Suppose you are doing a DIY Styrofoam project, or any of such related crafts. In that case, it is fundamental to make the appropriate choices regarding the adhesive that will be used because it dictates the quality and appearance of the project at the end of the day. Hot glues are one of the adhesive types that are most widely used and are appreciated for their practical application and flexibility. Nevertheless, employing hot glue with Styrofoam brings up a pertinent issue: Will hot glue melt Styrofoam because of the heat emanating from the glue gun? This paper critically examines hot glue and Styrofoam interactions, looking at their chemical and physical aspects, fundamentals of heat and material response, as well as other better ways of maximizing bonding capabilities. Even if you are an advanced user or just beginning, this article will show that you have the required insight for Styrofoam-related work.

The Chemistry of Hot Glue and Styrofoam

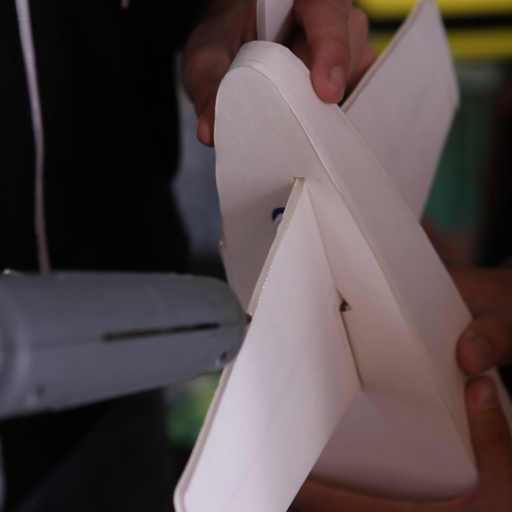

High-temperature hot glue is capable of melting the Stylus due to the heat that is generated when applying it. Styretit is a low-density foam that one can consider as a flexible type of polystyrene. And therefore, sometimes it melts even to the extent it disintegrates because of heat. This is because polystyrene is a form of thermoplastic, which means that it prevents softening of the shape of the object even when heat is applied to it. Lower temperature glue guns exist, designed to limit damage to heat-sensitive materials. These range limit the temperature of use enough to protect the adhesive from melting, yet still function to achieve a good joint. Another approach is to apply cold adhesives for gluing purposes. More specifically, styrofoam-safe glues provide adequate attachment without deforming the surfaces in any way.

What is Styrofoam Made Of?

Polystyrene polymers dominate the material used for Styrofoam production. It is produced by a process called polymerization of styrene which is a liquid hydrocarbon obtained from crude oil as well as natural gas. A lower density expanded bead polystyrene foam is produced by expanding beads of Polystyrene, which is done by heating the beads and mixing the beads with Pentane, an elongated blowing agent. These beads, during the expansion phase, form bubbles in the cells, and this is how Styrofoam can achieve insulating, low-density height and buoyancy properties. As well as the ones mentioned, various other additives could be added to achieve specific useful properties, such as flame ripening agents or stabilizers. The required combination of materials and process leads to this highly versatile product used in the packing, thermal insulation and building industries.

The Composition of Hot Glue

Hot glue, or more commonly known by its industry name, hot melt adhesive (HMA is a bond-forming material that hardens upon cooling. A typical HMA comprises a polymer, a tackifier, and a plasticizer. A synthetic adhesive’s structural or primary build-up depends on its base, particularly an elastomer such as ethylene-vinyl acetate (EVA), most commonly, or the more flexible and lower melting point polyamide. Tackifiers are mostly in the form of natural or synthetic resins, which increase the tackiness of the adhesive, making it easier to bond with surfaces. To further enhance the effectiveness of an adhesive, these additives are introduced into the formulation: viscosity modifiers and flexibility enhancers, also known as plasticisers. Waxes, oils, and other plasticizing agents help reduce the viscosity of the adhesive; hence, they enhance the flow of the adhesive when heated and also help maintain flexural properties when cold.

Other ingredients may be added to modify the characteristics of the adhesive for certain uses. In order to extend the useful life of the adhesive, some heat stabilizers may be added to prevent thermal or oxidative degradation associated with multiple heatings. Fillers may be added to either cut down on costs or change physical properties of materials such as making them lower in density or tougher. There may also be some pigments used in some products just to adhere color for aesthetic or identification reasons. Because of this unique composition, hot melt adhesive can be used in the packaging, joinery, electronics, and fabric industries where fast application and adhesion are essential aspects.

How Heat Affects Styrofoam

Expanded polystyrene (EPS), better known as Styrofoam, is particularly vulnerable to heat because it is a thermoplastic. Once this material is heated, it experiences multiple changes in that matter. When Styrofoam is heated to or around 212°F (100°C), the material begins to lose its structure as air pockets begin to escape. Prolonged heating at the mentioned temperature usually results in further deformation and even shrinkage of the material. If the temperatures exceed or rise to 464° F (240°C), the material is likely to thermally degrade and release the monomer styrene and other hydrocarbons, volatile organic compounds, as noted in the emissions. These emissions can be harmful to the environment and the people’s well-being, particularly when heat is used to manage waste, coal, or incinerators, or other similar heating devices used to deal with waste.

Why Hot Glue Can Melt Styrofoam?

It is so because the hot glue is able to melt the styrofoam due to the high temperatures used during the process of gluing. Styrofoam is made up of the material polystyrene, which belongs to a certain family of plastics that can be malleable and pliable due to heat. Normally, hot melt adhesive that is produced in a standard hot gun operates within the range of 250°F and 400°F successfully, or 120°C to 200°C, and hence enables the use of the foam without distorting it. So, this can be achieved by avoiding the use of hot glue guns or glues and opting for the use of low-temperature bedding, or specifically Styrofoam-friendly adhesives, which do not generate much heat and still manage to stick the objects as required.

Temperature Sensitivity of Polystyrene

Since polystyrene is sensitive to heat, there is often a demand for other forms of bonding other than the one that relies on the principle of heat. One particularly effective method involves the utilization of solvents containing adhesives that chemically stick to the surface of polystyrene without inducing any impact of the/melting/on otherwise rough surfaces. To illustrate, adhesive containing acetone or comparable solvents may also provide a succinct join, having mildly softened the polystyrene and allowing the two to converse as the solvent goes away. Furthermore, as for silicone-based or epoxy adhesives, there are recognized ways of adhesion where the materials heat after attaching, resulting in breakdown of the material. Standard methods in the industry of use establish that the heat that should be applied should be between 50°F and 85°F (10°C and 29°C) for the project.

The Role of Adhesive Properties

Adhesive properties can also be explained as the combination of adhesive ability (cross-linking effect) together with cohesive ability. Both values are dependent on molecular interactions. Cohesion, for example, often stems from the chemical structure and even the composition of an adhesive. The other aspect, which is the adhesion, is the purpose that has to be served regarding the applications of the adhesive, in that it has to adhere or bond to the surface of the other material. In this context, there are factors such as “wetting properties” and “surface energies” within us and between the materials which need to be perhaps equalized.

For example such substrates with low surface energy such as Polyethylene or Polytetrafluoroethylene (PTFE ) have macromolecular groups that cannot be wetted. As a result, adhesion of these more extreme and very high surface energy materials must include additional surface treatments such as plasma or corona to enhance the surface energy. Advanced visions of the issues show that adhesives having the qualities to function properly in hot and high-temperature conditions – thermal adhesives, like polyimides, surpass the advanced temperatures for about 300°F (150°C) without degradation. These features enable them to exert an accurate function in the areas of aerospace, automotive, and electronics, where precision and preservation are required, and the correct choice of adhesives is very important.

Comparing Hot Glue with Other Adhesives

|

Parameter |

Hot Glue |

Silicone Adhesive |

Epoxy Adhesive |

Solvent-Based Adhesive |

|---|---|---|---|---|

|

Application Method |

Requires hot gun |

Applied as a paste |

Mix resin and hardener |

Brush or squeeze application |

|

Curing Time |

Sets in seconds |

Takes hours |

Takes several hours |

Dries within minutes |

|

Bond Strength |

Moderate |

High |

Very high |

High |

|

Surface Compatibility |

Limited, ideal for porous |

Suitable for most surfaces |

Works on diverse materials |

Ideal for plastics and metals |

|

Temperature Resistance |

Poor, melts at high temps |

Excellent |

Excellent |

Moderate |

|

Flexibility of Bond |

Low, brittle at times |

High, flexible |

Rigid upon curing |

Varies by formulation |

|

Cost Effectiveness |

Low, inexpensive |

Moderate |

High |

Moderate |

|

Outdoor Suitability |

Limited |

Excellent |

Excellent |

Moderate |

|

Ease of Removal |

Difficult, requires scraping |

Easy with solvents |

Very difficult |

Solvent-dependent |

|

Environmental Impact |

Non-biodegradable |

Low emission formulas exist |

Contains VOCs |

Contains strong solvents |

Alternative Adhesives for Styrofoam Project

- Polystyrene-Safe Spray Adhesives

These are particularly dedicated to bonding types of foam without suffering the possibility of melting or decay. Their coverage is nearly uniform, which makes them best for use in the assembling of relatively minuscule objects

- Hot Glue (Low-Temperature)

Low-temperature hot melt glue is a quick-drying glue that works well for tasks that require rapid adhesion. When choosing the type of glue to use with your styrofoam, make sure you do not ruin the foam by using a glue intended for plastic due to excessive heat.

- White Glue (PVA)

White glue, as a matter of fact, is a more economic and also environmentally safe option contained in plastic easy squeeze bottles with no metal cap. While it is very effective in bonding styrofoam, prolonged application is required due to somewhat elongated drying time.

- Styrofoam-Specific Adhesives

However, the range of adhesives jointly applicable to polystyrene and similar materials is the most efficient and free from any corrosive additives. This has been well documented through the significant number of small scale and extensive projects that all involved the use of the non-toxic glue.

- Double-Sided Adhesive Tapes

In commercial or industrial settings, double-sided adhesive tapes offer an alternative method of joining. The benefits of a double sided tape include bonding without messing the foam surface.

Effective Application Techniques

For the adhesion to be perfect, the treatment of the surface has to be on another level. The very first stage would be to scrub the surfaces thoroughly and allow them to dry completely in order to extract any foreign bodies that may impede the bonding process, like dust, oil, or remnants of any adhesive that may have been previously used on the surfaces of interest. Depending on the adhesive, some surfaces may need scuffing with sandpaper to give them sufficient roughness and mechanical retention. In the case of high-performance adhesives, for example, during the application of epoxy adhesive, any deviation from the prescribed mixing ratios will lead to detrimental effects.

The period of curing is also a deciding factor and largely depends on factors of formulating an adhesive, as well as ambient temperature and humidity. Owing to the fact that these agents achieve the perfect balance of this and other criteria, essentially all the mechanical properties are achieved for the adhesive. More advanced techniques, such as applying heat or exposing the area to UV rays, are utilized in industries to break down the curing barriers and enhance the efficiency of the bonding. These practices increase adhesiveness and effectively achieve valuable performance from adhesive materials.

Choosing the Right Adhesive for Your Project

In selecting an ideal adhesive for the project, the following vital aspects must be analyzed to achieve the best performance and long service life:

- Material Compatibility

Consider the methals or structures to be bonded together including the chemical compatibility with the adhesive. There are adhesives available that cater more to one family of materials i.e. metals, plastics, wood, or composites while others can be applied on multiple substrates. For example, the cyanoacrylate adhesives serve only those that have impermeable materials like plastic or glass whereas there are adhesives for the resins for wood.

- Load Requirements

Evaluation of the type of bonded joint should account for shearing, tension, impact, compressive, or tensile methods within the construction. Structural adhesive epoxies reach up to 5,000 psi, and are capable of almost any load bearing application for high tension applications.

- Environmental Conditions

Define the working conditions or service environment; the effect of temperature, moisture, dust, UV lights, and chemicals, among others. For example, rubber silicone can be used in very cold conditions – 500°F and very hot -75°F with water and chemicals and they are very effective in external elements.

- Curing Time and Methods

The cure time for the adhesives available is highly impactful on the work schedules. Glues such as hot-melt patches can get dry in seconds while for epoxies or in some cases different kinds of glue, it can take more than a few hours to get a complete dry. Special techniques for making something harden faster, like UV full curing, can be performed in order to shorten the curing time and enhance the mechanical strength of the bonding.

- Application Method

Consider the ease and efficiency of the application, including the ease of the task. Adhesives with high viscosity, like construction adhesives, are useful for joints and gaps, yet those with low viscosity are more suitable for bond repairs. The process of glue application should take into account project specifics and usually varies in syringes, cartridges, or other automated equipment forms.

Practical Tips for Using Hot Glue with Styrofoam

- Thinning: simple processes like melting Styrofoam are something that planning to make them using hot melt glues, when you have to resort glue guns specifically avoid doing this at high temperatures and use low temperature hot glue gun instead.

- Creation in little measure: when it comes to bonding of polystyrene based products a very thin copacetic layer is expected to be used as to avoid temperatures incompatibility resulting in physical destruction of the polymers.

- Do not press immediately after the glue has been applied. Let the glue cool down for some time before squeezing the Styrofoam pieces together so that no heat is generated, leading to destruction of the layers. And lastly.

- Conduct tests: fix a small area to test the effect of the glue before applying it to larger areas to ensure safety and expediency.

- Glue sticks for foam. Gluestick can also help in these challenges yet it is specifically designed to ensure the comfort of the foam is not compromised during and after adhesion is done.Otherwise other stakes are dined related to glue especially for different materials.

Techniques to Prevent Melting

- Use Low-Temperature Glue Guns: For that reason, when working with materials made from polystyrene, glue guns of the low temperature are more effective. Such applicators come with predetermined temperature levels suitable for use with less heat-resistant or sensitive materials such as foam. The working temperature should not exceed 250°F, ideally ensuring that the process is safe

- Minimize Use of Glue: People who make stuff with thermocol usually end up making thick layers of glues and increase its application whenever it is about adhering blocks. Decrease this activity, and stick only the required amount and make it uniform in application and pattern so that long heat will not form.

- Sticking Barriers: The resistance against direct heat can be increased by placing any insulating barrier (e.g. wax paper or aluminum foil) between glued Styrofoam and the cold surface. This is most useful when working with hot melt adhesive as such adhesives tend to melt at very high temperatures.

- Provide Ventilation Before Going To Work: It is found that with more air movement, dissipating of heat become faster and there is little rise in the temperature over arousing’s alphamega’s which would take best out of the foam unlike during bonding procedures. The provision of such precautious measure increases protection to the materials as well as comfort to the user.

- Enough Time for Curing: In each bonding process, it is necessary that bonding gets properly cured without overdoing the pressure; there are many reasons for this rule and one of them is to avoid heat gen because they are capable of enhancing latent melting of a bond. Thus, observe the recommendation given by the maker for the curing time for the best performance of the sealing.

Tools and Equipment Recommendations

- Low-Temperature Glue Gun: A low temperature glue gun is a must-have while using Styrofoam since it helps to prevent the substance from getting melted. Most of these devices have settings that will allow delicate handling of styrofoam.

- Precision Applicator Nozzle: When you buy a glue gun, you can also acquire a precision applicator nozzle with which the adhesive can be accurately applied and wastage minimized. This is made in order to eliminate the excess and make it possible to apply the adhesive smoothly.

- Foaming Adhesives: Use adhesives tailor-made for bonding foam, for instance contact cements safe for styrene, and the low voc polyurethanes. Verify with the vendors’ specifications in each case.

- Heat-Protective Surface Mats: You may find the use of such mats beneficial as it prevents you from creating a sticky desk should you accidentally spill some adhesive liquid or suffer from accidental hot glue damage in the course of your work.

- Clamp and One Factor: In such cases, lightweight broad faced clamps or weights without any hard edges are commonly used in order to provide reasonable pressure while the glue sets tack free with a particular material. These tools provide sufficient stress on the bonding area without deforming or damaging the polystyrene.

Potential Risks of Using Hot Glue on Styrofoam

- Heat and Glue: using hot glue on Styrofoam will cause its melting or deformation. The extended periods of use certain hot glue guns may compromise the strength of the Styrofoam since the high temperatures may compromise it.

- Bottom line, where hot glue is always a good adhesive, under certain conditions it may not work very well while gluing Styrofoam due to issues of material strain and sharp temperature changes. This means that with time the adhered surfaces will become unstable or separate.

- Flame And Foam: Using huge amount of hot glue can burn the surface of the Styrofoam. The material may even develop bumpy textures, get perforations and look both unattractive and ineffective.

- Burn Hazard: Styrofoam can catch fire easily, that is to say, in extreme cases of exposure to very hot glue or trying to assemble any components together for too long, there is a possibility that the styrofoam melts and burns.

All these risks can be prevented by putting safety first; hence, the intervention of those who are at risk should be timely and properly done.

Flammability Concerns

Styrofoam is highly flammable by itself due to its configuration. This may include expanded polystyrene in the configuration of this mixture. In this case, in the presence of warm or open flames, the materials may catch fire, generating combustion with harmful characteristic polystyrene vapors as well as carbon monoxide pollution. A flash ignition occurs at 680°F (360°C), whereas a self-ignition temperature is 850°F (454°C). Hence, such characteristics increase the likelihood of causing Styrofoam to ignite and blaze if it is placed in a locale where exposure to certain elevated temperatures or flames is likely. Even accidental fires can be reduced with the hope of also being controlled by using logical solutions such as flame-resistant materials or else distance the subject from the odds of overheating. Moreover, it is of great importance to ensure that Styrofoam parts do not catch fire due to waste composition, which indicates that waste disposal is equally a critical issue rather than just carrying out waste management.

Toxic Fumes and Safety Precautions

At high temperatures, Styrofoam begins to decompose, which is dangerous for health, as it releases poisonous fumes – styrene and benzene. These compounds are able to cause a number of health problems, such as eye irritation, dizziness, and damage to various organs in the long run, and the risk of cancer becomes higher. General ventilation is of utmost importance when dealing with Styrofoam next to heat sources, as these odorless substances, when restricted to the room, substantially heighten the risk of poisoning.

Reference Sources

-

Melting of PCMs Embedded in Copper Foams: An Experimental Study (2021):

- Key Findings: This study explores phase change materials (PCMs) embedded in copper foams, focusing on thermal properties and phase transitions. While not directly about Styrofoam, it discusses thermal interactions in foam materials.

- Methodology: Experimental setup with bakelite plates glued to foam blocks to observe phase changes.

-

The Effect of Styrofoam Addition into HRS-Base on Marshall Characteristics:

- Key Findings: Investigates the impact of adding Styrofoam to bitumen for road construction, analyzing its mechanical properties.

- Methodology: Laboratory testing of Hot Rolled Sheet-Base Course mixtures with Styrofoam.

-

A Novel Filtration Model for Microplastics Using Natural Oils:

- Key Findings: Pulverized Styrofoam was used to create microplastic powders for filtration studies.

- Methodology: Styrofoam balls were mechanically processed into microplastic powders for environmental applications.

Frequently Asked Questions (FAQs)

Q: Will hot glue melt styrofoam when using a low temp glue gun?

A: Using a low temp glue gun can be a safer option when working with styrofoam. Standard hot glue can potentially damage the foam due to its high temperature, causing it to melt or warp. However, a low temp glue gun typically operates at a lower heat, which reduces the risk of melting. If you’re tackling a craft project that involves styrofoam, opting for low temp glue is advisable. Additionally, there are specific adhesives designed for foam, like foam bonding glues, that work effectively without damaging the material. Always test a small area if you’re unsure.

Q: Can I use gorilla glue on styrofoam without melting it?

A: Gorilla glue can be used on styrofoam, but caution is needed. While it is a strong adhesive, it expands as it dries, which can cause the styrofoam to deform. If you want to avoid melting or damaging your foam, consider using a craft glue or a glue specifically designed for foam. These types of adhesives provide a good bond without the risk of melting. For larger projects, ensure that the surface area is clean and dry before applying the glue for the best results.

Q: Is tacky glue safe for styrofoam in arts and crafts projects?

A: Tacky glue is generally considered safe for use on styrofoam and is a great choice for arts and crafts projects. It’s designed to provide a strong bond without the high temperatures associated with hot glue. This makes it a popular option for crafters looking to avoid potentially damaging their materials. While it may take a bit longer to set compared to hot glue, the results are often worth the wait. Just make sure to apply it evenly to ensure good contact with the styrofoam surface.

Q: What types of glue should I avoid on foam board and styrofoam?

A: When working with foam board and styrofoam, it’s essential to avoid certain types of glue that can be damaging. Hot glue is often too hot for these materials and can lead to melting. Similarly, contact glue and certain spray adhesives, like those not specifically designed for foam, may not bond well and could result in damage. Instead, look for adhesives labeled as foam safe or specifically designed for foam applications, such as Elmer’s or 3M products. This ensures that your materials remain intact and your project turns out as planned.

Q: Can I use PVA glue on styrofoam for craft projects?

A: PVA glue, commonly known as school glue, can be a suitable option for styrofoam in craft projects. It bonds well with porous materials and dries clear, making it ideal for various arts and crafts applications. However, for the best results, ensure that the surfaces are clean and free from dust. While PVA glue is not as fast-drying as hot glue, it provides a strong hold without the risk of melting the foam. If you’re looking for a more robust adhesive, consider alternatives like Weldbond or other craft glues designed for foam.