Understanding the Compatibility of Hot Glue with Styrofoam

While hot glue is typically effective on almost any surface, extreme caution should be observed during the application stage. Some types of Styrofoam do not react well with high temperatures, causing them to change density. It is generally a good idea to use such adhesives with relatively new glue gun appliances for several reasons. The amount of glue should be large enough to have the desired extremely strong bond; however, when applied to a delicate material like Styrofoam, this is not the best option. And it will require that what is glued down be free from dirt or any other stuff in order for the glue to hold very well.

Types of Styrofoam: Polystyrene and XPS Foam

To put it simply, Styrofoam or polystyrene foam is a type of thermoformed, light material made up of expanded polystyrene, abbreviated EPS. EPS is a foam of this kind that is made by expanding the beads of polystyrene through heat and steam, resulting in the formation of the material in this foam’s cellular structure. This high-strength material contains a network of closed air cells encapsulated within the foam as an insulating material, which is equally strong in all directions. Emerging technologies are adopting EPS for use in cold chain and other protective packaging applications, while its thermal insulation and shock absorption characteristics have made it dominant in boxes, trays and food serving cups. Such buildings are characterized by the presence of large scale expanded polystyrene blocks. Rigid insulation boards such as EPS have higher strength than projects comprising of rockwool and glass wool insulation. EPS insulation is appealing to the construction industry for its ability to resist thermal transfer, no matter the objective; unconditioned, passive, or conditioned warm or cold.

XPS (extruded polystyrene) differs from EPS in terms of the way it is produced and the properties of the resultant material. Unlike EPS, XPS is made by an extrusion process very similar to that used in the making of polyolefin foam, where a directive mould is used to make the material in the desired size with a very low perimeter but quite high thickness, creating a closed cell structure, hence a denser and harder material. The presence of the closed cells contributes to how it prevents water penetration, hence high longevity and better performance in tough applications. XPS is frequently found in many building works mainly in underground thermal insulation, construction of flat roofs, and Structural Insulated Panels (SIP) for walls and roofs. It also outdoes EPS in compressive strength thus rendering XPS appropriate for high load occupation. This being said, XPS is costly and not very eco-friendly due to its manufacturing process and the potential for hydrofluorocarbon (HFC) gases to be used as foaming agents.

Compare Common Kind of Glue for Styrofoam

| Glue Type | Adhesion Strength | Drying Time | Compatibility with Styrofoam | Environmental Impact | Best Applications |

|---|---|---|---|---|---|

| Hot Glue | Moderate | Fast (seconds) | Can melt foam, use low-temp | Low to moderate | Crafts, light-duty projects |

| Spray Adhesive | Strong (foam-specific) | Moderate (1-10 min) | High, foam-safe variants | Moderate | Large surfaces, insulation panels |

| White Glue (PVA) | Moderate | Slow (30 min+ dry) | Safe | Low | Crafts, basic bonding |

| Epoxy Adhesive | High | Moderate (5-30 min) | Can be incompatible, test first | Moderate to high | Heavy-duty, structural repairs |

| Silicone Adhesive | Strong | Slow (few hours) | High | Moderate | Versatile use, waterproof bonding |

| Urethane Adhesive | Very strong | Slow (hours) | High | Moderate | Durable, industrial applications |

| Double-sided Tape | Low to moderate | Instant | High | Low | Temporary lightweight projects |

Temperature Settings for Hot Glue Guns

Glue guns generally come in a variety of heat settings for particular materials and heat bond requirements. Specifically, low temperature glue guns may work in the vicinity of 250°F (121°C), and are applicable to more gentle fabrics such as foam, fabric and plastic which could melt under higher temperatures. On the other hand, high-temperature glue guns may burn up to 380°F (193°C) and are good to use when bonding materials like timber, metals, and ceramics, which are denser or heavier. For glue guns that have two temperature settings, they allow the users to bond different materials without any constraints.

Besides that, the temperature actually depends on what type of glue stick is being used. As an illustration, stamp-hot glue sticks are created for the guns with a very high temperature, but cold hot glue sticks are well designed for materials that high temperatures could damage. Certain effective adhesives may involve special temperature tolerance and temperature compounds. As such, the temperature in the glue guns must be matched to the nature of the adhesive and the substrate to enable effective bonding and to avoid damage to the substrate. This means that the onset of the high and low temperatures of these properties again becomes particularly important in achieving the most satisfying results.

Safety Precautions When Using Hot Glue and Styrofoam

- Select the Right Glue Gun: Lower-temperature glue guns are recommended if you value not melting or disfiguring the Styrofoam. Demonstrably, such materials are said to decay rapidly at high temperatures; thus, such temperatures should be avoided.

- Work in a Ventilated Area: Do not hesitate to manage the problem with the help of any available methods such as additional local ventilation or heat extraction systems.

- Protect Your Hands: Remember to put on gloves to keep your hands safe from being burnt when contacts with the glue by mistake.

- Test on a Small Area: Do Past Testing: Refrain from applying the glue on the main project due to its cost, materials may include gluing the craft without staining on the main piece.

- Supervise Usage: Parental Supervision if Children are Involved: If they are used, ensure that they do not cause harm in any way. For instance, sharp knives and hot glue guns require that the kids are attended to at all times.

Preventing Burns: Best Practices

- Maintain Safe Workspaces: Right size of the work area should be adapted, decluttered and fire retardant material set up to avoid hot glue burns as well as other damages due to carelessness. Whenever possible avoid flammable material and any spills for the possibility of worse burns.

- Monitor Glue Gun Temperature: In the majority of the glue guns available today, one can adjust the temperature. For instance significantly lower temperatures should be employed any time you are working with foams and such materials which may melt instantly like coffee beans, the higher range will be limited to heavy duty bonding of non-mobile surfaces.

- Use Protective Equipment: Silicone protector caps, that cover the fingers or the entire hand, are worn to prevent the application of burns. This is especially the case if one is working on a craft on which the hot glue will be applied and ‘touched’ close to the skin.

- Position Carefully: The glue gun should be in an upright position during work. Many models are provided with a stand that prevents the nozzle from inadvertently coming into contact with the surface or skin, so that the chapter in your training on avoiding risk burns remains a mere theory, while the glue has a satisfactory rate of flow.

- Understand Glue Gun Features: Up to date glue guns have ability incorporate safety measures (like turning off) for a person that would otherwise overheat in protection as a result of heat loss, and they reduce risks of accidents. It is paramount to remember all the peculiarities of the equipment’s functionality in order to use it more properly and safely.

Avoiding Harmful Fumes and Ensuring Proper Ventilation

When using a glue gun, particularly in an enclosed space, it is essential to consider the potential danger of hazardous vapors that can be emitted during operation. Hot melt adhesives can release volatile organic compounds upon heating, which can impose harm to human health if repeatedly inhaled. To avoid such dangers, it is better to work when plenty of air is circulating in the environment. Opening the windows, operating the ventilation fans, or using an air cleaner fitted with a HEPA filter will be a solution.

Scientific research confirms that some types of adhesives behave differently from others when in use, largely depending on the synthetic polymers they contain. In such cases, using low-VOC adhesives even glues can go a long way in cutting down the risk. People should generally try to prevent exposure to the fumes by avoiding to inhale the fumes directly. While operating the device under industrial circumstances or if the operation will last for a longer time, it is most important that the user wear a chemical protective mask and an N95-grade mask or any similar relevant mask. In addition, by cleaning the glue gun and getting rid of the accumulated ‘cakes’ of the adhesive, very foul ductless fumes are confined. Following these rules, it becomes overweight easier to reduce the impact of the generated fumes which stay within the operation surroundings of the glue gun.

Using Protective Gear While Crafting

Indeed, as an added safety during crafting, ventilation is a must for protective clothing. Many craft operations like painting, sticking, using resin etc release substances namely volatile organic compounds (VOCs) and other micro particles in the air which may present dangers to the respiratory system, gradually. According to some statistics, it was proven that large ventilation space apart from cutting down on toxic fumes, also increases ventilation of the place during the long crafting time of session. In these, there is adequate ventilation to the process work areas by keeping open windows; assist in air movement in the house by use of fans of the air; or, to remove particles and VOCs in the air, one can use scrubbers or cleaner systems. Other than that protective masks should also be worn at the same time; therefore all the methods offered are managed in many stages so as to offer management of the exposure in the crafting platforms.

Instructions for Crafting with Hot Glue and Styrofoam

Prepare the Workspace

Find a well-lighted area and a hard surface to work on. It is advisable to cover your working area with a protective padding such as a silicone mat or paper to save your surface from any damages arriving from hot melted glue droplets.

Gather Materials

Get your heat gun and sticks made for foam or general uses, prepare the template blocks of Styrofoam to bond, and have a pair of scissors or a suitable cutter to shape the foam if necessary.

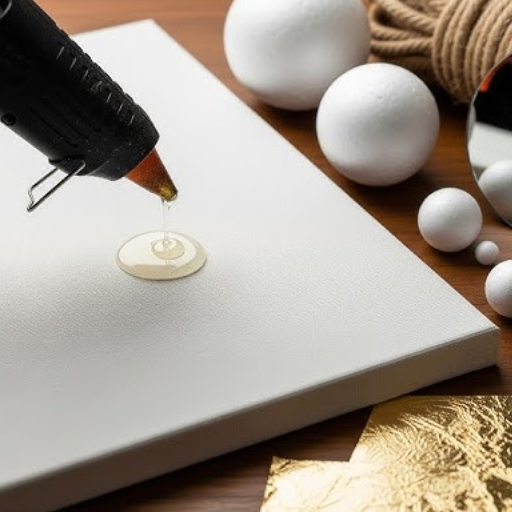

Preheat the Glue Gun

After plugging in the hot melt glue gun, make sure it has cured based on what the producer claims. Also, to prevent any potential issues add additional glue and ensure that it flows well.

Apply Hot Glue Sparingly

When working with the Styrofoam, ensure that an equal amount of adhesive is glued to one relevant Styrofoam surface only. This will prevent the situation where heat is exposed to the material as a result of excessive adhesive.

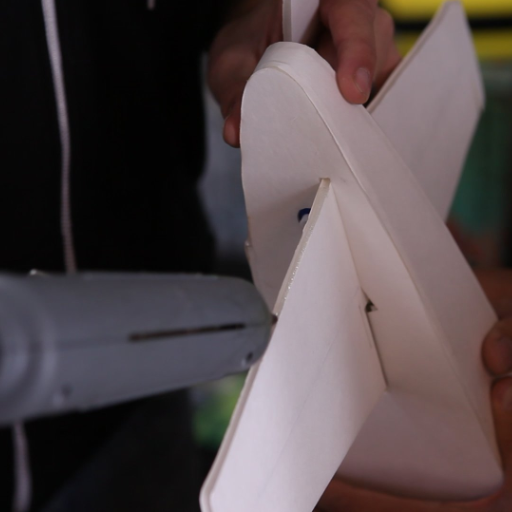

Press and Hold the Pieces Together

Carefully connect the pieces of Styrofoam together, and then press them tightly against each other. To make sure a solid bond is achieved, apply persistent force for 10 to 20 seconds.

Allow the Glue to Cool Completely

After all, suffice to say that for a few minutes after assembly, the entire bearing should be kept undisturbed in order for the nature of the connection to dry up.

Inspect the Bond

Examine the adhesion bond after the hardening of the adhesive. Lather weak points of the bond with extra adhesive until it holds sturdily together all the different parts, if required.

Basic Techniques for Using a Hot Glue Gun

Choosing the Correct Glue Stick

Choosing the correct adhesive stick for a particular work is very important. There are a number of hot glue sticks that are available in numerous designs including general purpose, high and low temperature. The high temperature sticks are designed to bond stiff materials such as wood and metal as opposed to low applications meant to adhere flimsy materials such as foam and fabric. Always use the right kind of hot glue stick for the right type of material for best bonding potential.

Proper Gun Maintenance

It is ordered that in order to maintain the efficiency and safety features of your hot glue gun, you shall do so at regular intervals. Prevent any blockages by flushing out the spare adhesive in the nozzle before you keep the tool – also, check any deep cuts and breakages on the power line and the combi injection mold unclosed. Neglecting to do such essential works only raises the possibilities of such devices failing. Otherwise, as technologies evolve on even simple gluing appliances as a type of adhesive application, some might have temperature regulation capability and such need to be taken in for checks to avoid failure.

Application Precision

When gluing something, control how much material is applied by braking over the trigger; use one’s index finger. For more intricate fastening work requiring pinpoint glue application, go for a gun with a thin line pulling nozzle. Therefore, do as the above tells you and refrain from excessive use of adhesive or spilling of the adhesive on an undesired area, especially the delicate or tiny structures.

Safety Considerations

Employing a hot glue gun mandates that one must strictly follow a number of safety precautions to prevent burns and other forms of injuries. It is imperative that the device is used on a surface that is resistant to heat and that extensive measures are employed when handling adhesives that are hot at lower temperatures, like heat-resistant gloves. Most importantly, during activities that require the use of glue sticks when some of them have to be heated, there should be enough air.

Creating Simple DIY Projects with Styrofoam

Styrofoam is a multitasking material which is frequently used in art due to its low weight, easy cutting properties as well as in various forms. If the objective is to make small decorations or models, for example, if you want to create a nice-looking vase or build a robust building’s structure, begin by determining the type of Styrofoam that is most suitable in terms of density and intended application. As for decorative embossing, Styrofoam with a higher density will be more adequate, as there is an increased resistance to damage in the edges fitted with less blunt edges. General cutting aids include hot wire, pen, craft knife, and sand paper for smoothing the cut-out shape.

To stick Styrofoam components together, it is necessary to utilize solid adhesives that are intended solely for working with expanded polystyrene foam. Adhesive guns can also be used to attach styrofoam but hot glue guns are more suitable, preferably with low heat, although they may melt if used too much at once. If styrofoam is to be used with paint, it is advisable to make use of acrylic paint as it genuinely contains oils that do not adhere well to the material, as well as paint-based paint where the oil content present in the medium may weaken the material. For a more interesting touch, it is possible to include a finishing touch with some textile, beads, and ribbons. Implementing some simple creative changes, it is possible to make styrofoam become a practical and satisfying element of almost any kind of creative activity.

Common Mistakes to Avoid When Gluing Styrofoam

Using Solvent-Based Adhesives

Glues that have solvents in them can easily melt Styrofoam, making it weak and causing an uneven/bumpy surface to occur. Look for glues that are good for foam such as foam safe glue or glue gun that is not too hot.

Applying Excessive Glue

Therefore, the application of excess glue in the bonding process may likely produce an uneven bond line or peel apart due to the poor curing of the adhesive. To prevent the undesired effect with curing glue plastic it is a must to spread an adhesive layer without forming any bubbles.

Neglecting Surface Preparation

It is not recommended to neglect the process of preparing the adhesive applied surface. Ensure that plastic surfaces – Styrofoam included – are clean and free of dust and oils, because such agents can prevent the secure adhesion of the necessary components.

Surface preparation that isn’t done as per the requirements is one of the most frequent reasons for failure in the case of protective coatings, adhesives, and other applications of materials. A critical component of this phase is the step that demands cleaning, drying, and sometimes abrading the surfaces to ensure adequate bond strength. Particles such as dust, dirt, or any other form of liquid, for instance, oils can have an adverse impact on the bond strength properties. All these, in turn, result in peeling off, cracking, breaking, or otherwise the failure of the whole structure. Studies have proven that the failure to clean substrates before the application of a coating is to blame for nearly 80% of the failures. Surface preparation methods such as solvent cleaning, (light) sanding, and abrasive blasting are employed to ensure that the surfaces do not have contaminations and are also rough enough to facilitate adhesion. In industries where the design and performance tolerances are fixed such as in the avionics and in building and construction, ignoring this need can be quite disastrous both financially and practically.

Placing Weight Too Early

It is not advisable to exert force onto the bonded area before the glue sets. Respect the curing time provided by the adhesive manufacturer for the best results.

Ignoring Compatibility With Other Materials

In cases where Styrofoam is intended to stick to a non-film surface, verify that the adhesive is common to both surfaces. Unmatched glues may even cause non-adhesive contact or papers and materials’ damage.

Using the Wrong Type of Glue

Not using the right tape can cause Styrofoam projects to fail, or the structure begins to deteriorate, or even the material starts to fail. Styrofoam is a heat treated polystyrene and it is a very light structural material. The lamination, however, is such that it is difficult to destroy. Still, some chemicals aggressively dissolve it. For instance, when solvent-based adhesives are used, the Styrofoam may end up being dissolved. Ensure that adhesion is in conformity by using specifically designed adhesives made for Styrofoam such as Foam-safe Spray Adhesives, Structural Adhesives and Silicones — this aids the removal of certain harmful components. It is in such formulation to assure secure bonds without undermining the material. And the thermal conditions, moisture retardation, as well as hardening properties of such adhesive have to be also accounted for during design and use to ensure serviceability for many years to come. Proper usage of adhesive is essential in creating a professional and durable Styrofoam project.

Excessive Heat and Its Effects on Styrofoam

Styrofoam, one of the most commonly used expanded polystyrene foams, is found to have very high sensitivity to elevated temperatures as it is such that it is a thermoplastic material. Should the temperatures go above 212°F (100°C), the material then turns soft and deformable thus losing its shape. With its softening temperature as high, it would not cause danger, yet without care, most traditional EPS foam gets completely destroyed when the temperature exceeds 464°F (240°C). Some materials such as styrene are produced as a result of heat which causes the polystyrene to either come apart or burn generating large amounts of carbon monoxide.

Chemically speaking, it is true that Styrofoam, a solid material mainly based on polystyrene blocks, is weakened when subjected to temperatures. This makes the object contract, warp, or even stops performing its insulation function effectively in some of its intended uses, such as packaging or heat insulation. Additional stressors, such as direct sun exposure though glass windows or neighboring heat-emitting items with no insulation, may worsen the situation. Thus, to prevent damage to the functional capability of Styrofoam, it is crucial to ensure the temperature requirements are observed in the storage, as well as in use especially under conditions where fluctuations of temperature can be expected.

Creative Project Ideas Using Hot Glue and Styrofoam

Model Building

Erect instances of various architecture or conceptualize projects using Styrofoam as prime material. Use hot glue for securing parts and creating interesting structures. In the case of assembly of any miniature item such as a model of building or landscape, this methodology is the most appropriate.

Custom Decorations

Design unusual elements of the interior, e.g. wall pictures, souvenirs, and decorations. Different shapes can be cut out of Styrofoam, and the hot-melt-applicator technology prevents displacement of Ornaments or decorations, such as Beads, ribbons or fabrics after the subsequent layers are added.

Costume Accessories

Create lightweight and sturdy components suitable for stage setups, masquerades, and other effects such as masks, scenic props or body armor. Styrofoam applications should be fine since hot glue is and it will achieve the desired effects when used in forming Styrofoam patterns. This is beyond impressive – the image has a stunning proof to that.

DIY Cosplay Props

A number of styrofoam items including swords and shields are perfect for the use in cosplay props. Useful hot glue doesn’t just stick elements but is essential for the component most prone to structurranning.

Educational Models

Build your own educational devices like model solar system, model of geometric surface, scientific exhibition and so forth. Hot glue is ideal when assembling complex objects or devices within a classroom environment, due to its fast bonding abilities.

Beginner-Friendly DIY Crafts

Decorative Picture Frames

Fashion your cute photo frames by the usage of styrofoam sheets as their base composition. As easier as it is to cut it, equally easier it is also to decorate it. The bare styrofoam ‘canvas’ can be enhanced indirectly by using – a fabric frame, ribbon bow, sequins, glitter or even paint. Hot glue is used to stick all those additional decorative elements, and their light weight makes them quite suitable to be placed on a wall or a desk.

Custom Planters

Make stylish plant pots using styrofoam block custom made shapes. Apply waterproof paint and most importantly make drainage holes for them to function effectively. Also use stones and tiles outside and in case cover and increase the visual appeal of the product, which can be done with less expense will decrease in actual outlay generated owing to this augmentation.

Seasonal Decorations

Not only is it helpful in the packaging of certain products, but Styrofoam can be excellent for creating decorations, suitable for a season, including wreaths, snowmen, or themed centerpieces. People who haven’t previously had any experience with arts and crafts might start with combining different elements, such as tapes or synthetic flowers, by means of a quick bonding hot gun. Using appropriate procedures for wrapping up, one can display back the items for consecutive periods.

Simple Wall Art

With given Styrofoam plates, liven up your inner rooms or solicit partial abstract and contemporary designs Images by cutting out interesting motifs. Bright designs ought to be made using acrylic colors and bekeba s or paper should be fixed with hot melt glue. This kind of art is light enough and can be hanged on the wall while also being very affordable for home improvements.

Professional-Quality Designs and Tips

In order to reach the full potential in creating pro-level designs, concentrated efforts is required to be put on the artful advice of the essentials and up-to-date skills. Let us check the option of high possibly suitable materials that will produce strong and attractive designs. In this case, use of reaming type of papers, acid resistant paste, and varnishes suitable for exposure to UV is advisable. Accurate measurement of angle and distance, thanks to tools like a compass or laser level, will improve layout precision. Last but not least, the benefit of using advanced design software such as – vector-based design software and 3D software – is it allows for detailed design which can be easily scaled.

When focusing on the last parts of your work, the techniques that have been developed will be given priority. When we are leveling up an element or its side, fine problem solving paper is for example utilized- every edge is its specialist varnish or protectant in addition. Lighting is another equipment that should not be placed in the backseat as it enhances the exposure of what one is doing, therefore one needs to have natural lighting with high CRI, if they do not wish to the color of their work becoming different. Such traceable methods are an integral part of bringing the most out of the features not to mention improving the final product as well as strategies for working in high competition environments such as graphic art sectors and professional effectiveness.

Reference Sources

-

WikiHow: How to Glue Styrofoam

- Summary: This guide provides detailed instructions on gluing Styrofoam for various projects. It recommends using white craft glue, spray adhesive, or low-temperature hot glue for different applications. The article also warns against using solvent-based glues, which can dissolve Styrofoam, and offers tips for achieving strong, durable bonds.

-

Hot Melt Blog: Guide to Bonding Foam Using Hot Melt Adhesive

- Summary: This blog explains the challenges of bonding foam with hot melt adhesives, such as melting and limited surface contact. It suggests solutions like using low-temperature or spray hot melt adhesives and highlights specific products for foam bonding. The article also lists common foam types and their applications, such as cushions and equipment cases.

Frequently Asked Questions (FAQs)

Q: What kind of glue works best with styrofoam?

A: Using hot glue is found to be more acceptable by many users working on a styrofoam due to the fact that it fixes quickly and has phenomenal adhesion. In case, you wish to change the approach there are also PVA and Elmer’s glue for light glue projects, where there is lesser emphasis on heating the glue. In addition, there certain instances where Gorilla glue may be an alternative, but there is one issue, it is that, upon drying, it collapses. This may not make it the best fit for safety foam inflatables, for example. Tacky glue is a common product used in arts and crafts especially as it tends to stick to more rough materials such as foamies. Just like in any other materials that use adhesives, it is quite obvious that the entire process will heavily rely on the glue’s behavior against the area of use and the particular foaminess one is working with.

Q: Can hot glue melt the foam when using it on styrofoam?

A: Certainly, extreme hot glued guns can erode the froth contents at an alarming rate. Compare the low heat hot glue guns, they are built to mitigate such danger and are hence very friendly to soft material like styrofoam. Applying a high-temperature adhesive, on the other hand, may possibly introduce some lasting hot-melt glues issues, which are again quite unsightly or deformation on the foam. By all means it is advised to test the strength of the bond in very small corner. If you require potting such that you have no alternative to peeling large sections together, be sure to squeeze some glue onto the surface and a bit more on top of the foam to avoid such disastrous results.

Q: How does hot glue work with different types of styrofoam?

A: Anyone can shrink any types of foams with the heat from hot glue. But that may differ especially based on whether the foam being applied is dense or porous. Decorative foam, for example, the one that is usually used for crafts and is available at various hobby shops, is made in such a way that it is easy to stick it onto the hot glue without using much effort. On the other hand, more rigid foam like metal requires more glue or a different type that can be soaked through such as contact cement. Please do not forget that you have to wait before holding hot glue in your hand so as not to get burnt. Useful information is that perpendicular glue application on the glued foam eliminates discrepancies.

Q: Is it safe to use super glue on styrofoam?

A: Nonetheless, It is advisable for one to desist from putting super glue, an adhesive on a porous material like styrofoam. It should be noted that super glue happens to be a cyanoacrylate adhesive known to excel in bonding non-porous materials with each other. Yet even as such, application when met with the styrofoam hardly ever produces the same results and does not always hold the pieces together. For more reliable results, one may use hot or craft glue as it is specifically designed for foam work. If it is an urge to use super glue the caution of testing it on another foam material instead of the one wanted to be glued. Also it is important to take all the necessary safety measures to ensure that the projects are not endangered at any time.

Q: Can you use wood glue on styrofoam?

A: Due to its impact on styrofoam, wood glue is not a very good choice because it requires moisture for it to become effective and hence the foam nor the glue can be effective. If you want to get a nice tight bond, hot glue can work; unlike wood glue, hot glue is a fast setting to hold just enough and is quite pliant without having to wait for it to dry using moisture. If you are working on aesthetics involving wood and styrofoam, a cool burner gun, low-temp hot glue or even contact adhesive may be a better option. According to the glue in use, compatibility with styrofoam and styrofoam glues are only applicable to specific cases since some form of styrofoam is intended for the use of the materials. Prioritizing the construction of the project, make sure to conduct a bonding test for each adhesive each used in the same project before building it.