3D printing with PLA has opened up the fields of creating, prototyping, and innovating for the end-user, with the professional sector being one of those areas. Bonding and repairing PLA parts remains a common difficulty: it’s the glue choice that matters most when gluing fine models or bonding the finish and design changes at some stage of testing. This guide covers processes for PLA, various glue types, their strengths, uses, and applications. Upon completing the course, you will be able to select the optimal PLA glue for finishing your 3D prints with a professional touch.

Understanding PLA and Its Adhesion Needs

Being versatile and easy to handle, PLA or polylactic acid is a 3D printing material widely used and familiar to most. Sometimes, bonding PLA can be challenging due to its smooth surface and relative heat resistance. Selecting an adhesive specifically designed for plastics yields the strongest bond. Cyanoacrylate adhesives (also known as super glue) and epoxy, along with certain specialized plastic cements, should suffice in most instances. Surfaces should be clean and dry; however, a certain degree of surface roughening may help improve binding strength. Correctly applied bonding methods and curing times are crucial for producing a robust bond.

What is PLA?

PLA, or Polylactic Acid, is a biodegradable thermoplastic polymer derived from renewable resources, such as cornstarch or sugarcane. Because they are easy to print, require only a low melting temperature, and are environmentally friendly, PLA stands as one of the primary materials used in 3D printing. Due to its appropriately non-toxic properties, PLA finds its use in areas ranging from prototyping to packaging and even medico-surgical implants. However, they do suffer from low heat resistance and high brittleness, which makes it challenging to work with them in demanding pharmaceutical or poly-industrial situations. Their environmental friendliness and versatility have made them a key component of sustainable manufacturing and innovation.

Why is PLA Tricky to Bond?

Currently, bonding PLA remains a challenging process due to its surface characteristics and chemical composition. Since PLA has low surface energy, it is generally hard for the adhesives to provide a strong and lasting bond. Moreover, adhesives usually do not work correctly with such smooth, non-porous surfaces since they are incapable of penetrating and anchoring. Generally, cyanoacrylate adhesives (also known as super glue) or epoxy adhesives are used to join PLA parts; however, depending on the circumstances in which they must operate, the bond strength obtained can vary significantly. Other methods for achieving this could include the use of solvent-based adhesives formulated explicitly for PLA and manual surface preparation to enhance adhesion. The bond choice sometimes relies on the actual requirements for the application, such as strength, flexibility, or heat resistance.

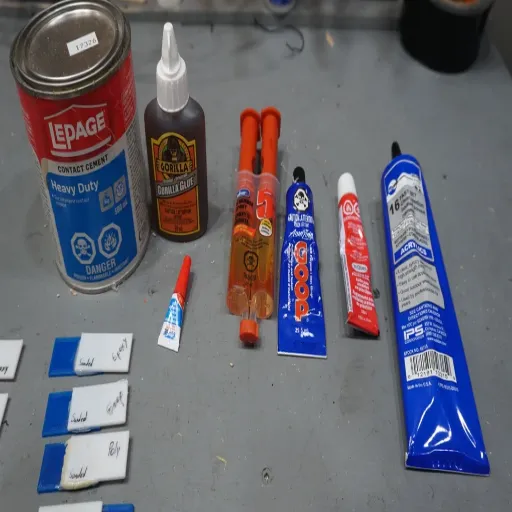

Top Glue Options for PLA

Super Glue (Cyanoacrylate)

A quick and convenient option for minor or moderate repairs. Works best when the surfaces are clean and fit tightly together. However, it may not hold well under high stress.

Epoxy Adhesive

Provides excellent bonding strength and some flexibility. Ideal for applications requiring durability, but takes longer to cure compared to super glue.

Hot Glue

Suitable for quick fixes and light-duty applications. It is less robust but easy to use and widely available.

Cyanoacrylate (Super Glue)

Super glue is an adhesive known for its rapid action; when touched by moisture, it bonds almost instantly. Consequently, it is helpful for minor household repairs, crafting, and industrial purposes, thanks to its ease of use and versatility. However, the glue mainly acts on non-porous surfaces, such as metals, glasses, or plastics; nevertheless, it does not bond well to materials like wood or cloth. Although the bonding is fast, super glue is not an ideal choice for applications that experience constant stress, exposure to water, or high temperatures.

Epoxy

Epoxy is a type of durable adhesive; the resin and hardener mix and chemically react with each other to form a strong bond. Super glues, on the other hand, have limited use and can only be used to glue specific items. Epoxy can bond to a wide range of surfaces, including porous materials such as wood and concrete. It is heat-resistant and waterproof, making it useful for heavy-duty activities or working in extreme environments. Due to its strength and dependability, epoxy is commonly used in construction, automobile repairs, and art projects that require both precise application and durability.

How to Properly Apply Glue on PLA Surfaces

Proper cleaning of PLA surfaces is necessary to ensure an appropriate layer of glue. Follow these steps:

Clean the Surface

Ensure the surfaces are clean and free from dust, grease, and other contaminants. Use isopropyl alcohol for thorough cleaning and allow it to dry completely afterward.

Roughen the Surface

Lightly sand the areas where glue is applied using fantastic sandpaper. The idea is to increase adhesion by enlarging the surface area that the glue can actually hold on to.

Choose the Right Glue

Choose a strong adhesive for PLA, such as cyanoacrylate or epoxy. Both these types create dependable and enduring bonds with PLA materials.

Apply the Glue Sparingly

Too many glues look unattractive if they ooze out, so just a dash of glue is sufficient for the surface. Spread it evenly to have uniform adhesion.

Press and Hold

With utmost care, position the pieces and apply firm pressure for the time prescribed by the glue manufacturer.

Allow Proper Curing

Allow the glued item to remain still for the curing time indicated in the instructions to assure an enduring bond.

Preparing the Surface

Prepping a surface before gluing is a crucial step in achieving a strong bond, especially with materials like PLA. During surface preparation, impurities such as dirt, grease, and other imperfections are removed, which can all hinder adhesion. With a clean, smooth surface, the glue will adhere to it and form a strong bond. Sanding PLA gently will impart some texture, thereby increasing the area the glue just has to grab, further reinforcing the bond’s strength. Put another way, when the grinder is not cleaned correctly, weak joints will result, and Valentine’s parties will fall away over time.

Curing Times

Adhesive curing times for PLA can vary significantly depending on the type of glue and environmental conditions. Cyanoacrylate, or super glue for short, sets air-dry in just an hour or so and is hence almost always useful for quick fixes. When fully cured, though, epoxy adhesives will provide a stronger molecular bond that is stress-resistant, taking 4 to 24 hours to do so. Curing time depends on environmental conditions, with higher temperatures and increased humidity generally expediting the glue-setting process. Consult the instructions provided by the manufacturer for a specific adhesive product to achieve optimal results.

Common Mistakes to Avoid

- Using Too Much Adhesive: Overapplying adhesive can result in weak bonds and messy outcomes. Use only the amount recommended by the manufacturer.

- Ignoring Surface Preparation: Failing to clean or prepare surfaces properly can prevent the adhesive from bonding effectively. Always ensure surfaces are clean, dry, and free of dust or grease.

- Skipping Curing Times: Not allowing sufficient curing time can compromise the bond strength. Patience is key—consistently adhere to the recommended curing times.

- Choosing the Wrong Adhesive: Using an adhesive that is not suitable for the materials or conditions can lead to failure. Match the adhesive type to your specific project needs.

- Improper Storage of Adhesives: Storing adhesives in conditions that are too humid, dry, hot, or cold can reduce their effectiveness. Follow storage instructions carefully.

Skipping Surface Preparation

Skipping the step of surface preparation is one of the most common mistakes made with adhesives, having a significant impact on the outcome of any project. Preparation of the surface ensures a strong, end-to-end bond between the adhesive and the materials. Thus, the surfaces must be clean, dry, dust-free, grease-free, and free of old adhesive residues. The absence of surface preparation results in reduced resistance to inconsistent bonding, ultimately leading to the project’s demise. It is interesting to know that search data reveals the term “how to properly prepare surfaces for adhesives” as a frequently searched query, emphasizing the importance of this step in the successful application of adhesives. Ultimately, dedicating a sufficient amount of time to surface preparation will ensure stronger and more durable adhesive bonds, while also reducing the likelihood of errors.

Ignoring Safety Precautions

Failing to observe the necessary safety measures when handling adhesives poses serious hazards. It may also lead to health hazards and accidents. Search engine data show that many users are typing queries like “The dangers of adhesive fumes” and “How to protect oneself when using adhesives,” thus reflecting widespread concern and awareness regarding adhesive safety. These hazards may range from toxic fumes to skin irritation and flames in some industrial adhesives. Any safety measure found to be worthy of saving a life shall be observed, including following the instructions for use, working in a well-ventilated area, and wearing personal protective equipment such as gloves and masks. The safety of all individuals involved in the work environment shall be assured by following all necessary precautions.

Expert Tips for Success

Understand the Material

Always familiarize yourself with the type of adhesive you are using. Read the label and safety data sheets to understand the product, its properties, and its hazards.

Prepare the Surface Properly

Surfaces to be bonded must be clean and dry. Any dust, grease, or moisture will weaken the adhesive’s power.

Use the Right Amount

Apply adhesive thinly and evenly to avoid wastage or excess, which can adversely affect the bond or make handling difficult.

Follow Curing Times

Allow adequate time for the adhesive to set and cure. Being in a hurry can reduce bonding strength.

Store Adhesives Correctly

Adhesives must be stored sealed in their original containers in a cool, dry place, as indicated by the manufacturer, to maintain their effectiveness over time.

Testing Adhesives

Testing adhesives of a particular type is essential to ensure that bonding operations deliver good performance and durability under real-world conditions. First, identify the materials slated for bonding and run small tests to verify compatibility. Apply the adhesive as recommended by the manufacturer, paying close attention to the surface preparation and application method. Before testing, the adhesive must be fully cured; after this, tests stressing its capability, such as tension or shear tests, will be performed to confirm its suitability for the particular application. After conducting thorough testing, you will be able to determine whether your hand remedy is compatible with the chosen application, thereby avoiding failure and ensuring reliability.

Proper Storage of Adhesives

For proper storage of adhesives, I ensure they are stored in a cool, dry place, out of direct sunlight and extreme temperatures. I always reseal the containers tightly after each use to ensure that no contamination or evaporation takes place. Adhesives should be stored according to the instructions; this maintains their performance and extends their shelf life.

Reference Sources

Here are five professional and authoritative sources on the topic of “what glue to use on PLA,” which you can check to see if your article is correct.

- Hollander Makerspace | Fabrication | 3D printing | MSU Libraries

This source discusses 3D printing materials, PLA included, and mentions compatibility with super glue for post-processing. - What Kind Of Primer Is Good For PLA Filament

This article examines various methods for adhering materials to PLA, including primers and adhesives. - Post-Processing Techniques for 3D Prints

A Parsons School of Design’s guide to post-processing 3D prints with adhesives. - Makerspace: 3D Printing and Design

This resource from Xavier University talks about adhesion techniques and post-processing of PLA prints. - Thermoplastics 3D Printing Using Fused Deposition Modeling

Research conducted at the University of Maine includes adhesive testing of PLA and other polymers.