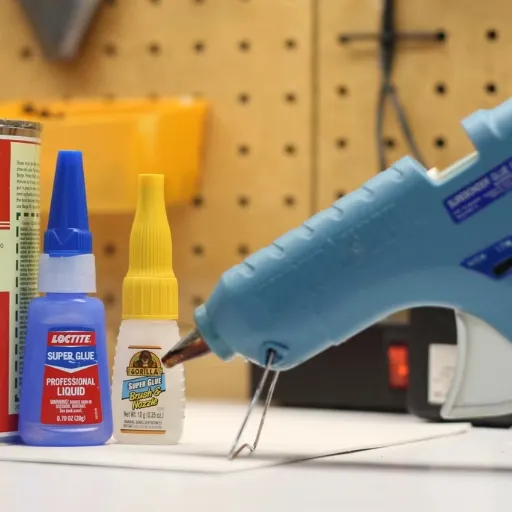

Selecting the right adhesive can make all the difference when it comes to homemade applications or quick fixes on a project. For some, the argument is often down to two popular contenders: Super Glue and Gorilla Glue. But depending on your needs, much can be said to favor the working of law for wood or plastic. Is the correct choice given to strength, versatility, or simple ease of application? These key differences will help you understand the materials contained within these adhesives and when to use each and which one wins out when creating strong bonds in durability. By the end of this article, you will be in a position to confidently choose the perfect glue for your next task.

Understanding Glue Types

What Is Super Glue?

Super glue (cyanoacrylate adhesive) is a fast-bonding and very strong glue, used for countless purposes. It was made to form bonds almost instantly as it reacts with moisture present either in the atmosphere or at the surface of the materials to be joined together. Super glue prevents the rapid drying of glue by blocking rapid air evaporation and hence works well on surfaces of metals, plastics, woods, and ceramics-an all-purpose choice for home repairs or industrial uses.

The main feature of super glue is the fast bonding of two surfaces together, strong enough to clamp or dry within minutes. This process is chemical, whereby the glue undergoes polymerization after contact with moisture-even the smallest moisture presence agents. That very trait would restrict the super glue from sticking to dirty or greasy surfaces very much.

Super glue is best put to use where strength and quick setting are paramount: small repairs or any work requiring fine detail. They weaken under high heat, long-duration soaking, or heavy pummeling. Safety precautions should be heeded upon using any superglue as it bonds skin quite fast and also gives out fumes that could be irritating if inhaled in large quantities.

What Is Gorilla Glue?

Gorilla Glue is a multipurpose industrial-strength adhesive incapable of an outright stronger bonding. A polyurethane-based formula, it can glue together a wide range of substances: wood, metal, stone, foam, glass, or ceramic. This could create a more natural set: from a repaired or two of kitchen cupboards to a few bigger projects.

From the other side, one of the defining features of Gorilla Glue is that it will expand with curing, thus filling voids and forming a highly secure bond. When the adhesive expands, it fills the uneven surfaces and provides strength to bond for a longer time. But this property requires that it be applied with utmost care, as overuse may cause an unwanted mess or expansion.

The glue is water-resistant and can withstand moisture and fluctuating temperatures; hence it will be suited for indoor use and outdoor use. Since it is a strong glue, the user must observe the safety precautions while working with Gorilla Glue. It is advisable to avoid contact with skin and ensure proper ventilation during application, as fumes from the adhesive may be detrimental to health if inhaled in large quantities. Its trustworthy-to-perform status and wide application have made it one of the go-to adhesives for permanent bonding.

Key Differences Between Super Glue and Gorilla Glue

The distinction between super glue and Gorilla Glue lies chiefly in the chemical composition and in its intended use. Super glue is an adhesive cyanoacrylate forming an almost instantaneous bond. It works best on small projects and materials such as plastics, ceramics, or metals. Because it dries fast, it is recommended for repairs that need precision and require very little setup time for clamping; the bond, however, is generally less elastic. On the contrary, Gorilla Glue is a polyurethane adhesive well known for superior strength and versatility. This glue works best for large projects and with porous materials like wood, foam, and stone; it expands as it cures.

Another difference stands in the curing process. Super glue typically dries quickly within seconds to minutes and forms a strong, stiff bond but does not hold up well to extreme temperatures or moisture exposure. On the contrary, Gorilla Glue requires more curing time, even several hours until fully cured, yet forms an extremely durable bond capable of handling various environmental conditions, including being underwater and exposed to heat. It is the ideal glue for indoor and outdoor projects where utmost durability is required.

Lastly, the application method also differentiates the two glues. The use of super glue entails nothing else besides assuring that the surfaces to be glued are clean and dry. As against, Gorilla Glue commonly requires surfaces to be slightly damp for better activation of the adhesive. Due to its expansion, it should be applied sparingly to avoid any overflow that would require cleanup after the glue has cured. By keeping in mind such glue characteristics, the user can tailor their selection of the right adhesive needed for their particular project.

| Feature | Super Glue | Gorilla Glue |

|---|---|---|

| Chemical Base | Cyanoacrylate | Polyurethane |

| Drying Time | Seconds to minutes | Several hours |

| Best For | Small, precise repairs | Large projects, porous materials |

| Expansion | No expansion | Expands during curing |

| Water Resistance | Limited | Excellent |

| Surface Preparation | Clean and dry | Slightly damp preferred |

Performance Metrics of Adhesives

Tensile Strength Comparisons

We use the term “tensile strength” to mean the resistance of adhesives to tearing apart when tension is applied. Gorilla Glue is said to have a strong bond, but some very particular adhesives can surpass it on the matter of tensile strength in some point of application. Epoxy adhesives are generally stronger than polyurethane adhesives. They do so by creating chemical bonding which are very resistant against the wear and tear environment factors like heat and moisture.

Epoxy adhesives offer higher tensile strength and much better bonding possibilities for metals, ceramics, and certain plastics, which makes them a good choice for industrial or structural use. Epoxies also tend to cure into a hard, rigid polymer which enhances the load capacity, a much-needed property in heavy-duty applications.

If maximum strength is in question, two-part epoxy adhesive may be the answer. These adhesives are specifically formulated for superior bond performance and find use in construction, automotive, and aerospace. Always consider whether the adhesive chosen is compatible with the materials being bonded.

Curing Times and Conditions

The curing times and curing conditions are essential to obtain the full strength and durability of the adhesive. Cure times vary with specific adhesive formulations, curing temperature, and materials involved. For example, a two-part epoxy may need accurate mixing and may cure for anywhere between a few hours to several days, depending upon the formulation in question. Every manufacturer will always provide curing times that must be adhered to; otherwise, the bond will not be sufficiently strong. Surface preparation also counts: one needs to clean the surface well and ensure it is suitable for bonding, as this strongly influences curing.

While Gorilla Glue can usually do the job of making a stronger bond, there exist adhesives used for doing specific applications that can perform even better. Two-part epoxy adhesives rank among the strongest that exist, and generally outdo also Gorilla Glue in tensile strength and resistance against heat, chemicals, or other extreme environments. Super glue or cyanoacrylates offer better bonding for some materials or certain plastics and metals than those polyurethane adhesives being able to bond just about anything that Gorilla Glue can. But general epoxy adhesives would somehow be stronger than those polyurethane or Gorilla-type glues. Ultimately, it depends on what materials, what environment, and what application you are considering in defining what stronger glue is. Consider always what the glue will be used for and its working environment.

Temperature Resistance of Adhesives

Temperature resistance comes first when choosing an adhesive as it basically denotes an ability of the material to retain its bond while being subjected to thermal cycles. High-temperature adhesives are set up to stay stable when heat is applied; hence, their applications embrace automotive, aerospace, and industrial environments where high temperatures are prevalent. These adhesives are known to resist their degradation or deterioration within a full range of existing temperature performance.

Low-temperature resistance, on the other hand, is crucial in an environment where adhesives might be exposed to freezing temperatures. Such adhesives must retain flexibility and should not become brittle or lose adhesion as the temperature goes low. They find their common use in construction or outdoor applications in chilling climates.

Hence, to get an adhesive fit for a given temperature, one considers the operating conditions and thermal stresses that the adhesive is going to encounter. One should always refer to an adhesive manufacturer’s specification as to the temperature tolerance to find an adhesive that best suits the needs in a given application. It will ensure that adhesives perform in forward reliability and maintain good bonding under all temperature fluctuations envisaged.

Applications of Super Glue and Gorilla Glue

Best Uses for Super Glue

Superglue is a type of glue that bonds quickly and is ideal for fast small household repairs. It works well on hard surfaces like metal, glass, ceramic, and plastic. Once an adhesive is placed on a non-porous material, it bonds spontaneously on clean surfaces; hence it is called a super glue, especially when it comes to repairing broken jewelry pieces or small ceramic pieces and few plastic parts.

Another common use for super glue is in craft or DIY-related jobs. Because of its fast-drying and strong properties, it can quickly bond the smaller pieces needing precision and firmness. The crafter uses it to fix very small partslike beads, fabric trims, or decorative embellishments–because it dries fast and does not need to be clamped.

Other uses for super glue include the odd fix in the automotive or household setting. It will seal tiny cracks or fine fissures in rubber seals, plastic housings, or even leather goods. The very fact that it bonds quickly makes it useful for a lot of things, although it needs to be used with proper ventilation and is not suitable for the things that will be exposed to extreme conditions or causes of heavy stress.

✓ Ideal Super Glue Applications:

- Repairing broken jewelry pieces

- Fixing small ceramic items

- Bonding plastic parts

- Craft and DIY projects requiring precision

- Sealing tiny cracks in rubber seals

- Quick fixes on leather goods

Best Uses for Gorilla Glue

Gorilla Glue is a versatile adhesive with excellent bonding qualities and is super-efficient for all sorts of bonding applications across multiple surfaces. It works on wood, stone, metal, ceramic, foam, and everything else really, earning the title of household glue for every conceivable project. One of its top characteristics is its strength; it bonds surfaces permanently that literally go through wear and tear.

Great for gluing up things with the woodworks where the changes in environment should be withstood. It is water-resistant glue-perfect for outdoors or anything that would have to tolerate being in water. Finally, it fills gaps hard to bind in irregular surfaces, as the glue slightly expands during curing. Filling the bond is needed most in major repair jobs or through under-surfaced material.

To obtain the best results, careful application must be observed. Surfaces must be clean and kept slightly damp for glue application. Holding the glued surfaces tightly between clamps must be maintained during the curing time to attain the highest strength in bonding. Unlike wood or very hard plastics, soft plastics such as polyethylene and polypropylene will not fare well-gorilla glue will have difficulty sticking properly. Follow all safety instructions, and work in a well-ventilated area.

✓ Ideal Gorilla Glue Applications:

- Woodworking projects

- Outdoor applications requiring water resistance

- Bonding porous materials (wood, foam, stone)

- Filling gaps in irregular surfaces

- Major repair jobs

- Projects requiring long-term durability

Gluing Wood vs Plastic: Which Glue to Choose?

When choosing the best adhesive for wood or plastic, one has to consider factors such as material type and required bond strength. For wood, an adhesive designed to bond porous surfaces offers the best results. These glues seep into wood fibers to achieve a strong, permanent bond. Most wood adhesives are easy to work with, dry within minutes, and resist various environmental conditions, making them safe for both indoor and outdoor uses.

Plastic adhesives vary. Hard plastics like PVC or acrylic can bond well with an all-purpose adhesive or one made specifically for plastics. Soft plastics such as polyethylene and polypropylene are more difficult to glue because of their smooth, flexible surfaces. Specialized plastic adhesives or those labeled as suitable for soft plastics are the types of adhesives recommended for best results.

There we have it: the ideal glue is project- and material-specific. Read your product label; there are different glues for wood and plastics. Another critical step is to try out adhesive in a small hidden place for a test just to confirm it’s compatible. In any case, safety recommendations should never be ignored, and curing time shall always be respected to achieve the strongest bond.

| Material Type | Recommended Adhesive | Key Considerations |

|---|---|---|

| Wood (Porous) | Gorilla Glue, Wood Glue, Polyurethane | Seeps into fibers, permanent bond |

| Hard Plastics (PVC, Acrylic) | Super Glue, All-Purpose Adhesive | Clean surfaces, fast bonding |

| Soft Plastics (Polyethylene, Polypropylene) | Specialized Plastic Adhesives | Difficult to bond, requires specific formulas |

Advanced Adhesive Options

Exploring 2-Part Epoxy

The two-part systems consist of resin and hardeners that, when mixed together, form a very strong and durable bond. The glue is known for strong adhesion and the ability to adhere to many materials such as metals, ceramics, glass, wood, and certain plastics. It is mostly preferred when the project calls for a connection that lasts long and can be resistant to heavy load.

The other advantage of 2-part epoxy is that it resists environmental factors such as moisture, heat, and some chemicals. This resistance makes it good for both indoor and outdoor uses. It can also fill the gap between two surfaces due to its viscosity, fitting them well when the materials are an uneven or imperfect match. However, always remember: it is essential to mix the resin and hardener exactly as prescribed since any deviation in the mixing ratio will compromise the adhesive qualities.

Consider giving the epoxy the best chance for excellent results by cleaning and preparing the surface thoroughly. Dust, grease, or any form of contaminant can weaken the bond. Also, give it time to cure as set forth by the instructions. This way, the epoxy would achieve its intended full strength, ensuring stability under heavy-duty applications. When properly prepared and applied as instructed, 2-part epoxy stands among the best bonding agents for heavy-duty applications.

Comparing Epoxy and Other Adhesives

Any comparison between epoxy and other adhesives must measure their uses, strength, and durability. At times, epoxy bonding is incredibly strong and is resistant to environmental stressors such as heat, moisture, and chemicals. Thus, this putty finds heretofore enormous applications for all heavy-duty purposes, industrial or structural, where long final strength is essential.

In contrast, an adhesive such as cyanoacrylate is good in quick bonding applications with small, light items of plastic, glass, or metal. They do not, however, have the wear and durability qualities of epoxy in carrying heavy loads or long-term exposure under harsh conditions. Also, the PVA glue used mostly in wood and paper applications is cheap and very user-friendly but cannot even come close to the strength and adaptability of epoxy.

In the end, the choice is due to specific project requirements. It is best to use an epoxy when a durable, high-strength bond is required in hostile environments. With lighter duties and less stress, other adhesives may even be a better choice-maybe curing time takes fast that for some applications, ease of application, or just that price is more viable. Armed with knowledge on what each has to offer and what their constraints are, you stand a better chance of making the right selection that guarantees the project’s success.

DIY Projects and Choosing the Right Adhesive

Tips for Selecting the Right Glue for Your Project

- Know Your Materials:

The first step to selecting the correct gluing agent is understanding the materials at hand. Some glues are specially formulated to bond a variety of surfaces-whether wood, metal, plastic, fabric, or glass. For instance, wood glue would work well in woodworking projects, whereas epoxy does fine on metals and ceramics. Always check and see if the adhesion method is suitable for the materials used to ensure holding power. - Check the Needs of the Project:

Think about the conditions and demands of your project. Will the final specimen be exposed to heat or humidity, or perhaps subjected to heavy loads? Is drying time the key, or is some extra working time essential for the correct alignment? Time-consuming or heavy duty outdoors use-choose glued that is durable and is resistance testing with extreme conditions. For light duties indoor, simple gluing would suffice and easier to handle. - Application and Cleaning:

The application and cleaning process of the adhesive determine its efficiency. Some adhesives require special application tools and mixing, while others come ready-for-use like squeeze tubes or sprays. Also, consider how to remove the dry adhesive should it spill onto a project where the look could be compromised. Go through the instructions given on the package while choosing the adhesive to have the best results with lesser mess or waste.

Common DIY Project Scenarios

🔧 Repairing Broken Furniture

Repairing broken furniture happens to be a standard DIY project that ordinarily involves adhesives to create the desired secure bond. When dealing with timber furniture, the work surface must be cleaned and dried prior to glue application. Wood glue creates a strong gravitational force on the pieces being joined. Usually, clamping improves the final result with the glue drying. With metal parts, an epoxy adhesive is generally best since it is both strong and gap-filling.

🎨 Craft and Decoration

Craftwork, such as making decorative pieces or fixing minor household objects, generally requires an all-round adhesive. Hot glue is most often used in crafts because it is easy to use and dries rapidly. On the other hand, adhesives with fine tip applicators are better for precision work involving light materials such as paper, fabric, or tiny gems. It is always a good idea to adjust your work to the glue drying times, as well as ensure that the adhesives are compatible with your materials in order to avoid damage.

🏠 Repairing Household Items

Household repairs, such as fixing broken ceramics or sealing leaks, can also be handled by means of DIY adhesives. For ceramic repair, a super glue with high bonding strength is generally preferable, however, it does dry quickly. Waterproof adhesive or sealant needs to be applied when trying to seal leaks on pipes or on surfaces that get in contact with water. Make sure the area is clean and dry before applying and follow safety instructions while handling adhesives for such work.

Safety Tips When Using Adhesives

When using adhesives, it is essential to work in a well-ventilated area to avoid inhaling any potentially harmful fumes. Open a window or use a fan to keep air circulating, especially when working with adhesives that tend to have strong odors or VOCs. Use gloves and safety glasses to protect yourself from accidental skin or eye contact with the adhesive.

Follow the directions laid out by manufacturers in detail, including any application techniques and curing times. Never use too much adhesive; excess glue could create a mess or even impede the bond’s effectiveness. Ensure that the surfaces to be bonded are clean, dry, and free of dust or grease for best results.

Last but not least, adhesives should be kept in a secure, dry place away from children and direct sunlight or heat. After each use, containers should be properly closed to prevent drying of the adhesive. Proper disposal of adhesives and empty containers is equally important; please refer to your local waste regulations for disposal guidelines.

Frequently Asked Questions (FAQ)

Q: What glue is stronger than Gorilla Glue?

Polyurethane glues come close to Gorilla Glue when strength is being considered. Polyurethane adhesives make an extra-strong bond and could work on wood and plastic applications.

Q: How does the Gorilla Super Glue stack against other glues?

The Gorilla Super Glue and its fast drying time and good strength of bonding are usually applied on smaller repairs; however, larger projects or working in filling gaps might present better results for two-part epoxies and such.

Q: Is there another glue that makes better wood joints than Gorilla Glue?

The Gorilla Wood Glue is considered the best of its class for gluing wood joints. It gives a strong bond that expands on drying, so it’s fully adequate for a variety of woodwork.

Q: Can Loctite Super Glue be used instead of Gorilla Glue?

Well, Loctite Super Glue is a good strong glue that can be used instead of Gorilla Glue for some applications, especially when very fast bonding is needed. Though it may not have the same versatility if the glue is to be used outdoors or with different materials.

Q: What are the advantages of using Gorilla Glue instead of white glue?

Gorilla Glue is a strong adhesive providing a stronger bond than white glue especially for projects requiring long-term durability and resistance to moisture. Unlike white glue, Gorilla Glue expands upon drying, filling in the gaps and providing an excellent connection.

Q: What is the best glue for wood and plastic?

For gluing together plastic and wood, Gorilla Glue or polyurethane glue will do great. Both glues put up a strong bond yet usually do not pose problems when another application needs to be done on the same materials. Basically, the two are good choices for different materials and applications.

Q: Does Gorilla Super Glue Gel work better than the regular Gorilla Glue?

It has a thick consistency; Gorilla Super Glue Gel makes its application suitable for the vertical side because it is less prone to dripping. For the project where application of glue and working time demands precision and control, Gorilla Super Glue Gel is probably preferred over the traditional one.

Q: Are there adhesives like Gorilla Glue with longer open times?

Yes, adhesives such as polyvinyl acetate or some other kinds of epoxy may allow longer open times, giving the user additional moments for adjustment of any object before curing happens. This may be very useful if the project requires fine alignment.

References

-

Which one is better out of superglue, epoxy, and gorilla glue? – Quora – A discussion comparing the strength of epoxy, superglue, and Gorilla Glue, highlighting epoxy as a potentially stronger option.

-

Gorilla Glue vs. Super Glue – Which One is Stronger? – TradeNRG – A comparison of Gorilla Glue and super glue, focusing on their strength and practical applications.

-

Any Alternatives To Polyurethane Gorilla Glue? – Tech Talk Forum – A forum discussion on alternatives to Gorilla Glue, such as Elmer’s Ultimate, which offers similar strength and easier application.