Polystyrene foam, also known as Styrofoam, is a versatile material used mainly for crafting, packaging, and insulation projects. The entire working process with Styrofoam can be challenging in its own way, particularly gluing pieces together. If you’ve had a hard time finding the right glue or if you’ve suffered from the dire consequences of applying the wrong glue, you are definitely in the right company. This guide is meant to make that process easier for you. We will discover the best and most powerful methods for bonding Styrofoam, discuss the glues explicitly engineered for this light material, and finally list preventive measures to avoid common mistakes. So whether you are a DIYer, a crafter, or a home improvement tasker, you’ll have everything you need to ensure your Styrofoam projects stand the test of time.

Understanding Styrofoam and Its Properties

Styrofoam, or expanded polystyrene (EPS) as it is scientifically known, is a very light, versatile material commonly used for insulation, packing, and even arts and crafts. The property that makes it unique is its resistance to water, its tendency to mold, and, most importantly, its good insulating properties. On the downside, Styrofoam usually melts when exposed to chemicals like acetone or solvents in glue. Therefore, it is advisable to use glue that will not affect the material, and to handle it carefully if you want to keep its structure and function in good condition.

What is Styrofoam?

Technically, Styrofoam is a registered trademark of The Dow Chemical Company and refers to a specific type of extruded polystyrene foam (XPS). Most people confuse it with expanded polystyrene (EPS), which is used for disposable coffee cups, food containers, and craft work. The primary use of Styrofoam is in the construction industry as an insulator, thanks to its high thermal resistance and moisture protection. The closed-cell structure of the material gives it strength and lightness, making it a perfect candidate for reducing energy costs in buildings. Styrofoam has a lot of practical applications but it still cannot decompose naturally, hence the environment is concerned about its long life cycle and the difficulties in recycling it. The search for eco-friendlier alternatives or better recycling processes is becoming increasingly pronounced to mitigate its environmental impact.

Why is Styrofoam Challenging to Bond?

The main reason bonding Styrofoam is hard is its highly smooth, non-porous surface, which makes it challenging for adhesives to get a good grip. Moreover, Styrofoam which is a type of expanded polystyrene (EPS) is resistant to many of the most common glues and solvents, which means that bonding techniques are pretty limited. In addition, many adhesives contain chemicals that react with or dissolve Styrofoam, causing damage rather than creating a strong bond. The use of specialized adhesives, like certain spray adhesives or epoxy glues made for Styrofoam, is often necessary for successful bonding which points to the necessity of meticulous material selection.

Common Applications of Styrofoam

- Insulation: Styrofoam is an excellent heat insulator so it is widely used for thermal insulation in buildings.

- Packaging: Styrofoam is ideal for shipping fragile items due to its lightweight and shock-absorbing properties.

- Crafting: Artists and crafters often use Styrofoam in their projects to build models, create decorations, and set up displays.

- Food Containers: Styrofoam is a standard material for disposable cups, plates, and food boxes because it is easy to use and helps keep hot or cold items insulated.

- Floral Arrangements: Florists put Styrofoam as a base for holding flower stems in place and making stable, lasting arrangements.

Choosing the Best Glue for Styrofoam

If you are looking for the best adhesive for Styrofoam, use a glue specifically for foam. Choose those glues that are marked as safe for foam, they can be tack glue, spray glue, or epoxy, for example. Do not use adhesives with solvents, such as super glue, because they melt Styrofoam. Consider application needs—drying time, strength, and compatibility with other materials — to choose the adhesive that is right for your project.

Types of Adhesives Suitable for Styrofoam

- Foam Tack Glue

Foam tack glue is a glue that has been especially made for foam, it gives a firm hold and does not harm the material at the same time. It is suitable for craft projects and delicate applications. - Spray Adhesive

Spray adhesives can apply a thin layer of glue over a large area and dry quickly, making them the best option for bonding Styrofoam to materials like cardboard or fabric. - Epoxy

The two-part epoxy adhesives offer strength and durability hard to beat; thus, they can be used for very tough applications involving Styrofoam. - Silicone Adhesive

Silicone adhesives are flexible and multipurpose, providing a strong bond to Styrofoam that won’t cause the material to age or deteriorate over time. - Polyurethane Glue

Polyurethane adhesives are also waterproof and they expand as they dry, thus providing a powerful bond for Styrofoam in moisture-prone projects.

Comparison of Popular Styrofoam Glues

The most popular Styrofoam glues include hot glue, foam-specific spray adhesive, two-part epoxy, silicone adhesive, and polyurethane glue.

|

Glue Type |

Strength |

Flexibility |

Waterproof |

Ease of Use |

Dry Time |

Best Use |

|---|---|---|---|---|---|---|

|

Hot Glue |

Moderate |

Low |

No |

Easy |

Fast |

Craft Projects |

|

Spray Adhesive |

Moderate |

Moderate |

No |

Easy |

Fast |

Light Projects |

|

Two-Part Epoxy |

High |

Low |

Yes |

Moderate |

Slow |

Heavy-Duty Uses |

|

Silicone Adhesive |

Moderate |

High |

Yes |

Easy |

Moderate |

Flexible Needs |

|

Polyurethane Glue |

High |

Moderate |

Yes |

Moderate |

Moderate |

Moisture Areas |

What to Avoid: Adhesives that Melt Styrofoam

When handling Styrofoam, be very careful not to use any adhesive that contains solvents or chemicals that can dissolve or melt it. As a result of this interaction, Styrofoam will lose its strength, and depending on the adhesive used, it may either turn into a gooey substance or form holes. Strong solvents in spray adhesives can also have a similar effect. You can also consider glues specifically stated as safe for Styrofoam or foam products, such as low-temperature hot glue, silicone adhesive, or foam-compatible epoxy. If you apply the correct adhesive, your Styrofoam projects will remain solid and long-lasting.

Techniques to Join Styrofoam Pieces

For effective joining of Styrofoam parts, the first step is to choose a foam-friendly adhesive such as low-temperature hot glue, silicone adhesive, or epoxy which is specifically labeled for working with foam. Then spread the adhesive evenly on one side and lightly push the parts together so the Styrofoam is not damaged. If the project is big or complicated, toothpicks or wooden skewers can be used as supports, introduced quietly into the foam for extra strength. Lastly, be sure to give the glue enough time to set, as directed by the product, to ensure a strong, durable connection.

Step-by-Step Guide to Gluing Styrofoam

- Gather Your Materials

Make sure you have all the necessary supplies within reach, including the correct adhesive (e.g., foam-safe glue, silicone adhesive, or epoxy), protective gloves, a clean work surface, and, if needed, toothpicks or wooden skewers as aids. - Prepare the Styrofoam Surfaces

The surface of the Styrofoam should be cleansed to ensure no dust, dirt, or oil is left that could, for instance, prevent a good bond of the adhesive. - Apply the Adhesive

Apply the adhesive evenly to one of the Styrofoam surfaces. Be sure to use the skinny layer so you don’t have to deal with a mess or an uneven bonding area. - Join the Pieces

The Styrofoam pieces should be brought together with gentle but firm pressure. You have to watch it, though, as too much pressure could damage the soft material. - Add Reinforcements (Optional)

If your undertaking is big or intricate, then pinned or skewered toothpicks or wooden skewers give the extra support and stability thereby creating your project. - Allow the Adhesive to Cure

Remember to adhere to the manufacturer’s guidelines for drying and curing times. Ensure that the adhesive is fully dry before handling or moving the glued Styrofoam pieces. - Test the Bond

Once the adhesive has fully cured, lightly check the connection to ensure it is strong and secure. In the case of an insufficient bond, it may be necessary to apply adhesive again or reinforce it further.

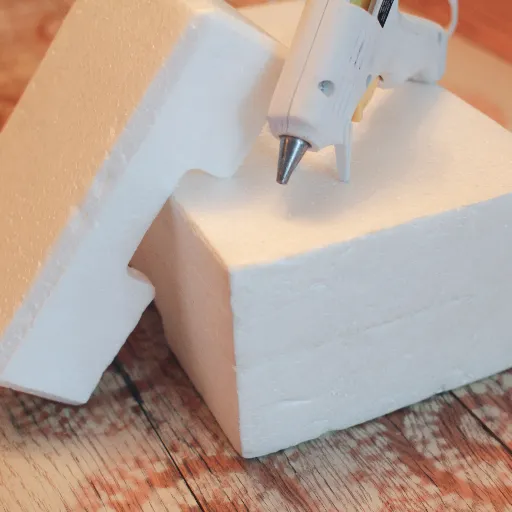

Using a Hot Glue Gun on Styrofoam: Tips and Tricks

Using a hot glue gun on Styrofoam requires specific techniques to prevent melting and maintain bond strength. The following tips can be of great help:

- Low-Temperature Glue Guns Should Be Used

Glue guns of high temperatures can melt the Styrofoam or deform it because of the heat they give off. A low-temperature glue gun designed for delicate materials like Styrofoam should be your go-to every time. - Try It out on a Small Area First

Before applying glue to the main piece, test it on a small, inconspicuous area of the Styrofoam to confirm compatibility and avoid damage. - Small Amounts of Glue Should Be Applied

The glue used should be minimal so the Styrofoam does not overheat. The adhesive should be applied quickly and evenly to create a secure bond without damaging the material. - Use a Ventilated Area for Your Work

Melting glue produces fumes and this is especially so when the glue is used on synthetic materials like Styrofoam. Always ensure you are working in a well-ventilated area for your safety.

If you follow these tips, using a hot glue gun on Styrofoam will be safe and strong, with less risk of damage to the material and stronger, longer-lasting bonds.

Alternative Joining Methods

If the hot glue gun isn’t your choice, there are plenty of other methods you can use to bond Styrofoam effectively.

- Double-Sided Tape

For lightweight applications, this is a very straightforward and neat method. This tape offers an instant bond without heat or extra tools. - Foam-Safe Adhesives

The use of foam-safe sprays and liquid glues, as well as specialized adhesives for foam materials, ensures a strong bond without melting or damaging Styrofoam. - Toothpicks or Skewers

If you are looking for nothing less than temporary or lightweight connections, putting toothpicks or wooden skewers between Styrofoam parts might be a good idea, as it would offer stability without adhesives. - Clips or Clamps

If gluing is not an option, using clips or clamps to hold pieces together for projects might be required when flexibility or easy disassembly is needed.

All these methods come with their respective advantages thus making it possible for you to choose the one that best suits your needs for that particular project.

Setting and Curing Your Styrofoam Bond

The setting and curing of your Styrofoam bond should be done by ensuring the pieces fit tightly first, then applying the adhesive. Use adhesives designed explicitly for Styrofoam for the best results, as they form strong, permanent bonds. Once applied, clamp the pieces together firmly and let them cure for the time specified by the glue manufacturer. Do not disturb the glued parts during curing; this will yield the strongest bond.

How Long Does Styrofoam Glue Take to Set?

The setting time for Styrofoam glue depends on the type of adhesive used. The majority of adhesives intended for Styrofoam, including contact adhesives and polystyrene-safe adhesives, usually take about 15 to 30 minutes to be set. Nonetheless, complete curing generally takes about 24 to 48 hours for the bond to reach its full strength. The manufacturer’s instructions should always be consulted for the exact setting and curing times.

Factors Affecting Bond Strength

- Type of Adhesive Used

The selection of adhesive is a determining factor in bond strength. Some glues are for Styrofoam only, while others might either decrease the material’s strength or even cause melting. - Surface Preparation

The Styrofoam surfaces need to be thoroughly cleaned and prepared to attain the best possible adhesion. Bond effectiveness will be reduced by presence of dust, grease or unevenness. - Environmental Conditions

The strength of the bond can be affected by temperature, humidity, and airflow conditions at the time of application and curing. Extreme cold or heat, for example, may impair the adhesive’s performance. - Glue Application Method

By applying the glue evenly and using the right amount, one would not only prevent weak spots but also increase the bond’s strength and durability. - Curing Time

Complete curing of the adhesive according to the manufacturer’s instructions should be considered the condition for achieving maximum bond strength. Speeding up or shortening the curing process can result in a weak bond.

Safety Precautions When Working with Adhesives

- Work in a Well-Ventilated Area

Adhesives do indeed emit fumes and some of these fumes may be harmful if inhaled. To ensure there is enough fresh air, the working area could be an open space or air circulation via fans. - Wear Protective Gear

Wearing gloves is recommended to avoid skin contact, and using safety goggles is advisable to prevent splashes to the eyes. - Follow Manufacturer Instructions

Make sure to read the adhesive’s packaging and follow the manufacturer’s instructions for safe handling and application. - Store Adhesives Properly

Store the adhesives in their original, tightly sealed containers and place them in a cool, dry place, away from heat, flames, and direct sunlight. - Dispose of Adhesives Safely

To avoid environmental damage or hazardous situations, you must comply with the local regulations concerning the disposal of adhesive materials.

Troubleshooting Common Glue Issues

Weak Bonds: Causes and Solutions

- Improper Surface Preparation

The adhesive should not be applied until the surfaces are clean, dry, and free of dust, grease, or oil. If necessary, a capable cleaning agent should be used. - Incorrect Adhesive

An adhesive designed for the materials being bonded must be selected. The effectiveness of the glue can be reduced if the wrong type is used. - Insufficient Drying Time

Follow the curing or drying time indicated on the adhesive’s packaging. Weakened bond may result from hurrying the process. - Uneven Application

To ensure complete contact, the adhesive must be applied uniformly across the surface. Weak spots can result from gaps or inconsistent coverage. - Environmental Factors

Application should not be done in extreme heat or areas of high humidity as such conditions can affect the performance of the adhesive.

Dealing with Melting or Damaged Styrofoam

The melting or destruction of Styrofoam is usually the result of its contact with substances that release a lot of heat, or of chemical reactions or solvents. In dealing with such a problem, the first step is to determine the cause of the damage. In the case of melting due to heat, ensure the Styrofoam is far away from sources of direct heat like flames, and high-temperature tools, or that it does not get exposed to sunlight for long periods. If Styrofoam melting is due to chemical reactions, do not work with solvents such as acetone or certain adhesives that degrade Styrofoam.

To repair, small cracks or dents can be filled with Styrofoam-compatible fillers or special glue for polystyrene. After the filler dries, lightly sand the area to smooth it. For large areas of damage, replacing the ruined piece may be better than repairing it. Preventive actions, such as applying protective coatings or ensuring Styrofoam is not used under less-than-optimal conditions, can help extend its life and prevent similar issues in the future.

How to Achieve a Stronger Bond

A stronger bond is guaranteed in my practice if surfaces are clean, and dry, and not contaminated with any sort of dirt or dust when the adhesive is applied. Then I go for a top-grade adhesive that matches perfectly the materials I work with and lets the curing time go till the end of the manufacturer specification. Moreover, I exert uniform pressure on the joint during setting to strengthen the bond. Correctly done preparation and delayed action are essential factors for a bond that lasts and is trustworthy.

Reference Sources

-

How to Glue Styrofoam: Tips for Styrofoam and Polystyrene – Provides detailed advice on using spray adhesives, such as Loctite, for bonding Styrofoam.

-

How Can We Stick Styrofoam Back Together After Cutting It – Offers practical tips on using low-temperature glue sticks for Styrofoam repairs.

-

Can You Glue Styrofoam Together? A Comprehensive Guide – Discusses the best adhesives for Styrofoam, including water-based and polyurethane adhesives.

Frequently Asked Questions (FAQs)

What is the procedure to join Styrofoam with Gorilla Glue?

Gorilla Glue can be used to bond Styrofoam, provided the surfaces are clean and free of moisture. Next, lay down a skinny layer of glue on one side, bring the two parts together, and keep them pressed for a few minutes. After that, let the glue sit for at least a day to get a powerful bond.

Which adhesive is the strongest for bonding Styrofoam layers?

Contact cement or construction adhesive is often regarded as the strongest adhesive for bonding Styrofoam layers. These types of adhesives are non-toxic and will not harm the material. Just make sure to follow the manufacturer’s directions for the best outcome.

Is it possible to use wood glue to make Styrofoam at the same time?

Using wood glue on Styrofoam is discouraged, as it can dissolve the foam. Choose glue that makes a strong bond, like white glue or Liquid Nails, designed explicitly for the foam.

What is the procedure to bond Styrofoam using 3M adhesive?

Bond Styrofoam using 3M adhesive by spraying the adhesive onto one surface, then pressing it evenly and firmly against the other piece of Styrofoam. Retain for a few seconds to ensure a robust joint forms. Crafting projects will really benefit from this technique.

Is superglue a suitable option to glue Styrofoam?

Superglue can be used to join Styrofoam; however, its use must be strictly controlled. A tiny drop can make a powerful connection, but too much can cause the foam to melt. Testing on a small area is mandatory before proceeding.

Is it possible to use caulk as an adhesive for Styrofoam?

It is not standard practice to use caulk to glue Styrofoam together, as it may not provide a sturdy bond. However, if you are looking for a flexible joint, then some types of caulk may be a good fit. Just make sure to pick a caulk that is suitable for use with foam materials.