Leather and wood can make exquisite pieces, and enduring ones at that, if you know what you are doing. For example, while gluing leather to wood might sound simple, there is a lot more that goes into achieving proper adhesion other than just slapping on an adhesive. Subsidiary measures can result in unsightly damage such as peeling which could ruin decades worth of craftsmanship and effort that was invested into the piece. In this article, we will show you the proper protocols, equipment and adhesives for effectively adhering leather to wood using the right techniques. This article will provide every beginner, experienced woodworker, or creative professional with suitable guidance that will enable you to achieve a robust and flawless final product. So, without any further ado, let’s get started so that you can master the techniques of precise adhesion.

What’s the Best Glue for Wood to Leather?

Weldwood Contact Cement and Barge All Purpose Cement are both excellent examples of contact cement glues, which are the best option for attaching wood to leather. These flexible adhesives work best when the materials to be bonded are as different as wood and leather because they ensure durable, flexible bonds. As with most contact cements, they work best when a thin layer is applied on both surfaces, allowed to reach a tacky state, and is pressed together without moving after. For very small projects, high-strength cyanoacrylates, often referred to as super glues, can also work, though they tend to be more rigid with adjustments. Maintaining clean, dry surfaces prior to applying glue will always promote stronger adhesion.

Understanding Different Types of Adhesives

|

Adhesive Type |

Key Features |

Best Applications |

Key Limitations |

|---|---|---|---|

|

Contact Cement |

High strength, flexible |

Leather, wood, laminates |

Requires precise application |

|

Cyanoacrylate (Super Glue) |

Fast curing, high strength |

Small repairs, plastics, ceramics |

Minimal adjustment time |

|

Epoxy Adhesive |

Extremely strong, waterproof |

Heavy-duty repairs, metal, concrete |

Long curing time |

|

Polyurethane Adhesive |

Expands when curing, waterproof |

Woodworking, construction, outdoor use |

Difficult to clean post-application |

|

Silicone Adhesive |

Flexible, heat-resistant |

Glass, weather sealing, electronics |

Limited structural strength |

|

Hot Glue |

Quick bonding, versatile |

Arts and crafts, lightweight materials |

Weak under high temperature |

|

PVA Glue (Wood Glue) |

Easy to use, non-toxic |

Woodworking, paper, porous materials |

Low water resistance |

|

Structural Adhesive |

High chemical resistance |

Automotive, aerospace, industrial bonding |

Complex, requires precise mixing |

|

Acrylic Adhesive |

High-impact resistance |

Metal, plastics, signs |

Surface prep often required |

|

UV-Curing Adhesive |

Cures under UV light |

Electronics, glass, medical equipment |

UV light access required |

Choosing the Right Glue for Your Project

Performance requirements, material compatibility, and working environment all need to be considered when choosing an adhesive, as they are critical for successful project execution. Each type of adhesive has its intended applications and therefore comes equipped with special capabilities.

- Material Compatibility

Determine which materials are going to be glued together and their characteristics – for example: openness (porosity), flexibility (rigidity), and surface characteristics. As an example, with porous materials like wood and paper, PVA glue works best. Metals and plastics work well with acrylic adhesives.

- Environmental Factors

Think of the conditions where the bonded materials will be exposed to. Regions with high humidity will require more water-resistant adhesives like epoxy or structural adhesives. On the other hand, applications with exposure to UV light benefit from UV curing adhesives

- Strength and Durability

Remember the mechanical demands of the joint. Structural adhesives have been shown to perform well in high-stress applications and are also exposed to chemicals, making them ideal for industrial and automotive applications.

- Application Methods and Curing Time

Evaluate how simple the application and curing processes are for the adhesive. Also, consider the target area: while UV curable adhesives need direct access to the curing source, they are great where precision and speed are required, such as in electronics and medical equipment. PVAs are best for moderately complex tasks where ease of use is required.

Considering these aspects will provide a minimum operational and technical requirement needed alongside efficiency and durability for the project.

How to Properly Attach Wood to Leather?

- Prepare the Surfaces

Before starting with the gluing process, both surfaces made of leather and wood need to dust, dirt, grease, and moisture removed. If any of the wood is rough, sanding it smooth helps ensure stronger adhesion.

- Choose an Appropriate Adhesive

Bond both surfaces using specialized leather-to-wood glues or contact cement. A test patch on a small area would allow confirmation of compatibility, allowing full surface application later on.

- Apply the Adhesive

Put an even, thin coat of glue on both the leather and the wood. Drying time varies so follow the instructions on the particular adhesive being used as some need to be tacky prior to bonding.

- Position and Bond

Be careful to place the leather directly over the wood. Smooth over the top in a firm manner, ensuring you remove every last air bubble for proper adhesion. You can even use a roller for even pressure distribution.

- Allow Sufficient Curing Time

During the curing period, put a weighted object or clamp over the surfaces to keep pressure consistent. Wait the full recommended curing time to ensure it is the most durable it can be.

Following through with these simple steps will allow you to successfully bond leather and wood together so that they do not come apart easily.

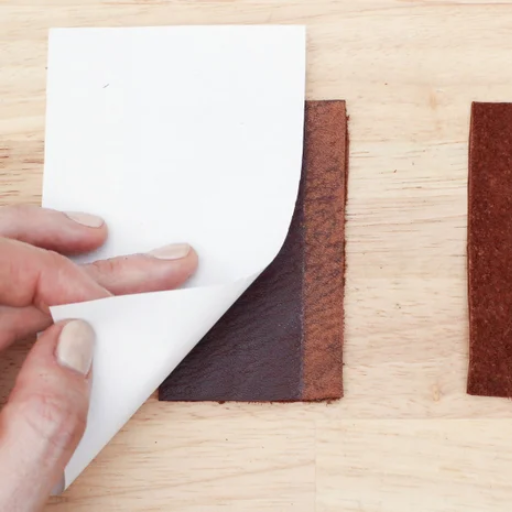

Preparing the Surface for a Strong Bond

Steps to prepare the surfaces of the leather and wood properly are very important. The parts to be glued must not contain dust, grease, previous glue remnants, or other unwanted grime. The leather must be brushed thoroughly to remove anything hanging onto its surface and the oils can be removed with a cloth that has been dampened in isopropyl alcohol. The wood requires a bit more attention as well. Sanding it with fine sandpaper will produce the desired smooth but roughened patch which will provide better grip for the adhesive. To finalize this step for wood, make sure to remove all dust residue with a vacuum or damp cloth.

For treated or finished wood, check if lacquer or varnish would impede bonding as they would chemically interfere with the glue. You may have to sand or strip the bond line for treated wood. For porous wood, apply a thin layer of glue and let it dry before main application. Taking these steps will provide a stronger connection between the materials.

Tips for Achieving a Secure Attachment

- Surface Preparation

As for the contribution area, make certain that all surfaces are well cleaned and bonded together. Failure to do so will result in dust particles, grease and residual glue Movie Magic contaminates. It has been determined that the above-mentioned contaminants can reduce adhesion by 45%, therefore using alcohol to clean up the surfaces is essential as well as ensuring that these surfaces are dry at all times before applying glue.

- Select the Appropriate Adhesive

Ensure that both materials to be bonded are under the same environmental conditions before gluing. For the initial connections, use the correct epoxy while for further connections apply cyanoacrylates for quick but strong bonds. Obtain adhesive strength, temperature tolerance, joint shear area and other relevant information that are often provided by adhesive manufacturers.

- Optimize Environmental Conditions

Like most adhesives, temperature and humidity will also have a direct relationship on its effectiveness. For optimial performance, most adhesives require a temperature of between 65°F and 85°F (18°C to 29°C). In highly humid areas, it is better to work in temperature controlled conditions as curing time and adhesion quality is adversely impacted with humidity.

- Apply Adhesive Evenly

Adhesives should be spread evenly to remove chances of uneven bonding and weak points in the structure. Tools such as spatulas and brushes designed specifically for adhesives should be used to apply an even layer. Most adhesives will sit between 0.05 mm and 0.1 mm which warrants precise thickness.

Failure risk is minimized with these helpful tips, but any attempt to troubleshoot will allow you to achieve long-lasting and secure attachment.

What Are Common Adhesives Used for Leather and Wood?

- Contact Cement

Contact cement is widely known for being an efficient adhesive used to bond items such as wood and leather. It instantly bonds which makes it useful for tough jobs that require immediate adhesion, especially when no clamps are available. For these reasons, the bond created is both flexible and strong.

- PVA Glue (Polyvinyl Acetate)

PVA glue is also known as wood glue and is excellent for used for bonding wood surfaces and can also work with leather. The bond is durable and requires some form of clamping for best results.

- Epoxy Adhesive

Epoxy is ideal for woodworking and crafting high-strength bonds with leather. Its durability and strength against prying environmental factors is superb, but like most epoxies, thorough surface preparation is a must.

- Cyanoacrylate (Super Glue)

Super glue works best for precise applications and small repairs. Although it delivers fast a result, super glue is not flexible and in case of heavy stress, or used on flexible leather materials, its hold softens.

Every adhesive offers unique strengths in flexibility and durability making them suitable for different assignments. Surfactant cleaning is critical, no matter which adhesive is selected, to achieve an optimal bond.

Advantages of Using Spray Adhesive

- Even Application for Broad Surfaces

With spray adhesives, issues of weak points and uneven overlapping that is caused with manual application are removed. The spray type results in consistent and even coverage which aids in getting more accuracy on larger surfaces.

- Ease of Use

The use of aerosol makes the application process easier and more accessible, saving time. Exact control over volume dispensed minimizes mess and makes for precise application of the adhesive.

- Versatility Across Materials

Leather, wood, paper, metals, foam, plastics, fabric and even lightweight plastic products can all be attached using spray adhesive. Such versatility makes it valuable for both home and industrial projects.

- Fast Bonding Time

Spray adhesives can save project time and overall waiting time, especially in time-sensitive projects, while offering a rapid tack time.

- Strong, Flexible Bond

Flexible bonds are often overwhelmed by stress, vibrations, or environmental changes. Using rigid adhesives in such situations may prove to be ineffective over time.

These advantages outlined make spray adhesives appealing to trusted professionals and DIYers.

When to Use Wood Glue vs. Leather-Specific Adhesives

Carefully selecting an adhesive affects durability and reliability of the project. For porous wooden surfaces, the best option is wood glue that consists of PVA or aliphatic resin. It often penetrates wood fibers, forming strong bonds internally and can endure a lot of shear stress. For carpentry, furniture assembly or woodworking where enduring structural stability is desired, wood glue works perfectly.

On the contrary, leather adhesives are made as solutions to the distinctive features of leather. For instance, its ease of bending and its surface smoothness. Such adhesives could be contact cement, rubber cement, or specially formulated water-based adhesives. They allow the leather to retain its vital pliability, which is very important for use in upholstery, repair of shoes and other crafting works.

Besides, leather requires flexible adhesion. While wood glue is strong enough for wooden materials, its rigid composition is unsuitable for leather and may lead to cracking or separation over time. Similarly, leather-specific adhesives would not work for wood projects because they do not provide the necessary depth of penetration or compatibility. Each material has an adhesive specifically designed for leather, wood, or any other material ensuring peak performance and optimum longevity.

Can You Repair Leather to Wood Bonds?

Certainly, with the right type of glue, it is feasible to fix the leather to wood joints. Their repair requires a flexible, high-strength adhesive, which may be either contact cement or polyurethane glue. These types of adhesives work best where differences in material behaviors are involved; for example, between the flexibility of leather and the rigidity of wood, providing effective adhesion. The hygiene of the surface to be glued is equally critical; ensure both are clean and dry. Compliance with the manufacturer’s recommendations on the use of glue provide the best outcomes.

Identifying Bond Failures in Leather to Wood Attachments

The bond failures of leather-to-wood attachments are often attributed to a lack of appropriate glue choice, surface treatment, or Temperature and Humidity Box environmental conditions. The use of porous material (wood) and non-porous material (leather) often leads to adhesive not performing to expectation. In addition, the presence of dust, oil or moisture on surfaces renders the bond weak irrespective of adhesive used.

Wood and leather, as an example, are porous and non-porous materials, respectively. They can suffer from extreme dry or humid conditions, leading to bond failure through expansion or contraction at different rates. Adding humidity leads to weakened bonds in wood and non-porous materials, while drought can make adhesives too brittle. Repeated bend or pressure at the joint can ease joint failure too, especially if the glue isn’t strong and flexible.

Maintenance Tips for Glued Leather Projects

- Control Humidity Levels

Keeping humidity within 40% to 60% is ideal. Leather exposed to high humidity for extended periods of time can cause moisture to seep into the leather which weakens the fibers along with the adhesive bond. On the other hand, dry conditions may lead to cracking or shrinkage of the adhesive.

- Avoid Extreme Temperatures

Keep the shaping the work piece in an environment with a controlled temperature of 60°F and 77°F (16°C to 25°C). Continuous exposure to heat over 80°F (27°C). Portions of some glues exposed to high Heat may soften, and Cold may cause the material to become brittle or crack.

- Regular Dust Removal

Use a slightly damp microfiber cloth or dry microfiber towel to clean the leather surface gently. The dust particles that accumulate on the surface over time, and if the leather undergoes regular handwork or movement, can lead to weak spots at the adhesive interface due to dirt abrasion.

- Condition the Leather Periodically

Condition the leather with a high-quality conditioner every six to twelve months. Hydrating leather lasts longer but make sure the conditioner doesn’t sink into glued joints because excess oils can weaken the adhesive.

Adhering to the recommended practices effectively retains the structural and aesthetic features of glued leather projects over time.

What to Consider When Choosing the Right Glue?

When selecting adhesive for a leather project, keep in mind the following criteria:

- Material Compatibility: Confirm the glue is made for leather or flexible materials to ensure proper adhesion and a reliable bond. Lacking leather compatibility will disqualify generic adhesives.

- Flexibility: Leather items require that the adhesives used must be able to withstand bending, stretching, and movement.

- Drying Time: Faster bonding procedures are suitable for simple tasks. With intricate work, longer-drying adhesives are better as they allow for adjustments.

- Water Resistance: Select a waterproof glue for items subjected to moisture or regular use so that bond strength is maintained.

- Application Method: Select a glue that matches with your skill grade and project requirements. For detailed application, brush on and squeeze tube options work best.

Ensuring the above factors will guarantee quality and reliability for your leather project.

Environmental Considerations for Adhesives

Your environmental impact is crucial, focusing on the safety of materials and sustainable practices. Chemical composition along with biodegradability, and the adhesives potential to release volatile compounds deem focus. Highly volatile adhesives contribute to air pollution causing health concerns so choosing low or no VOC alternatives is better for the eco.

Moreover, the steps taken to make adhesives need to be analyzed to ensure that energy use and waste creation are kept to a minimum. Water based adhesive and similar products are highly regarded because they provide the necessary strength while using a minimal amount of solvents.

At last, think about the potential environmental impact stemming from adhesive use and its compostability or recyclability attributes. With regards to packaging or single-use items, some adhesives may sabotage the recyclability, compostability, or the environmental friendliness of the materials they bond. However, adherence to eco-certification bodies like GREENGUARD or the EU Ecolabel assures stakeholder commitment to rigorous environmental wellness, sustainability, and public health protection.

Durability and Flexibility of Different Glues

Reference Sources

-

Assessment of Some Basic Engineering Properties of Fibres Extracted from Thaumatococcus danielli Plant: This study evaluated the performance of two adhesives, Topbond (water-based) and Evo-Stik (hydrocarbon-based), for bonding natural fibers.

Frequently Asked Questions (FAQs)

Q: What is the best way to glue leather to wood?

A: The best way to glue leather to wood is by using a contact adhesive, which creates a strong bond. Make sure to apply an even coat on both surfaces for optimal adhesion.

Q: What type of adhesive is recommended for a piece of leather?

A: For a piece of leather, you should choose the best adhesive like contact adhesive or gel-based options, as they provide a good bond and stay flexible once dried.

Q: Can I use Loctite super glue to glue leather to wood?

A: Yes, Loctite super glue can be used, especially the gel control version, as it dries clear and allows for precise application on small areas.

Q: How do I clean up my tools after using glue on leather?

A: To clean up your tools, use warm soapy water if the glue is still wet. For dried glue, you may need to use a solvent based on the type of adhesive used.

Q: Does the type of wood affect the glue used for leather?

A: Yes, the type of wood can affect the glue you choose. Some woods may require a stronger adhesive or a specific type of contact adhesive to ensure a lasting bond.

Q: How long does it take for glue and contact adhesive to dry?

A: Most contact adhesives will dry within 20 to 30 minutes, but it’s best to allow up to 24 hours for a full cure to achieve the best bond.

Q: Is it possible to glue leather to a piece of furniture?

A: Absolutely. You can glue leather to a piece of furniture using the right glue for leather, ensuring you prepare both surfaces properly before application.

Q: What should I do if the leather fails to adhere to the wood?

A: If the leather fails to adhere, check if you used the right adhesive and if both surfaces were clean and dry. You may need to reapply the adhesive or choose a stronger option.

Q: Can I use a spray-on adhesive for leather to wood projects?

A: Yes, a spray-on adhesive can be effective for larger surface areas. Make sure to apply an even coat and follow the manufacturer’s instructions for best results.

Q: What is hide glue and is it suitable for leather to wood applications?

A: Hide glue is a traditional adhesive made from animal collagen. It can be suitable for leather to wood applications but is less flexible than modern adhesives, so consider your project’s needs before using it.