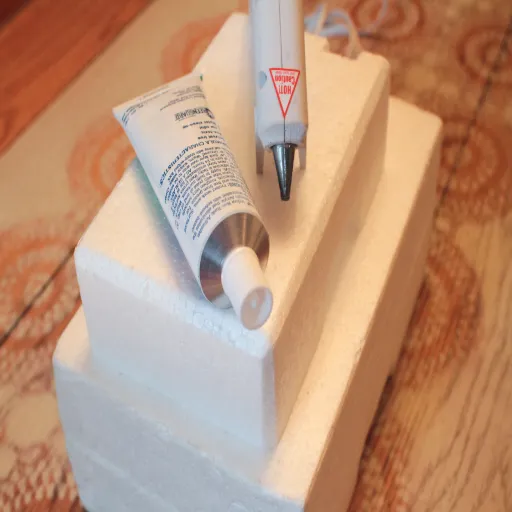

Styrofoam is such a flexible material that it is not only used in arts and crafts but also in packaging and DIY projects; however, finding the appropriate adhesive for it can be tough. One of the frequently asked questions by crafters and DIY enthusiasts is, “Can you hot glue on Styrofoam?” Even though hot glue is a familiar option for many projects, using it with Styrofoam can be challenging. So, through this tutorial, we will explore the specific traits of Styrofoam, the dangers of using unsuitable adhesives, and a range of glues that work pretty well. This all-inclusive guide will tell you the necessary things to know for picking the most suitable adhesive for your Styrofoam projects, whether you are making decorations, models, or doing other creative works.

Understanding Styrofoam

Styrofoam, one of the many forms of expanded polystyrene, is a very light material with multiple uses in insulation, packaging, and arts and crafts. It is made of a structure formed by millions of tiny, expanded, and then fused polystyrene spheres. Some of its main advantages include thermal insulation, impact resistance, and moisture resistance. Nevertheless, Styrofoam is very sensitive to some glues and solvents, which calls for the careful selection of an adhesive for the particular application concerned to avoid degradation and melting.

Properties of Styrofoam: Lightweight, Insulating, and Fragile

Major environmental issues accompany the extensive application of Styrofoam. Although it is highly convenient due to its lightweight and insulating properties, it is not decomposable and may thus remain in landfills for hundreds of years. Improper disposal of Styrofoam materials usually causes pollution, as the bits get smaller and are washed into nature, where they can endanger animals. Wildlife may swallow these tiny particles, mistaking them for food, which can result in digestive obstructions and injuries. Furthermore, the manufacturing process of Styrofoam heavily depends on nonrenewable resources like petroleum and emits toxic substances, collectively making the material’s ecological footprint quite large. The use of Styrofoam in production can be significantly reduced, or environmentally friendly alternatives can be adopted, thereby minimizing its environmental impact.

Common Uses of Styrofoam in Various Industries

Styrofoam (expanded polystyrene or EPS) is a commonly used material in many different industries because of its exceptional properties, such as versatility, lightness, and high insulation. The application of Styrofoam in the packaging industry is very significant. It is mainly used as a protective and insulating material for shipping fragile items and food containers, keeping the products fresh and their temperature constant. The construction industry makes the most of Styrofoam by using it for the production of insulation panels, which in turn leads to the incorporation of energy-efficient measures in buildings. Moreover, the advertising and events industries prefer using Styrofoam to produce signs, displays, and detailed props due to its easy cutting and molding properties. Although industries still use Styrofoam for its beneficial functionalities, they are gradually switching to more sustainable alternatives due to environmental concerns.

The Science of Hot Glue Adhesion

The adhesion of hot glue is a process that involves both heat and the glue’s physical attributes. To be specific, when heated, hot glue melts from its solid state to a liquid state, allowing it to flow and bond surfaces together. Meanwhile, as the glue loses heat and solidifies, a secure attachment is created through mechanical interlocking and surface contact. This whole procedure works perfectly for various materials like wood, plastic, fabric, and paper. The strength of the bond will differ according to the type of glue, the surfaces being joined, and the temperature at which the glue is applied. The hot glue is highly regarded for its fast drying time and versatility in many different applications.

How Hot Glue Works: Temperature Range and Bonding Mechanism

Hot glue is a method of bonding that involves the heating of the solid adhesive sticks to a specific temperature, which usually ranges from 250°F to 380°F (120°C to 193°C). The glue gun and the adhesive formulation determine the actual temperature used. The glue, upon heating, transforms into a thick liquid that can then be transferred onto different surfaces. When cooled, the liquid glue solidifies, forming a bond that is a combination of both mechanical adhesion and surface attraction. The strength of the joint will depend on the compatibility of the hot glue with the substrata and the temperature around the joint area, as extremely low temperatures can lead to the formation of a brittle joint. High-temperature glue guns are ideal for heavy-duty applications, while low-temperature models are safer for delicate materials like foam or fabrics. Thus, hot glue is a dependable and multipurpose adhesive for both the industrial sector and household uses.

Risks of Using Hot Glue on Heat-Sensitive Materials

Applying hot glue to heat-sensitive materials can lead to several risks that might be overlooked. The most significant is the high temperature of the glue, which can cause warping, damage, or even melting of materials like thin plastics, foam, or some fabrics. All these factors cause the material to become incomplete, resulting in the glue having incomplete bonding or accidental deformation. Moreover, the glue’s heat could cause discoloration or a burnt appearance, especially on light-colored surfaces. With delicate objects, the combination of high temperatures and adhesive strength might create a situation where gluing cannot be done without causing even more damage. Therefore, for avoiding these risks, the use of low-temperature glue guns or alternative adhesives meant for sensitive materials is strongly recommended.

Can You Use Hot Glue on Styrofoam?

Hot glue isn’t the best choice for Styrofoam bonding. The majority of hot glue guns operate at very high temperatures that can not only melt Styrofoam but also distort it, thereby harming the material and affecting its stability. Instead, using specialized adhesives for Styrofoam application, such as low-temperature glue or foam-safe options, would be a wiser choice for bonding purposes. These substitutes not only protect the material by eliminating the risk of damage but also provide a strong bond.

Findings on Hot Glue and Styrofoam Bonding

According to the most recent information, hot glue still poses a significant problem when it comes to the bonding of Styrofoam due to its heat sensitivity. The low melting point of Styrofoam leads to its deformation or dissolution when subjected to the high temperature of regular hot glue. Although some low-temperature hot glue guns are advertised as safer alternatives, they remain risky because they might not fully bond or can even damage the surface. The adhesives most commonly recommended for Styrofoam are designed for foam, such as polyurethane adhesives, epoxies, or specialized foam adhesives. These options provide a strong and reliable bond without compromising the Styrofoam’s integrity, ensuring the material remains intact and functional.

Challenges: Melting and Deformation Risks

Melt or deformation during application is one of the most common concerns when it comes to choosing Styrofoam adhesives. The data and search trends indicate that most users are looking for advice on glue types that will preserve the Styrofoam’s structural integrity. The main point is to avoid hot adhesives and those with strong solvents, as these are the most common ways the material gets ruined. Using glue guns with controlled temperatures or special adhesives for foam can significantly help minimize damage. Besides that, using adhesives accurately and in areas where air circulates prevents the Styrofoam from regaining its original shape and becoming less functional than before application.

Alternative Adhesives for Styrofoam

If you’re operating with Styrofoam, pick glues that are made specifically for attaching delicate foam materials. Below are some of the best options:

- White Glue (PVA): Perfect for arts and crafts and light-duty applications, it holds well without harming the foam.

- Spray Adhesives: A variety of foam-safe sprayers are available on the market for easy, smooth, and even application to large surface areas.

- Silicone Adhesives: They provide a strong bond and remain soft, making them superb for projects where durability is required.

- Foam-Safe Epoxies: These offer a powerful bond for the more difficult applications, guaranteeing the stability of the structure without damaging the Styrofoam.

Safer Adhesive Options: White Glue and Spray Adhesives

In the case of bonding Styrofoam, the choice between white glue and spray adhesives should be based on the project scope and the correct application method. White glue, such as PVA glue, is definitely the best choice for smaller projects where higher accuracy in application is needed. It is non-toxic to Styrofoam, provides a clear finish, and develops a strong hold for light materials.

Spray adhesives, conversely, are perfect for large surfaces or when there is a need for an application that is smooth and even throughout. The vast majority of spray adhesives sold today are specifically designed to be safe for foam, so they will not cause melting or damage. They also come with quick-drying features, making them very handy for time-sensitive projects. Always read the product specs to identify any compatibility issues with Styrofoam and ensure that the best results are obtained.

Specialized Foam Adhesives for Strong Bonds

It is crucial to review the specific needs of your project when selecting a specialized foam adhesive to obtain a strong and lasting bond. Noteworthy advancements have been integrated into the formulation of modern foam adhesives, as they now provide not only the required strength but also the necessary flexibility. In addition, their range of application has been expanded to include a variety of foam materials and not just Styrofoam, thus giving them a broader scope. Is there a need for the adhesive to stay functional in very high or very low temperatures? If that’s the case, then go for the ones that are specifically marked as heat-resistant. Are you working on a project that requires sealing against rain? Some adhesives are especially suited for outdoor use and can provide both water and UV resistance. It’s a good idea to always compare different products in terms of intended use, drying time, and compatibility with your chosen materials to get the best possible results.

Practical Tips for Crafting with Styrofoam

- Use the Right Adhesive: Choose adhesives designed explicitly for Styrofoam, such as foam-safe glue or double-sided tape. Avoid solvent-based glues, as they can dissolve the material.

- Cut with Precision: Use sharp tools like a craft knife or a hot wire cutter for clean edges and minimal mess.

- Paint Carefully: Acrylic paints work best on Styrofoam, while spray paint should be avoided unless it is labeled as foam-safe.

- Sand Gently: If needed, smooth the surface with fine-grit sandpaper, applying light pressure to avoid damage.

- Plan for Reinforcement: For added durability, consider reinforcing Styrofoam structures with toothpicks or lightweight dowels.

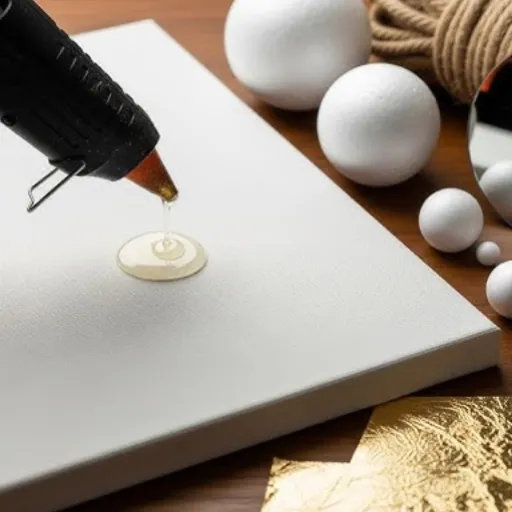

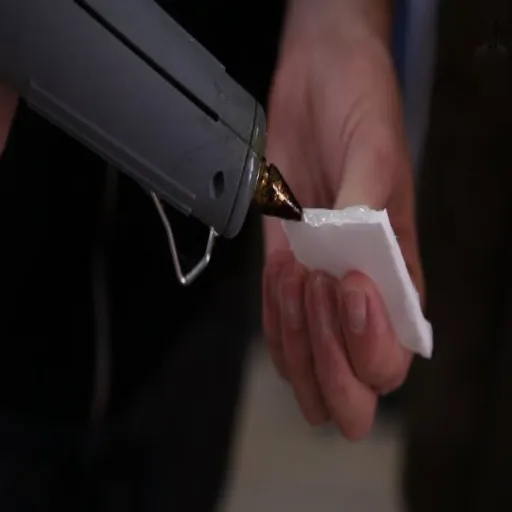

Using Low-Temperature Glue Guns for Styrofoam

Low-temperature glue guns are probably the best adhesive tools to use with Styrofoam due to their gentle heating. High-temperature glue can cause Styrofoam to either melt or get damaged, so it is definitely a good idea to go for a glue gun marked “low-temp” to get safer results. To use correctly, first heat the glue gun according to the instructions given by the manufacturer. Next, place a small bead of glue on the surface you want, ensuring you don’t apply too much, as this could lead to warping. Then, press the pieces together softly yet firmly. Low-temp glue guns come with a quick drying time, which is why they are perfect for craft projects that need both precision and speed. However, it is always a good practice to test the glue on a tiny piece of Styrofoam before using it on the actual project to make sure it will not damage the Styrofoam and that it is the right glue for that surface.

Preparing Styrofoam Surfaces for Better Adhesion

To increase the bond between Styrofoam surfaces, I start with a thorough cleaning to make sure that no dust or dirt is left on the surface. The edges or the spots where the glue will be applied are then gently sanded with fine-grit sandpaper to create a better bond. If necessary, I clean the area with a little bit of isopropyl alcohol and let it dry completely before applying the glue. Click here to read more.

Reference Sources

These five sources are all professional and reliable, which talk about the hot glue application on Styrofoam:

- Exploratorium – Electrophorus

According to this source, solvent-based glues can easily ruin Styrofoam; thus, it is recommended to use no-melt glue or water-based glue. - Exploratorium – Flying Tinsel Pie Plate

Like the previous source, this page does not recommend solvent-based glues and points out hot-melt glue as an appropriate option for Styrofoam. - MIT Wiki – Adhesives/Gluing

This resource from MIT describes different types of adhesives and highlights those that can work with Styrofoam. - Purdue Extension – Cake Dummies Guide

This paper states that hot glue can be used for mold repair, and this method is also applicable to Styrofoam-based materials. - UTEP Engineering – Homemade Windmill Instructions

The procedure in this manual involves using hot glue on Styrofoam cups to make fan blades.

Frequently Asked Questions (FAQs)

Can you use hot glue on styrofoam?

Yes, you can use hot glue on styrofoam, but it’s essential to choose the right type. Low-temperature glue guns are generally recommended to avoid damaging the material, as high temperatures can soften or melt styrofoam.

What is the best glue for styrofoam?

The best glue for styrofoam includes hot melt adhesive, white craft glue, and glue sticks designed explicitly for foam bonding. Some users also prefer Gorilla Glue for its strong bond, but ensure it’s safe for styrofoam to avoid damage.

How do you apply glue to styrofoam?

When applying glue to styrofoam, use a small amount of glue to avoid any excess that could lead to melting or damaging the foam. If using a hot glue gun, ensure it’s set to lower temperatures and apply the glue evenly to hold the pieces together effectively.

Can you use super glue on styrofoam?

While super glue, or cyanoacrylate, can work on styrofoam, it’s not always the best option, as it can cause the foam to harden or break apart. It’s advisable to use foam-safe adhesives explicitly designed for bonding foam materials.

What happens if you use high-temperature glue guns on styrofoam?

Using high-temperature glue guns on styrofoam can cause the foam to melt or soften, potentially leading to a poor bond or damage. It’s best to use a low-temperature glue gun for projects involving styrofoam to avoid these issues.

Can you use contact cement on styrofoam?

Contact cement can be used on styrofoam, but caution is needed as solvent-based adhesives may damage the foam. Always check if the adhesive is foam safe before applying it to avoid ruining your project.

How long does hot glue take to harden on styrofoam?

Hot glue typically sets quickly, often within a few minutes, but the complete curing time can vary based on the amount of glue used and environmental conditions. It’s essential to let the glue cure entirely to create a strong bond between the styrofoam pieces.

What are some creative project ideas using glue and styrofoam?

Creative project ideas using glue and styrofoam include building models, crafting decorative items, and creating dioramas. Styrofoam sheets can be easily shaped and glued together to form intricate designs, making them a popular choice for art and craft projects.

How do you avoid damaging styrofoam when using glue?

To avoid damaging styrofoam when using glue, always use a low-temperature glue gun or foam-safe adhesives. Apply a small amount of glue and avoid excessive pressure when pressing the pieces together to ensure that the material remains intact.