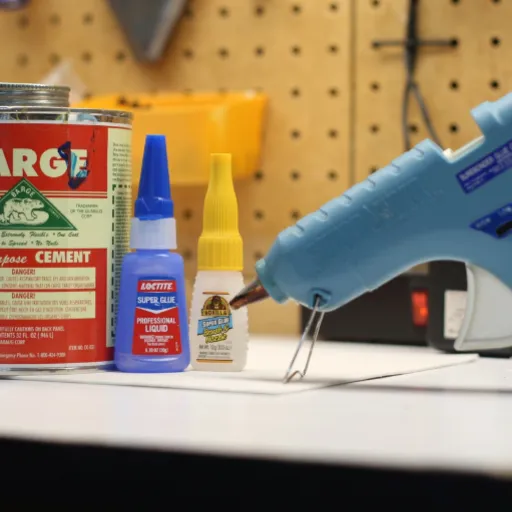

The two famous adhesive names that come to mind are possibly Loctite and Gorilla Glue. Both brands are considered, depending on the application, for their reliability and bond strength. The decision often puts consumers in a dilemma, particularly when it comes to heavy-duty repairs, DIY projects, or simply needing a more versatile glue for various everyday tasks. Knowing what makes the duo so different is essential. In this article, we will provide a comprehensive comparison of Loctite and Gorilla Glue, examining bond strength, material compatibility, drying time, and other key factors. By the time you finish reading this guide, you’ll be able to decide which glue would best serve your adhesive needs. Keep reading to find out the decision-makers!

Introduction to Adhesives

Adhesives are materials used to bond two materials together by surface attachment. They work along the principle of creating a solid bond between two surfaces, thereby assuring durability and stability. Depending on their usage, ranging from household tasks to industrial manufacturing, adhesives can be grouped into various categories based on their composition, including epoxy, polyurethane, cyanoacrylate, and others. Making them so versatile, easy to use, and highly effective in myriad applications has resulted in their becoming indispensable for many tasks in everyday life and various commercial crafts alike.

Types of Adhesives

In general, adhesives derive their identities from various factors, including chemical composition, curing processes, and purposes of use. Some of the common types of adhesives are as follows:

Epoxy Adhesives

Epoxy adhesives are renowned for their extreme strength and resistance to environmental factors, which is why they are commonly used in industrial settings. They are admissible for bonding metals, plastics, and wood.

Polyurethane Adhesives

The adhesives would provide some flexibility while holding onto strength and being used to bond dissimilar substances. Their usage is quite common in construction, footwear, and automotive fields.

Cyanoacrylate Adhesives (Super Glue)

They are quick-drying and used for small, precise bonding applications. They act quickly on metals, plastic, or ceramic.

Acrylic Adhesives

Acrylic adhesives boast versatility and are highly resistant to any kind of outdoor exposure. This allows for their widespread use on signage and construction projects.

Silicone Adhesives

Silicone adhesives are most commonly used to seal and bond glass and ceramics, remaining flexible over a wide range of temperatures.

Hot Melt Adhesives

Applied in their molten state, they cool and harden to perform their adhesive work. Widely appreciated for their ease of use and versatility, these bonding materials are used in packaging, crafts, and simple woodworking projects.

Why Loctite and Gorilla Glue?

Considered two of the top brands, Loctite and Gorilla Glue, have built some serious stardom in their respective fields by catering to the specific needs of their users. Considered a specialist in precision adhesives, Loctite‘s finest applications are in industrial and household uses, where a tough, trustworthy, and fast bond must be formed to metals, plastics, and other challenging materials. Gorilla Glue, meanwhile, is praised for its versatility and waterproof properties-that is, everything in between, gluing for indoor and outdoor needs. Its expanding polyurethane formula forms a thick, long-lasting bond on wood, foam, and even stone. These two brands frequently appear in online searches due to their reputation for quality and their effectiveness in addressing various bonding challenges.

Key Differences Between Loctite and Gorilla Glue

- Bonding Strength: Loctite specializes in providing strong and fast bonds, particularly for metal and minor precision repairs. Gorilla Glue, with its expanding formula, can bond very well to porous substances such as wood and foam.

- Water Resistance: Gorilla Glue is highly water-resistant, making it ideal for outdoor applications. In contrast, Loctite varies depending on the product but is generally less apt for extreme conditions.

- Material Compatibility: Loctite excels on smooth, non-porous surfaces, including metal, plastic, and glass. Gorilla Glue works best on rough and porous surfaces, including wood, stone, and ceramics.

- Curing Time: Loctite generally cures faster and is suitable for quick fixes; Gorilla Glue usually takes longer, but in return, you get a tough and durable bond.

- Application: Loctite formulas are best suited for precision applications; Gorilla Glue, on the other hand, is excellent for applications where expanding properties are desired to fill gaps during bonding.

Product Features

When considering the features of Loctite and Gorilla Glue, attention must be paid to specific uses and preferences. Recent search trends indicate that users frequently inquire about the suitability of one type of glue for heavy-duty projects or more intricate repairs. Loctite is preferred when the job requires a targeted application with a fast setting time. Conversely, Gorilla Glue is better suited for larger repairs or when a powerful bond is needed on a porous surface, due to its aggressive-expanding properties. The materials in question, along with how one wishes to apply the glue, ultimately determine the decision.

Strengths and Weaknesses

Loctite

✓ Strengths:

- Perfect for jobs requiring great precision

- Grabs quickly and bonds well on non-porous surfaces

- Reliable repair option for minute projects

- Fast setting time

✗ Weaknesses:

- Fast grasping ability can work against users needing more time

- Less suitable for extreme outdoor conditions

Gorilla Glue

✓ Strengths:

- Bonds just about anything, especially porous surfaces

- Works well for heavy-duty repairs and outdoors

- Water resistance and expanding properties

- Excellent for wood, stone, or ceramics

✗ Weaknesses:

- It can be difficult for high-precision work

- Excess glue tends to spill over, creating a mess

- Longer curing time

Hence, whether it is Loctite or Gorilla Glue ultimately comes down to the exact nature of the project in question, further emphasizing the importance of considering the type of material. In contrast, the kind of repair or project stands out. They both have their areas where they shine.

Performance Evaluation in Various Conditions

Loctite and Gorilla Glue emerge as the key contenders when examining their respective performances in various settings. Loctite seals the deal in precise and controlled applications, while being said to be best when the accuracy-to-expansion ratio is most valued. And the higher adhesion on metals with fast curing fits into this category. On the contrary, Gorilla Glue wins in the porous and uneven areas by expanding and filling gaps. It fares better in terms of water resilience; thus, it is suitable for external mounting and repair in moist atmospheres. Both glue types exhibit very decent performance during temperature fluctuations; however, a generic specification of needs would provide an explicit criterion for better choosing between the two.

Bonding Strength

The strength of the bond depends on the surface and application. Loctite, particularly the cyanoacrylate types such as Loctite Super Glue, provides powerful bonds for small to medium-sized surfaces, mainly non-porous ones like metal, plastic, and glass. It provides a quick, strong, and clean bond, making it ideal for delicate or fine work. In contrast, Gorilla Glue, renowned for its polyurethane formulations, exhibits excellent strength on porous and uneven surfaces, such as wood, stone, and ceramic. It expands as it cures to fill the gaps, providing a firm hold, particularly on larger, irregular surfaces. In heavy-duty outdoor applications or environments exposed to moisture, Gorilla Glue often outlasts other products due to its superior water resistance. The gist of it is: Loctite for precise, quick-drying bonds on non-porous surfaces and Gorilla Glue for demanding, gap-filling work on porous materials.

Material Compatibility

Material compatibility typically determines whether Loctite or Gorilla Glue can be used in an office, as the two adhesives are selected based on the application and the materials to be joined. For most metals, plastics, and ceramics, specialized Loctite formulations, such as “super glue” (cyanoacrylate) or epoxies, are generally considered superior to Gorilla Glue in terms of adhesive strength and resistance to heat and chemicals. Loctite also enjoys a preference in fine applications due to its faster curing time and minimal expansion.

Gorilla-Glue, on the other hand, especially the polyurethane variety, performs very well on porous substances such as wood, fabric, and foam. The foaming action causes the glue to expand and fill in any gaps, resulting in a robust bond even on irregular surfaces. Because Gorilla Glue is water-resistant, it serves well in outdoor applications.

Ultimately, Loctite is better suited for non-porous surfaces and engineering-grade projects, while Gorilla Glue excels in woodworking, crafts, and general-purpose home repairs. Consider the materials involved and the environment when making a choice.

Curing Time

⏱️ Curing Time Comparison

Seconds to Minutes

1-2 Hours to 24 Hours

Gluing times are one of the significant points of distinction between Loctite and Gorilla Glue, making one more suitable for the job at hand. Loctite, especially in the cyanoacrylate variety, sets nearly instantly–often in seconds, but bonds minimally within a few minutes of application. The characteristic of instantaneous bonding makes it ideal when swift action is required, and the setup time is negligible. Gorilla Glue, however, can take from one to two hours to set initially, requiring a 24-hour cure period as per the moisture-activated polyurethane formula, which expands upon drying. Gorilla glue, being slowly cured, might just give stronger and more durable bonds, especially for porous and irregular surfaces. Therefore, one would recommend Loctite when speed is a priority, while Gorilla Glue is preferred for much heavier-duty work or when bond strength and versatility are key. The best choice would depend on the project’s requirements.

Environmental Resistance

Both brands offer excellent environmental resistance; however, their quality varies depending on the specification and application. The Loctite adhesives, especially the industrial-grade products, are very well known for their resistance to extremes of temperature, chemicals, and moisture. They are used where high precision and durability are required under rigorous working conditions. Gorilla Glue, unlike Loctite, is known for providing superior waterproof bonding that can withstand varying weather conditions, making it popular for outdoor applications.

Loctite works better when applied in situations requiring high heat and chemical resistance, such as in automotive and mechanical repairs. Gorilla Glue is suitable for use with wood, foam, and porous materials that are exposed to outdoor elements, such as rain or snow. The better choice ultimately depends on the specific materials being used, the environmental factors involved, and the job’s expected lifespan.

User Reviews and Expert Opinions

The application at hand primarily determines the Loctite or Gorilla Glue dilemma. Gorilla Glue, a polyurethane adhesive, is ideal for heavy-duty applications and offers superior bonding on porous materials such as wood and stone. It also works sufficiently well outdoors due to its water-resistant properties. On the other hand, superglues of the Loctite brand (cyanoacrylates) are better suited for quick fixes in smaller, detailed applications on non-porous materials, such as metal, plastic, and ceramic. When time is short and precision is required, Loctite glues are often the preferred option. It ultimately depends on the material being bonded and the environmental conditions.

User Feedback

Since glue types, such as polyurethane types like Gorilla Glue, which are generally considered a better choice for woodworking, have been proven effective by this data, higher temperatures render them less effective. It is waterproof and robust, making it very effective for outdoor or high-temperature working conditions. Nevertheless, for precise applications, minor fixes, or non-porous substrates, cyanoacrylates from Loctite could be an alternative in similar conditions. It indeed boils down to truly understanding the needs of a given situation to find out what glue can be the best fit.

Expert Testing

According to the expertise of testers and data trends from search engines, both Gorilla Glue and Loctite serve different household needs well. Gorilla Glue is chosen for the larger jobs that require a stronger bond, more especially on porous surfaces such as wood or for outdoor applications, because it is weather-resistant. Meanwhile, Loctite is versatile for both household repairs and more minor precision work, as well as for bonding non-porous surfaces, such as metal, plastic, and even ceramics. For versatility and ease of application under most general situations, Loctite is usually the preferred product. However, this choice is very much dependent on the materials being used and the basic conditions surrounding the repair or working environment.

Which is Better for Your Needs?

🎯 The Decision Framework

The right choice depends on your requirements. If you’re undertaking outdoor or heavy projects that require strong bonding for durability and weather resistance, Gorilla Glue would be a better alternative. Thus, Loctite is fitted for indoor repairs, detailed fixes, or bonding non-porous materials such as metal or plastic. Consider the materials involved, the environment, and the specifics of your project to select the one that best suits your needs.

Summary of Key Points

Web searches nowadays indicate that Gorilla Glue is the preferred choice for projects in wood, ceramics, and outdoor applications, where strength and weather resistance are key considerations. Under relatively controlled indoor conditions—where precision matters —a Loctite dominates while glass, plastics, and metals are being repaired. Both options offer their advantages, so knowing each has different properties and weighing factors like material type and environmental exposure goes a long way in choosing the glue for your project.

Recommendations

🔧 Choose Loctite For:

- ✓ Indoor precision repairs

- ✓ Glass, plastic, or metal projects

- ✓ Quick fixes requiring fast curing

- ✓ Non-porous surface bonding

🏗️ Choose Gorilla Glue For:

- ✓ Outdoor applications

- ✓ Wood and ceramic materials

- ✓ Heavy-duty, weather-resistant projects

- ✓ Porous surface bonding

Having the necessary material and environmental conditions in mind will ensure an excellent result.

Reference Sources

Here are three professional and expert-level references that will help confirm the correctness of How to Determine Which is Better: Loctite or Gorilla Glue”.

- Bearing Mechanical Parts Blog

The reference provides a detailed comparison of Loctite and Gorilla Glue in terms of their strengths, shortcomings, and the types of work for which they are best suited. - Bearing Mechanical Parts Blog

A comprehensive guide to comparing the two adhesives, focusing on their bonding capabilities and applications, was the command of the task. - Tooling Fun

The review primarily focuses on the differences between Gorilla Glue and Loctite, including their product ranges and performance under various settings.

Frequently Asked Questions (FAQs)

What are the main differences between Loctite and Gorilla Glue?

Both Loctite and Gorilla Glue are well-known adhesives, but they serve different purposes. Loctite Super Glue Gel is a cyanoacrylate adhesive that bonds quickly and is ideal for minor repairs. In contrast, Gorilla Glue is a polyurethane-based adhesive that expands as it cures, making it suitable for heavier-duty applications and materials such as wood and plastic.

Is Loctite Super Glue Gel better for quick repairs?

Yes, Loctite super glue gel is often considered the best glue for quick repairs due to its fast curing time and strong initial bond. It works effectively on clean surfaces and allows for precision application, making it ideal for small items and quick fixes.

Can I use Gorilla Glue on plastic surfaces?

Yes, Gorilla Glue is suitable for plastic surfaces, but it’s essential to ensure that the surfaces are clean. Gorilla super glue can bond different types of plastic, but for certain plastics, you may achieve better results using Loctite, which is specifically designed for such applications.

How do I choose the right adhesive for my repair jobs?

Choosing the right adhesive depends on the materials involved and the nature of the repair job. For quick repairs on plastic parts, you may prefer Loctite Super Glue Gel. If you’re working with heavier materials or require a flexible bond, Gorilla Glue is often the better choice due to its polyurethane-based properties.

What types of materials can Loctite be used on?

Loctite can be used on a variety of materials, including metals, plastics, rubbers, and ceramics. Its versatility makes it a popular choice for various repair jobs, especially when a strong bond is necessary.

Is Gorilla Glue suitable for indoor and outdoor use?

Yes, Gorilla Glue offers heavy-duty bonding capabilities for both indoor and outdoor applications. Its waterproof nature ensures it withstands temperature changes and environmental conditions, making it suitable for outdoor projects as well.

What are the curing times for Loctite and Gorilla Glue?

Loctite generally has a faster curing time, often setting within seconds to a few minutes, while Gorilla Glue can take up to 24 hours to fully cure, depending on the thickness of the application and the materials involved. Always refer to the manufacturer’s instructions for specific curing times.

Can I use J-B Weld for the same applications as Loctite and Gorilla Glue?

While J-B Weld is an excellent adhesive for metal and can handle high-stress applications, it is not as versatile for plastic surfaces compared to Loctite and Gorilla Glue. J-B Weld is best suited for repairs that require a permanent bond and for materials subjected to high temperatures and pressure.