In securing threaded fasteners, the man often finds himself debating two very popular options-Loctite thread lock or super glue. They may appear interchangeable at first, but this may be very deceptive. For a DIYer, an experienced mechanic, or just someone looking to solve a simple problem, using the correct adhesive can mean a flawless job versus frustration filling up the time. Let’s take a plunge into the watership rabbit: the difference between thread lock and super glue, exploring their pros and cons and discussing if super glue is an alternative at all to Loctite in some instances. So read on to know which one makes the right choice for your project!

Understanding Super Glue

What Is Super Glue?

Super glue is an extremely fast-acting fast-setting adhesive that bonds almost anything into an instant. Cyanoacrylate is its main ingredient and forms a strong, permanent bond when it reacts with moisture. It is basically the best glue to use in small repairs and crafts on metals, plastics, wood, ceramics, or rubbers because of its application convenience and effectiveness.

In action, the adhesion arises from the chemical reaction between the glue and the water molecules present in humidity or from any other source. It forms a great deal of pressure upon adhesion by immediately sealing the materials together with a hardening effect. Fast drying up enables the super glue to provide the glue exactly when the glue is required, but this limits most of its practical applications where elongation or bonding over broad surface areas is necessary.

Super glue can find a place in different kinds of applications, but it is not fully suitable for any one application. This glue can be brittle if it is under great stress or extreme temperatures and does not stand well on porous irregular surfaces where it cannot completely bond. Furthermore, most accidental adhesions can be heinous when unintended: it can glue the skin together or bond fingers to the wrong surface, so it must be used with extreme care.

Chemical Properties of Cyanoacrylate Adhesives

Instantly bonding cyanoacrylates owe their behavior to the peculiar nature of this chemical system. The adhesives are essentially acrylic resin-bearing substances that polymerize almost instantaneously in moisture or, more specifically, in water molecules. This rapid reaction creates a strong, permanent bond, with cyanoacrylates hence being ideal for application in a plethora of areas. Chemically, they have the ability to bond with a variety of materials such as metals, ceramics, plastics, and human tissue.

Stability of cyanoacrylate adhesives depends on temperature and environmental conditions. They work well at room temperature, but they tend to get degraded in high extremes of temperatures or below freezing points. Their tackiness below strong humid conditions or full-time soaking into water is also adversely affected as the polymerized bond’s long-term stability gets challenged under these conditions. Despite these limitations, they are really good, practically efficient adhesive tools with crease strength in combining with any non-porous surfaces.

Another solvent-resistant characteristic is possess by cyanoacrylates, which renders them difficult to remove once cured. On the contrary, acetone, as well as many other solvents specifically formulated against cyanoacrylates, dissolve the polymerized structure. When working with these adhesives, caution must be exercised, particularly with regards to bonding of human skin as this constitutes one of the most frequent accidents. Knowledge of these chemical properties assists in safe and resourceful application with maximal benefit of the potential for this adhesive in varied scenarios.

Common Applications of Super Glue

Super glue is widely used in everyday household repairs because it can form a strong bond fast. It is great to join a broken piece of ceramic, plastic, wood, or even metal. Since it can bond almost any combination of materials, it seems to be the go-to for small repair jobs that normally would warrant buying new items or asking for professional help.

It finds applications in industrial and construction domains too. Assembling small components or reinforcing materials under low stress is best achieved by a strong and durable bond from super glue. It is also involved in modeling, electronics, and crafting, all of which require speed and exactness. Such capability makes it suitable for the requirements of different professional applications.

Finally, super glue is used in some medical cases to close minor wounds or surgical incisions. Medical-grade cyanoacrylate adhesives have been used as a fast alternative to suturing in certain isolated cases, providing a less invasive closure method. While not suitable in every case, its medical uses stress the adaptability and wide utility of super glue.

Exploring Loctite and Thread Lockers

What is Loctite?

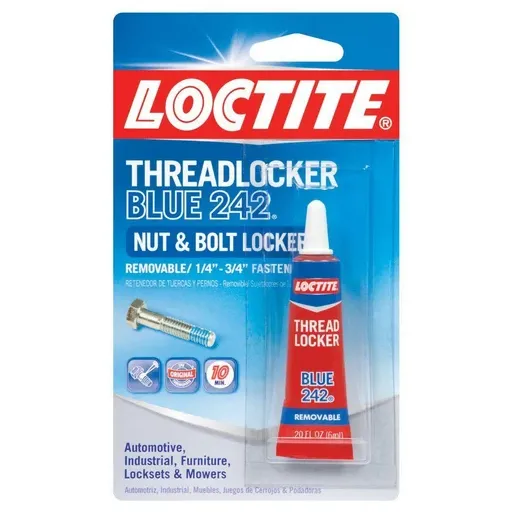

Loctite is a brand of adhesives and sealants that are most popularly recognized for their thread lockers. Thread lockers are adhesives that keep fasteners from loosening due to vibration, shock, or thermal expansion. These adhesives contribute to the reliability and longevity of joints within mechanical assemblies.

Loctite thread lockers are primarily used to keep bolted joints secure by filling the gaps between threads. This creates a strong bond resistant against movement and seals the joint to protect it from corrosion or leakage. They come in different grades to suit particular applications, ranging from those that allow disassembly within a short period to those for permanent application in more demanding applications.

Loctite products are used in industries such as automotive, aerospace, construction, and manufacturing. They furnish safety and security in high-stress conditions where fasteners undergo heavy vibrations or some environmental factors. In situations where thread lockers have proven their reliability, they reduce maintenance and enhance service life.

Types of Thread Lockers and Their Uses

Thread lockers are further subdivided into many formulations to suit application needs. They are classified as removable, permanent, and resistance to heat, each presenting specific features and benefits:

- Removable Strength Thread Lockers: In cases where disassembly is expected, removable-strength thread lockers, like Loctite 243 and 222, will hold the parts together and allow for easier removal through the use of any standard hand tool. They are used mostly in fasteners of electronics, pumps, and small engines. For example, Loctite 243 is deemed a medium-strength thread locker which is suited to oily surfaces and is resistant to vibration and corrosion.

- Permanent Strength Thread Lockers: In permanent strength grade, thread lockers such as Loctite 271, are applied in high stakes situations, where it is needed for the threaded fasteners to be bonded tightly with no loosening from vibration or shocks. It is used in heavy machinery, automotive transmissions, and structurally mounted applications requiring long-term connections.

- High-Temperature Resistant Thread Lockers: High-temperature thread lockers such as Loctite 272 are intended for extreme heat environments and are, therefore, appropriate for power plants being considered for industrial ovens and automotive exhaust systems.

- Wicking Grade Thread Lockers: The wicking thread lockers, represented by Loctite 290, are low-viscosity solutions that are meant to flow into fasteners that have been pre-assembled, making them ideal for securing existing bolts without disassembly. They find their uses mostly in electrical connections or in difficult-to-reach places.

Each thread locker species serves to ensure the safety, durability, and longevity of fasteners in various industrial and mechanical scenarios. When selected according to needs-basis formulations, the user is able to cater for reversibility, environmental resistance, or high stress types. Today, with the promise of performance and reliability, thread lockers remain fundamental to both manufacturing and maintenance.

Advantages of Using Loctite

A thread locking solution can provide countless benefits in instances where strength and reliability are of utmost importance. These products prevent loosening due to constant vibration or operational stresses over time, ensuring that the fasteners remain secured. This condition alleviates any possibility of the equipment drifting toward failure or maintenance issues, applying to their overall performance in the long run.

Another advantage is the prevention of corrosion or wear of threaded components. Keeping moisture, chemicals, and any other contaminant away extends the life span of the fastener and the part connected. Such protection would be best fit in environments that involve exposure to harsh conditions, such as heavy industries or outdoor applications.

Finally, these solutions increase efficiency by making the costs for maintenance and replacement lower. Therefore, once applied, they almost eliminate the chances that these fasteners will go for further checks or manual re-tightening, thus saving time and effort for technicians. This sort of dependability, in turn, allows for smooth running in both industrial and simple everyday applications, making it a good option relative to its cost.

Super Glue vs. Loctite: Key Differences

Adhesive Strength and Durability

Several custom features can make an adhesive strong and durable and application dependent, thereby requiring specific conditions. Both form excellent bonds, but depending on the materials and usage conditions, one adhesive may have higher tensile strength and would work well for heavy-duty applications, whereas another would undergo better usage under flexibility and resilience induced by stresses.

In durability, the factors affecting it are usually environmental-medial conditions such as moisture, heat, or chemicals. Some adhesives favor higher temperature environments and will keep their bond strength over time, whereas others would resist water or chemical exposures better. Hence, it would be important to first look into the environment in which the adhesive is going to be exposed and analyzed.

The decision is made finally, depending upon the operation. One might suffice in cases requiring short jobs with moderate strengths. The other will be preferred for hard ones that need to endure harsh environments. Appreciating the difference will ensure that the respective adhesive is chosen so as to give the intended application assurance of performance and longevity.

Drying Time and Application Techniques

Time is of the essence for an adhesive application as it simultaneously influences the quality and strength of its bond. A myriad of factors come into play in determining the drying time of an adhesive, including the weather of the day and custom bonded materials. Fast-setting adhesives tend to lend themselves best to time-bound projects; however, slower-drying ones may be used in projects where utmost precision is required, or a stronger bond must be established.

Application techniques are quite crucial in making sure that the adhesive does exactly what it was meant to do. These include surface preparations that should ideally maintain cleanliness-wipe-free from any greasy substances or forms of debris that may get in the way of adhesion. Making sure the adhesive is evenly applied thinly over the surfaces to be bonded will help in preventing possible places of weak adhesion. Depending on the adhesive consistency or size and scope of application project, brushes, rollers, or perhaps applicator nozzles may be employed.

Using the adhesive after application must be done carefully and according to the curing time recommended for its use. This period allows the adhesive to develop full strength to optimize its performance. Guidelines for the product should be referenced, for failure to observe these will very often be to the detriment of the result. Carefully adjusted drying time combined with appropriate environmental conditions and application approaches will hopefully deliver an adhesive bond that performs well in the long term.

Material Compatibility: Plastic and More

Adhesives find several applications with different materials, with plastics presenting unique challenges. Plastics differ with respect to surface energy, chemical structure, and texture, which, in turn, impacts the bonding performance of an adhesive. High surface energy plastics such as polycarbonate or ABS generally bond well compared to low surface energy plastics such as polyethylene or polypropylene. Surface treatments like flame treatment, abrasion, etc., may enhance compatibility to improve bonding performance.

Besides plastics, adhesives are versatile and work well with metals, wood, ceramics, and composites. Each material type places a demand on the adhesive’s properties from the strength it exhibits to flexibility under various environmental conditions. For instance, metals may require adhesives that resist moisture and corrosion very strongly while wood may require adhesives that permit some degree of movement as the wood expands or contracts.

Matching the proper adhesive to each material thus ensures performance and reliability in the long run. It is important to match an adhesive type such as epoxy or cyanoacrylate, or polyurethane adhesive to the actual requirements of materials being bonded. When working with complex or different materials, tests and consulting accepted practices significantly increase the odds for success.

When to Use Super Glue Instead of Loctite

An Ideal Glue Project

Primarily, superglues are suited for projects that require quick bonding with minimal surface preparation. Superglue is great in small repair jobs and precision operations where materials such as plastic, metal, ceramic, and rubber are used. It fixes a variety of broken household objects quickly and holds them together securely while you fix on delicate parts or make small décor items.

Instant bonding with great strength is probably its best feature when working with non-porous surfaces. This makes an excellent application where the joint is expected to be invisible and strong without relying on clamps or external supports. For example, supergluing is often used on cracked ceramics, small dirt-smudges on hobbies or models, and also fixing slight cracks in everyday objects.

But it does have its shortcomings. It will not give good results if used for flexible materials and porous ones such as fabrics. Exposure to moisture, and heat may weaken the bond. If your project requires the glue to demonstrate durability under stress, temperature changes, or across wider surface areas, then other adhesives might be more imperative. When choosing an adhesive for any project, always weigh the requirements before deciding that super glue fits.

Considerations for Using Super Glue on Threads

Super glue can be used on threads with careful consideration. Being strong and fast-drying, super glue does not really see the best uses for joinery with threads because they are often porous and flexing. Since super glue is best on rigid non-porous surfaces, the application of super glue on threads might not provide a durable bond, especially when the material will be subjected to motion or strain.

When applying super glue to threads, make sure the surface is clean and dry. Dirt and moisture can obstruct the bonding process, yielding weaker results. Furthermore, the glue should not be applied in large amounts; large quantities make threads stiff and cause the glue to clump, ruining both the texture and function of the tread.

For projects that require flexibility or long-term durability under constant movement, a more suitable adhesive might be considered, such as fabric glue. They are made especially for the use of threads and fabrics and hence provide higher flexibility and resilience. Always test on a small, inconspicuous area to ensure proper bonding and no damage to the material.

Practical Examples of Super Glue Applications

Super glue is widely utilized and allowed, by the populace, to bond things aggressively and for various purposes. One such practical application is home repairs. It works on broken ceramics, glass, and wooden items quickly and efficiently. For example, a cracked coffee mug or a chipped piece of furniture becomes usable again in a matter of minutes. With its rapid-drying nature, super glue stands out as a very handy item for small quick fixes around the house.

Another important use for super glue occurs in arts and crafts, followed by various DIY works. Whether super glue is assembling complicated models, attaching tiny decorative bits, or repairing fragile jewelry, it claims to be the one that provides that neat hold over numerous materials. Its ability to glue different surfaces, for example, metal and plastic, is a boon for creative work that requires bonding of different textures.

The glue is apt for use in professional employment and industrial sectors as well. It is geared into business fields by firms like electronics or small parts for automobile repair, which aid the component from shifting during use. For example, it might attach wiring for use or repair tiny cracks in a car’s interior. When used as specified, its dependability ensures it is surely a tool of great consideration among several professional stages.

Safety Considerations with Adhesives

Handling and Storage Tips

The proper handling of adhesives is essential for safety and to ensure their effectiveness. Ideally, adhesives should be used in a well-ventilated area so that toxic fumes are not inhaled. Skin and eye exposure to adhesives must be prevented; hence, gloves and safety goggles are recommended while working with adhesives. If the adhesive comes into contact with skin or eyes in spite of precautions, care must be taken to remove and clean it according to manufacturers’ instructions.

Until use, adhesives should be kept in a cool and dry place, away from sunlight and heat creatures. After use, containers should be tightly closed so as not to absorb contamination or dry out. Check the instructions for storage conditions, as some adhesives may require refrigeration or special precautions.

Prepare adhesives for disposal in accordance with local environmental regulations. Residue of any sort must never be poured down a drain or into the environment. If adhered to these handling and storage tips, adhesives will be used safely and on time in industry or home applications.

Health Risks and Precautions

Improper handling of adhesives can sometimes pose health hazards. Depending on the type of adhesive, skin irritation and allergic reactions may be occasioned or, in some situations, respiration may be hampered by fumes in the atmosphere or by some chemical present in their constitution. Continuous contact with the skin might develop dermatitis, whereas exposure to the inhaled VOCs might cause dizziness and headaches and cause much more dangerous effects as per the duration of the exposure and OD level.

To counter such pose-the-risk situation, one should always wear the appropriate PPE: gloves, goggles, and respirator, when needed, depending upon the kind of adhesive used. Because of possible fume buildup, work in a place with good ventilation; be sure spills and residues of adhesives are cleaned up at once; and dispose of them properly. Do not allow any adhesive to contact your skin and wash your hands thoroughly even if you’ve used gloves.

If there’s exposure, follow first-aid instructions given in the adhesive’s safety data sheet. For instance, rinse the skin for several minutes with running water if adhesives get on it; seek medical advice if irritation persists. Move to fresh air if fumes have been inhaled; see a doctor urgently if any adverse symptoms, including dizziness, are noticed. With precautions and good safety practices, doing away with dangers would be easy, and the safe use of adhesives becomes possible for various requirements.

First Aid for Adhesive Accidents

When handling adhesive accidents, it is paramount to act fast and appropriately in minimizing harm. Below are important first aid steps adaptable to common situations faced with adhesives:

- Skin Contact: In the event of skin contact with an adhesive, do not attempt to peel or pull the substance off, as this might damage the skin. Wash the skin with plenty of warm, soapy water. Pat the skin dry gently and if irritation occurs, apply a mild, unscented moisturizer to alleviate discomfort. If symptoms such as redness, swelling, or irritation persist, urgent medical attention should be sought.

- Eye Exposure: Any adhesive accidentally introduced to the eyes must receive urgent attention. Gently flush the eyes with clean, lukewarm water for at least 15 minutes, ensuring the water runs away from the face to prevent spreading the adhesive. Do not rub the eyes, as this may cause further injury. Cover the eye with a clean, dry dressing after rinsing and seek medical advice immediately, even if there is no pain or visible damage.

- Fume or Vapor Exposure: Fumes from adhesive may irritate the respiratory system, especially if in an environment with deficient ventilation. Immediately move the affected person into open, ventilated spaces or down to the fresh air level. Encourage calm breaths and avoid physical exertion. If symptoms like dizziness, nausea, and difficulty breathing present, report to emergency services without delay.

Following these organized first-aid actions aids in managing risks posed by adhesive accidents and hence makes for a safer environment in use, whether at work or in a home setting. As a precautionary measure, always review product-specific directions.

Frequently Asked Questions (FAQ)

Q: What is the difference between super glue and Loctite?

A: Super glue is known for being quick-setting, and can attach many things. Loctite, however, sells an array of adhesives, including super glue types such as Loctite super glue ultra. Both have the disadvantage of being fast-setting, while Loctite products also have so-called patented additives for durability.

Q: Can I use super glue as a threadlocker?

A: Super glue can hold threads for the short term. However, it is not an actual threadlocker. It is better to use blue or red Loctite, as they are specialized for locking threaded fasteners from vibrating loose.

Q: Can Loctite super glue be used in woodworking?

A: Yes, Loctite super glue is a very good incidental and primary adhesive for woodworking projects. Other materials might also bond with this glue, such as wood, and it works on surfaces that can be either porous or non-porous. It is best if surfaces to be bonded are clean and dry.

Q: What about Loctite super glue for bonding metals?

A: It is meant to provide a very strong adhesive bond between metal surfaces. Due to its fast-bond, it adheres quickly without restraits or clamps, which is ideal for metal-to-metal applications. In the case of some heavy-duty purposes, a threadlock might be applied for a guarantee.

Q: On which surfaces does Loctite super glue work?

A: Loctite super glue works on many porous and non-porous surfaces, such as plastic, metal, wood, and ceramic. It works efficiently on materials that may either be flexible or rigid, rendering it a versatile adhesive for many types of tasks.

Q: Can I use nail polish instead of threadlocker?

A: Nail polish might offer a short-term hold, but it really isn’t a substitute for dedicated threadlocker like blue or red Loctite. Threadlockers resist torque and vibrations and assure that fasteners do not loosen through use.

Q: What is the viscosity of Loctite super glue?

A: The usual characteristic of Loctite super glue is its low viscosity, which allows a little product to be applied quickly and to seep into the thinnest of voids. This maintains compatibility between a strong bond and working with several types of materials, including polystyrene.

Q: How should I apply Loctite super glue?

A: Surface area application should be performed with Loctite super glue on clean, dry areas. Specifically, use the precision tip of the glue applicator to apply a small drop on just one surface, then press those surfaces together firmly for several seconds.

Q: What happens if my adhesive bond loosens?

A: The bond may loosen due to inadequate surface preparation or too much force put on the joint. To fix an adhesion, first clean the bonding surfaces, then reapply Loctite super glue, or use a more heavy-duty glue that’s better suited to that job.

Q: Are there safety recommendations when using super glue or Loctite?

A: Yes. Work in a ventilated area and avoid skin contact with Loctite or superglue. If you get adhesive on your skin, use acetone or nail polish remover to take it away. Always follow the manufacturer’s instructions on safe use and storage.

References

-

Super Glue vs Loctite: Which Adhesive Reigns Supreme? – This article discusses the differences and applications of super glue and Loctite, highlighting their strengths and limitations.

-

Loctite vs Other Brands: Which Glue Holds Best? – A comparison of Loctite with other super glues, focusing on bond strength and versatility.

-

Loctite Vs Super Glue? – DIY Forums – A forum discussion that explains the curing mechanisms of Loctite and super glue, and their suitability for different applications.