As soon as PLA is in use, one of the most recurring problems that most hobbyists, 3D printing enthusiasts, and even professionals face is permanently attaching individual pieces without damaging the projects in any way. Be it assembling different parts intricately, fixing a broken model, or even multicolored designs, picking out an ideal PLA adhesive is critical to achieving lasting results. This article will discuss best glues for PLA, how to use them, and tips to help the project remain seamless and durable. This way, the reader can walk away with the confidence that whatever adhesive solution they choose for their 3D printed models, it will be the right choice.

What is the Best Way to Glue PLA?

Cyanoacrylate (CA) glue or super glue has a unique property that makes it the best way to glue PLA, it is easy. Aside from being easy, CA glue is powerful, fast curing, and becomes easy to apply which makes it very useful for PLA parts. For larger structural pieces, added strength and durability can be provided by two-part epoxy. For best results, make sure to clean and dry the surfaces that need stickiness before any form of bonding is applied. Roughing up the interface a little by sanding can also improve the bond as a result of an increased area due to surface porosity. Follow any given instructions and you will not regret it.

Why Choose the Right Glue for PLA?

Selecting the right adhesive for PLA is pivotal when it comes to the strength of the seals as well as the 3D part’s practicality and durability. PLA, thermoplastics as they are, have their origins in renewable resources such as cornstarch and sugarcane. Their distinctive features include subdued strength, low resistance to heat, and a fairly smooth surface. Because these characteristics pose challenges to adhesion with generic glues, an adhesive specifically design for PLA or one with proven effectiveness is a must. An example of this are cyanoacrylate based glues which, because of their quickly curing time and precise application, work best for small and intricately detailed components. On the other hand, two-part epoxies work best with structural applications or big part repairs because of their superior durability and gap filling capabilities. Ensuring that the adhesive used matches the intended purpose will not only maximize the lifespan of the 3D-printed object, but also avert failures when subjected to stress or load-bearing scenarios.

What Are the Most Common Adhesives for PLA?

Adhesive options for PLA range from epoxy chemicals to cyanoacrylate glues; all differ with mechanical and PLA’s chemical surface properties. Super glue, also known as cyanoacrylate glue, is one of the best options to bond PLA as it provides remarkable initial adhesion and is very easy to use. It is also not very time consuming as it cures quickly; however, it works best for small precise joints.

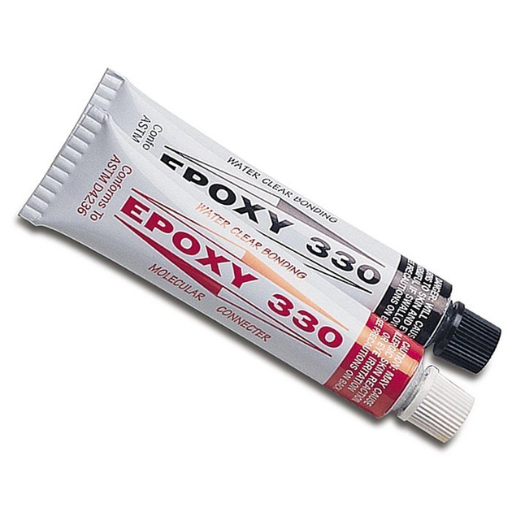

For enhanced bond durability like in structurally demanding applications or where surface geometry is uneven, two-part epoxy adhesives are preferable. They provide gap filling and mechanical stress resistance while maintaining low structure integrity. PVA glue would also work but its effectiveness is weaker than the latter two. Though they are environmentally friendlier, PVA glue’s less durability makes the application only feasible in non-argumentative structures.

For people who work on big projects, hot glue is one of the other options available. Although not as strong as cyanoacrylate or epoxy, hot glue does offer a reasonable bond strength. It is also more forgiving in that it allows for repositioning during assembly and becomes solid only after some time. The best choice of adhesive is determined by how much stress is expected of the joint, the joint configuration, and the conditions in which the final product will be used. The simpler steps, like cleaning the surface and light abrasion, greatly improve the performance of the adhesive.

How to Prepare PLA Surfaces for Gluing?

Achieving the optimal bond when gluing PLA requires careful preparation of the adhesive surface to increase the bond strength. The first step is to clean the PLA surface using an IPA 70% solution to remove all dirt and grease as it is highly effective and does not leave any residue. After cleaning, the bonding area also needs to be slightly sanded using 200-400 grit sandpaper. This makes the rougher, enhances the bonding mechanically, and the PLA. Lastly, make sure to clear all the dust from sanding as it can result in poor adhesion with the help of compressed air. Other activation treatment like flame treatment or applying plastic primer does improve the bonds but this alters the underlying chemistry and has a directly proportional effect on how well certain glues stick. Best results try to achieve solid prep work before surface and removing all contamination.

How to Use Glue for PLA 3D Printed Parts?

- Prepare the Surfaces

In order for the adhesive to be effective, the components must be clean from any dust, hand grease marks or any foreign matter. A better bond can be achieved by sanding the bonding surfaces with fine sandpaper, then cleaning everything using compressed air or a lint free cloth.

- Select the Right Glue

Adhere to PLA-compatible glues, like cyanoacrylate (super glue), epoxy, or other such specialized plastisizing adhesives, as gealyz. tint.tw states. Most users find Cyanoacrylate the most useful for a wide variety of applications.

- Apply the Glue Evenly

A thin, even coating of glue should be applied to one of the surfaces. As with all instructions contained herein, do not stray too far from the guidelines; in this case, overly applying glue.

- Join the Parts

Use parts together with adhesives in a careful alignment, pressing the parts firmly. While the glue dries, if clamps are available, use them to ensure the parts remain in place until sufficient strength is achieved affording a tight bond.

- Allow Adequate Curing Time

As noted by various manufacturers, avoid all restraining and skeletal forces until the desired glue bond strengthens past the full curing stage for enduring bonds providing maximum strength.

To get the required mechanical and robust bond you seek for the PLA 3D printed parts, follow these steps adjust as necessary.

What Type of Glue Works Best with PLA?

Due to the thermoplastic nature of PLA, it can be effectively bonded by several types of adhesives. Super glue (cyanoacrylate glue) is well-liked for use on smaller parts as it provides a near instantaneous bond. For larger or more complicated assemblies, two-part epoxy resin works best as it is extremely strong and embraces gaps well. Specialized plastic adhesives for thermoplastics also include those which bond PLA plastically or chemically which makes the bond stronger than most other methods.

A dichloromethane solvent PSA will give a stronger bond mechanically by partially dissolving the PLA surface, but these solvents are extremely poisonous and must be carefully handled. When choosing an adhesive, its specific intent and environmental conditions like temperature, humidity, and stress level need thorough consideration as well. Sanding or cleaning with isopropyl alcohol greatly increases adhesion along with the right surfaces.

How to Achieve a Strong Bond with PLA Glue?

Accomplishing a robust bond using PLA glue involves thoughtful material treatment, selection of proper adhesive, and application technique control. First and foremost, surface preparation is the most important of all steps. Sanding the bonding surfaces with fine-grit sandpaper helps as it increases the surface area for the glue to adhere. Make sure that the surface is cleaned properly as the next step which involves washing with isopropyl alcohol to get rid of any floating dust, oil, residues, or bond weakening materials.

When it comes to selecting the adhesive, cyanoacrylate-based glues offer speed and strong bonds making them the most PLA popular choice as they cure rapidly. Epoxy adhesives are a better choice for flexible, durable, and environmentally resistant applications because of some of their unparalleled qualities. Furthermore, the careful application of clamping force provided with exact alignment during the curing stage aids in achieving a well distributed bond. Balance the environment with adhesive attributes in mind and strategic approaches can be created while ensuring the material structure stays intact.

Can You Use Super Glue on PLA?

Indeed, super glue, or cyanoacrylate adhesives, can be used on PLA as they are effective for binding center PLA pieces due to quick curing times. All that needs to be done is make sure that the surfaces are clean as well as aligned straight. Having said this, while super glue does work for most PLA projects, those more complicated may involve needing flexible bonds. In this case, masonry super glue is the best option. If long term stress is an issue, industrial strength epoxy adhesives are the best alternative.

Benefits of Using Super Glue for PLA Parts

The use of super glue for bonding PLA parts has numerous benefits that make this method reliable for different applications. For instance, super glue can be set and fully cured in a short amount of time, which is beneficial for quick assembly projects and workflows. Static and low-stress assemblies benefit from super glue since it creates a strong, durable bond, ensuring that the pieces will not fail over time.

Super glue is fast becoming popular because of its availability, accessibility and ease of use. Now, professionals and beginners alike can solve their bonding problems with ease. However, it does not require mixing and complex preparation, making it a go to for easy tasks, and bonds effectively at room temperature. In addition to the bond with PLA super glue is known to be effective with many other materials including wood, metals, and ceramics.

Super glue is easy to apply, but its chemical composition is more complicated. The main ingredient, cyanoacrylate adhesives, contains chemicals that allow it to seep into the PLA ‘s surface on a molecular level. Keep in mind that while super glue is remarkably effective for static applications, it does not provide optimal performance when components require high flexibility, impact resistance, or thermal endure. Alternatives such as epoxy adhesives are better suited for these scenarios.

How to Properly Apply Super Glue on PLA Surfaces?

- Prepare the Surface

Make sure both surfaces of the PLA are clean, dry and free from dust, oil, or any other particles. The adherence strength of the bond will be hampered greatly by contaminants, therefore the bonding surfaces must be cleaned using isopropyl alcohol which has a 90% concentration at a minimum.

- Lightly Sand the PLA

To achieve the best bonding results, roughening the bond surfaces with light sanding using fine sandpaper (200-400 grit) will micrometrically increase the area available for the adhesive to grab on to.

- Apply the Adhesive Sparingly

Precision and care during the application are crucial, as super glue’s (cyanoacrylate adhesive) rapid bonding time only enables limited maneuvering time. All excess glue should be removed prior to application as it slows down curing time and creates an unwanted mess.

- Join the Surfaces Immediately

Diligently align the two surfaces before pressing them together since super glue adheres instantly. Apply moderate pressure for a few seconds to create a lasting bond.

- Allow Sufficient Curing Time

Super glue works efficiently, but leaving the item undisturbed for 24 hours allows the greatest strength. Do not let the glued surface face any stress until the bonding firmly settles.

- Enhance Results with Accelerator (Optional)

Using a cyanoacrylate accelerator will shorten the curing time. This chemical will make the adhesive set immediately, which is useful for cases when time is limited.

These steps will maximize the bonding efficiency of super glue on PLA, providing optimum joint strength for multiple applications.

What is the Difference Between Epoxy and Super Glue for PLA?

When discussing PLA, epoxy and super glues have striking distinctions in the manner they are applied and their respective strengths. Epoxy binds to the material with extreme durability, surpassing the performance of super glue making work with higher stress more efficient. Though slower, the chemical reaction of an epoxy resin and its hardening agent provide remarkable strength once bonded. Super glue’s quickness, however, provides lackluster reliance for overpowering forces or climate stress. Super glued structures will collateral damage prolapse during rapid environmental transition. Long lasting and unyielding forces require epoxy, while lower haunt the lower surface area offer super glue’s support.

When to Use Epoxy Adhesive for PLA?

When parts made from PLA must resist strong bending forces or high temperatures, epoxy adhesive works best. To ensure the bond’s durability, mechanicl stresses, heat or other environmental factors should not alter the bond. As a thermoplastic polymer, PLA gradually softens when subjected to elevated temperatures and can deform or melt under pressure. Joining the components using epoxy where PLA parts will contain long-term external elements is ideal because epoxy has high tensile strength, is not thermally degraded, and protects the PLA parts from structural damage. Furthermore, epoxy adhesives will smoothen and fill gaps over the surfaces, thus, aiding uneven PLA parts. These qualities make epoxy advantageous in the fabrication of 3D-printed structures or in the repair of components where accurate interfitting of parts and structural strength is critical.

Application Techniques for Epoxy on PLA

- Surface Preparation

Adhesive bonding of epoxy on the surface of PLA requires optimal adhesion and exceptional epoxy bond strength. As for adhesion and durability, proper surface preparation is a cornerstone. So, take some time to scrub the surface of the PLA part to get rid of oils, dust. Any grease, dust, or other foreign matter should be removed for efficient annealing. IPA alleviates the cleaning process because it dissolves impurities efficiently, especially those that are oil-based. Boosting adhesion can be achieved through lightly abrading the sanded PLA surface, aka mechanical bond, where 220-400 grit paper creates a desirable epoxy bond. Finally, wash the surface with IPA to remove all the sanding particles. In this case, epoxy is very well bound to the PLA.

- Mixing and Application

Epoxy resin is usually made up of two parts—the resin and the hardener—which have to be mixed in a very particular ratio set out by the manufacturer. Balance and proportionality are crucial, as any blend would truly hinder the combination’s strength and its curing process. While applying epoxy on PLA, a small brush or a spatula can be utilized to apply an even layer while avoiding excess residue and not being too thick by leaving a bare surface underneath. During curing, parts that require precise orientation can be held in position with clamps or jigs.

- Curing Process and Environmental Considerations

Curing, being time sensitive, is one of the first elements to determine how the epoxy will work on PLA. The majority of epoxy resins need to rest at room temperature during curing, with some exceptions for certain high-performance ones that need them hotter to improve outcome. The surrounding factors like temperature and wind velocity should also be accounted for, as both have an effect on the bond’s lifespan and strength. In order to keep the assembled components safe from air pollution and dust, put them in a well-ventilated while covered box.

- Final Refinement

After the epoxy has fully cured, it can be sanded and painted for a clean surface finish. Aesthetic-sensitive projects can benefit from smooth finish achieved through wet sanding with finer grit sponges. Progressively finer grits can also be used to boost strength in weak areas or in areas requiring additional reinforcement.

How to Glue Large PLA Pieces Together?

To ensure a strong bond on large PLA pieces, it is critical to clean the surfaces to be glued. The edges should be cleaned with a rough surface to increase adherence. Smaller PLA pieces should be super glued while larger ones should be bonded with epoxy glue. One side of the joint should be coated with glue, pressed, and held still until the glue hardens. As a nature strengthen, a waterproof glue bead can also be applied to protect the joint. A full bond cure time recommended by the super glue instruction should be met.

Best Practices for Gluing Large PLA Parts

For optimal bonding when parts are glued together, the surfaces should be cleaned first. Start with checking that both sides are dry and have no leftover materials. Sanding the GLUed areas with fine sandpaper is the best option for achieving strong adhesion; the dust must be removed with isopropyl alcohol afterward to ensure the rough surface is clean.

The right adhesive for large PLA parts is critical. Structural bonding two-part epoxies are very strong and effective for PLA parts because they both bond the structure at the surface and fill gaps, making them ideal for rough surfaces. When using epoxy, the resin and hardener must be mixed in the proportions given by the manufacturer to guarantee optimal curing strength. Another option is a proprietary PLA adhesive based on urethane plastics that can bond a variety of materials while still being compatible with them.

To improve alignment of joints as well as decrease warping during bonds curing, it is advisable to apply clamps or fixtures which hold parts during curing. Uniform distribution of pressure aids in joint stress reduction and improves with lower joints’ mechanical strain. Also, for some chemicals, the PLA bond strength is increased when the joint is welded at the ambient temperature or some low temperature above the room temperature.

Finally, seams can be treated with sanding or painting making the part more visually appealing while concealing the mechanical components, thus enhancing structural rigidity. The strength, reliability, and assurance of longevity required of joined components are best achieved through the proper selection of adhesives along with proactive surface treatment procedures.

Reference Sources

-

Investigation of Adhesive Bonding Strength of Wood-Added PLA Materials (2023)1: Loctite 9466 provided the highest shear strength for bonding wood-added PLA and Scotch pine materials. Additives improved bonding strength, highlighting the potential of PLA composites in industrial applications.

-

Plywood Wood-Based Composites Using Crystalline/Amorphous PLA Polymer Adhesives (2020)2: Amorphous PLA adhesives outperformed crystalline PLA in shear strength and water resistance due to better substrate penetration and wetting properties. However, neither formulation met the requirements for exterior-grade plywood.

-

Improvement of Mechanical Properties of PLA Adhesion Joints with Bio-Based Adhesives Using Air Atmospheric Plasma Treatment (2015)3: Plasma treatment significantly increased shear strength (from 50 N/cm² to 168.7 N/cm²) by introducing polar groups and micro-etching the surface. This method proved to be both environmentally friendly and effective for improving PLA adhesion.

Frequently Asked Questions (FAQs)

Q: What is the best glue for PLA?

A: The best glue for PLA includes superglue, specifically Loctite Super Glue, and acrylic glue. These adhesives provide strong bonds for PLA parts.

Q: How can I effectively glue PLA together?

A: To effectively glue PLA together, clean the surfaces, apply a compatible adhesive like superglue or acrylic glue, and clamp the parts if necessary. Allow the glue to set according to the manufacturer’s instructions.

Q: Can I use superglue to bond PLA parts together?

A: Yes, you can use superglue to bond PLA parts together. Superglue, particularly Loctite Ultra Gel, is ideal for creating strong glue joints on PLA materials.

Q: Is Gorilla Glue suitable for gluing PLA together?

A: While Gorilla Glue can bond PLA together, it may not be the best choice as it expands during curing. It’s recommended to use superglue or acrylic glue for a stronger and more precise bond.

Q: What is Weld-On, and is it good for PLA?

A: Weld-On is a type of solvent cement used for bonding plastics. Weld-On 16 is generally not recommended for PLA, but some users have reported success with specific formulations. Always ensure compatibility with PLA before use.

Q: How do I prepare PLA surfaces for gluing?

A: To prepare PLA surfaces for gluing, clean them with soapy water and some acetone to remove any oils or debris. This ensures a better bond for the glue.

Q: What are the advantages of using acrylic glue for PLA?

A: Acrylic glue offers a strong bond for PLA and dries clear. It is especially useful for larger parts and can fill gaps, making it an excellent choice for gluing PLA parts together.

Q: Should I use an activator with superglue for PLA?

A: Using an activator with superglue can speed up the curing process, allowing the glue to set quickly. This is particularly useful for larger PLA parts that need a strong bond in a shorter time.