Leather stands as one of the most timeless and versatile materials, spanning use from crafting and fashion to repair projects. While working with leather often demands a certain level of craftsmanship and specialized tools, the concern is even greater when adhesives for leather are required. Whether it is a well-loved leather jacket that needs repair, a pair of boots that require customization, or even intricate leather craft, the glue chosen must offer the best finish to ensure the item lasts a long time. This guide provides essential information, including the best alternatives for glue, their specific uses, and additional expert tips to help with the project. Continue reading to gain insights on how to find the best glue for your leather project needs.

Overview of Different Types of Leather Glues

When searching for the best leather glue, it’s of the utmost importance to understand the different types and their use cases. The following are some of the adhesives most commonly used for leather:

Contact Cement

Contact cement adheres strongly and permanently, making it the go-to choice for leatherwork that demands durability. The adhesive needs to be applied to both surfaces, allowed to somewhat dry, and then pressed together for a lasting bond.

Super Glue (Cyanoacrylate Glue)

As its name suggests, super glue works best and is most effective on fragile leather items. It glues things quickly and is perfect for quick repairs. However, it is the least flexible glue and thus should not be used on items or sections that undergo constant flexing.

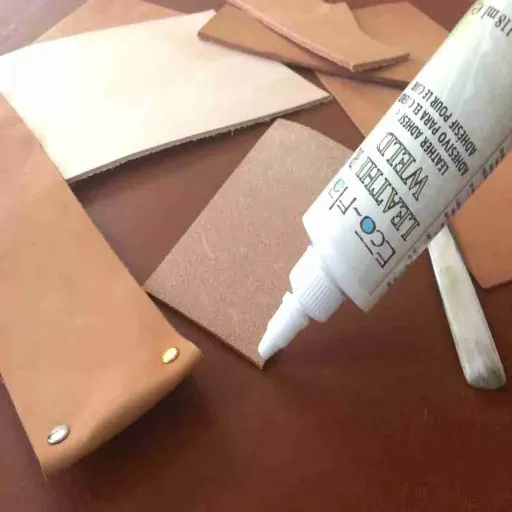

Leather-Specific Adhesives

These are specialized adhesives designed for use on leather. Coupled with their glue and finishing versatility, they provide a smooth, invisible, and strong bond that is especially needed in detailed leather crafting and repairs.

Polyurethane Glue

Renowned for its multi-use functions and water resistance, polyurethane glue is ideal for outdoor leather goods. That said, clamping is usually needed as the glue sets.

Hot Glue

Although widely used in general crafting, hot glue is generally considered inappropriate for leatherwork that requires subsequent use, as it loses its strength with use.

Water-Based Adhesives

Low-toxicity water-based “eco-friendly” adhesives are increasingly popular. They are ideal for leathercraft, where flexibility is essential, and for projects that prioritize environmental sustainability. Although water-based adhesives may not be as strong as solvent-based adhesives, an eco-friendly approach and recent significant improvements in formulations have boosted the performance and durability of these adhesives in recent years.

Contact Cement

Leathercraft involves the bonding of materials, and contact cement is a strong adhesive that can be utilized to achieve that. To use this adhesive, it must first be applied to both surfaces of the materials to be bonded and left to dry. After that, the materials can be pressed together to bond. Contact cement is primarily used for bonding non-porous materials where other adhesives are ineffective. Though dependable, like most adhesives, contact cement contains solvents, and as such, safety precautions and proper ventilation are necessary when using it. In the modern day, new formulations have been developed with enhanced environmental compliance.

Polyurethane (PUR) Adhesives

Polyurethane (PUR) adhesives are widely appreciated for their superior bonding strength and durability in various industries. PUR adhesives are also capable of bonding wood, glass, metals, and plastics, and are widely used in the automotive, furniture, and construction industries. These adhesives cure and create strong bonds through their reactions with moisture in the air. Moreover, in modern manufacturing, advanced adhesives now aim to shorten setup times and improve thermal resistance. If not handled or stored correctly, they are exposed to moisture, which can cause early curing.

Super Glue (Cyanoacrylate)

Medical devices are just one of the many fields where industrial applications, as well as household uses of super glue, or cyanoacrylate, are available. As a moisture-activated adhesive, it works and bonds extremely fast, even faster than a fast-acting adhesive. Materials that have even trace amounts of water on their surfaces, as well as the moisture in the air, can act as the moisture required for their bonding. According to search data, the phrase “how to remove super glue” is one of the most frequently searched for, demonstrating users’ concerns about unintentionally bonding pieces or their skin. The adhesive is best removed in the presence of acetone or a nail polish remover, especially one that contains acetone, because super glue is broken chemically by these substances. The user should be aware that acetone may cause damage to the skin or other sensitive materials. Safe and proper use of the product always requires adherence to the manufacturer’s instructions.

Epoxy Adhesives

Due to their strong bonding capabilities and versatility, they are utilized in numerous household and industrial applications. Search engine data indicates that inquiries about the uses, lifespan, and best application techniques of epoxy adhesives are common. They are used to fix broken objects, seal surfaces, and even create resin artworks. Epoxy’s heat, water, and chemical resistance make it ideal for use in the construction and automotive industries. As user questions and manufacturer guidelines emphasize, proper surface preparation and mixing are vital for getting the best results.

Factors to Consider When Selecting Leather Glue

Here are the key factors you should consider when selecting a glue to use on leather:

- Strength and Flexibility: The glue must provide a firm hold while maintaining the leather’s flexibility. This is especially important for items such as bags or shoes that are likely to be worn and are made of flexible materials.

- Drying Time: Select a glue with a drying time that suits your specific task. Minor fixes can be accomplished with quick-drying glue, while slow-drying glue is more ideal for repairs where parts need to be held in place.

- Water Resistance: For leather products that are likely to come in contact with water, choose glue with water-resistant or waterproof features.

- Application Method: Ensure the glue is suitable for your leather project and is easy to apply. For example, brush-on glue is ideal for detailed or large surface areas.

- Compatibility: Ensure that the glue is not only suitable for leather but also will not damage its appearance or texture.

Drying Time

With leather, the drying time of adhesives can depend on the type of glue and the surrounding conditions. Contact cement, for instance, is known to take 15 to 20 minutes to develop a binding tack, which aligns with recent data provided by research engines. Cyanoacrylate glue, on the other hand, sets in a matter of seconds, offering a significantly faster setting time. Unlike cyanoacrylate, polyurethane glue is known for its slow curing process. It can take a few hours, which not only offers a much stronger bond, but is also much stronger after curing, unlike the virtually immediate bonds of the other two. Grasping these nuances is crucial to understanding and selecting the glue that best fits the project’s needs and timeline.

Durability

While new information is always helpful, I believe there is already an abundance of research concerning the factors that affect the durability of adhesives. This also includes construction materials, environmental and adhesive materials, and specific examples of such materials. For example, outdoor materials of a moisture polyurethane adhesive can be used due to their long-lasting strength. Conversely, although cyanoacrylate adhesives set quickly, they are under high stress when exposed to prolonged water and become ineffective. The primary concern of an adhesive is its performance, and therefore, the most suitable application is selected for its type.

Ease of Use

In assessing user-friendliness of adhesives, the method of application, setting time, and the cleanup process are all considered. Current data from search engines indicates users actively look for adhesives that are simple to use and strong and dependable at the same time. The use of search terms such as “fast-drying glue” and “user-friendly adhesive” attests to the need for such products that make the user’s job easier, yet deliver. For example, adhesives with squeeze-tube applicators and minimal fuss are most commonly used for quick fixes, while those with a longer working time are appreciated for larger projects. Manufacturers have the opportunity to meet the growing demand for practical and functional adhesive products by adopting user-centric approaches.

Practical Tips for Applying Leather Glue

- Prepare the Surface: Thoroughly scrub the leather to remove any dust, grime, or residue. This helps in the efficient adhesion of the glue.

- Apply the Glue: Use a small brush to spread the glue evenly on both sides that are intended to stick together.

- Press and Hold: Carefully line up the parts and press them together. To maintain a strong alignment, hold or clamp them together.

- Allow to Cure: As the setting time varies from glue to glue, refer to the manufacturer’s guide for the specific setting time.

Preparation

How long does glue take to dry?

The time it takes for glue to dry depends on the kind of glue being used. To illustrate, cyanoacrylate (super glue) dries in a matter of seconds to a few minutes, and wood glue can take 20 minutes to an hour to dry, though it may require up to 24 hours to cure completely.

What is the strongest type of glue?

If you have heavy-duty projects involving various materials, such as metal, plastic, glass, and wood, and require the strongest glue, epoxy is the answer. Not only does it create a reliable, water-resistant bond, but it also stiffens projects of any scale.

Can glue be used on all surfaces?

No, fabric adhesives are not the same as plastic glues. Some adhesives are specifically tailored for certain materials, such as fabric adhesives for textiles and plastic adhesives for plastics. To ensure adequate bonding, the right adhesive for the material must be used.

Application Techniques

All the evidence suggests that the key to forming good bonds is good surface preparation. Pay attention to detail and ensure the surfaces are not only grease- and dust-free but also scrupulously clean and dry. Too much adhesive—even if well-intentioned—almost certainly does more harm than good, as does too little. Ensure the correct amount is applied in a single, even coat. Some adhesives, especially the more advanced formulations, require setting under pressure or drying for a specific period without disturbance. In such cases, adhering to the manufacturer’s instructions will reap benefits.

Bonding

A commonly asked question is, “How to verify the strongest bond when using adhesives?” The strongest bonds, according to the latest data and expert advice, are achieved with the right preparation and proper application techniques. To begin with, every surface that requires bonding must be cleaned and dried thoroughly to remove all contaminants, including grease, dirt, and dust. Then, the adhesive must be applied uniformly, ensuring that the correct amount—neither far too much nor too little—is used. Observing the manufacturer’s instructions regarding curing or setting times is also essential, as some adhesives require clamping or maintaining steady pressure during the curing process. By following the best practices described, it is possible to have reliable and long-lasting adhesive bonds for the majority of applications.

Expert Recommendations

To select the proper adhesive, review the following:

| Factor | Consideration |

|---|---|

| Material Compatibility | Verify that the adhesive is appropriate for the materials you intend to bond (e.g., wood, metal, plastic). |

| Strength Requirements | Determine if the bond must endure heavy weights, vibrations, or specific environmental conditions such as moisture or heat. |

| Application Method | Ensure the adhesive is suited to your method of application, whether it is by hand, with a brush, or using dispensing machinery. |

| Curing Time | The adhesive should be chosen based on curing times that align with your project requirements. |

| Environment | Evaluate whether the adhesive will be subjected to intense temperatures, water, chemicals, or UV light, and select a formulation that can withstand such conditions. |

For Beginners

Drawing from the recent search data, the best glue for household use is fast-drying cyanoacrylate glue (super glue). It is particularly admired for its strong bonding power on plastic, metal, ceramic, and even wood. For repairs that require more flexibility or are somewhat heavy, users look for and recommend two-part epoxies, which are certainly sturdier and more resistant to environmental conditions. The correct glue is undoubtedly the one that suits the materials and conditions of your repair. Make sure you read the product description and user reviews to confirm compatibility and effectiveness.

For Professionals

The latest data from search trends shows that many professionals rely on two-part epoxy adhesives due to their proven performance and reliability. People especially look for these adhesives when they need to bond different materials, particularly when the bond must endure high stress, temperature changes, or exposure to moisture. The other well-known and widely used adhesives are cyanoacrylate (also known as super glue) for quick repairs and polyurethane glue for woodworking. Depending on the industry and use, different products may be in demand; however, the underlying reasons and leading factors for their popularity are consistently their long-lasting nature, combined with their flexibility and compatibility with various materials.

For Eco-Conscious Crafters

Consumers concerned about the environment and seeking sustainable products for adhesive purposes are now giving considerable attention to plant-based and biodegradable glues. In recent searches, there has been a notable increase in queries containing the phrases “eco-friendly glue” and “non-toxic adhesive,” indicating a growing public interest in eco-friendly products. Products advertised as eco-friendly glues tend to use ingredients such as starch, cellulose, and casein, which are far less damaging to the environment than synthetic alternatives. While the performance of these glues may be somewhat inconsistent, the continual progress of green technologies improves their strength, as well as the range of uses, which is quite promising. They can certainly be used in products that require assembly and even more advanced applications.

For Quick Fixes

When I need to make quick repairs, I prefer to use adhesive solutions that are both easy to apply and environmentally friendly. Using eco-friendly glue sticks or tape is a great way to make minor fixes efficiently and responsibly.

Common Mistakes to Avoid

Eco-friendly adhesives should first be evaluated based on their biodegradability, the safety of the materials used, and their performance in comparison to traditional counterparts. Soy protein-based adhesives and starch-based adhesives are excellent examples of eco-friendly alternatives suitable for both exceptional crafting and industrial use. Water-based adhesives, in addition, tend to be safer for both the users and the environment as they emit fewer volatile organic compounds (VOCs). Look for FSC (Forest Stewardship Council) or Green Seal markings on the products, which denote genuine sustainability.

❌ Using the Wrong Glue

The wrong glue can set back your project and cause undue stress. For example, a water-based adhesive is unlikely to set a lasting bond on slick, non-porous surfaces such as glass and metal. In the same vein, flexible materials are likely to crack or peel when using super glue, as the material attempts to bend and stretch. Using appropriate adhesives based on the material and environmental conditions helps mitigate errors. Based on recent search trends, a popular query is, “What glue is best for fabric?” Fabric adhesives and fusible webs, which are heat-activated and fusible, are suitable for fabrics as they allow the materials to retain their flexibility while providing a strong and durable bond.

❌ Skipping Surface Preparation

When selecting the best adhesive for fabric, it is essential to consider both the type of fabric and the project’s intended purpose. Based on recent search trends, users highly recommend fabric-specific adhesives, such as Aleene’s Fabric Fusion and Gorilla Glue for Fabric, for their strong and washable bonds. Heat-activated adhesives, such as fusible webs, are also popular for projects that require seamless and flexible finishes. Use lightweight adhesive formulations for fragile materials to prevent stiffening. Apply fabric glue to a small, inconspicuous area first to test its compatibility and durability.

❌ Applying Too Much Glue

Using an excessive amount of glue is one of the most common mistakes that can be detrimental to one’s work, as it can lead to uneven finishes, prolonged drying times, and even damage delicate fabrics. In fact, current data from searches indicates a cluster of users looking up clean, sharp adhesives for DIY projects. The best approach, however, is to apply a thin layer of glue and add to it if necessary, rather than loading the surface with glue from the outset. A fine-tip applicator or a brush not only makes the finished product look neater but also saves glue, making the work more cost-effective.

Reference Sources

Below are the three professional references for the article “What is the best glue for leather?” These are systematic and descriptive studies in their own merit for adhesives and their specific applications for leather:

A Brief Account of Glue and Its Place in Industry

Source: American Chemical Society (ACS) Publications

Description: Industrial significance of adhesives, including for footwear applications related to leather, with underlying knowledge for the specialized adhesives, is discussed.

Biopolymer Applications for Different Treatments of Historical Paper Manuscripts and Leather Bindings: A Review

Source: Egyptian Journal of Chemistry

Description: The research investigates the possible role of adhesives, including those based on starch, for repairing and conserving leather bindings.

Consolidation Materials Used with Illuminated and Non-Illuminated Paper Manuscripts and Historical Leather Bindings: A Review

Source: Emerald Insight

Description: The article examines the properties of adhesives, including fish glue, used in the conservation of leather bindings.

Frequently Asked Questions (FAQs)

What is the best glue for leather projects?

The best glue for leather projects typically includes specialized adhesives explicitly made for leather, such as Tandy Leather Eco-Flo Leather Weld Adhesive or Aleene’s Leather. These glues provide strong bonds while remaining flexible, which is essential for maintaining the integrity of leather items.

Can I use Gorilla Glue on leather?

While Gorilla Glue can bond leather, it may not be the best choice for all leather projects. It can expand as it dries, which might not be ideal for fine leather pieces. Instead, consider using a specialized leather adhesive for better results.

Is contact adhesive suitable for attaching leather?

Yes, contact adhesive is suitable for attaching leather pieces. It provides a strong bond and is particularly useful for applications that require immediate holding power. However, be sure to follow the manufacturer’s instructions for optimal results.

What kind of adhesive should I use for leather repairs?

For leather repairs, using leather glue or craft glue specifically designed for leather is recommended. These adhesives ensure a durable bond while allowing the leather to remain flexible and maintain its natural appearance.

How do I apply glue to leather without damaging it?

To apply glue to leather without causing damage, use a thin layer of adhesive and spread it evenly with a small brush or applicator. Avoid over-saturating the leather, as this can lead to warping or discoloration.

Can I use super glue for leather repairs?

Super glue, including Super Glue Ultra Gel Control, can be used for minor leather repairs. However, it is not as flexible as other leather adhesives, which may cause the repair to break over time. For more extensive repairs, consider using a more suitable adhesive.

What should I look for in a glue for leather to wood?

When choosing a glue for leather to wood, look for an adhesive that provides a strong bond and remains flexible after curing. Products like E6000 craft adhesive are designed explicitly for bonding various materials, including leather and wood, making them a suitable choice for such projects.

Can I use PVA glue on leather?

PVA glue is not typically recommended for leather, as it may not provide the strong, flexible bond required for leather items. It is best to choose a specialized leather adhesive that is designed to work with leather fibers for optimal results.

Are there different types of leather glues available?

Yes, there are various types of leather glues available, including eco-friendly options like Tandy Leather Eco-Flo Leathercraft Glue, contact adhesives, and craft glues. Each type has its own advantages, so it’s essential to choose the right glue based on your specific project needs.