Finding the correct adhesive is paramount for construction or repair projects that involve bonding metal to concrete, as only such an adhesive can guarantee durability and performance. Whether you are installing structural beams, fixing damaged surfaces, or fabricating industrial art, the adhesive you choose can make or break your project. This comprehensive guide explores three robust bonding solutions—Epoxy, Loctite Epoxy, and Polyurethane adhesives—helping you understand their individual characteristics, applications, and benefits. By the end of this article, you’ll be equipped to select the perfect adhesive for your project, whether your priority is strength, versatility, or resistance to extreme conditions.

Understanding Adhesives for Metal and Concrete Surfaces

Choosing a bonding agent appropriate for the surfaces to be joined is crucial for bonding metal to concrete. Epoxy adhesives stand out as among the best bonding agents, primarily recognized for their incredible strength and longevity. The chemical bonding achieved with these adhesives is so powerful that they can carry heavy loads, making them the perfect choice for industrial or structural applications. If curing times are a concern, fast-setting epoxy options provide powerful results without long waiting times.

Polyurethane adhesives, on the other hand, offer exceptional flexibility and demonstrate remarkable bonding capability to non-standard and porous surfaces, such as rough concrete. They excel in conditions with frequent temperature fluctuations and movement, situations that require some elasticity in the bond.

⚠️ Important: Appropriate performance is guaranteed only when surfaces are properly cleaned and prepared before adhesive application. Removing dirt, grease, and dust significantly enhances bonding strength, ensuring a reliable, durable connection.

What is Metal to Concrete Adhesive?

Metal-to-concrete adhesive is a specialized bonding agent designed to create permanent connections between metal surfaces and concrete substrates. These adhesives typically contain advanced epoxy or polyurethane compounds that form strong, durable, and weather-resistant bonds. They are primarily used in construction, engineering, and maintenance applications where mounting metal components—such as beams, brackets, or fixtures—to concrete structures is required.

Key Characteristics

- Exceptional resistance to moisture, temperature changes, and vibrations

- Ability to withstand environmental factors over extended periods

- Ease of application with manageable curing times

- Suitable for both professional and DIY projects

- Maximized performance through proper surface preparation

Types of Adhesives: Epoxy and Polyurethane

Epoxy Adhesives

Epoxy adhesives have earned industry recognition for their exceptional strength and durability in metal-to-concrete bonding applications. They consist of a two-component system comprising a resin and a hardener that create a powerful chemical bond when combined. The bonding created by these adhesives can endure substantial stress, making them ideal for structural applications.

Advantages of Epoxy Adhesives:

- Superior Load Capacity: Can withstand significant stress and heavy loads

- Environmental Resistance: Excellent resistance to moisture, chemicals, and extreme conditions

- Extended Working Time: Allows for accurate application and adjustments before full curing

- Long-Term Performance: Ensures extended durability in demanding applications

Polyurethane Adhesives

Polyurethane adhesives are widely recognized for their versatility, delivering high performance in both metal and concrete bonding applications and offering added flexibility. A notable feature of these adhesives is their ability to absorb and counteract vibrations while allowing slight movement between bonded surfaces. This characteristic makes them particularly suitable for applications subject to dynamic stress or temperature variations.

Advantages of Polyurethane Adhesives:

- High Flexibility: Accommodates movement and vibration between surfaces

- Quick Curing: Typically cures within 24 hours, ideal for time-sensitive projects

- Versatile Application: Suitable for both professional and DIY use

- Multi-Surface Bonding: Works well with various materials including wood, concrete, steel, foam, and ceramic

Note: While polyurethane adhesives offer excellent flexibility and quick curing, their environmental resistance may not be as robust as epoxy counterparts. They are best suited for indoor or moderately exposed projects rather than harsh outdoor applications.

Comparing Loctite Epoxy and Polyurethane Construction Adhesive

When selecting between Loctite Epoxy and Polyurethane Construction Adhesive, understanding the key differences in strength, flexibility, curing time, durability, and environmental suitability is essential for project success.

| Parameter | Loctite Epoxy | Polyurethane |

|---|---|---|

| Strength | Very High | Moderate |

| Flexibility | Low | High |

| Cure Time | Moderate | Quick |

| Durability | Excellent | Good |

| Use Cases | Indoor/Outdoor | Indoor |

| Moisture Resistance | Resistant | Moderate |

| Temperature Range | Wide | Limited |

| Ease of Use | Moderate | Easy |

Understanding Metal and Concrete Surfaces

Metal and concrete surfaces differ radically in composition, texture, and bonding requirements. Understanding these differences is essential for selecting appropriate adhesives, ensuring durability, and achieving optimal results.

Characteristics of Concrete Surfaces

Concrete surfaces have earned a reputation for their robustness and versatility, making them widely used in construction and interior design. The inherent porosity of concrete can be advantageous for adhesive bonding when properly sealed or primed. However, unsealed concrete may result in weak, uneven bonds due to moisture absorption.

Surface Porosity

Can enhance adhesive grip when properly sealed, but may weaken bonds if untreated due to moisture absorption.

Surface Texture

Typically rough and coarse, which enhances mechanical grip for adhesives and coatings

Preparation Requirements

Regular cleaning and surface preparation ensure long-term performance under varying conditions.

Properties of Metal Surfaces

Metal surfaces are characterized by their durability, strength, and wear resistance, making them ideal for industrial and engineering applications. They typically exhibit high thermal and electrical conductivity, reflective properties, and minimal deformation under normal conditions.

Durability & Strength

Excellent wear resistance and structural integrity for demanding applications

Surface Characteristics

Usually smooth and non-porous, requiring special treatments for optimal adhesive bonding.

Corrosion Concerns

Susceptible to corrosion when exposed to moisture; protective coatings are essential

Challenges in Bonding Metal to Concrete

Bonding metal to concrete presents several technical challenges due to fundamental material differences. Understanding these obstacles is crucial for achieving successful, long-lasting bonds.

Key Challenges:

- Thermal Expansion Differences: Dissimilar expansion rates between metal and concrete create interface strains that can lead to cracking or bond failure over time.

- Surface Incompatibility: The rough, porous nature of concrete contrasts sharply with the smooth, non-porous nature of metal surfaces, requiring specialized surface treatments for proper adhesion.

- Moisture Issues: Concrete’s moisture retention can cause metal corrosion, rapidly weakening the bond and compromising structural integrity.

Solutions for Successful Bonding:

- Thorough surface preparation using appropriate cleaning and roughening techniques

- Selection of specialized adhesives designed for dissimilar materials

- Integration of mechanical fasteners or anchors to reinforce the bond

- Proper assessment of environmental conditions and load requirements

- Application of protective coatings to prevent moisture-related corrosion

Types of Adhesives for Bonding Metal to Concrete

Various adhesives are available for metal-to-concrete bonding, each with distinct properties suited to specific applications. The following comparison helps identify the most appropriate option for your project needs.

| Adhesive Type | Strength | Durability | Flexibility | Cure Time | Primary Uses |

|---|---|---|---|---|---|

| Epoxy | High | Excellent | Low | Moderate | Structural Applications |

| Polyurethane | Moderate | Good | High | Fast | General Construction |

| Silicone | Low | Moderate | High | Fast | Sealing Applications |

| Construction | High | Excellent | Moderate | Slow | Heavy-Duty Projects |

| Acrylic | Moderate | Good | Moderate | Fast | Repairs & Quick Fixes |

Overview of Epoxy Adhesives

Epoxy adhesives are renowned for their exceptional strength and durability, making them ideal for heavy-duty applications across multiple industries. Their versatility in bonding various materials—including metals, plastics, wood, and ceramics—combined with remarkable resistance to environmental factors, establishes them as a premier choice for demanding projects.

Key Features of Epoxy Adhesives

🔧 Superior Strength

Forms powerful chemical bonds capable of supporting heavy loads and withstanding significant stress

🌧️ Environmental Resistance

Excellent resistance to moisture, heat, and chemical exposure for an extended lifespan

⏱️ Moderate Curing

Provides adequate working time for precise application and adjustments before complete setting

🏗️ Multi-Industry Use

Extensively used in construction, automotive, and manufacturing sectors

Loctite Epoxy: A Reliable Choice

Loctite Epoxy stands out as a trusted solution, delivering exceptional bond strength and reliability even in harsh conditions. Its ability to maintain consistent performance across extreme temperature ranges makes it suitable for diverse environmental applications.

Why Choose Loctite Epoxy?

- Rapid Setting: Quick set time of 5 to 20 minutes (depending on formulation) allows for efficient project completion

- Temperature Stability: Performs consistently in both high- and low-temperature environments.

- Strong Rigid Bonds: Creates powerful, inflexible connections capable of supporting various materials including metal, wood, ceramic, glass, and plastic

- Versatile Applications: Suitable for both repair work and large-scale construction projects

- Professional Performance: Delivers reliable, durable bonding solutions across multiple industries

Polyurethane Construction Adhesive: Advantages and Applications

Polyurethane construction adhesive extends far beyond basic bonding applications, offering remarkable versatility and performance. Its ability to bond to diverse surfaces—including wood, concrete, steel, foam, and ceramic—makes it an invaluable choice for a wide range of construction and repair applications.

Advantages of Polyurethane Construction Adhesive

💧 Superior Waterproofing

Creates completely waterproof bonds, ideal for high-humidity environments or areas with potential water exposure

⚡ Quick Curing Process

Cures rapidly within 24 hours, significantly reducing project timelines

🔄 Exceptional Flexibility

Allows controlled movement between bonded materials, perfect for applications experiencing vibrations or stress

🛠️ Wide-Ranging Applications

Ideal for flooring installations, cabinetry, outdoor fixtures, and general construction projects

Application Techniques for Effective Adhesion

Achieving strong, lasting metal-concrete joints requires proper surface treatment and correct adhesive application. Following systematic procedures ensures optimal bonding performance and long-term durability.

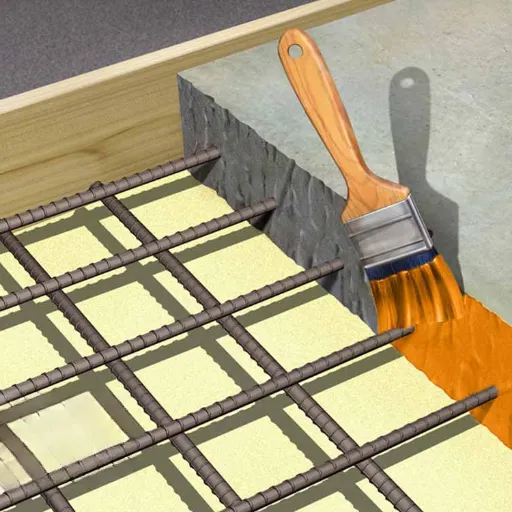

Preparing Surfaces for Bonding

Appropriate surface preparation is the foundation of securing a strong, reliable bond. This critical process determines the ultimate success of your adhesive application.

✓ Surface Preparation Checklist

- Clean Thoroughly: Remove all dirt, grease, oil, and debris using appropriate cleaners or solvents suitable for both metal and concrete.

- Ensure Complete Drying: Verify surfaces are dehydrated before adhesive application, as moisture significantly weakens bonds.

- Roughen Smooth Surfaces: Lightly sand very smooth materials with fine-grade sandpaper to create texture that enhances adhesion

- Remove Residual Dust: Wipe surfaces with a clean, dry cloth after sanding to eliminate all dust particl.es

- Verify Surface Condition: Inspect prepared surfaces to ensure they meet cleanliness and texture requirement.s

Step-by-Step Guide to Applying Adhesives

Follow this comprehensive application process to achieve professional-quality results in your metal-to-concrete bonding projects.

Complete Application Process

Prepare the Surfaces

Clean both metal and concrete surfaces thoroughly to remove all dirt, oil, and contaminants. Use a cleaner or degreaser suitable for both materials to eliminate all residues.

Dry the Surfaces

Before proceeding, verify that surfaces are completely dehydrated. Moisture can significantly weaken the adhesive bond and negatively affect overall performance.

Roughen the Metal Surface

Lightly roughen the metal surface using sandpaper, a wire brush, or another abrasive tool. This creates enhanced mechanical grip for superior adhesive performance.

Ensure a Dust-Free Surface

After sanding or roughening the metal, use a clean, dry cloth to wipe away all dust or debris. This ensures smooth, even adhesive application.

Mix the Adhesive (If Applicable)

For two-part adhesives, carefully follow the manufacturer’s instructions for mixing components. Ensure thorough, uniform mixing for optimal performance.

Apply the Adhesive

Apply adhesive evenly to the concrete or metal surface as directed by product instructions. Use an appropriate applicator—such as a brush, trowel, or caulking gun—to spread the adhesive uniformly.

Press the Materials Together

Carefully position the metal component on the concrete and apply gentle but consistent pressure. Ensure complete contact between the adhesive and both surfaces.

Clamp or Secure the Bond

Use clamps, weights, or other securing methods to hold the metal and concrete in position while the adhesive sets. This eliminates movement that could weaken the bond.

Allow Proper Curing Time

Consult the adhesive manufacturer’s guidelines for required curing time. Avoid touching or stressing the bonded area until the adhesive is completely cured.

Inspect the Bond

After complete curing, thoroughly inspect the bond to verify security. Test the adhesion gently to ensure the bond has set correctly and meets quality standards.

Tips for Ensuring Strong Bonds

🧼 Clean Surfaces Thoroughly

Ensure both surfaces are spotless, dry, and free of dust, grease, or debris. Use suitable cleaners to enhance adhesion quality.

🎯 Use the Right Adhesive

Select an adhesive specifically formulated for the materials you’re bonding. Material-specific adhesives ensure optimal bond strength.

💪 Apply Even Pressure

Hold surfaces tightly together during curing with clamps or weights to maintain uniform pressure for a strong, even bond.

📋 Follow Instructions

Always comply with the manufacturer’s guidelines for application methods, curing time, and temperature requirements.

🌡️ Optimal Conditions

Avoid extremely hot, cold, or humid conditions, as they can reduce adhesive effectiveness and compromise bond strength.

Expert Insights and Recommendations

Choosing the Right Adhesive for Your Project

Selecting the appropriate adhesive is fundamental to project success and longevity. Your choice should be guided by careful consideration of multiple factors that influence bonding performance.

Key Selection Criteria

💡 Professional Tip

When selecting adhesives, prioritize those suitable for various materials or adaptable to different conditions. Reading professional reviews and consulting experts ensures you select the right product for your specific project. Always test the adhesive on a small area first before full-scale application to verify suitability and performance.

When to Seek Professional Help

While many bonding projects are suitable for DIY approaches, certain situations warrant professional expertise to ensure optimal results and prevent costly mistakes.

Situations Requiring Professional Assistance:

- Complex Projects: Applications involving specialized adhesives or intricate bonding techniques beyond standard procedures

- Valuable Materials: Projects using expensive or irreplaceable materials where errors could result in significant financial loss

- Delicate Substrates: Bonding fragile materials that require expert handling and precise application methods

- Structural Applications: Load-bearing bonds critical to structural integrity and safety

- Uncertain Specifications: When unsure about adhesive selection or application procedures

Professional specialists provide expert guidance, ensure correct application, prevent damage, and ultimately save time and resources.

Future Trends in Adhesive Technologies

The adhesive industry continues to evolve rapidly, driven by technological innovation and increasing environmental consciousness. Several emerging trends are shaping the future of bonding solutions across multiple industries.

🌱 Eco-Friendly Adhesives

Sustainable adhesives are gaining prominence as industries prioritize environmental responsibility. Bio-based, solvent-free formulations represent the shift toward greener bonding solutions without compromising performance.

🤖 Smart Adhesives

Intelligent adhesives that adapt to environmental changes—such as temperature fluctuations or humidity variations—offer enhanced performance in dynamic conditions, expanding application possibilities.

🔬 Nanotechnology Integration

Advances in nanotechnology enable production of stronger, lighter adhesives with superior performance characteristics. These innovations expand applications in aerospace, electronics, and precision manufacturing sectors.

Industry Outlook: These developments indicate the adhesive industry is progressively moving toward more efficient, environmentally responsible, and adaptable bonding solutions that meet the evolving demands of modern construction, manufacturing, and engineering applications.

Reference Sources

-

Development of Epoxy Materials for Highway Use (PDF)

Discusses the development of epoxy adhesives for bonding steel and concrete in highway applications. -

DeepMaterial Technologies’ Epoxy Adhesive Glue (PDF)

Explores the versatility of epoxy adhesives for bonding materials like metal, concrete, and composites. -

Novel Adhesive Anchoring Systems through Engineered Adhesive-Concrete Interface

Examines adhesive anchoring systems using epoxy to bond metal inserts in concrete for construction applications. -

Repair of Epoxy-Coated Reinforcement (PDF)

Provides insights into the use of epoxy coatings and adhesives for repairing and reinforcing concrete structures. -

Comprehensive Investigation of Epoxy Adhesives for Construction Applications

Highlights the strength, durability, and chemical resistance of epoxy adhesives for bonding metal and concrete.

Frequently Asked Questions (FAQs)

❓ What is the strongest adhesive for attaching metal to concrete?

Premium epoxy resin adhesives typically provide the strongest bonds for metal-to-concrete applications. Products such as Loctite Epoxy Metal and Gorilla Glue offer exceptional durability and resistance to moisture and most common solvents. These high-performance adhesives form bonds strong enough to withstand diverse environmental conditions and heavy loads, making them ideal for structural and industrial applications.

❓ What is the process of adhesion between metal and concrete?

Metal-to-concrete adhesion occurs when an adhesive penetrates the microstructure of both surfaces and forms chemical bonds with each material. High-strength epoxies—composed of an epoxy resin and hardener—penetrate concrete pores while bonding to the metal surface, creating an exceptionally durable connection. Proper surface preparation significantly enhances this adhesion process by improving mechanical grip and chemical bonding potential.

❓ Does electricity pass through when concrete and metal are in contact?

Concrete does not conduct electricity under normal circumstances. This characteristic is beneficial for metal construction applications, as you can safely attach metal to concrete without concern about electrical conduction. When using high-strength epoxy or similar adhesives, the bond remains reliable over time without any electrical complications or safety concerns.

❓ What is the advantage of using a double syringe applicator for epoxy adhesives?

A double syringe applicator ensures optimal performance by automatically mixing components in the correct ratio. This feature is essential when joining dissimilar materials, such as metal and concrete, to form strong, reliable bonds. The applicator simplifies the mixing process while providing precise control over application, making it significantly more user-friendly and reducing the risk of mixing errors that could compromise bond strength.

❓ Can construction adhesive be used to join metal to concrete?

While construction adhesive can be used to join metal to concrete, it is advisable to use a high-strength epoxy specifically designed for this challenging application. Products such as Loctite PL Premium Polyurethane Construction Adhesive are cost-efficient alternatives that provide excellent bonding surfaces and enhanced durability. However, for critical structural applications or harsh environmental conditions, dedicated metal-to-concrete epoxy formulations offer superior long-term performance.

❓ Is there a sure way to prepare concrete surfaces for adhesives?

Yes, proper concrete surface preparation is critical for achieving optimal adhesive performance. Follow these essential steps:

- Thorough Cleaning: Wash the concrete extensively to remove all dust, dirt, and oil contaminants

- Surface Roughening: Create texture using a grinder or sandpaper to enhance mechanical bonding

- Complete Drying: Ensure the surface is completely dry before adhesive application

- Final Inspection: Verify the surface is clean, rough, and ready for bonding

These preparation steps significantly improve the bond strength between metal and concrete, ensuring long-lasting, reliable connections.

Final Thoughts

Selecting the right adhesive for bonding metal to concrete is a decision that significantly impacts project success, durability, and long-term performance. Whether you choose the superior strength of epoxy adhesives, the trusted reliability of Loctite Epoxy, or the flexibility of polyurethane construction adhesives, understanding each option’s unique characteristics empowers you to make informed decisions. Remember that proper surface preparation, correct application techniques, and adherence to manufacturer guidelines are just as important as adhesive selection. By following the comprehensive guidance provided in this article, you’re equipped to achieve professional-quality bonds that stand the test of time, environmental challenges, and demanding applications.