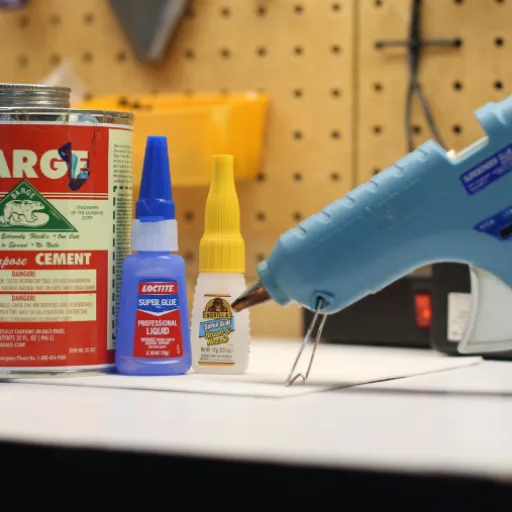

World-renowned for their strong and reliable adhesives, Gorilla Glue and Loctite are often mentioned in the same breath. Whether for a DIY project, repairing a broken item, or professional work, the right glue makes the difference. However, both brands are considered powerful in terms of strength, versatility, and durability. Which, then, does really set itself apart? In our comprehensive overview, we will examine the features, benefits, and limitations of Gorilla Glue and Loctite, enabling you to make an informed decision. From materials to ease of use, we will cover everything to help you choose the right adhesive for your specific requirement. Stay with us as we review which brand rules supreme in the glue wars!

Understanding Gorilla Glue and Loctite

Since Gorilla Glue and Loctite are two major brands of adhesives, they have different capabilities and best uses. Gorilla Glue has gained fame for the durability and adaptability of its bond. It has been primarily used as a heavy-duty glue for outdoor tasks, as it adheres to a wide range of materials, including wood, metal, ceramics, and foam, among others. Loctite, alternatively, focuses on application precision and is preferred when the job requires a quick and neat application. It is best for gluing plastics, metals, and glass, particularly for minor and more intricate repairs. Most of your decision depends on the materials being bonded and the extent of your project.

What is Gorilla Glue?

Gorilla Glue is actually a very versatile and highly durable adhesive, acclaimed for its strength and waterproof qualities. Initially designed for extremely tough industrial uses, this hardware glue gained popularity among DIY enthusiasts and professionals for its ability to cement practically any material, including wood, stone, metal, ceramic, foam, and glass, to name a few. It is a polyurethane glue that expands as it cures, ensuring a very tight hold for an extended period. Resistant to heat and weather, this glue is suitable for both indoor and outdoor use. Gorilla Glue is the trusty kind that you can depend on to form powerful and permanent bonds.

What is Loctite?

Loctite is a globally recognized brand of adhesives, sealants, and surface treatments, renowned for its effectiveness and versatility. Developed by Henkel, Loctite’s product range finds applications in various industries, including construction and automotive, as well as in household repairs and maintenance. The brand is primarily known for threadlockers, superglues, epoxies, and gasket sealants, all of which form a strong, reliable bond between various materials, including metal, plastic, wood, and many others. Loctite is extremely popular due to its precision and strong bonding power, and its products are designed for heavy-duty use, featuring temperature resistance, chemical stability, and long-term reliability. Whether it’s high-end projects or simple repairs, Loctite remains the most preferred choice for ensuring secure and lasting connections.

Key Differences Between Gorilla Glue and Loctite

Both Gorilla Glue and Loctite are leaders in their respective industries, although they have somewhat different uses and excel in other circumstances. Gorilla Glue is regarded as a flexible glue, capable of bonding with various materials by slightly expanding into the inner surface of the material. It is best for porous surfaces such as wood, stone, and ceramics. However, such a property is detrimental to applications that require high precision.

Loctite, on the other hand, is famed for its precision and special formulations. It is suitable for delicate and high-temperature applications, and it is resistant to chemicals. The range of Loctite products includes super glues, threadlockers, and epoxies, which are especially beneficial for their applications in metal, electronic, and industrial uses.

Depending heavily on the types of projects at hand, the choice rests between these adhesives. From heavy-duty and multi-surface bonding to high precision and reliability over time, Gorilla Glue works in the former, while Loctite excels in the latter.

Performance on Various Materials

| Material | Gorilla Glue Performance | Loctite Performance |

|---|---|---|

| Wood | Works incredibly well on wooden surfaces, forming a strong, water-resistant bond. | Also capable of bonding wood, but seems to be geared toward smaller, precise applications. |

| Metal | It can be used on metals, but it may lack durability or precision. | Superior for bonding metal, offering a range of formulations suitable for industrial and professional use. |

| Plastic | May work on some plastics but struggles with others, such as polypropylene or polyethylene, unless properly prepared. | Creates robust adhesion on most plastic materials, especially those with specific plastic properties. |

| Ceramics & Glass | Provides a strong bond for ceramics and glass applications. | It could serve well due to its precision and precise finish for pinpoint repairs. |

| Fabric & Foam | Tends to stiffen on such applications and is not preferred. | More reliable with fabric and foam, especially the spray or fabric-specific kinds. |

💡 Key Point: Every type of material exhibits different adhesive properties for these two products, so choosing them carefully is crucial for the success of your project.

Bonding Wood: Gorilla Glue vs Loctite

While both Gorilla Glue and Loctite offer different types of advantages in bonding wood, depending on the project’s requirements, Gorilla Glue, being a polyurethane glue, is typically known for its strength and durability in heavy-duty woodworking projects. The glue expands during the curing process, creating a tighter bond that is particularly helpful when working on uneven surfaces or when gaps between two pieces of wood form glare. The expansion will need cleanup to remove any unwanted excess.

Loctite wood glues, however, such as the ones specially formulated for wood, perform best when precision and surface cleanliness are paramount. Generally, Loctite glues cure quickly than Gorilla Glue, therefore shortening the project times. Gorilla Glue has stronger water resistance; however, Loctite can also provide some water resistance, which is beneficial for interior wood projects. Whether pure strength and gap-filling capacity are needed or precision and speed are the focus for the project will dictate what to choose.

Effectiveness of Plastic

Both Gorilla Glue and Loctite will work on plastics; however, each will work to different degrees, depending primarily on the type of plastic and the formulation of the glue. Gorilla Glue will work better with porous materials than with smoother, non-porous plastics, such as polyethylene or polypropylene. Loctite, however, manufactures special formulas, such as the Loctite Plastics Bonding System, that work in difficult situations with many types of plastic. For any plastic projects, it is essential to ensure that the glue used is compatible with the specific plastic to guarantee a strong and lasting bond.

Metal Adhesion Comparison

Choosing Gorilla Glue or Loctite for bonding metal surfaces both demonstrates the best adhesion; however, their performance depends on the needs of the application. Being a polyurethane-based adhesive, Gorilla Glue bonds well to both porous and non-porous metal surfaces with great strength and water resistance, making it suitable for outdoor or serious projects. Still, it requires clamping and a longer curing time. Loctite, particularly its epoxy formulas such as Loctite Epoxy Metal/Concrete, has been engineered specifically for metal bonding, yielding a strong bond in a relatively short time. For more minute applications involving small metal parts or repair, Loctite super glue varieties compatible with metals offer better control. Ultimately, factors such as the type of metal, environmental conditions, and the project’s structural requirements determine the choice of product.

Repairing Ceramic and Glass

When renewing or restoring ceramic or glass, the right glue choice means an undetectable, long-lasting finish. Epoxies and specialty glues for ceramics are typically recommended because they can form strong bonds and withstand high temperatures. Glass, on the contrary, favors adhesions with clear finishes; for example, UV resin works wonders to join pieces while giving an imperceptible finish. Other variables that influence the choice of adhesive are the possibility that a repaired item may become subject to water exposure or high stress. Tested in that environment and disintegrating after being wet, it means no choice should be made. Together with careful selection and observance of application guidelines, broken ceramic and glass items can often be traced back to their original function and appearance.

Key Features and Benefits of Each Adhesive

🦍 Gorilla Glue

- Versatility: This glue can bond a wide variety of materials, including wood, ceramic, metal, glass, etc.

- Water Resistance: Suitable for both indoor and outdoor use, considering its superior grade of water resistance.

- Expansion During Drying: While it cures, Gorilla Glue expands to fill out the gaps, providing a strong bond.

🔧 Loctite

- Precision: Locking the precision application, including gel formulas, is perfect for detailed repairs.

- Quick Drying: Quicker drying qualities than Gorilla Glue give the product an edge when immediacy is required.

- Specialized Strength: Depending on the product line, Locktite provides strong and reliable bonding for specific materials, including metals and plastics.

Strengths and Weaknesses of Gorilla Glue

✅ Strengths

- Versatility: Highly versatile adhesive that forms strong bonds with a wide range of materials, including wood, stone, metal, ceramic, foam, and more.

- Water Resistance: Water-resistant and weatherproof by nature, the glue is suitable for a variety of projects, both indoors and outdoors.

- Expanding Properties: Its expanding formulation will provide for utmost grip, binding together even if there are minute gaps in the materials being fixed.

- Durability: Once dried, Gorilla Glue yields an impact-resistant, long-lasting bond that can withstand significant disturbances and stresses.

❌ Weaknesses

- Expands Excessively: While Gorilla Glue can be used to fill gaps, its expansive properties can sometimes lead to over-expansion, damaging any finely worked or precision application.

- Drying Time: Typically, Gorilla Glue cures and dries more slowly than most other adhesives, which may not be suitable for time-sensitive applications.

- Surface Preparation: The glue may require surfaces to be damp to form a strong bond, which can involve additional steps in the application process.

- Messy Application: It can be a little tricky to clean if spilled or if it expands excessively, leaving stains or marks on unintended areas.

Strengths and Weaknesses of Loctite

✅ Strengths

- Versatile Formulas: Loctite boasts an extensive line of adhesives for every type of material-you name it, metal, plastic, and wood, and it’s there for it, making it very versatile for application.

- Fast Drying Time: Unlike ordinary glue, which requires waiting endlessly, Loctite offers quick drying in some products, well-suited for time-limited activities.

- Strong Bond: By providing greater tensile strength compared to others, Loctite ensures the durability and permanence of the glue in even the toughest environments.

- User-Friendly Packaging: Easy-to-use tips and applicators enable easy application of the glue, minimizing messes.

❌ Weaknesses

- Material Specificity: Certain products are limited in their usability to specific materials.

- Brittleness Over Time: Certain formulas, when subjected to varying temperature extremes and UV light exposure, can develop brittleness, thereby reducing their durability.

- Cost: Loctite adhesives may be more expensive than generic varieties, which could serve as a deterrent for users on a limited budget.

- Removal Difficulties: Disassembly can become challenging once Loctite has set; often, a solvent or special tools are required.

Application Processes and Ease of Use

Loctite Adhesives, which require user application, have been designed to include many products with easy-to-use applicators, allowing the adhesive to be dispensed in precise amounts. Most formulation methods require minimal preparation and generally exhibit good adhesion to clean surfaces. Specific instructions on the packaging ensure proper use in any circumstance, making it suitable for both professionals and DIY enthusiasts.

Application Process for Gorilla Glue

Gorilla Glue is a one-part adhesive known for its exceptional strength and durability. For best results, adhere to the following application procedure:

- Prepare the Surfaces: The surfaces to be bonded must be kept clean and dry, free from dust and any foreign particles that can settle therein. The glue will fail if the surface is heavily polluted by dust, grease, or dirt.

- Lightly Moisturize the Surface (if required): Gorilla Glue expands during curing, and the small amount of moisture helps initiate the bonding process. For non-porous surfaces, just lightly damp one surface with a cloth or spray bottle. Do not over-wet.

- Apply a Thin Layer of Glue: Use a very small amount of glue. Keep it an even layer of Gorilla Glue across one surface. Too much glue will lead to excessive foaming by the time the glue has finished expanding during its curing process.

- Clamping for a Strong Bond: Put the surfaces together and ensure even pressure is applied constantly by clamps, heavy objects, or any other suitable means to keep the surfaces in place during bonding. The clamping procedure should last at least 1-2 hours for the strongest adhesion.

- Allow Full Cure Time: Although Gorilla Glue cures and holds quickly and powerfully initially, its full strength is achieved within 24 hours. Do not subject the bonding to stress throughout this time period.

How to Use Loctite Effectively

Using Loctite correctly provides a strong and reliable bond for various purposes, including household repairs, assembly, and industrial projects. These are the proper steps to do this with perfection:

- Prepare the Surface: Ensure that the bonding surfaces of the material are clean, dry, and free from oil, grease, and dust. Wipe using a clean cloth, solvent, or mild abrasive.

- Select the Right Loctite Product: Loctite offers a range of adhesives, including threadlockers, instant glues, and construction adhesives, each specifically designed for particular materials and applications. Go for one that spectrally matches your project.

- Apply the Adhesive Sparingly: Usually, a small amount of Loctite will suffice. Apply it evenly to one surface, but use a moderate amount, as excessive application may interfere with bonding or cleanup.

- Join and Align Surfaces: Press the surfaces together and align them until the adhesive begins to set. Typically, the working time available ranges from a few minutes to a few seconds, depending on the Loctite product used.

- Allow Curing Time: Generally, most Loctite adhesives cure to working strength within 24 hours, although this may vary depending on the type. Refer to the product guidelines for precise curing times and instructions.

Choosing the Right Adhesive for Your Project

If you consider the materials you want to bond together and the demands of your particular application, you will be led to the glue most suitable for your specific purpose. For something lightweight and thin as paper or cardboard, a craft glue or glue stick would suffice. For wood, you have the option to use wood glue, which provides a strong bond between the wood surfaces. Plastics, however, require specialized adhesives for different types of plastic materials, such as epoxy types or cyanoacrylate (commonly known as Super Glue). Where metal or glass is involved, epoxy- or silicone-type adhesives should be chosen. Always read the product label to ensure it is compatible with your materials and suitable for use under the specified conditions, such as working underwater, in high temperatures, or under a heavy load. Performing any of the surface preparations, such as cleaning or Roughening of surfaces, may also sharpen bond performance.

When to Choose Gorilla Glue

When durability, versatility, and a strong bond are involved, Gorilla Glue is always an extraordinary choice. It adheres to a wide range of materials, including wood, metal, ceramic, foam, glass, and stone, making it a versatile adhesive suitable for professionals and DIY enthusiasts.

It is particularly fitting when water damage is a concern, as it provides waterproof bonding upon curing. Plus, Gorilla Glue flexes and expands as it cures, bridging small gaps to guarantee a solid bond.

If you require a glue that withstands temperature extremes, heavy-duty applications, or outdoor conditions, the answer is Gorilla Glue. However, its expansion needs to be taken into consideration so that the product is not in excess or messy, and needs to be clamped down vigorously for best results.

When to Choose Loctite

Loctite is suitable for any project that requires precise bonding on a variety of surfaces. Most recognized for their specialty adhesives, Loctite offers options for metal, plastics, wood, and virtually any surface; therefore, it is the most versatile option.

During application, it allows for a better degree of control, which might be critical for precise repair work or art. If you find yourself working with materials that require high chemical resistance or have to absorb vibrations, then you can rest assured that Loctite will do the job.

To make your work easier and faster, time-saving, quick-dry formulas of the Loctite brand are an excellent choice. Ensure you use the exact product Loctite has designed for your materials and needs to achieve the best bond.

Final Recommendations on Adhesive Use

Due to the variations in adhesives, I always consider the nature of the project, including the type of materials, strength requirements, environmental conditions, and other factors such as temperature or chemical exposure. I usually adhere strictly to the manufacturer’s instructions for optimal use and safety. Choosing the correct glue for the application ensures the reliability and longevity of the results.

Frequently Asked Questions (FAQs)

Reference Sources

Here are five professional and authoritative reference sources you can use, depending on your subject material, for checking the correctness of your article: “Is Gorilla Glue or Loctite Better?”:

- Bearing Mechanical Parts Blog

Deals with Gorilla Glue vs Loctite and so on: Uses, strengths, and areas of weakness. - AZ Billiards Forum

Provides users with insight and preferences for using specific Gorilla Glue and Loctite applications. - ScienceDirect

Offers an in-depth scientific approach to understanding adhesive performance, essentially providing a foundational knowledge of how adhesives work. - PubMed Central (PMC)

Measures adhesive performance within controlled study parameters, thus giving insight into bonding strength and reliability. - MDPI (Processes Journal)

Examines the effects of surface treatment on adhesive performance, which is significant for understanding how well a material will bond with a specific surface.