Concrete adhesives are referred to as ‘Concrete glue’ and serve as an innovative adhesive solution friction and mounting heavy materials, or doing repairs on aging architectural concrete. This guide provides the ultimate information needed about concrete glue covering its properties, types and surface applications. It is our goal to provide you information with which you would be able to professionally achieve the desired results such as how it works, what issues need to be kept in mind, and what factors need consideration to execute any project successfully. Concrete Glue has earning potential due to the wide range of applications it is used for. It is the scope and scale of the project that the use of this bonding agent is needed. Make sure to stick around as we explain everything needed to know about frictions and the secret to successfully using glide adhesives is.

What is Concrete Glue?

Bonding reinforced concrete horizontally and vertically, as well as uniting it with other materials, is made possible through concrete glue, colloquially referred to as concrete adhesive. Its mode of action consists of penetrating the concrete body surface pores and later creating a robust chemical bond, thus enhancing the adhesion while preventing cracks and assuring durability. Polymers like acrylic or epoxy resins are used as bases for concrete glue. It is applied directly to clean, dry surfaces for the desired outcome and can be utilized in a range of work, from simple repairs, to massive construction projects. Like all other adhesives, concrete glue’s effectiveness is dependent on proper surface preparation, along with ratio of dry and wet concrete, as well as the type of the adhesive selected for the specific case.

Understanding the Composition of Concrete Adhesive

Concrete adhesives are composed of a blend of polymers which form the basis of its mechanical properties alongside concrete. Some products based on these formulas utilize acrylic, epoxy or polyurethane resins which have specific construction benefits. Acrylic based adhesives are known to dry very quickly so they can be used on vertical and horizontal items. In contrast, epoxy resins are extremely strong but lackactic endurance and chemical resistance deem them better suited for heavy-duty construction tasks or environments with exposure to harsh chemicals. Futhermore, polyurethane adhesives are extremely useful for their unparalleled construction on flexible substrates, temperature fluctuations or extreme conditions.

Improvements to moisture, freeze-thaw cycles, and UV exposure resistance have become the focal point of recent work done in additive technology. For example, specific formulations with nano-silica par- ticles have shown to increase adhesion through enhanced molecular interlocking on a micro- scopic scale. In addition, the concern for the environment has also triggered the production of low VOC (volatile organic compound) adhesives that meets environmental compliance laws for VOC and improves working conditions. This concrete adhesive composition allows meeting the stringent requirements of modern construction while providing sustainable, enduring performance.

Different Types of Concrete Glue Available

Concrete adhesives are placed in various classes depending on their chemical structure and particular use. The main divisions include epoxy-based adhesives, polyurethane adhesives and latex based adhesives.

- Epoxy-Based Adhesives

Epoxy based adhesives are well-known by the industries for their exceptional bonding strength. They are used in construction for structural repairs, anchoring, and also in the repair of masonry. bonds are durable with concrete, wood, metal and other mast supporting elements and structures. Other domains impose no restriction because they are bonded firmly to metals, chemicals, water or extreme temperatures.

- Polyurethane Adhesives

Polyurethane adhesives are relatively new but versatile in usage. They exhibit remarkable flexibility, making them ideal for hot applied Welded membrane waterproofing materials exposed to sunlight and UV. Their unique qualities permit significant movement within concrete joints while maintaining structural integrity and heat and pressure resistant.

- Latex-Based Adhesives

These latex-based adhesives for water resistance are undemanding in terms of the application process. Their environmentally friendly nature is due to the low VOC content which can be used with a number of substrates such as drywall, masonry and the outer layer of concrete. These adhesives enable quick setting times which adds to the efficiency where the application does not require structural support.

Choosing the appropriate adhesive for a project while maintaining structural integrity and modern construction standards requires an understanding of each adhesive’s distinct attributes.

What Are the Best Applications for Concrete Adhesive?

Concrete adhesives are ideal for surfaces that need solid bonds with other materials which include concrete, stone, brick, and tiles. Other applications include patching and securing concrete and masonry, bonding and fixing components of pre-cast concrete, and fitting up a various of ornamental pieces. Such adhesiveness is very useful in a merge of construction and repair works that require quick adhesive application and setting time. When applied appropriately, the adhesive provide efficient longevity for environmental and structural stress, indoors and outdoors.

Using Concrete Glue for Repair Projects

Concrete glue possesses extraordinary characteristics while fixing broken parts of constructions. The strength of bond attainable with the use of the adhesive is extraordinary and can endure tensile and compressive forces which would exceed structural elements brutal strength, thus allowing it to be used in more advanced applications. Modern formulations often use additional flexible polymers to make the glue effective with expansion and contraction due to changes in temperature. In addition, these glues are also strongly resistant to water, chemicals, and ultra violet light, making it ideal for alternating surroundings.

Technological advancements have made it easier to apply glue on concrete. Now, there are many products in the market that have quick curing times which reduces the negative impacts on downtime during repair work. Because of certain improvements in epoxies, they now provide a bond strength of over 2000 psi making them useful in high load situations. Also, the ability to change temperature has some value with others adhesives, allowing them to function well in extreme heat and freezing condition without losing bond strength. These attributes make concrete glue stand out as a proactive and reliable repair solution.

Exterior Applications: When to Use Concrete Glue Outdoors

Concrete glue is a very reliable tool for outdoor settings where structural strength and weatherproofing is important. Reinforced concrete grouting adhesives bond quickly within fifteen to thirty minutes. For instance, outdoor polyurethane adhesives withstand extreme cold and heat, effective between -40°F to 176°F, a full seal can be achieved in warm or cold climates.

Common outdoor applications include repairing retaining walls, loosening paver stones, restoring cracks in patios, and more. In addition to these, the incorporation of freeze-thaw resistance in advanced formulations minimizes bond failure risks during cold weather. Heavy-duty glues without shrinkage, for exterior steps or driveways, require at least 3,000 psi for reliable compression strength. Optimum propellants and grades of adhesive also ensure dependability in repairs.

Versatile Uses: From DIY to Professional Construction

Concrete adhesives are one of the most useful materials for everything from improving the home to professional construction. Do-it-yourself (DIY) enthusiasts can apply these adhesives for repairing cracks, loose tiles, and even complex decorating tasks like gluing brick veneers. Builders use specialized tools in complex tasks, for example, heavy rebar anchoring along with fastening precast concrete elements. Builders also attach new components of structures with old ones seamlessly using these adhesives.

Research indicates mounting strengths over 4,000 psi with some modern chemical formulations, professionally labeled as mortars. In addition, some other products also managed to include moisture tolerance and longer open times, thus improving their capability for building work under extreme weather. Economically elongated deadlines not only improve project cost effectiveness but greatly reduce the overall dwelling time, enhancing productivity across residential, commercial, and industrial construction sectors.

How to Apply Concrete Glue Correctly?

- Prepare the Surface

To start, ensure the area is scrubbed clean of any dust, debris, grease, and contaminants. Old grease or maintenance oils may be removed with solvent cleaners, while hardened residues call for a wire brush. Even surfaces may require sanding or grinding, and loose particles, cracks, and unevenness should be checked and cleared as they will weaken the bond.

- Choose the Correct Adhesive

Pick the right concrete adhesive that matches your application needs and environment. Load-bearing requirements, weather, and chemical exposure resistance must be taken into account, as well as curing time. For example, epoxy adhesives have immense tensile strength and durability, while polyurethanes are more flexible and resilient under stress.

- Mix the Adhesive (If Required)

Multi-component adhesives will need both parts; resin and hardener mixed in set amounts. Make certain that mixing is done thoroughly to avoid cubes of unmixed material that could complicate curing. Follow the container’s stir time for best results when mixing.

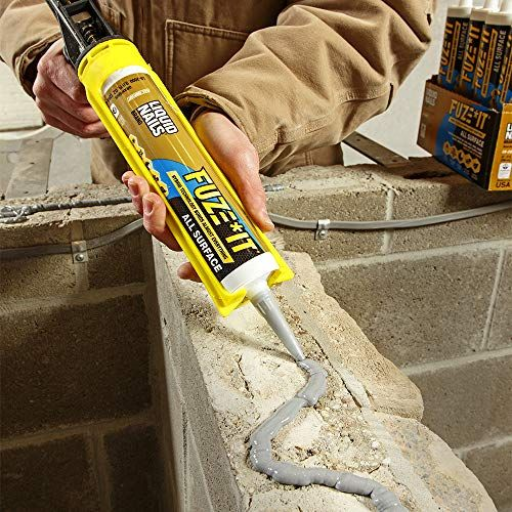

- Apply the Adhesive

Using a brush, or a trowel, or an applicator gun, uniformly spread the adhesive on the surface to the set thickness. Also, take note of the coverage rates provided by the manufacturer to ensure proper bonding and strength. If needed, the adhesive can be applied to both joining surfaces per requirements for contact adhesives.

- Join the Materials

While the adhesive is still usable, press the surfaces together—this is the timeframe where glue is sticky and works for joining. Support uniform application of pressure to the bond area to prevent gaps and enhance contact during polishing. If needed, use clamps or pressure to hold the adhesive joints in line during curing.

- Allow Proper Curing Time

Do not allow disturbance for adhered parts until the curing duration specified in the technical data sheet expires. The surrounding region also has an impact on curing, for example, temperature or the presence of water. Always keep an eye on these parameters to make sure their values are suitable. Avoid carrying out these works in freezing conditions, as these conditions can hinder or delay the curing process.

- Inspect Post-Curing

After the bond has been tested and passed the preliminary criteria, check for uniformity and adhesion strength. To verify that the bond is actually secure, conduct some light-use scenario burden tests. For critical applications where bond failure is highly undesired, rely on non-destructive test techniques. An example is checking with ultrasound to confirm non-destructive reliability testing.

Following these steps will enabled achieving a reliable lasting bond, with the latest adhesive developments and material sciences supporting it for concrete works.

Preparing the Surface for Adhesive Application

Surface prep sets the stage for a good and lasting adhesive bond. Start by cleaning every surface you plan to glue together by removing any form of contamination like dirt, grease, oil, or rust. Contamination weakens adhesion because they act as a protective layer between the adhesive and its substrate. Depending on the surface, cleaning can be done by either, wiping the surface with isopropyl alcohol, using soap and water, or using actively scrubbing surfaces for metals and heavily oxidized surfaces.

After cleaning, check the surface for bumps and rough edges. If the surface is smooth, more work must be done. To increase mechanical bonds, the surface must be roughened using sand paper so it has a greater surface area. It is advisable to avoid over doing it as the material’s strength may be reduced due to excessive abrasion.

Follow the manufacturers instructions regarding surface treatment which sometimes includes priming. Primers are important due to their ability to adjust surface energy and wetting for better adhesion which are crucial qualities for the adhesive to work. Ensuring the surface is dry before the sticky part is applied is just as important as the drying period, any moisture present, accumulative delays and dampen bond strength.

What Products Are Used for Heavy Duty Concrete Projects?

For demanding concrete projects, epoxy-based and polyurethane adhesives as well as cementitious repair mortars are some of the products used. Epoxy based adhesives are suitable for bonding and structural repairs because of their chemical resistance and strength. The strength and resistance of polyurethane adhesives make them some of the most preferred for harsh environmental conditions. Cementitious repair mortars offers remarkable bond strength and compatibility with old concrete and is used for patching or resurfacing concrete. The selection of these products is highly dependent on the project at hand and the surrounding conditions.

Top Heavy Duty Construction Adhesives on the Market

- Loctite PL Premium Polyurethane Construction Adhesive

This adhesive product has received accolades for its exceptional bonding strength with almost any materil such as stone, wood, metal or even concrete. It is expertly formulated for long durability, high moisture resistance and to withstand extreme temperatures which enables use both outdoors and indoors.

- Gorilla Heavy Duty Construction Adhesive

This type of adhesive has a faster application process as it has a fast-grab formula which leads to reduced project timelines and decreased need for clamps. This product is also versatile as it can bind glass, foamboard, and ceramics with a guaranteed 100% waterproof seal which ensures reliability in demanding environments.

- 3M Scotch-Weld Epoxy Adhesive DP100 Plus

A two-part epoxy system makes this adhesive specialized for high-performance bonding. It provides excellent shear and peel strength while remaining flexible enough for vibration and impact applications. Bonds readily to metals, composites, and plastics.

- DAP Dynagrip Heavy Duty Adhesive

This product is specially designed for heavy domestic purposes and provides lasting adhesion to construction materials like brick, drywall, and plywood. The solvent free composition of the adhesive also greatly reduces environmental impact while maintaining strong performance under challenging conditions.

Every one of these products is crafted to work under unique circumstances which makes them great for construction and DIY projects. As professionals know, selecting the right adhesive requires careful consideration of the substrate material, environmental conditions, and unique requirements of the task to achieve desired outcomes.

Comparing Epoxy vs. Traditional Concrete Glue

Traditional concrete glue and epoxy serve different functions and each has different properties Epoxy is a type of adhesive that is classified as a polymer-based compound. It is well known that epoxy is one of the most durable materials, offers exceptional strength, and is resistant to chemicals. It bonds easily with concrete, metal, and even wood; therefore, they can be used in exposed environments and for structural repairs. Because of its exceptional moisture and chemical resistance along with its temperature toleration, epoxy can be expected to retain its integrity over time.

On the contrary, standard concrete glue which is popularly known as PVA or latex adhesives have a greater use in non-structural works. They are easy to work with since they form bonds between concrete and even other porous materials. However, concrete glue does not have the tensile strength epoxy possesses. As such, standard concrete glue can be relied upon for decorative works, light repairs, and small scale DIY projects, but does not tolerate high stress, moisture, or extreme temperature.

In selecting the two adhesives, it is vital to think about the load bearing capacity, environmental conditions, and also the level of difficulty with respect to the project. Heavy-duty applications requiring long-term adhesion tend to prefer epoxy while simplistic tasks that are not as demanding use traditional concrete glue because of its cost effectiveness and practicality.

How to Choose the Right Concrete Glue for Your Project?

- Assess the Project’s Scope and Requirements

Evaluate the requirements for your particular project first. If the job is epoxy flooring or any such work which is mission critical and needs important load bearing and abrasion resistance capabilities, epoxy is best to use. For smaller and less critical tasks, ordinary concrete adhesive may be adequate.

- Evaluate Environmental Conditions

Assess the specific conditions in which the adhesive will be used. For methods susceptible to water, temperature change, or external working conditions, go for epoxy as it withstands these better than concrete glue.

- Check Compatibility with Materials

Confirm the adhesion properties for the materials to be used. Certain concrete adhesives have more favorable adhesion properties with particular surfaces or substrates.

- Compare Application Methods

Take into account the skills necessary to carry out the operation, as well as the elements of the work at hand, such as the tools on hand. Epoxy requires accurate measurement and application, while concrete glue can be used at a lower skill level.

Adhering to these factors will enable you choose the proper adhesive in a way that resonates with the specific requirements of the given project, achieving the objectives in a reliable manner while confirming the needed strength.

Special Features to Look for in Construction Adhesives

Evaluating construction adhesives requires attention to some details that affect their performance, longevity, and practicality. Analyzing these parameters can maximize the chances of success for the adhesive in its environment and application. Here are the most important parameters to take into consideration:

- Adhesion Strength

Strength of adhesion describes the effectiveness of the adhesive bond to the substrate. Durable construction adhesives have shear strengths greater than 2500 psi and are able to withstand significant loads as structural components. Check the pull-off test results from the manufacturer’s documents.

- Curing Time

Both the timeline of the project as well as long-term durability of structure depend on Curing Time. Fast setting adhesives can set in 5-15 minutes while some other high strength structural adhesives may take even 48 hours to fully set. There is a trade off between speed and strength when setting time is to be picked.

- Moisture and Temperature Resistance

As construction adhesives are made in different climates they can be subjected to various environmental conditions. Products must be sought for that can endure temperatures from -40°F to 200°F. Water-resistance must be the standard ASTM D3498 for wet environments and for wood projects that are meant to be placed outdoors.

- Chemical Compatibility

Certain surfaces or coatings may react adversely when some adhesives are used, which may weaken the bond. It is important that products state compatibility with fundamental materials such as wood, metal, concrete, PVC, and composites so that such products can serve universal purpose or rise to specific project needs.

- Elasticity

In highly dynamic environments, Flexible adhesives which permit expansion and contraction, as well as substrate induced vibrations without cracking or losing adhesion, tend to be invaluable. Such is the case of polyurethane adhesives which tend to have an elongation percentage of greater than 200%.

Careful evaluation of these characteristics along with project requirements allows construction and engineering professionals to select the best adhesive for dependable and durable performance with Multi-Purpose Construction Adhesives.

Reference Sources

-

A Review of Durability of New and Old Concrete Joints:

-

- Chloride ion transport and freeze-thaw cycles significantly impact joint durability.

- Different interface treatments (e.g., epoxy glue joints) affect the resistance to environmental factors.

- Mechanical chiseling can damage joint interfaces, while epoxy joints show mixed durability results.

-

-

Efficiency of CFRP and GFRP in Strengthening Concrete Columns:

-

- CFRP and GFRP significantly improve compressive strength and ductility, with CFRP being more effective.

- The bond between FRP and concrete is critical, with failures often occurring at the FRP-concrete interface.

- Proper surface preparation and adhesive application are essential for optimal performance.

-

Frequently Asked Questions (FAQs)

Q: What are the best products used for adhesive for concrete projects?

A: Some of the best products used for adhesive for concrete include construction adhesive heavy duty, cement glue, and gorilla glue. These options provide strong bonding capabilities for various concrete surfaces.

Q: How do I determine the amount of adhesive for concrete needed for my project?

A: The amount of adhesive for concrete needed can be determined by the size of the area you’re working on. For example, if you’re using a 1-gal container, you can cover a larger surface area compared to smaller oz containers. Always refer to the manufacturer’s instructions for coverage specifics.

Q: Can I use glue for concrete on stone surfaces?

A: Yes, glue for concrete can be used on stone surfaces. However, ensure that the adhesive you choose is compatible with the specific type of stone you are using to achieve the best results.

Q: What is the recommended usage of construction adhesive heavy duty for concrete projects?

A: The recommended usage for construction adhesive heavy duty involves applying it to clean, dry concrete surfaces. For best results, follow the instructions for curing times and application thickness provided by the manufacturer.

Q: Is there a specific technique for applying cement glue effectively?

A: To apply cement glue effectively, use a caulking gun or a syringe for precision. Apply a consistent bead along the area you wish to bond and press the materials together firmly to ensure a tight seal.

Q: Can I use adhesive for concrete on ceramic tiles?

A: Yes, adhesive for concrete can be used on ceramic tiles. It is important to choose a suitable adhesive that can bond well with both ceramic and concrete to ensure durability.

Q: What should I do if I accidentally spill construction adhesive heavy duty?

A: If you spill construction adhesive heavy duty, it is crucial to clean it up immediately. Use appropriate solvents as recommended by the manufacturer and ensure that the area is well-ventilated during the cleanup process.

Q: How do I achieve a thicker consistency when using glue for concrete?

A: To achieve a thicker consistency when using glue for concrete, you can mix in a filler material or select a construction adhesive heavy duty that is specifically designed to be thicker. Always check the manufacturer’s guidelines for mixing recommendations.