Styrofoam can be found in different applications such as crafting, DIY, and construction, as well as in packaging. However, there are some challenges that come with working with Styrofoam, most especially when gluing it without breaking its structure. In this case, be you a Maker, a professional, or a one-off project, there are measures for bonding Styrofoam that will help you avoid wasting time and effort. Here comes a step-by-step guide that will provide you with the basic techniques and the most effective practices in achieving a reliable and durable bond while still being on the right side of Styrofoam’s fragility. Such practices will make you successful in executing your different projects without much ado.

What is the Best Way to Glue Styrofoam?

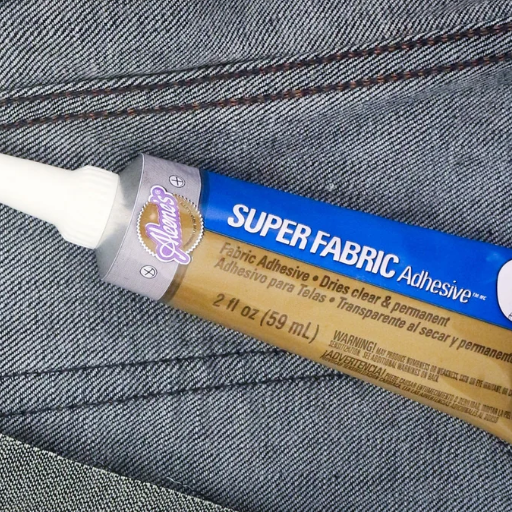

To bond Styrofoam together, the best possible approach is to make use of the adhesives targeted towards foam materials, such as low-temperature hot glue, spray glues, or styrofoam-safe craft glues. Such options keep the bonding material from deteriorating or melting due to strong chemical reactions. Make sure to apply the glue evenly, let it dry for a decent time, and ensure both surfaces are clean to enhance the lifespan of the bond. Always confirm that the glue is safe to be used with Styrofoam to ensure no damage is caused.

Understanding Different Types of Glue

I emphasize the correct adhesive selection, and for that, understanding the properties of each material is very critical. Styrofoam, for example, is a larger context as not all glues are compatible with its fragile structure. I have experienced so much that most of the works are spoiled because of the wrong usage of adhesive, as overuse of strong solvents will melt the foam in actuality. Going with foam-safe options like spray adhesives or low-temperature hot glue is what I’d recommend; they’re effective and straightforward to use. But remember, the main thing is application—clean the surface before application, apply it, and use even distribution while drying. Mark my words, attention to this level of detail is crucial.

How to Choose the Best Adhesive for Your Project

When it comes to making the best choice of adhesive for your project, I would like to start with some parameters that can ease the decision-making process. Here’s what I consider every time:

- Material Compatibility

Before we begin working with the adhesive materials, let us study the materials to be used. Many types of adhesives have different specifications, such as glue for wood, which would work perfectly as an adhesive on wood but would fail for other surfaces such as plastic. In other words, Always use foam-safe adhesives when working with foam, as any other form of adhesive can cause harm to the foam. It is always a wise decision to put on a small patch first before applying the glue on the surface that is to be glued.

- Strength Requirements

Now, we must decide how much power should be applied when merging the two items. In metal and glass fusions, construction and epoxy adhesives are usually recommended; more specifically when heavy-duty constructions. For ornamental crafts or paper projects, white glue or spray glue are less powerful alternatives. Using glue that is excessively strong might spoil your materials and make it a hassle to use some materials later.

- Drying Time

Now that we have gathered an understanding of the concept, how long do you have to completely set the adhesive on the material. Super glue, for example, sets in an extremely short period, making it ideal for short-term repairs but disastrous if you need to reposition the work. When working on larger projects such as furniture, I usually use wood glue or some epoxies that allow me to use one type of glue for longer periods.

- Environmental Factors

What would finally be the destination of your completed project? Environmental factors such as humidity, temperature variations, or even water T can be very crucial. If you want to work in external or damp environments, then the adhesives should be waterproof or weatherproof. Polyurethane glues and silicone sealants work excellent for projects that are exposed to the elements.

- Ease of Use and Safety

Lastly, try to determine how simple an adhesive is to apply, as well as what safety measures you may need to take. Some adhesives require mixing, for example, two-part epoxy, while others come ready to use in tubes. One of my favorite adhesives is a Low-temperature hot glue because it is easy to use and safe for a wide cross-section of materials. Also, ventilation and protective measures should always be considered, especially in the case of strongly smelling adhesives.

Understanding these parameters—the compatibility of materials, strength, shrinkage, environment, and ease of use—will help you in choosing the right adhesive suitable for the requirements of the project you are working on. As I said, a little bit of preparation saves a lot of stress and mess later on!

The Role of Spray Adhesive in Styrofoam Applications

the spray adhesive really is a revolution for professionals and amateurs like me. It is such a simple product that coats the surfaces quite evenly and helps make a strong bond without the usual residues that glue leaves. In my experience, the most important thing is to apply foam spray that is designed to work with foam to prevent the material from ruining. It’s especially useful in working on crafting, insulation, or theatrical items, where it can be simply applied to large areas quickly and efficiently. The convenience that such a simple product brings, coupled with the attributes of the product, makes it a very handy tool in my collection of tools for working with styrofoam materials.

How to Properly Glue Styrofoam and Polystyrene?

Undoubtedly, the correct type of glue is required for polystyrene or styrofoam gluing. The glue that will not damage the material should be used, like a foam-safe spray adhesive or a polystyrene glue. To begin with, make sure both surfaces are clean and free from moisture. While attaching the pieces together, ventilate the area, apply the glue evenly, and press the pieces together so that they stick well. Do not use glue that has strong solvents since this may dissolve the foam or make it weaker. Follow these steps, and the connection will be strong and reliable.

Step-by-Step Guide to Apply the Glue

Before applying the glue, you need to get the materials and the workplace ready. Make sure that the foam parts are dry and clean and have no dust particles or debris on them. Be sure to use a foam-safe spray adhesive or a polystyrene-compatible glue that won’t cause any havoc. Apply the adhesive evenly on both surfaces and let it sit for a couple of seconds to get a little sticky. Carefully put the pieces together to align them, then press them together. Or, clamp the parts together and let the joint cure according to the specifications given by the manufacturer of the adhesive for a proper bond.

Tips for Ensuring a Strong Bond

Several components must be taken into consideration in order to create a robust and reliable bond when dealing with foam surfaces. Also, this is what I would suggest to you:

- Surface Preparation: That’s where it all begins. It is my habit to ensure that foam surfaces are without dust, dirt, grease, or residues of any other kind. Just a speck of impurity can compromise the strength of the adhesive. There are fundamental steps, such as wiping the surface with a clean cloth or cleaning it with a light vacuum.

- Choosing the Right Adhesive: It is understandable that not every adhesive is fit for foam application. Therefore, to hinder such material dissolving or distortion, I always go for a foam-safe spray adhesive or a glue that is modified to remain polystyrene-enhanced. There are steps like paying attention to product labeling and compatibility, which is self-explanatory.

- Uniform Adhesive Application: For maximum bonding strength, I apply the adhesive in a thin, uniform layer on both surfaces to be joined prior to the adhesive application. Too much adhesive can result in a messy bond or uneven curing. It is also recommended that the adhesive reach a semi-dry state before applying pressure.

- Alignment and Pressure: But after applying adhesive it is critical to align the pieces with great precision before finally gluing them. Otherwise, the misalignments may cause various issues once the adhesive is cured. It is important to apply firm pressure to unify the two surfaces in order to distribute the adhesive completely and improve the bond. If possible, I sometimes use clamps to hold the pieces in position.

- Curing Time: After you place the adhesive, you must allow it to cure for the appropriate period determined by that specific adhesive type as indicated on its packaging or label. However, most patients tend to be impatient and skip waiting for the curing time, which negatively affects the adhesive bond strength. And I’m practically buffering for the manufacturers while performing the procedure as well.

Concentrating on these steps, I am able to obtain dependable outcomes on my tasks. Do not forget that it is the blend of preparations, a technique, and the employment of appropriate products that guarantees success.

Common Mistakes When Gluing Polystyrene Foam Together

In my particular knowledge, one frequent error seems to be the inability to adequately prepare the various surfaces that are to be cut and bonded. It is a given that polystyrene foam might be clean, but there are oils or debris that can compromise the bond. Another mistake that happens frequently is the use of unsuitable adhesive, normal glues have the ability to dissolve or damage the foam due to the chemical incompatibility. I’ve also spotted people who put excessive glue on a surface; this will throw out the alignment of the parts and cause uneven finishing. Testing the compound first on a small area is imperative as some individuals don’t bother with this, and this is most definitely essential as it prevents any adverse reactions. Avoiding these errors will save time, material, or frustration while guaranteeing that a clean result is left.

Can You Use Construction Adhesive for Styrofoam?

Construction adhesive can be used for Styrofoam, but special care should be taken while selecting one. Not all construction adhesives are compatible, some contain solvents which will destroy or dissolves the foam. To ensure that harm is not done to the material, only use solvent-free or foam-safe adhesives which are specifically introduced for use on Styrofoam. Just a little advice: Always test the adhesive on a small section before full application.

Advantages of Using Foam Board Adhesive

One of the best glues for foam boards is the foam board adhesive since it does not destroy or separate from the Styrofoam. Now, a level of D or solvent-free design helps prevent Styrofoam from deterioration. It is also easy to use, sets quickly, and has a strong bond, making it an ideal choice for both professionals and do-it-yourself projects.

When to Opt for a Hot Glue Gun Instead

Hot glue guns are great tools for projects that require heat-sensitive surfaces like foam or fabrics. They deliver so much in terms of adhesion and bond speed. But keep in mind these tools are also suited for a variety of materials like wood and plastic. The only issue we see is the excessive heat, which may lead to surface warping or damage. But fear not; when picking between a foam board adhesive and hot glue, always consider the material compatibility and the project needs.

Consult Your Product’s Instructions for Information

Never ignore the instructions provided with the equipment you are working with. These particular instructions are applicable to a certain type of glue or tool and provide adequate information and safety. They provide coherent information on how to use the equipment, the materials to mix, and the safety measures to take so as to enable you to perform aptly in your work.

What Are the Best Practices for Craft Projects?

When it comes to the best practices for craft projects, there are fundamental aspects that I always suggest so as to make the process seamless and the end product worthwhile. Regardless of the fact that you are a crafty person or an amateur, these steps can possibly change the situation for the better:

- Plan Your Project

Starting with a creative idea will greatly help you accomplish your craft. Don’t skip to gather material, instead make initial drawings, material lists, and plan a step-by-step procedure of your work. This saves time and minimizes mistakes later.

- Choose the Right Materials

Choosing the right materials is crucial for the effectiveness and visual appeal of the project. For example, acid-free paper should be used on scrapbooking so it does not yellow with age, or heat-resistant glue should be used for projects that require much heat.

- Use the Right Tools

For any task, the right tools ensure adhering to the standards of that particular task. Hot glue guns are ideal for quick, strong bonds but not for precision, as there might be more effective tools. It’s important to use the correct tools appropriate to the size and type of the material being used.

- Maintain a Clean Workspace

While working, make sure that your work area is tidy and uncluttered. A clean space reduces distractions and states that almost everything is in its right place and that there is no danger of something being spoilt or lost.

- Follow Safety Guidelines

To begin with, safety is of utmost importance. If working with hot materials, use gloves and goggles for cutting or sanding, and ensure that you are not working far from a window/mouth so as not to inhale the glue/spray fumes.

- Test Before Committing

Whenever working with new materials or methods, make sure to test on a small piece first. For accuracy’s sake, this is prudent as it allows for a possible dry run before the full project begins.

- Take Your Time

Crafting is not meant to be done in a hurry, therefore have a reasonable amount of time all in your hands. This is to say that materials shouldn’t be handled in a way that alters the end product in an unsatisfying manner.

Wishing you a joyful crafting experience, with all your worries being kept to a minimum. Not only will your creations be along the lines of long-lasting and beautiful, but they will also be stress-free to make.

How to Attach the Styrofoam Securely

Avoid using all-purpose glue on foam, as it can damage the material. When dealing with Styrofoam crafts, using foam-safe glue is essential; thus, searching for the keyword “Styrofoam glue” would be required like…a foam crafting glue, low-temperature hot gun glue, or a spray adhesive that is made for Styrofoam. Always get spare clothes to test foams, books, materials, and glue before starting the crafting process to prevent any undesirable results.

Choosing Styrofoam Glue for Crafts

I always start with gluing Styrofoam by deciding on the right kind of glue for the job and not just any glue. This is because not all adhesives work well for Styrofoam, therefore I go for foam-safe glue or a low-temperature hot glue instead. To achieve maximum adhesion, the glue is never applied excessively, which ensures that the foam does not melt or bond the pieces unevenly. With this step done, I move on to applying even pressure on the two contact points for a few seconds, followed by waiting until the glue dries completely. Sometimes, in larger projects, I use toothpicks or wooden dowels for support, but this isn’t always necessary, and with my method, I get strong bonding every time.

Ensuring the Glue Has Dried Properly

Patience is crucial in making certain that the glue has effectively cured. In any case, it is essential to give the glue sufficient time to dry, as advised by its manufacturer. In this instance, you would be looking for glitches in the production process, like feeling a specific joint that is impassive to the touch and soft when pressed. Avoid straining the joint to limit bonded suffering during the semi-dry stage. By providing a strong airflow, one may encourage and speed up the drying phase, ensuring maximum durability.

How Does Foam Insulation Affect Adhesion?

Foam insulation is known to alter the properties of the surface, such as surface texture and porosity, which have an effect on adhesion. Since foam is porous, it increases the surface area of the adhesive, allowing it to flow and grip in a mechanical way. However, it is critical to consider what type of foam and what type of adhesive is applied; there are some types of adhesives that do not stick well to closed-cell foams which are smoother. Furthermore, environmental conditions can contribute to a decrease in adhesion, such as using a lot of foam due to it being very insulating, which thermally does not allow adhesives to dry or cure well in poorly ventilated areas. It is important to use an adhesive that has been developed specifically for foam in order to augment adhesion.

Understanding the Nature of Porous Surfaces

porous constituence rather significantly alters how adhesives behave with the given material. Whenever we talk about porosity, we are referring to the number of very small holes or spaces in an area, which directly affects the adhesion of an adhesive on a material. So let me go ahead and separate those into the key factors that elucidate this relationship:

- Absorption Capability – Wood, foam, or even unpainted concrete as a porous surface tends to absorb adhesives more, allowing for a more penetrating bond. This can result in a strong mechanical bond; however, it also indicates that more adhesive may have to be supplied to replace the amount that is absorbed by the material.

- Surface Area – The combination of rough surfaces with glue increases the bonding strength, but this factor is definitely dependent on the glue being used, for example some glues might like rough surfaces, others may not like rough spreads.

- Environmental Conditions – Moisture can be trapped within porous materials like wood or even styrofoam, which can disrupt the granulation of the glue; for instance, too much moisture may cause a porous material to break the binding or even take time to fully dry out. All of this indicates that drying the area before applying glue is important because it saves time.

- Adhesive Compatibility – There are some adhesives that do not go well with a porous material. In such a case where you have selected your material, simply ensure that the adhesive is compatible with it also, for example pore filling adhesives should penetrate deep into the materials surface and for that polyurethane adhesives should be used.

In taking into account these factors and preparing your surfaces as necessary, you can improve adhesion effectiveness substantially – even for tough porous materials. It all comes down to adapting your strategy to fit the various characteristics of each surface!

Impact of Plastic Materials on Adhesion

Adhesion problems can arise with plastic materials, and in my opinion, adhesion is strictly based on the understanding of the surface characteristics of the plastics to some extent. Plastics are usually characterized by chemically inert surfaces low in porosity and surface energy, which adversely affect the strength of the bond between the adhesive and the surface. To solve this problem, I have observed that surface treatments such as sanding, chemical etching, or plasma activation can considerably enhance adhesion. Moreover, the selection of the adhesive must be made properly—For instance, various types of plastics work well with cyanoacrylate, epoxy, or polyolefin-specific adhesives. To solve the problem at hand, the preparation and the adhesive are matched to the plastic type to produce a reliable joint.

Preventing Melt Styrofoam Issues

If you want to glue styrofoam together, then there are some adhesives that are styrofoam-friendly and won’t melt it. Some glues, on the other hand, contain solvents that can harm polystyrene and should be avoided. The glues that work best are water-based adhesives, hot glues at low temperatures, or special polystyrene-based adhesives. You would also have to use a thin layer of glue and let the area remain airy so as not to cause harm to the styrofoam. Considering all these factors, you can form safe joints while preserving the construction material without any issues.

Reference

- LePage: How to glue Styrofoam together – Professional tips and advice

- Quora: What are some ways to glue styrofoam together?

- Loctite Products: How to glue Styrofoam – Tips for Styrofoam and polystyrene

Frequently Asked Questions (FAQs)

Q: What is the best way to glue styrofoam together?

A: When it comes to gluing styrofoam together, it’s important to choose an adhesive that bonds well with the material. Styrofoam glue can be purchased at most home improvement stores and works well for this purpose. Gorilla glue is another popular option that can provide a strong, permanent bond.

Q: Can I use school glue to glue styrofoam together?

A: School glue may not be the best choice for gluing styrofoam together, especially for construction projects or when bonding large surfaces. It typically doesn’t create a strong bond, so it’s better suited for lightweight crafts.

Q: How do I prepare the foam board surface before applying glue?

A: Before applying glue to polystyrene foam boards, make sure to clean the foam board surface. You can use a vacuum to remove any dust or debris. This ensures a better bond when you press the board into place.

Q: What is the best technique for applying glue to styrofoam?

A: To show you how to glue styrofoam effectively, consider pouring the glue in sections and spreading it evenly across the surfaces to be joined. A spray foam adhesive can also be used to even cover expanded polystyrene foam.

Q: How do I ensure a strong bond when gluing large pieces of styrofoam?

A: When bonding large surfaces, apply the adhesive to the foam board evenly and use a sharp blade to cut the boards precisely. Press the board into place firmly and, if possible, use weights to maintain pressure until the glue dries.

Q: Is it necessary to wear safety glasses when working with glue?

A: Yes, it is advisable to wear safety glasses when applying glue to protect your eyes from any splashes or debris, especially when cutting the edge of the board or handling large pieces of styrofoam.

Q: Can styrofoam be glued to other materials?

A: Yes, styrofoam can be glued together or used in other materials such as wood, metal, or plastic. Ensure the adhesive is compatible with both surfaces for a successful bond.

Q: Are there any tips for using styrofoam in crafts?

A: When using styrofoam in crafts, it’s important to choose the right adhesive and apply it carefully to avoid melting the foam. Also, consider the weight of the materials being attached to ensure the glue works well for the intended purpose.

Q: How can I achieve a neat finish when gluing styrofoam?

A: For a neat finish, use a sharp blade to trim any excess styrofoam and clean up the glue edges. This will help maintain a tidy appearance and ensure that the surfaces are flush.