as PLA and wood, effectively. Which two-part epoxy adhesives give a strong bond, are resistant to wear and tear, and can be used for many situations? Other alternatives include cyanoacrylate, also known as super glue, for smaller, contracting contrasts or light-duty bonding. It is the fastest-drying option that sticks firmly to both surfaces. Sand and clean the surface thoroughly to ensure optimal adhesion before applying the adhesive for the best results.

Cyanoacrylate (Super Glue)

The cyanoacrylate we commonly refer to as super glue is known for its rapid curing time and strong bonding capacity. With PLA or any other such material, it creates an almost instant bond that works well for light applications. Based on current trending search queries, one of the common questions people wonder about is whether super glue is safe and effective for use on plastic. Yes, it works very well for binding PLA and other plastics, with one exception: the surfaces on which it is to be applied have to be prepared correctly. Light sanding and cleaning of the surfaces smooths them, making the glue more effective and ensuring strong, long-lasting adhesion. For heavier-duty bonding, a combination of super glue with an accelerator spray may be beneficial in speeding up the curing process and achieving the best results.

Epoxy Resin

Epoxy resin is a highly versatile adhesive, boasting powerful bonding capabilities and exceptional durability, making it a welcome choice for numerous applications. If glue needs to be asked, “Is epoxy resin good for bonding plastics?” practically, the answer is to be considered based on the type of plastic. For instance, epoxy resin must bond very well to plastics such as ABS and PVC, provided that the surface has been treated adequately by means of light sanding and cleaning to ensure dryness. Some plastics, such as polyethylene and polypropylene, would otherwise require additional surface treatments for optimal adhesion, including the use of a plastic primer or flame treatment. The epoxy will withstand heat, chemical attack, and moisture, making it an excellent choice for heavy-duty bonded applications that require long-term service. For optimal results, always verify this resin against the specific material you intend to use.

Preparation Steps for Successful Bonding

- Clean the Surfaces: Ensure that both surfaces are free from any contamination, such as dirt, grease, or other foreign matter. Use an appropriate cleaning agent, such as isopropyl alcohol, for the best cleaning results. The surfaces must be allowed to dry completely before moving on.

- Sand the Surfaces (if needed): Sand lightly anywhere, from smooth to rough, to smooth out the surface and improve adhesion. Wipe away any debris created after sanding.

- Apply Surface Treatments (if required): For materials such as polyethylene or polypropylene, consider using a plastic primer or performing a mild flame treatment to improve adhesion.

- Mix the Epoxy Resin Properly: Mix the epoxy resin and hardener in the exact ratio specified by the manufacturer. Ensure that the mixing is thorough; uneven mixing can result in improper activation of the adhesive.

- Apply the Epoxy: Apply a layer of epoxy evenly to one or both surfaces as indicated. A full coat must be given to ensure the strongest bond.

- Clamp or Hold the Bonded Parts Together: Clamp the bonded parts or use another method to maintain steady pressure on the materials until the epoxy cures.

- Allow Proper Curing Time: Do not interfere with the bonding and curing process. Whenever possible, let the materials sit undisturbed for the time specified by the manufacturer. This will ensure maximum strength and bonding properties.

Cleaning the Surfaces

Before any bonding operation, the surfaces must be well-cleaned. Once cleaned of loose dirt, dust, or debris with a clean, dry cloth, and if necessary, a solvent like isopropyl alcohol or acetone may be used to remove grease, oils, or other contaminants. Avoid using water-based cleaners, as they may leave residue that could hinder adhesion. Complete surface drying must be allowed before applying any epoxy. Following these steps will ensure the best results of your binding project.

Sanding PLA and Wood

Sanding PLA and wood involves specific methods that result in smooth and polished finishes. With PLA, coarse sandpaper, such as an abrasive with a grit of about 120, would be used initially to remove larger imperfections or layer lines from the 3D prints. Using sandpaper with gradually finer abrasives, such as 220 or above, would then smooth out the surface. Wet sanding is best for PLA because it allows for minimal heat build-up and prevents clogging of the sandpaper. Sanding wood, on the other hand, is a parallel process. Begin with coarse grit to remove surface roughness, splinters, or inconsistencies. Proceed with finer grits to accentuate the natural grain and prepare for staining or finishing. Wipe-tack during inter-sanding stages to keep dust off the surface and prevent scratching. Whether PLA or wood, patience and the right tools are the very essence of a good finish.

Troubleshooting Common Issues with PLA and Wood Adhesion

Insufficient Adhesion

Problem:

The PLA does not form a strong bond with the wood surface.

Solution:

Ensure the surface is clean, dry, and free from dust particles and oil. Apply a light sanding to the wood to create a slight texture that aids the bonding process. Use an adhesive specifically designed for bonding plastic to wood, such as epoxy or cyanoacrylate glue.

Warping of PLA

Problem:

The PLA part warps and pulls away from the wood surface after bonding.

Solution:

Make sure your PLA is completely cured or cooled before bonding. Clamping the materials during glue curing is a good idea anyway, as it helps keep them aligned and prevents shifting.

Peeling Over Time

Problem:

The PLA peels off from the wood after a certain amount of time.

Solution:

The high-quality adhesive should be selected because of its durability and ability to resist environmental factors. For outdoor applications, choose an adhesive that can withstand temperature fluctuations and exposure to moisture.

Uneven Surface Contact

Problem:

Gaps between the PLA and the wood result in weak adhesion.

Solution:

Make both surfaces even and flat. Sand down surface imperfections or use a filler adhesive to fill in small gaps. Flatten the PLA print base during post-processing if required.

Weak Bond Problems

Weak requests may arise due to reasons related to PLA and wood, primarily resulting from disturbances in their material properties or variations in preparation techniques. These pairings can be affected by improper adhesive selection, inadequate surface preparation, or environmental factors such as high humidity or drastic temperature changes. According to the strong bond, adhesives suitable for bonding porous to non-porous materials (i.e., wood to PLA) should be utilized; prime examples include epoxy or polyurethane glue. Moreover, sanding the plaster areas for an enhanced grip and ensuring dust- and oil-free cleanliness goes a long way already toward good adhesion. The environment should also be taken into consideration: working within a stable climate diminishes many of the bond failures indirectly caused by moisture or temperature variation. This will eliminate any bonding problems caused by weak adhesion, resulting in a sturdy connection.

Bond Failure Over Time

Bond failure over time can occur due to various reasons, including external environmental stress, material degradation, or faulty application techniques. According to new information, one of the more common types of adhesive failures occurs after prolonged exposure to moisture and temperature fluctuations. Particularly when the materials expand and contract over time, such conditions can worsen the bond. Additionally, another common issue is selecting an unsuitable adhesive for a particular surface. These failures can be avoided through regular inspection and the use of adhesives that are specifically designed to withstand long-term adversity.

Practical Examples of Gluing PLA to Wood

- Using Cyanoacrylate Glue (Super Glue): Apply a small amount of cyanoacrylate adhesive to the PLA material and press it firmly against the wood for a quick bond, which is most suitable for light applications.

- Epoxy Adhesive: Mix a two-part epoxy adhesive and apply it to the whole surface of the PLA. Press the PLA onto the wood and allow enough curing time. This method assures a strong and long-lasting bond suitable for heavier or more demanding applications.

- Sanding for Better Adhesion: Lightly sand the bonding surfaces of the PLA and the wood before applying glue. This way, the adhesive gets a better grip, resulting in increased durability and strength.

- Hot Glue for Temporary Bonds: If you want temporary or non-load-bearing joints in a hurry, the hot glue would do the trick! It sets fast but doesn’t last for very long.

Creating a Custom Wooden Frame with PLA Elements

When a wooden frame is combined with PLA elements, take care to make all fittings; only then can the desired result be attained. First, model the PLA components with a 3D modeling software explicitly tailored for the exact wooden frame dimensions. The specifications should include the thickness of one or both materials, ensuring they fit neatly against each other. One has to consider how PLA elements will be fastened to the wooden frame, depending on the strength of the bond required. Epoxy is, of course, a great choice—and preferred —in any case where a very durable bond is desired; it hardens clear and can adhere to all sorts of materials, including PLA and wood. When screws or nails are to be used, it is advisable to pre-drill holes in the PLA pieces to avoid cracking. Sanding the mating surfaces of both the PLA and wooden parts will increase friction between the two materials, thereby improving the strength of the bond. Finally, after assembly, apply a paint or wood stain finish to homogenize the two materials, resulting in a smooth, fine finish for the final product. This strategy enables the creation of both usable and visually appealing frames that incorporate modern hybrid aesthetics.

Repairing a Broken Wooden Chair with PLA

When repairing a broken chair with PLA, I first inspect the damaged areas. Then, replacement parts with reinforcements are designed in CAD software to fabricate the pieces with a precision fit. After the PLA parts are 3D-printed, I sand the contact surfaces and pre-drill holes where necessary to prevent cracking of the PLA material from dependent changes in thickness. Next, the PLA parts are secured to the wooden chair using wood glue, screws, or a combination of both to enhance stability. Finally, paint or stain is applied to complete the integration of materials, resulting in a neat and durable repair.

Reference Sources

Below are five informative and reliable reference sources that will help in verifying queries on “how to glue pla to wood”. Each reference given is scholarly and contains more information regarding PLA and wood bonding.

- Investigation of the adhesive bonding strength of wood added PLA materials

This research work examines the challenges and applications of PLA materials blended with wood, as well as their adhesive properties. - Plywood wood-based composites using crystalline/amorphous PLA polymer adhesives

This research aims to prove strategies for the application of pLA in plywood composites as an adhesive through the use of both the crystalline and amorphous forms of the polymer. - Bonding wood veneer with biobased poly(lactic acid) thermoplastic polyesters

This review aims to analyze the advantages of using PLA, a biomaterial, as an adhesive in overlaying and wood veneer products. - Modification of interfacial adhesion with a functionalized polymer in PLA/wood composites

This study examines the process of gluing PLA to wood, specifically how to enhance the adhesion properties of PLA to wood using modified polymers. - Understanding the PLA–Wood Adhesion Interface for the Development of PLA-Bonded Softwood Laminates

The study examines the interface between PLA and wood to gain a better understanding of how PLA-bonded laminates are made.

Frequently Asked Questions (FAQs)

What is the best way to glue PLA to wood?

The best way to glue PLA to wood is to use adhesives specifically designed for both materials. Superglue and epoxy are commonly recommended. Superglue provides a quick bond, while epoxy offers a stronger hold for larger 3D printed parts.

Can I use Loctite to glue PLA to wood?

Yes, Loctite is a well-known brand that produces strong adhesives suitable for bonding PLA to wood. It is effective for both small and larger projects, providing a reliable bond that can withstand stress.

What are some cheap ways to glue PLA to wood?

Some cheap ways to glue PLA to wood include using white glue or PVA glue. While these options may not offer the same strength as superglue or epoxy, they can be effective for light-duty applications where a strong bond is not essential.

How long does it take for glue to dry when bonding PLA to wood?

The drying time may vary depending on the type of adhesive used. Superglue typically sets within minutes, while epoxy may take about 5 minutes to start curing, but it reaches full strength over several hours. Always check the manufacturer’s instructions for specific details.

Are there ways to strengthen the bond between PLA and wood?

To strengthen the bond between PLA and wood, consider using an epoxy adhesive, as it provides a stronger hold compared to other options. Additionally, roughening the surfaces of both the PLA and wood can improve adhesion by increasing the surface area for the glue.

Is using acetone a good option for gluing PLA to wood?

Using acetone is not recommended for gluing PLA to wood. Acetone can dissolve PLA, making it unsuitable for bonding with timber. It’s better to use adhesives specifically designed for these materials.

What should I consider for the consistency of the adhesive?

The consistency of the adhesive is essential when gluing PLA to wood. A thicker epoxy may fill gaps better, while a thinner superglue can seep into small crevices for a stronger bond. Select an adhesive that suits the specific requirements of your project.

Can I glue soft PLA to wood?

Yes, soft PLA can be glued to wood using suitable adhesives such as superglue or epoxy. However, ensure that the soft PLA is clean and dry before applying the adhesive for the best bond.

What are the technical specifications to look for in adhesives for PLA and wood?

When selecting adhesives for bonding PLA to wood, look for specifications such as tensile strength, curing time, and resistance to temperature and moisture. A strong adhesive with a quick curing time will often yield the best results for various applications.