Selecting the most appropriate adhesive for your needs is frequently bewildering. In the landscape of adhesives that are strong and reliable, both Gorilla Glue and Gorilla Super Glue always seem to be contenders. Both products offer great bonding and multi-use capabilities but are made for different needs and uses. How do you choose the appropriate one for you, though? In this guide, we will discuss the differences, strengths, and recommended cases of use for both adhesives so you can make the right choice for your next fix, craft, or construction project.

What is Gorilla Glue?

Gorilla Glue falls under the category of polyurethane cleaving adhesives due to its smooth finishes and customizable strength mid-setting. It withstands expansion and curing processes. Remanence of foam plastic happens during bonding with porous fiber substrates (wood, ceramic, foam, etc). As mentioned earlier, this glue remains unaffected by water. Temperature resistance is also imperative, especially for prolonging the life of the glue outdoors. Gorilla glue will be the most effective adhesive solution for harsh repairs and projects with high durability requirements. Its expanding traits also make it useful for gap filling on uneven workpieces, especially useful for tough bond applications.

Understanding Gorilla Glue and Its Properties

Employed Wonder Banner is mostly polyurethane, one of the best bonding and weather-resistant polymers there is. As moisture activated glue, it undergoes a chemical reaction known as polymerisation after a certain timeframe. During this reaction, polyurethane will impose its will upon everything, whereby it will aggressively expand and solidify while mounding on top of other materials. The glue’s expansive attributes helps it form seamless joints to irregular work pieces, and aids it scant not only in filling gaps but also off opposing surfaces.

Gorilla Glue and other polyurethane adhesives have applications indoors, then taken seven steps away from direct sunlight or dried extreme heat, we would be better off with a water connection, offering lightning security, aka do not rot from the glue’s water, heat, and UV rays, and in those regions. In addition to that, the glue’s curing process means that bond will be created mechanically strong and resistant to tension, shear, and impact forces which is critical for sustaining the bond. This is the reason it is the preferred glue in woodworking, home improvement, and even in industrial manufacturing.

How Does Gorilla Glue Work on Different Materials?

Gorilla Glue manufactures its products to be versatile while still being reliable adhesives for a variety of materials. When applied to wood surfaces, the polyurethane component of Gorilla Glue penetrates the wooden pores and forms both mechanically and chemically bonded glue joints. This bond is common in carpentry and furniture production due to its ability to withstand considerable strain.

For metal surfaces, adhesion is achieved by coating the surface with the glue and curing the moisture-activated way. The smooth and non-porous nature of the surfaces aids in keeping the glue coating evenly distributed and affixed, increasing its use in automotive and metal repair work.

With plastics, the capability of the glue to expand forms of foam as it cures and ensures that irregular surfaces are bridged over gaps and reinforced. It is noteworthy that the PP and PE plastics are incompatible with the glue unless specially treated.

Gorilla Glue utilizes its transparent glue joints with ceramics and glass to enable seamless repairing of household items and fragile components that require securing under environmental stress. These bonds are difficult to break and resist water or temperature shocks, making them suitable for indoor and outdoor usage.

Each material-specific interaction relies on the glue’s unique chemical composition, which guarantees efficient curing and adhesion for a variety of applications. Its performance attributes define the extent of its use range, from specialized industries to universal applications.

What is the Shelf Life of Gorilla Glue?

Typically, placing open Gorilla Glue where it is exposed to air can significantly reduce this time. The trigger of the curing process can be air moisture, which starts to initiate the glue’s expiring process. As such, the glue should be kept in a cool and dry place, with the cap on tightly such that air incursions are barred. At room temperature, 55°F to 75°F (13°C to 24°C), is where it should ideally be kept. Some users further suggest the glue be kept in an air-tight container or the fridge to increase longevity even further. Monitoring the consistency is very important as thickening or hardening can signal the demise of the product’s shelf life. The manufacturer’s instructions and packing should always be checked in order to obtain precise details on storage directions and expiration.

What is Gorilla Super Glue?

Gorilla Super Glue is a strong fast-drying adhesive and is perfect for several materials such as wood, metal, ceramic, and plastic. Its no-run formula makes it ideal for vertical surfaces and allows for an impact resistant bond. Because of its reliability and ease of use, this glue is normally used for repairs and projects.

Exploring Gorilla Super Glue and Its Uses

Both professionals and homeowners can benefit from the diverse use cases of Gorilla Super Glue. It is excelent for fixing broken ceramics, bonding metal pieces, and securing wooden joints. With its fast curing formula, there is no need to clamp for most situations as it sets in roughly 10-45 seconds.

Moreover, with the exception of polyethylene and propylene, Gorilla Super Glue can be used on several types of plastics. Additionally, with its unique rubber enhanced formula, super glue gained even more impact-resistive capabilities, enabling tools, furniture, and mechanical parts to withstand binding stress. Along with tools and furniture, these items are important in everyday operations, and so durability in this glue makes it an excellent choice. Ultimately, thorough cleaning and drying of surfaces maximizes strength.

What Makes Gorilla Super Glue Gel Different?

Through it’s precise application features and advanced formulation, Gorilla Super Glue Gel delivers reliable performance. Unlike ordinary super liquid glues, gel consistency offers better control and drastically reduces dripping. More controlled bonding is now possible even on vertical surfaces. The gel form of glue is ideal for complex repairs or difficult angles. The super glue gel also has enhanced impact resistance due to rubber particles added to the formula that help the glue absorb stress and prevent damage from impact or vibration. There is no clog cap which ensures that the freshness of the glue is preserved; this ensures that there is no excess glue wasted. In addition to these benefits, Super Glue Gel works with wood, ceramics, metal, and some plastics which makes it ideal for many jobs. Together, these remarkable features exceeded the expectations of users, blending convenience and strength.

How Long Does Gorilla Super Glue Take to Dry?

Gorilla Glue has been designed to set quickly, and the average glue bond sets to 10-45 seconds with some variations based on the materials and bond used. For a strong bond, waiting 24 hours before trying to peel it apart is recommended, as that is when it will have fully cured. Its quick-drying feature ensures effective repairs, while the enduring bond that results from full curing enables diverse surfaces to be bonded together. The best fix is accompanied by low humidity and warm temperatures because poor conditions can slow down drying

Gorilla Glue vs Gorilla Super Glue: Key Differences

The remarkable adhesive strength, durability and versatility offered by both, le Gorilla Glue and Gorilla Super Glue, is widely acknowledged. Nonetheless, the two products differ greatly in formulation, application and intended use.

- Formulation: Gorilla Glue utilizes polyurethane, while expanding as it cures for a bond that is notably strong and gap-filling. Gorilla Super Glue, on the other hand, uses a cyanoacrylate formula that bonds quickly without expansion.

- Drying Time: Curing time for Gorilla Glue is longer, requiring it to be clamped and constantly set during the curing stage. Full curing is achieved after 24 hours. Gorilla Super Glue on the other highly known short setting times, fully curing within 1-2 hours.

- Surface Compatibility: Both porous and non-porous surfaces including wood, stone and metal will allow Gorilla glue to perform well. Super Glue is perfect non-porous surfaces based metals and plastics which can be ceramic.

- Water Resistance: Apart from making it useful for outdoor or even underwater application, Gorilla Glue excels in water resistance. Super Glue is water resistant but weaker when used with moisture in the long run.

Knowing these differences helps the user choose the most ideal adhesive for their distinct project or repair requirements.

What Type of Glue is Best for Specific Surfaces?

The functionality of an adhesive rests upon proper selection considering the nature of the material and the environmental conditions it will face. Following are suggestions to achieve optimal adhesion performance:

- Wood: For woodworking projects that involve the repair of wooden pieces, PVA-based wood glue such as Titebond has proved to yield the strongest bonds. For outdoors construction of wooden items, polyurethane type adhesives such as Gorilla Glue can be used, as they are remarkably waterproof and durable.

- Metal: For the bonding of metal surfaces, highly effective epoxy adhesives are considered the best due to their strength and resistance to extreme heat and chemicals. For small precision repair works in metal, Cyanoacrylate based super glue can be employed.

- Glass: Acrylic based glues and UV curing adhesives are recommended for glass bonding due to the fact that they form invisible bonds that show no signs of weakness, even under harsh conditions of temperature.

- Plastic: Various types of plastics may need a certain type of glue. Solvent-based adhesives are ideal for ABS and PVC rigid plastics, since they create strong chemical welds. Softer plastics should be paired with specialized plastic adhesives specifically marked for their use.

- Ceramic: Employ epoxy or super glue with high thermal resistance to repair chips and cracks in circular items, as these require great care such as kitchen wares or tiles.

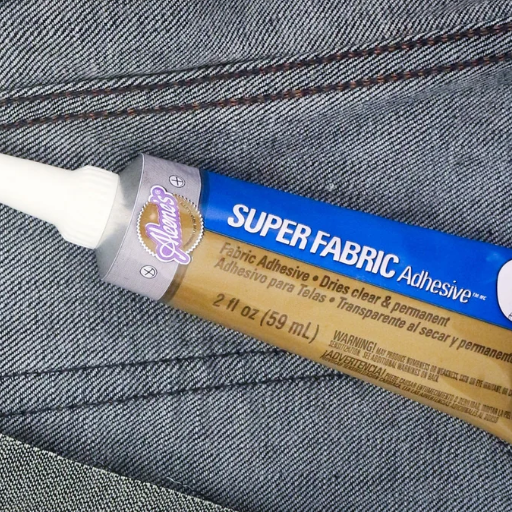

- Fabric: For sewing purposes, adhesives in glue sticks or tubes containing latex and acrylic polymers work well since they form a reliable bond while maintaining elasticity in wet conditions.

The assessment of surface compatability, glue needed bonding strength, environmental conditions, and the glue’s required bond strength all play an equally important role that helps define the ideal selection for any given use. Paying attention to these needs helps prevent repair failure and extend the project life.

How Do the Curing Times Compare Between Gorilla Glue and Super Glue?

Gorilla Glue and Super Glue adhesives have varying curing due to their differing chemical properties and how they bond. Gorilla Glue is a polyurethane glue that takes a full day to cure, but will begin to bond within one to two hours. This bond is highly dependent on humidity and temperature. The curing period for Gorilla Glue helps when trying to adjust loose parts during assembly but also requires a clamp to be applied for the strongest hold.

Super Glue is very fast when it comes to curing and needs only seconds to form a strong initial bond. Super Glue is a cyanoacrylate-based adhesive and needs 10 to 30 minutes to fully cure. This speed of curing bond makes Super Glue ideal for small projects. These small projects usually require precision and immediate hold. Due to these properties of Super Glue, applying it leaves no time for adjusting placement. It is very important to know the curing requirements of the adhesives because this determines which product to choose based on how the job is done. These factors include precision level and need for adjustments during work.

How to Use Gorilla Glue and Gorilla Super Glue Effectively?

- Prepare the Surfaces

With a clean dry surface, ensuring no dust and grease is present, provides for better results. For Gorilla Glue, the surface can be dampened lightly too with a bit of water to activate the glue.

- Apply the Adhesive

- Gorilla Glue: One should adhere one surface and put a thin layer of glue, and do keep in consideration not to put excess amount because Gorilla glue expands while curing.

- Gorilla Super Glue: One should only place a small drop to one side because little does go a long way.

- Join the Pieces

Do focus and gently put the surfaces together as required with adequate pressure. As per the further steps clamp or hold in position:

- Gorilla Glue requires clamping of about one to two hours. After that let it sit undisturbed for a whole day in order to achieve full bonding.

- Gorilla Super Glue on the other hand, does not require clamping which is set to 10-30 seconds. Let it sit for a few hours if you want it to be at max strength.

- Clean Up Excess Glue

Wipe away the remaining parts with a damp cloth and for jawed glue do keep in consideration that it needs to glue in order to come off.

These steps ensure dependable and very reliable bonds and fix any problem you might have during the process of gluing.

Best Practices for Using Gorilla Super Glue Gel

- Store in Optimal Conditions

To keep Gorilla Super Glue Gel working at its best, proper storage is important. The glue should be placed somewhere cool and dry, away from sunlight and humid conditions. Unused glue tubes have a long shelf life if kept in the right conditions. However, once opened, the cap must be sealed tightly so that air doesn’t get in, as this can cause the glue to harden prematurely.

- Surface Preparation is Key

It is vital to thoroughly prepare surfaces to be glued together to ensure the strongest binds. Debris like dust and grease must be removed using a lint free cloth, and for tougher grease, isopropyl alcohol works well. Sanding down very smooth surfaces also help improve adhesion and grit is recommended for gluing smoother metals and plastics.

- Use the Right Amount of Glue

To one of the surfaces to be bonded apply a small, even amount. Overapplication is discouraged as the glue could weaken the bond, excessive amounts will also spread to undesired surfaces. Designed with a controlled application formula, max precision minimizes waste.

- Clamping is Usually Not Required

There aren’t many glues that enhance bonding strength, but Gorilla Super Glue Gel bonds strongly to joints more than 10 mm thick and quickly. With overs and straws of glue to joints above 10 mm thick, the blonds are instant withces. Clips are not required. Simply align the surfaces and apply moderate presure for 10-30 seconds for a firm initial bond.

- Limit Exposure to Water and Heat

Gorilla Super Glue Gel bonds quickly without additional components for most materials, however it will weaken when subject to extended water exposure or extreme hot and cold temperatures. If use is intended for these harsh environments, a protective sealant can be applied over the cured bond to enhance durability and shield against inflicted damage.

Users can achieve optimal performance and enduring bonds by following these precise guide with comprehensive material selections using Gorilla Super Glue Gel.

What are the Applications of Gorilla Glue and Super Glue?

Both Gorilla Glue and Super Glue are multifunctional adhesives useful for the following:

- Household Repairs: Both work effectively in ceramic and wood items, and plastics. Super Glue is best for small item fixes and Gorilla Glue excels in large projects where a strong, foaming bond is needed.

- DIY Projects: For woodworking and construction projects, Gorilla glue excels because it fuses porous and non-porous materials. For craft based projects, Super Glue is most suitable due to more precise nature of the task.

- Automotive and Outdoor Uses: Works great for outdoor repairs because it resists water exposure. Also serves well for parts exposed to moisture. Super Glue is most suitable for minor repairs to the interiors of cars as it dries quickly.

- Office and School Uses: Ideal for repairs on classroom projects because Super Glue adheres quickly and is convenient.

All users should tailor their fades to the materials and specifics of the project in issue to achieve the most desirable results.

Common Uses for Gorilla Glue in Household Repairs

With its numerous applications, Gorilla Glue is a popular choice for different household repairs. It easily bonds wood, metal, and ceramic due to its marine-grade waterproof and temperature-resistant properties. It is permanently strong which makes it easy for homeowners to fix their broken furniture. Chairs and table legs can now be glued instead of replaced. It’s also great at sealing water leaks from cracks in tiles or countertops. For restoration projects, DIY enthusiasts stick different parts of decorative items with glue. For the best results, users are advised to dampen the surface being glued along with the waiting period to improve cycle time before returning to use the area.

When to Choose Gorilla Super Glue for Quick Fixes?

Gorilla Super Glue is great for repairs that need to be done quickly and accurately. Unlike most glues which take time to gain bond strength or even require some form of clamping, this glue achieves a strong bond in 10-45 seconds, making it highly efficient for small fixes. It also is able to fully bind with materials such as ceramics, plastics, metal and wood which makes it highly useful in repairs. The precision-tip applicator ensures control in the amount of glue dispensed to enhance the Neatness of repairs enhancing control in the neatness of repairs. Cleaning the surfaces improves adhesion and is best done n dry surfaces free of moisture which helps you avoid unnecessary steps in getting surface prepped. For touching household items like broken ornaments or dealing with swift emergencies, this product is particularly useful for repairing appliances, ensuring reliable domestic use. Its impact resistant glue formulation also makes it ideal for light industry work and domestic uses.

Reference Sources

-

“The Wonders of Glue”: This article contrasts Gorilla Glue and Super Glue, noting that Gorilla Glue doesn’t dry instantly like Super Glue, allowing for more working time. It also highlights Gorilla Glue’s unique expanding properties.

-

“Fully biobased adhesive from chitosan and tannic acid with high water resistance”: This study compares Gorilla Glue and Loctite Super Glue in terms of water resistance and adhesive strength, providing insights into their performance in specific conditions.

-

“Improved Usability of a Novel Biomimetic Surgical Adhesive for Craniomaxillofacial Fractures”: This research evaluates the adhesive strength of Gorilla Glue and Loctite in surgical applications, offering a perspective on their use in medical settings.

Frequently Asked Questions (FAQs)

Q: What is the difference between Gorilla Glue and Gorilla Super Glue?

A: Gorilla Glue is a polyurethane adhesive that expands as it cures, making it suitable for larger projects and porous surfaces. Gorilla Super Glue, on the other hand, is a cyanoacrylate adhesive that bonds quickly and is ideal for small repairs.

Q: How do I remove Gorilla Super Glue?

A: To remove gorilla super glue, you can use acetone or nail polish remover. Apply it to the affected area, let it sit for a few minutes, and then gently scrape or wipe away the glue.

Q: What is the approximate shelf life of Gorilla Glue?

A: The approximate shelf life of Gorilla Glue is around 12 months when stored in a cool, dry place. However, it’s best to check the manufacturer’s instructions for specific guidance.

Q: What is the shelf life of Gorilla Super Glue?

A: The shelf life of Gorilla Super Glue is typically around 6-12 months when kept in a cool, dry environment. Always check the label for the exact expiry date.

Q: How long does Gorilla Super Glue take to cure?

A: Gorilla Super Glue sets in about 10-30 seconds and reaches full strength in 24 hours. For optimal results, ensure the surfaces are clean and dry before application.

Q: Is Gorilla Glue clear when applied?

A: Yes, Gorilla Glue Clear is available in a formula that dries transparent, making it suitable for projects where aesthetics are important.

Q: Does Gorilla Super Glue require moisture to activate?

A: No, unlike Gorilla Glue, which requires moisture to activate, Gorilla Super Glue does not require any additional moisture and bonds quickly upon contact with surfaces.

Q: Can I use Gorilla Super Glue on polypropylene surfaces?

A: Gorilla Super Glue is not recommended for use on polypropylene or other similar plastics, as it may not provide a strong bond. Instead, use a specialized adhesive designed for these materials.