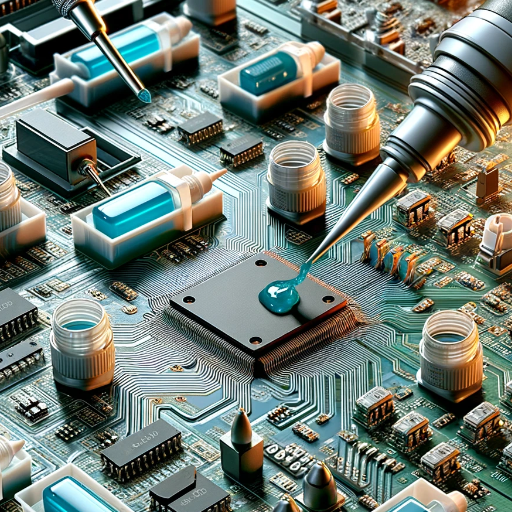

When dealing with electronics and specifically the reparation of printed epoxy resin board, extreme skill, accuracy and appearance should always be considered. As such, the application of a correct and suitable adhesive is what ensures the board’s integrity once repair or modifications have taken place. Such is the case with cyanoacrylates, a modern glue that is highly suited to repairs of small printed circuit boards. Although not all cyanoacrylate glues are equally effective, selecting the right one for the focus of our article —PCB and its applications— requires an understanding of its properties and limitations. This resource seeks to identify the reasons why cyanoacrylate glues are used in electronics, compare the best types of superglue offered by the market and provide practical advice on how to use it for dangling chip bond wires. If you are involved in innovations or have a home workshop, that’s precisely what will help you to know which type of glue is appropriate for chip bonding and such problems.

Understanding Super Glue in Electronics

An adhesive called super glue is well-suited for the technology industry due to its excellent adhesive properties and fast curing time. What makes it even more effective is that the bond it forms with readily available materials in the industry, such as plastics, metals, and ceramics. Since super glue tends to be very stiff, this property makes it unsuitable for many applications in electronics, especially when subjected to thermo-mechanical stress conditions. It is not only mechanically stiff but also a poor electric conductor, which means the bonding should not affect other wire-to-wire or wire-to-component assembly or circuit functionalities. Whenever there is written-up work on an electronic PCB, engineered materials that are resistant to electromigration are highly recommended for improved long-term performance in such constructions, facilitating further operations within the field. Additionally, an ideal ratio of tensile and compression forces is maintained in devices composed of such materials, i.e., built-up stress, throughout operation as well as after use.

Properties of Cyanoacrylate Super Glue

Fast-Acting Adhesion

The cyanoacrylate cures within 30 seconds upon exposure, usually less than 10 seconds if it is in contact with moisture. This fast cure results because the adhesive is polar and reacts with the negative hydroxide-containing counter-ion available in water or the air naturally.

Strong Bond Strength

There are many advantages of using adhesives. Adhesives are able to resist tensile forces quite well, typically from 1,800 to 5,000 psi (12 to 34 MPa), as long as the adhesive is composed correctly and the materials being joined are reasonable. In this way, they can be applied in the construction of chemically stable, resistant joints.

Thermal Resistance

Common cyanoacrylate adhesives range in temperature rating from -54°C to 82°C (-65°F to 180°F). Hence, at 121°C (250°F), a part of the inspected cyanoacrylates is identified to be stable.

Material Compatibility

The adhesive is suitable for a wide variety of materials, such as metallic articles, drycos, plastics, ceramics, glass, rusts, and wood. Despite this, it is also useful at a diminished rate on porous materials, as the material absorbs the adhesive and causes the weakened joint to fail.

Low Shear Strength

Although the option of using cyanoacrylate gives a good bond, tensile force is high but not the shear force, thus inappropriate for use in situations of lateral loads or flexibility.

Viscosity Variability

Cyanoacrylate glues come in many different designs, each of which is used for various purposes, beginning with low-viscosity substances for narrow cracks, all the way up to dense pastes for horizontal and even porous textures.

Advantages of Using Super Glue for Electronics

Rapid Bonding Time

When it comes to curing times, cyanoacrylate adhesives are unique in that they can bond in seconds upon contact with vapor or water in the atmosphere. This enables the user to significantly reduce the time for assembling something, which is beneficial in the rapid process of making reactive adhesive electronic devices in particular.

Strong Dielectric Properties

Due to their characteristics and the type of adhesive they are, it is understandable that most adhesives have a breakdown voltage of between 10 and 25 kV/mm. So they will be better for mounting electrical components to a printed circuit without the current flow, prohibitively.

Precise Application

A range of thin or low-viscosity formulations suitable for the electronics sector enables the precise application of adhesive to components with restricted space and shape, thereby avoiding concerns and yielding a neat and firm adhesive bond.

Versatile Material Compatibility

Reactivity of cyanoacrylates is an attractive and common connection property enjoyed by the bonds, such as metals, plastics, ceramics, and composites which are typically used in the electronics industry. This ensures that diverse assembly requirements are the least of a concern as cyanoacrylates are invariably reliable in a variety of situations.

Low Thermal Conductivity

While cyanoacrylate adhesives have formulae with low thermal conductivity rates, typically ranging from 0.15 to 0.25 W/mK, super glue allows for the minimization of heat exchange between parts bearing a bond, thereby preserving the operational performance of attached electronic gadgets.

Minimal Outgassing

It is essential to note that cyanoacrylate adhesive of good quality is not volatile and as such, will not outgas. Such attributes are crucial for the preservation of enclosed, somewhat fragile, complex, and long-lasting electronic products.

Types of Glue for Electronics Repairs

Cyanoacrylate Glue (Super Glue)

The product in consideration excels in minor repairs, largely due to its ease of application. It is practical to keep together items that aren’t electrifying, although it is recommended to restrict this in non-heat-sensitive areas.

Epoxy Resin

Epoxy, on the other hand, which is known for its excellent adhesion properties, durability, and resistance to adverse environmental effects, especially when bonding metals and plastics, is the solution that provides no possible match for this demand.

Silicone Adhesive

Silicone adhesive remains flexible, is heat- and water-proof, and can be effectively used to seal certain areas or create a shielding barrier from external interference, the latter providing additional strain relief to the components through careful assembly of the enclosure.

Conductive Adhesive

With most applications requiring electrical conductivity, the use of silver or carbon-laden and conductive types of adhesives is dictated by the need for bridging the gap in the current flow between the bonding components. It includes most of the users, please, and it is seldom contradicted; most used forms of PCB can be effective.

Super Glue vs. Epoxy: Which is Better?

| Key Points | Super Glue | Epoxy |

|---|---|---|

| Adhesion Strength | Moderate | High |

| Curing Time | Seconds to minutes | Hours to days |

| Temperature Resistance | Limited | Excellent |

| Moisture Resistance | Moderate | High |

| Flexibility | Low | High |

| Best for Small Repairs | Yes | No |

| Best for Large Applications | No | Yes |

| Material Compatibility | Limited | Broad |

| Durability | Short-term | Long-lasting |

| Ease of Use | Simple application, quick dry | Requires mixing; time-intensive |

| Cost | Generally inexpensive | Can be more expensive |

Choosing the Right Adhesive for Plastic Components

Choosing a design of an adhesive for connecting plastic components first of all demands full comprehension of the materials in regard to the plastics and this has also to take set environmental conditions. Some of the factors to pay attention to include:

Material Compatibility

The interactive behavior of adhesives with different plastic types, namely thermoplastics, thermosets, and elastomers, is dissimilar. Certain adhesive formulations are oxymoronically manufactured to address problem plastics like polypropylene (PP) and polyethylene (PE), which have very low surface energies.

Mechanical Requirements

Selecting an adhesive for household objects is also reliant on the level of bond strength that needs to be reached and the level of flexibility. For static applications, cyanoacrylate can be preferred the most, when considering high loadings, elongation, as it has a very high tensile strength. If applications involve machinery, then particularly applications of polyurethane adhesive as well as like elastomers or even silicone, have quite effective flexibility and even shock absorption.

Chemical and Environmental Resistance

Some adhesives can get damaged by moisture, UV radiation, heat, chemicals or over time. An example is epoxy adhesives, which are not affected by the above-mentioned culprits and are ideal for installation in industrial or outdoor environments.

Application Process and Curing Time

It is absolutely the user-friendliness of the adhesive and the curing component that deserves examination. In the case of some of the solvent-based adhesives as a single component, further using them hardly calls for curing delays. Two-part systems, which are dominated by adhesives such as epoxies, require not only trailing components in their manufacture but also form similar bonds under adverse conditions.

Aesthetic Finish

When working with a polymer that is susceptible to plasticizers, layer adhesives are important, as they can be easily withdrawn. An amended adhesion should be made possible by setting an acceptable value and a cut-off value to ensure withdrawal after layer rugs are split.

Cost Considerations

Although more expensive than general adhesives such as structural acrylic or epoxy, the performance of these high-performance adhesives is higher in critical applications, meaning reducing the costs of maintenance in the future.

After considering these points, it is possible to identify a glue that is the most advantageous concerning the adhesion quality and maximum sustainability of the materials and therefore limits low performance of the plastic parts in different applications.

Practical Tips for Using Super Glue on Electronics

Choose the Right Type of Glue

Make sure that the use of adhesives included in the package comes with the safety precautions and instructions noted. Some adhesives may cause short circuits or permanently damage important electronic components.

Clean the Surface Thoroughly

Clean the components from dust, oils and in some cases moisture using pure isopropyl alcohol. It is best to adhere to the steps for surface cleaning so as not to leave any film and residue, which may impede electrical connection.

Use Sparingly

Use as much glue as necessary to avoid overapplying glue in joints, particularly when working with paste joints. This is because it is very common for cyanoacrylate, for instance, to expand a bit after being cured, hence enabling one to apply smaller quantities.

Allow Proper Curing Time

Also, strictly adhere to the instructions given directly or indirectly by the manufacturer, regulating the duration of drying out of the adhesive to ensure safety in using the gadget before the adhesive is completely dry.

Avoid High-Heat Areas

Additionally, super glue should not be used in areas with high heat generation, such as breadboard power supplies, as the high temperatures may weaken the adhesive bond or even release fumes that could harm the health of electronics.

Test on Non-Critical Components First

Implement safety procedures in handling the adhesive, it is also best practice to carry out a trial on a non-critical area before actually using it on areas with fixtures in place.

How to Apply Super Glue Safely

- Prepare the Surface: Make sure that both surfaces being bonded are neat, completely dry, and free from any dirt, oil and other extraneous materials. Wipe the surfaces with isopropyl alcohol In case such need arises. Performing this particular technique significantly contributes to the bonding of the adhesive, and if it is done carelessly, it does a poor job of enhancing adhesion.

- Use the Right Amount: Spread a modest quantity of superglue evenly. It is true that putting a lot of it results in inadequately affixed parts and it will take a long time for the adhesive to sit accordingly. Accuracy, applicators may require precision tips or a nozzle that is the best suited to ensure that the measure is adhered to.

- Allow Adequate Curing Time: Despite the fact that super glue bonds initially quite fast, it is common for it to dry only after 24 hours. For the specific product at play, see whether it is possible to contradict the directions of the manufacturer given, for the continuous bonding under ideal conditions.

- Avoid Humidity During Application: Though conditions such as high moisture in the air may hasten the drying time, the risk is that the bonds that are formed are weak and resorting to uneven adhesion. It is recommended to execute the process under lenient air dampness quotient that is characterized by normal to mild humidity levels.

- Store Glue Properly After Use: When done using this container, ensure its lid is tight and place it in a place without much temperature fluctuations or humidity. Any exposure to air or moisture can lead to an increase in the viscosity of the adhesive, which may, in turn, render the adhesive less useful in the future. To lengthen the period of its storage use, place it in a polypouch, sealed with a zip lock, and refrigerate.

Common Mistakes to Avoid When Using Adhesives

Critical Mistakes That Can Ruin Your Repair

- Failing to Prepare Surfaces Properly: One of the more common problems is the failure to prepare surfaces for adhesive application. Even the most power adhesives will fail immediately when invisible by the eyes substances like dust, dirt, oil, getting in the way. It is essential that the surfaces are clean, bone-dry dry if necessary, and in extreme cases lightly roughened so that the adhesive would work properly.

- Using the Wrong Adhesive for the Material: Applying different types of adhesive or using yet another material in most cases will lead to weak strength or even loss of the bond completely. So before using adhesive, make sure that the adhesive is appropriate for the materials being bonded. For example, fast curing strength adhesives work great for metallic and plastic materials but not for rubber parts.

- Applying Too Much or Too Little Adhesive: Applying too much adhesive can make a lot of mess and will take a longer time to cure, while insufficient amounts of adhesive may cause poor bonding. Hence, to achieve the best bond strength and efficiency one has to adhere to the proper amount of application as recommended by the manufacturer or as per specification.

- Ignoring Cure Times: A well-done and adequate cure is essential for baking the highest possible strength. One should never rush to handle or stress the parts that have been cured immediately after the adhesive has been applied, as this can weaken the bond’s effectiveness. It is essential that the designated time for the cure is adhered to taking into account the ambient conditions like temperature and humidity.

- Storing Adhesives Incorrectly: Some of the ways of inadequate storage, such as an appetite towards overheating, long stay in the sunlight or extreme humidity can have similar effects on the performance of the adhesive. In excess, such adhesives are stored as indicated by the manufacturer, more often than not, in a dark, cool, and air-free place to increase their useful life and potential.

- Overlooking Safety Guidelines: Neglecting the safe handling practices such as working in a well-ventilated environment, and or wearing protective hand gloves, will lead to complications such as inhalation of toxic gases and fuming or skin complications. It is also essential to make sure that one studies the Manufacturer’s Safety Data of Material (MSDM) or the safety procedures of the adhesive being used.

Comparing Popular Brands of Electronics Glue

Loctite

Loctite is famous for its adhesive’s high bond strength and its ability to bond to various surfaces. It is also accommodating to multiple materials such as metals, plastics, and ceramics when used in electronic applications. Moreover, the fast-curing product that Loctite provides is used for urgent projects, thus known for having the shortest time lapse between application and adhesive curing.

3M

3M adhesives are known for being robust and excellently formulated. Their line of electrical adhesives are intended to operate at locations that are subjected to constant quality depending on temperatures, moisture, and chemicals.

Gorilla Glue

Such a brand offers excellent bond strength and does not need too much effort for application. Water-resistant Gorilla adhesive products usually work extremely well on multiple surfaces, provided one doesn’t require them for delicate work in the highly sophisticated microelectronics design.

Araldite

Araldite, a pioneer in epoxy-based adhesives, presents an array of solutions to be deployed in high-stress and delicate electronic contour repairs. The adhesives from this brand are most impressive for their tolerance to high temperatures and stress.

Loctite: Strengths and Weaknesses

Loctite has completely lived up to its fame, bringing some of the best adhesive applications to the market, most notably in industrial. Consumers as well can find equally many, if not more, adhesives and they are the most widely used in adhesives and sealants manufacturing. It creates products in certain categories where adhesives are such as threadlockers, super glues, and epoxies that are user-specific and high in qualities. Loctite adhesives, like most other adhesives, aim mainly to withstand the most hostile environments, such as vibration, moisture, and extreme temperatures. Thus, they are more preferred and used in the electronic, motor vehicles, and construction industries. Besides, their hi-tech adhesives’ field bonding properties are put to good use in both professional and domestic repairs by way of reducing the waiting time and coming up with stronger bonds.

Yet, there have been some issues regarding the Loctite merchandise. To clarify, their use may require proper treatment of surface so that the adhesive can attain its maximum strength which can be a problem in adhesive applications where there is contamination such as dust and oil. Some Loctite adhesives may also not be very good since they are not flexible enough, which may cause them to crack if the objects they have joined together are subjected to expansion or contraction forces. Regardless of that, their track record for trustworthiness and effectiveness as an industrial adhesive keeps Loctite at the helm.

Other Recommended Brands for Electronics Repair

Upon selecting the adhesive for the electronics repair, there are many other brands which shine through for their industry-grade ability and a also the selective formulations. One such brand that is worth mentioning is 3M, which creates a multitude of electronics-adhesives specifically for such applications. Particularly notable models are kept under their Scotch-Weld banner, & they are highly stable at high temperatures, such that they can withstand temperature changes and yet have a very firm bond with the structure.

Another excellent brand is Permatex, which offers a comprehensive range to suit units found in both industrial and household settings. For its part, Permatex has, over time, developed electronic-grade silicones and sealants that are primarily designed to shield delicate sections in any electronics. Silicone and seal kits often extend their role in offering protection against damage caused by clouds of contaminants or rough handling scenarios in multiple industrial equipment.

Another popular choice of adhesive to fulfill the demands of both precision and rapid curing in application is Henkel’s Hysol system adhesives as they appear to bear pleasant consequences in close repairs which require highly precise application of adhesives. The range of which is engineered with a higher degree of acceptance and is subjected to a higher level of intensity in operation of such units as mini micro assemblies.

There is also MG Chemicals, which is dedicated to the production of adhesives and chemicals designed especially for the electronics industry. Their assortment contains thermally conductive and ultraviolet light-cured adhesives that are useful for heat dissipation and immediate solid curing for repairs. These types of products come in handy where the right quantities used and the necessary standards maintained are of crucial importance.

User Reviews and Experiences

Users love these products because they are reliable and work well in almost all applications. Plus, the electronics professionals often speak highly of MG Chemicals adhesives, saying that they are strong and durable, and able to meet the strict requirements when it comes to such power and industrial applications. The satisfaction of all the clients is rather high, as they can note impressive characteristics of UV glue adhesives: it cuts the healing time of a repair (maintenance) work and thereby reduces the workload. Moreover, these products are highly appreciated by clients since they are compatible with various systems in the industry, including metal, plastics, and even ceramics, allowing them to be used across different projects.

Recent studies and individual experiments have also shown that these kinds of goods meet market requirements which improves customer confidence. In fact, the thermal adhesives stand out for their high thermal conductivity, critical for effective heat soaking, especially in high-power or compact electronic devices. In summary, the output of quality that comes from the advantageous reuse of materials adds to the satisfaction of MG Chemicals’ reputation to an extent that engineers and technicians keep coming back to it.

Conclusion: Best Practices for Repairing Electronics with Super Glue

When fixing broken electronics with the help of superglue, the safety and the method of working are the most important components. It is excellent to start on a clean surface where there is no dust, oils and other foreign materials which might hinder the adhesion. Cleans it with isopropyl. Wait for the components to be dry thoroughly, and we will use cyanoacrylate adhesive for electronics. In order to ensure that the electronic components are not affected by the glue, carry out only the necessary amount of glue because any excessive can lead to unwanted mess or entry of the glue into the wrong areas. Based on the manufacturer’s manual, wait for some time for the adhesive to cure as it cannot be weakened since it directly affects the purpose of the glue. Then do not put super glue in the high-temperature area or where connections are made, as it is very likely to damage the repaired part or injure the person who is using it further. Adhering to best practices will always result in a reasonable and sufficient repair.

Summary of Key Takeaways

Proper application of the right type of glue under the best conditions can work better or the bond may not end up sticking properly. The kind of respiratory support must be applied to whatever materials and equipment are being bonded in order to prevent toxic responses or loosening of the bond. Forward pressure should be used when performing the work, but not too much, to prevent it from dribbling or damaging the delicate parts. Curing correctly in terms of time and other relevant factors, as prescribed by the manufacturer, is fundamental if the intention is to have strong joints. It is also important to note that superglue doesn’t work in areas exposed to high temperatures or electrical current, as this may pose a safety threat or impair the operation of electrical connections. This is because, if in any case people follow these conditions, it in turn enhances the quality and life of the repairs done.

Final Recommendations for DIY Enthusiasts and Professionals

When bonding with adhesives, the following norms should always be followed in order to achieve complete success. Firstly, give all the internal surfaces of the materials to be joined a thorough clean by washing the surfaces and drying them so as to ensure that any oils, dust or water vapour contaminants do not halt the bonding process. Second, select the bond by checking the adhesive’s characteristics, such as hardening time, viscosity, and compatibility with different surfaces, to determine the best rheology and connection to the project. Some new trends in adhesives have produced more sophisticated adhesives that can withstand stronger conditions, such as extreme temperatures and higher loads, which offer an easy way for people to apply them both at home and in industries.

Performing precision work requires applicators with narrow openings or multi-use dispensers to prevent overapplication and waste. Furthermore, using adhesives from trusted sources will result in improved performance and a reduction in total lifetime maintenance and repair costs. It is expected that a construction agreement, as well as safety policies, will in the future increase the useful life of the work. By employing these measures, both amateurs who enjoy working with their hands and seasoned craftsmen can enhance their skills and carry out tasks safely to meet commercial standards.

Encouragement for Safe and Successful Repairs

In order to complete repairs that are safe and effective, there is a profound need to know the latest in tool, material and technique improvement, understanding these facts is the key to the industry. The construction and repair sector is constantly evolving, adopting newer approaches and equipment aimed at enhancing productivity and safety. For example, in the field of adhesive science, advances in formulations have meant that now adhesives that can take higher temperatures and exhibit stickier properties are available, and this has increased their utility in substantially varied sectors. Furthermore, well-engineered instruments have been introduced to reduce fatigue and enhance accuracy in both professional and amateur tasks.

How can you use everything that is known and all the best practices to achieve successful results during repairs without risks growing rather than the reverse: Reduce risks by using the means, dowels or any other ways that you have been using more efficiently. Ensure you have relevant protective gear for the job and maintain a conducive working environment. It is only through the observance of such details that not only exceptional quality can be guaranteed, but also that no worker will ever suffer injuries during project work.

Reference Sources

1. The Future of Energy: Analyzing the Topography of Solar Cells

- Key Findings:

- This study explored the use of super glue to attach solar cell samples to glass slides for topographical analysis.

- The research compared the surface area and efficiency of polycrystalline and organic solar cells.

- Polycrystalline panels showed higher efficiency (14.74%) compared to organic panels (8.81%).

- Key Findings:

- Super glue was used to stabilize samples during polishing and surface roughness testing.

- The study found that polishing systems with diamond abrasives produced smoother surfaces compared to those with aluminum oxide-silicone dioxide abrasives.