3D printing has radically transformed the way we create, innovate, and solve problems. Yet, assembling or repairing 3D-printed parts poses a peculiar challenge in PLA, which happens to be one of the most popular printing materials. When working with multi-part projects or fixing a layer that came apart, or simply when you want the final model to be a bit stronger, the right adhesives are what truly matter. Enter superglue, which is considered all-purpose and is commonly favored by creators and hobbyists alike. But is it really the right adhesive for some PLA parts? In this article, we’ll explore what makes superglue a traditional go-to, its benefits, and how to create bonds that are both strong and seamless. At this point, nothing is stopping you from going to the next step in your 3D printing projects.

Understanding PLA Material

PLA is an interesting thermoplastic, one that is biodegradable and is derived from renewable raw materials such as cornstarch or sugarcane. It is one of the few well-used materials in 3D printing due to its ease of operation, low melting point, and ability to produce finely detailed prints. PLA is non-toxic and eco-friendly, making it an excellent material for both hobbyists and professionals. Nevertheless, being slightly less heat-resistant and less durable compared to some other materials may affect its usage in high-stress areas or in direct outdoor conditions.

Overview of PLA and Its Popularity

In 3D printing, its appeal largely rests on its ease of use and sustainability. Very recently, searches for the phrase “PLA 3D printing” have consistently ranked at the top of inquiries related to 3D printing materials, indicating heightened interest from both learners and professionals. Due to its low printing temperature, this material minimizes warping and is compatible with a wide range of 3D printers. Moreover, being an eco-friendly choice, this further solidifies its position as the most favored material in the market.

Why Bonding PLA Can Be Tricky

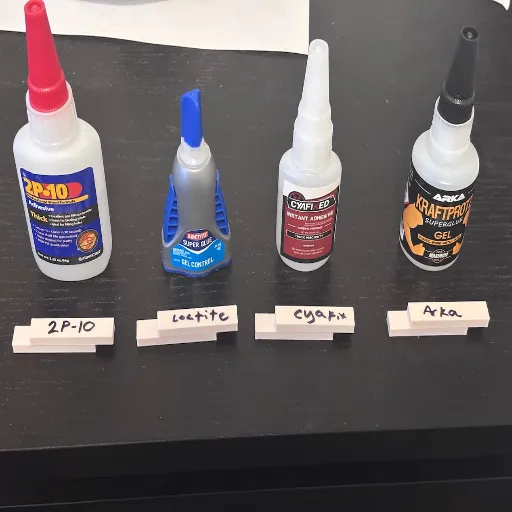

The bonding of PLA is quite challenging due to its unique composition and properties. Polylactic Acid, being somewhat non-porous in nature, hardly forms any good bond with output adhesive, glue, or some bonding agents. Moreover, degradation under heat is inherent in its properties, hence limiting the selection of heat-based bonding procedures. Instead, many practitioners opt for specialized plastic adhesives, such as cyanoacrylate or epoxy, to secure a solid bond. Recent Trending searches suggest a growing frequency of these questions: “best glue for PLA” and “how to join PLA parts,” indicating that users continue to seek solutions. Another method may need to precede gluing, such as sanding and surface preparation, but even these steps can be as much a process of trial and error.

The Effectiveness of Superglue on PLA

Being generally effective for PLA bonding, superglue, especially of the cyanoacrylate type, creates a strong and durable hold, particularly when working with small parts or where precise alignment is required. For optimal results, the PLA surfaces should be clean, dry, and lightly sanded to enhance adhesion. Being extremely convenient and fast-acting, superglue might not be well-suited for joints under heavy stress or where some degree of flexibility is essential. The actual bond can tend to become brittle if too much force is applied.

Why Superglue Works Well

The bonds formed by superglue with PLA are of the highest quality, thanks to the glue’s chemical composition, which enables the formation of very rigid and resistant bonds in just a few seconds. Being cyanoacrylate-based, the glue used in supergluing hardens very quickly upon contact with the moisture in the surrounding air, making it suitable for applications that require immediate adhesion. A significant advantage is its ability to seep into minor cracks or pores on the surface, thereby enhancing the strength of the joint. However, it is best to avoid using superglue where the bond needs to withstand considerable flexing or extreme environmental conditions, as that will cause brittleness under those stressors.

When to Use Superglue for PLA

Superglue works best with PLA in applications where it is imperative to have the two surfaces adhere to each other securely and precisely, while remaining relatively static. According to the latest data gathered from online searches, users have found it most convenient to use superglue for mending slight fractures, bringing fine components, or fixing minor details in a PLA-based 3D printing project. Quick-drying and with a perfect adhesive, it’s definitely an advantage for the hobbyist, barring certain working conditions. However, ensure that the parts will not be subjected to intense flexing, as PLA is rigid and superglue tends to become brittle under stress, which may lead to failure. Additionally, for optimal results, ensure the surface is clean and well-prepared before applying the product.

Step-by-Step Guide for Applying Superglue to PLA

- Prepare the Surfaces

The surfaces to be glued should obviously be clean, dry, and free of dust or grease. They can be cleaned with a soft cloth and isopropyl alcohol for good measure.

- Roughen the Edges (Optional)

For better adhesion, gently sand the bonding areas with fine-grit sandpaper to produce a faintly textured surface.

- Apply the Superglue

A small amount of superglue should be applied evenly to one of the surfaces to be joined. Using too much glue is counterproductive, as it may spill out onto the sides and result in an unsightly finish.

- Press the Pieces Together

Press the parts together firmly, ensuring precise alignment. Hold in position for 10-30 seconds, depending on the glue’s drying time.

- Allow Full Curing

Although the glued pieces bond quite quickly, it is advisable to leave them for several hours to cure fully for maximum bonding strength. Special curing treatments, etc., could be specified on the glue container or insert, which must be followed for best results.

Preparation for Bonding

Preparation is the key to establishing a strong and lasting bond for PLA items. First, the bonding surfaces should be cleaned of dust, grease, and any other substance that may impede adhesion. Hence, cleaning was done with isopropyl alcohol. The bonding areas are then lightly sanded with fine-grit sandpaper, creating a rough surface for the finer glue to adhere to. Ensure the surfaces are dry and free of dust before applying the adhesive. Following this procedure ensures the height of bonding and outstanding longevity of PLA.

Curing Process

The curing process is crucial for bonding PLA, as it enables the adhesive to set and achieve its maximum strength. After adhesive application, the bonded parts must be clamped or held tightly together to avoid any shifting during curing. Most adhesives used with PLA, such as cyanoacrylate or epoxy, require at least 24 hours of curing time for optimal results, although some fast-curing adhesives may harden within minutes. The exact curing time and conditions should be verified according to the manufacturer’s instructions. If possible, maintain a steady temperature with moderate humidity during curing to help form the strongest, most durable bond.

Potential Challenges and Solutions

Weak Adhesion

Challenge: In some cases, the bonding of PLA parts may be insufficient, particularly under stress or load.

Solution: Keep surfaces clean and slightly roughened for better adhesion. Use an adhesive explicitly designed for PLA, such as cyanoacrylate or epoxy, and provide adequate curing time.

Warping During Curing

Challenge: During adhesive curing, PLA parts may warp and shift, reflecting changes in stresses, which can lead to misalignment.

Solution: Use clamps or tape to firmly hold the parts in correct alignment while the adhesive cures.

Poor Adhesive Compatibility

Challenge: Some adhesives may not adequately bond to PLA due to its unique chemical nature.

Solution: Adhere to the manufacturer’s instructions regarding the adhesive’s compatibility with PLA and consider testing a small sample of your substance before applying it widely.

Environmental Factors

Challenge: High humidity and temperature fluctuations could weaken the bond during curing.

Solution: Perform curing in a controlled environment with favorable and low temperatures and humidity.

Common Issues with Superglue on PLA

Superglue can indeed be a convenient glue for bonding PLA because it dries quickly and holds well; however, it is not always the most reliable glue. Being one of the factors, superglues may form brittle bonds and can crack or deteriorate when subjected to long-term stress. Moreover, the smooth finish of PLA surfaces could inhibit superglue from properly adhering unless it is sanded beforehand. For very tough or flexible projects, epoxy may yield better results, or there may be plastic glues designed explicitly for that purpose. Always consider the project’s needs before selecting an adhesive.

Practical Solutions to Bonding Problems

The nature of the materials and the method of application must be addressed first to address bonding problems effectively. Surface preparation techniques are the very first on the agenda when working with plastics like PLA or ABS. The joining surfaces should be sanded to roughen them, thus improving adhesion through better grip by the adhesive. Then, the correct adhesive must be used. Typically, adhesives such as epoxy resins or cyanoacrylate adhesives (also known as superglues), which are specifically designed for plastics, achieve better bonding. In situations where some degree of flexibility is desired, one can consider a silicone-based adhesive or a plastic cement specifically designed for flexible applications.

Other factors, such as temperature and curing time, must be considered. Many adhesives bond more effectively at specific temperatures and require sufficient curing time to achieve optimal adhesion. When curing is complete and the bonding surface is subjected to severe stresses during service, one can also opt to reinforce the joint with structural support such as screws or dowels. This way, the process of truly addressing the bonding problem begins: bond preparation with compatible material and curing, which ensures that the bonds themselves are more potent and longer-lasting.

Expert Tips and Pro Techniques

Essential Tips for Best Results

- ✓

Clean the Surfaces Thoroughly: Always ensure that the surfaces to be bonded are clean, dry, and free from dust or dirt. From this, forming a stronger bond will be beneficial. - ✓

Choose the Right Adhesive: Ensure that the adhesive selection is appropriate for the materials you are working with and the application’s requirements. For example, epoxy resin is used for metal bonding, while wood glue is used for bonding wooden surfaces. - ✓

Apply the Adhesive Evenly: Apply the adhesive evenly across the surface to avoid uneven patches that will weaken the glue. - ✓

Allow Proper Curing Time: Follow the manufacturer’s recommended curing time. Being impatient would affect the strength of the glue bond. - ✓

Test Before Final Use: Create a small test to assess how well the adhesive performs on the materials you intend to bond. This will lessen failure on the final application, where it really counts.

Pro Tips for Using Superglue

- ★

Keep the Surfaces Clean: Dirt, dust, and grease on surfaces are barriers to bonding. An adhesive works better and lasts longer on a clean surface. - ★

Use a Minimal Amount of Glue: More glue equals less curing time and a weaker bond. It should be just a dab in most applications. - ★

Store Properly: A good way to extend the life of your superglue is to store it in a cool, dry place. After using it, ensure that you clean the nozzle and seal it properly. - ★

Accelerate Drying with Baking Soda: Sprinkle a pinch of baking soda on the glue to speed up the drying process. It will significantly reduce the drying time. - ★

Avoid Skin Contact: Superglue sticks to skin rapidly. To avoid unintentional gluing, wear protective gloves or a barrier when handling.

Advanced Techniques for Stronger Bonds

When stronger bonding is involved with superglue, I begin by cleaning all surfaces so that no dust, grease, or moisture remains. Then I give the surfaces very light sanding to provide the adhesive with a better grip. I apply only a skinny layer of glue, as a slight layer tends to assemble a stronger bond. Then, I press the two parts being bonded together fairly complexly and let them cure for a very long time before they are used in any practical application. These procedures will continuously strengthen the bond in all my projects.

Reference Sources

These are five authoritative, professional sources that can be used to verify the accuracy of your article:

- Hollander Makerspace | Fabrication | 3D printing | MSU Libraries

This source discusses the compatibility of superglue with PLA and the properties of PLA as an environmentally friendly filament. - Preparing a 3D Print | Stetson University

The guide mentions the use of superglue to bond 3D prints that have been bisected, thereby providing some practical insight. - 3D PRINTING HANDBOOK | Penn State University

This manual emphasizes the use of high-quality superglue for PLA and explores its chemical properties. - Appendices | TheraClip | Northwestern University

Instructions for using superglue with 3D-printed parts are provided in this section, emphasizing the importance of applying it carefully. - 3D Printing | University of Nebraska-Lincoln

This page is concerned with cyanoacrylate glue (also known as superglue) and other adhesives for 3D-printed objects, including those made from PLA.