Glues and adhesion can oftentimes create dilemmas in terms of the nature of exhibits and strong holding power. For craft projects, packaging, or even structural applications, ultimate attention must be paid to selecting the right adhesive. Hot melt glue offers the most flexibility and is also ranked among one of the best options for bonding given its ease of use and strength. Hot glues, however, do not all behave the same with foam materials, and if applied incorrectly, it can yield poor results. This document covers everything at a glance for bonding foam and Styrofoam with hot melt glue-from choosing the right glue to correctly applying it. In the end, you will be able to professionally bond foam on any project.

Understanding Different Types of Foam

Styrofoam and Its Properties

Styrofoam or Expanded Polystyrene (EPS) is a lightweight and multifaceted medium used ubiquitously in packing, insulation, and craft-work scenarios. Choices require excellent thermal resistance, low density, and buoyancy; hence, it finds applications in punishing and insulation. Styrofoam is made from about 98% air and 2% polystyrene, conferring it strength against weightlessness. But these low-density cells also mean that this Styrofoam is extremely brittle and breaks easily under pressure.

One of the weird things about Styrofoam that many people would not know is that it reacts to heat and certain solvents. In exposure to the laying heat, it warps or melts: one has got to be careful not to use hot melt glue. On the flip side, Styrofoam comes in contact with some adhesives or coatings, contraindicated products will deteriorate or entirely dissolve it. Thus, it is very important to use the right glue for fixing Styrofoam in any project.

Styrofoam in many of its applications is a great insulator; hence, it does no biodegrading and poses problems in recycling and disposal. Increasing activity, therefore, is being brought pertaining to its environmental impact, with efforts being made in some industries to replace it, or for better recycling of Styrofoam products. Having a knowledge of such Styrofoam properties ensures efficient and responsible application of the material, especially when working with assistance from hot melt adhesive for a professional finish.

EVA Foam: Durability and Flexibility

EVA foam stands as one of those plastic materials with properties of durability and flexibility. This type of foam finds various applications where shock absorbance is desirable, comfort is a priority, and performance over time is important. The foam consists of a closed-cell structure giving it water resistance, and would stay free of many environmental factors like moisture or changes in temperature; hence, it would resist complete destruction over time.

One of the most important features of EVA foam is its flexibility. It is this material that can be molded into various intricate shapes and cemented onto many surface applications in sports, construction, packaging, or even more. EVA foam further acts as a cushion and protector of athletic equipment, among other uses, and even shoe soles. Being light in weight just adds to the flexibility of this foam by not being a hindrance to the design.

Another perk of EVA foam is its very durable nature. It is prone to wear and tear, which means that it requires constant durability, such as that required in long periods of usage. This foam cannot be crushed or cracked with time, even under constant pressure or abrasion. This sturdy nature makes it possible for any product made of EVA foam to retain its functionality and quality for a long time and hence making it a good option commercially and industrially. Its combined flexibility and durability traits have positioned EVA foam as a must-have material in numerous applications.

Upholstery Foam: Comfort and Support

Upholstery foam stands in the way when comfort and ergonomic support are desired in furniture design. Its reason for being is to offer that soft cushioned feeling while giving structural support in seating and other upholstered services. The density and hardness of foam greatly decide the performance of foam; consequently, those with a higher density tend to give better support and longer comfort. For this reason, upholstery foam is used to put together furniture that astrology brings with relaxation and makes for great durability.

One big prerogative that upholstery foams have is being adaptable to shape and design. Used for sofas, chairs, or mattresses, it could be shaped to further embellish the furniture itself, either aesthetically or functionally. The thickness and softness of the foam can also be adjusted to develop different applications, such as softer for sitting and harder for supporting right posture. That very same versatility bestows upon a piece of furniture the flexibility to respond to different tastes of the user and lifestyle needs.

Upholstery foam further provides cushioning by absorbing energy and alleviating body weight from pressure points, thus generating comfort if used for prolonged periods. The advanced manufacturing processes ensure it does not get crushed or lose shape for a far longer period. Thus, upholstery foam truly offers a trifecta of qualities: comfort, durability, and adaptability-to-be incorporated into the making of quality furniture for homes, offices, and public areas.

Hot Glue: The Basics

What is Hot Melt Adhesive?

Hot melt adhesive, or HMA in short, is a thermoplastic adhesive that is applied in a molten state and then solidifies as it cools to create a strong adhesive bond. The adhesive melts upon heating while cooling very fast to harden, thereby providing very efficient bonding for different materials. Hot melt adhesive is considered to be one of the best adhesives since it does not require solvents or prolonged curing, generally resulting in a stable bond that is clean.

Its main characteristic is versatility. Hot melt adhesive can bond to all kinds of substrates: paper, wood, fabrics, plastics, and metals. It finds its utility in several industries such as packaging, woodworking, electronics, and crafting. Thanks to its strength and short setting time, it is especially useful in made-to-order and assembly-line operations.

The environmental and practical advantages of hot melt adhesives are always uttered in praise. The absence of water or solvent in their composition means little to no emissions of volatile organic compounds (VOCs), hence lessening their environmental impact and safety concerns at the time of use. They are easy to use and possess a long shelf life, making them a very convenient and sustainable alternative for almost any industrial or domestic application.

How a Hot Glue Gun Works

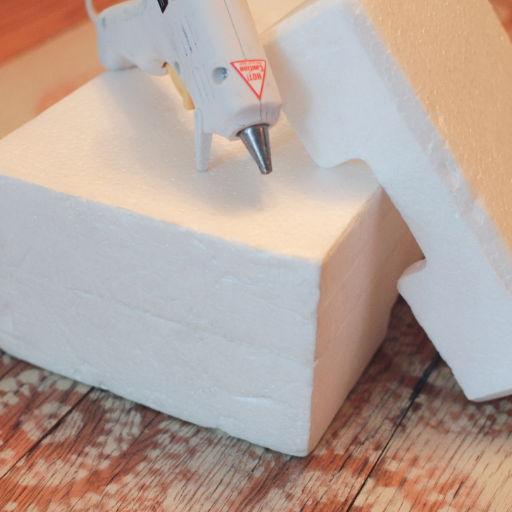

Essentially, the hot glue gun operates by heating solid glue sticks until the adhesive becomes liquid enough to be applied. Inside, an electrical heating element heats up the stick of glue once the gun is plugged in and switched on to the melting temperature. The melted glue is forced out from a nozzle as the user squeezes the trigger and pushes forward the glue stick. This molten glue solidifies pretty quickly after application and strongly bonds two materials.

The user first pushes a glue stick through the rear loading port going all the way to the front. The heating element is calibrated to keep the temperature right at the glue’s melting point, just warm enough not to incinerate the glue. Some glue guns feature a temperature adjustment function to allow users to increase or decrease heat with respect to glue stick type and materials being glued. Very user-friendly, the trigger mechanism gives the glue user controlled application to dispense just the glue needed, with no waste.

Hot glue guns are very versatile apparatuses used to bond various items such as wood, plastic, fabric, and paper. It is considered to be the basic glue used in different arts and crafts for instantaneous bond, and it comes handy in repair and industrial applications, as well. On account of the fact that the glue gets extremely hot, and the nozzle also gets hot during glue application, one must exercise some degree of caution. The very best way to ensure the tool works well and in safe operation manner is proper handling and keeping to the safety guidelines.

Advantages of Using Hot Glue for Foam

Hot glue is good in many ways for glueing foam, as it really sticks quickly and is very easy to apply. Unlike many adhesives which require longer drying times, hot glue bonds instantly to a million-pound fast working-away weightless foam having porous surfaces. This instant bonding ensures quick setting of glue, and pieces can be held immediately without using clamps or long drying times. Such a glue is great for crafts and sets-fast dry repairs alike.

Another major advantage of working with hot glue on foam is its versatility. It bonds well to many different types of foam, such as polystyrene, polyurethane, and memory foam, through an excellent and durable connection. Since it may also adhere to different surfaces, it may be used to bond foam with other things such as wood, fabric, or plastic. Also, the dried glue remains flexible, so it won’t create a stiff or brittle bond that could reject slight pressures and movements without cracking.

Lastly, hot glue is convenient and easy to handle for amateurs. Glue guns grant supply control of the adhesive and level control in eyeing the actual areas on the foam. Less mess is hot glue, meaning little to clean after when compared with some liquid adhesives. However, in order to achieve the best results, and as a matter of safety when dealing with foam, using a decent setting temperature and undertaking reasonable safety steps must be paramount. Adhering to these recommendations allows hot glue to be a very fulfilling and reliable substance for glue-related projects.

Foam Bonding with Hot Glue

Safe Application Techniques

⚠️ Safety First: Safety must come first in using hot glue on foam for successful bonding, avoiding damage to the foam, or injury to the user.

- Begin by selecting a glue gun with temperature control, since high heat may melt or deform the foam

- Low-temperature or dual-temperature glue guns are generally recommended for foam work to avoid damage

- Always test the glue on a small, hidden corner of the foam first

- Apply glue in small sections with even and gentle pressure

- Allow a little cooling time after dispensing before putting the foam into place

Make sure to take safety measures, such as wearing heat-proof gloves, to prevent possible burns on your hands. Always operate in an adequately ventilated room so that any fumes that develop are not inhaled. Also, make sure the glue gun is unplugged when not in use; otherwise, it may overheat and cause incidents. By following these simple yet effective safety measures, one can ensure smooth and trouble-free bonding of foam using hot glue.

Testing Hot Glue on Foam

The testing of hot glue on foam is necessary to ascertain its compatibility and efficacy. Begin by choosing a small inconspicuous area of the foam material to be tested. Put a small amount of hot glue and gently press it onto another foam surface. Watch out for any signs of melting, warping, or any sort of gross damage to the foam because of heat. This is a very important first step that helps determine if the foam being used can take the temperature of the hot glue.

Once the glue has cooled down and hardened, it is time to evaluate the strength of the bond between the pieces of foam. Try pulling the pieces asunder and observe if the glued site holds well. Strong gripping power of glue while being mild enough on the foam is an indication that hot glue is suitable for that type of foam. Otherwise, if it fails to bind or even damages the major surface, you will have to consider other kinds of adhesives meant for foam materials.

Are you noticing fumes or strong odors during the test? Intense fuming may indicate incompatibility or a possible health hazard. Ensure good ventilation when you work with adhesive materials. Observing all protocols, careful testing will help find the bonded solution best for your particular use, safely and with maximized efficiency.

Common Risks and Precautions

⚠️ Important Safety Information

Working with adhesives exposes one to many hazardous chemicals that may cause skin irritation, respiratory issues, or allergic reactions. In order to prevent chemicals from coming into direct contact with bare skin, protective gear such as gloves and masks must be worn. A well-ventilated environment is necessary to keep the build-up of toxic fumes at bay, for any time spent inhaling these fumes irritates the short run-a persistent problem in the long run.

Another risk-hazard posed by adhesives is accidental spills, leaks, or even fire hazards because of improper storage or handling. These adhesives should be stored in a cool, dry place away from direct sunlight or heat sources. To avoid the occurrence of spills as well as evaporation of volatile compounds, containers should be tightly sealed after every use. Above all, adhesives must be stored out of the reach of kids and animals so that they cannot be ingested or deliberately applied.

The most frequent errors with adhesives and their use include applying too much, or using the adhesive in a manner not consistent with instructions, leading to a weak bond, failure of the project, or damage to the materials in question. Read instructions that came with the adhesive carefully and make a test on an inconspicuous corner of the materials to ensure compatibility. With adequate knowledge about the risks and appropriate care, adhesives can be used effectively and safely for the projects in question.

Alternative Adhesives for Foam Projects

Foam-Specific Glues

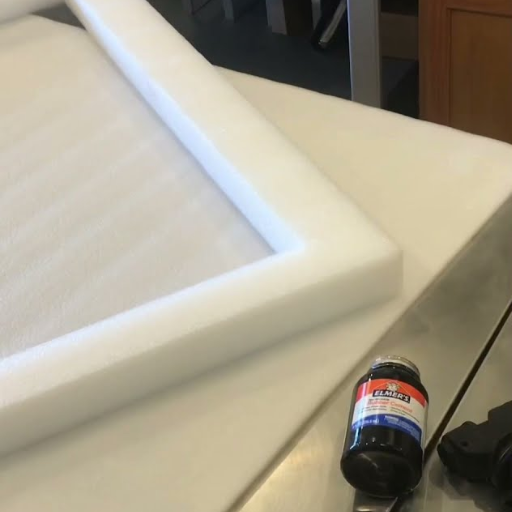

Foam-specific glues are specially formulated to provide strong bonds while protecting the delicate structure of foam materials. Unlike general-purpose adhesives, these glues are designed to make sure no chemical reaction occurs that turns the foam to somehow deteriorate or melt. Using a different adhesive could result in weakened adhesions or damage to foam, so it’s essential to use the appropriate glue for the foam project.

Some of the distinguishing features in these foam glues are that they provide firm yet flexible bonds. Most foam glues retain some slight amount of flexibility once they set, which is practically helpful for foam bonding because foam is soft and slightly compressible. The elasticity will help to prevent the bond from cracking or breaking up when the foam is subjected to force or movement.

Foam-specific glue should be bought after considering the kind of foam involved and the purpose the project serves. For example, some adhesives have higher preferences for open-cell foams than closed-cell varieties, and some just wouldn’t work at all in closed-cell variants. In addition to that, considerations of curing time, moisture resistance, and mode of application should be taken into account to benefit your foam project truly. Compatibility always tested beforehand on a small hidden area is a must-have guarantee that it would work as expected.

Double-Sided Tape for Foam Bonding

Double-sided tape is nice to have available as an easy solution for bonding foam materials practically. Some tapes may adhere well to open-cell foams and others do well with closed-cell ones, so the selection should take into consideration the nature of the two surfaces being joined. Most double-sided tapes with very high adhesion properties are ideal for lightweight foam applications or when temporary, semi-permanent, or semi-temporary coatings on foams are desired.

Choosing double-sided tape for foam bonding requires attention to a few important parameters: how well it bonds to the surfaces, its thickness, and its ability to interact well with the foam material. For example, thinner double-sided tapes normally bind better with smooth surfaces; thicker ones if the surface is rough and uneven. Furthermore, some of them are resistant to exposure to moisture, heat, and UV, which may prove critical on assemblies meant for outdoor use or subjected to heavy-duty criteria.

Before application, make sure to prepare the surface by cleaning, drying, and dusting or oil removal to give the best adhesion. Pressing hard helps the adhesive to activate, securing a good bond for interiors. For heavy-duty or load applications, it is best to test the tape first on a small hidden area to see if it works well on the particular foam in question.

When to Use Alternative Adhesives

Consider alternatives when:

- The primary adhesive cannot withstand UV rays or extreme temperatures

- Working with materials like plastic, metal, or textured surfaces

- Original adhesive strength is insufficient for the application

- Health and safety concerns with the original adhesive

- Environmental cleanliness requirements (medical or food-grade applications)

Alternative adhesives should be considered once the primary adhesive does not fit the specific requirements of your project. If the tape or adhesive adhesive in your use can never withstand the glare rays of the sun or extreme temperatures, never go for an alternative adhesive but always use one that is more suited for the conditions involved, or one must use another alternative adhesive. Also, the adhesives of one type may not work on materials like plastic, metal, or some textured surfaces, thus necessitating the alternative formulations.

Another reason why one may be forced to consider the use of alternative adhesives is when the original adhesive strength is not enough. For instances where there will be considerable stress exerted on the adhesives, like affixing heavy objects or the outdoor settings, higher durability and wear resistance should be necessary for the adhesives. Some alternatives, such as epoxy or construction adhesives, might actually require that strength and that long-lasting bond.

Last but not least, health-and-safety factors should come into consideration while choosing an adhesive. If the original adhesive creates strong fumes or contains potentially hazardous chemicals, an alternative that is non-toxic and environmentally friendly would serve better. In addition, the adhesives applied in environmental cleanliness-leaning firms require meeting requisite standards-e.g., medical or food-grade. Always analyze the project’s individual requisites and test, beforehand, to make sure that it performs well.

Creative DIY Applications

Decorative Projects with Foam and Glue

🎨 Creative Ideas

There is little limit to what can be done with glue and foam to achieve textures and designs for home décor, gifts, or personal crafts. Foam sheets, for instance, can be cut into different shapes: flowers, stars, or abstract patterns, to be glued on surfaces like picture frames, notebooks, or wall art to give that personal touch. Painted designs or glitter could complement these and create a more sophisticated look, making the end product really shine.

The other big project is making three-dimensional decorations out of foam blocks or molded shapes. Construct faux plants, ornaments, and little figurines by gluing foam bits together. This method generates lightweight decor that can be easily customized with paint, fabric, or embellishments. These are perfect projects to undertake for holiday décor or themed parties when creative designs can really look good in the festive atmosphere.

Foam can take on various density levels and thicknesses to create different patterns or geometric shapes. Layering foam in different densities and thicknesses will help to design more complicated patterns or geometric shapes. Gluing important in securing the independence if layering or in adhesion of vertical surfaces is involved. Such projects can do much in building the aesthetics of a room without going hard on investing in materials or time.

Using Foam in Costumes and Props

Foam is versatile in creating costumes and props due to its light weight and the ease with which it can be manipulated. It can be cut, formed, and painted to simulate many textures and materials, which would be appropriate for armor, weapons, or decorative costume elements. Because of its flexible nature, foam also lets creators bring very intricate ideas into realization without adding much weight, something that is important for comfort and utility while being worn for a long time.

Selection of the types and thicknesses of foam for the costuming and prop activities lies at the heart of being able to make proper use of foam. Usually, thin foam will be employed for intricate detailing, while thick foam will mostly be used in structural elements that need durability. Tools like craft knives and heat guns allow one to cut very exact shapes and smooth curves. Moreover, adhesives fill materials can serve to hide the seams, giving the item a clean, professional look.

Finishing treatments are excellent for making the foam pieces look pretty good. The foam is sealed with products such as primer, both to preserve it and to give it a surface to adhere to with paint. At this stage, one can apply various paints and weathering methods to gain a realistic or stylized look. Step out of this crashing water flow; these techniques on foam make fantastic costumes and props that interrupt the gallery and scream for attention.

Home Improvement Hacks with Foam Board

Depending on the glue’s temperature and the type of foam, hot glue may melt it. Most foams, such as expanded polystyrene (EPS), are heat sensitive and can deform or melt when exposed to high temperatures. Standard hot glue guns operate at temperatures that are often too high for delicate foam materials, causing damage or weakening the foam’s structure.

To glue foam with hot glue without harming it, use a low-temperature glue gun. The device puts out the adhesive at a lower heat setting so as not to melt or scorch the foam structure. Also, always glue test on a small, inconspicuous piece. This prevents accidental damage and helps you gauge glue compatibility with the foam.

Another option is using an adhesive that is safe for foam and is intended for crafts with foam. Also, one can select adhesives that do not require heat application, thereby grueling the bonds without risking any damage to the foam. Hence, your projects shall stay intact and elegant.

Frequently Asked Questions (FAQ)

Q: Is hot glue capable of melting foam?

A: Yes, hot glue will melt foam if it is the kind of foam that includes EPS or XPS. The usual high temperature of hot glue guns (approximately 380 degrees Fahrenheit or 193 degrees Celsius) is more than sufficient to melt these materials, hence creating a melted mess.

Q: What temperature is best to go with when really working with foam?

A: Use a low temperature heat wax glue gun when working with foam. These generally operate at about 250 degrees Fahrenheit (121 degrees Celsius) and represent a lesser chance to damage or melt foam materials.

Q: What glue is best to bond foam together with?

A: For bonding foams, PVA glue and low-temp hot melt glue are recommended. Both of these form a strong bond without melting the foam, therefore good for working with foam.

Q: Can I use a high temp glue gun on foam projects?

A: Using a high temp glue gun is not advisable for foam projects because the higher temperature can lead to melting or damaging the foam. Instead, opt for a low temp glue gun for better results.

Q: How do I prevent hot glue from melting my foam?

A: To prevent hot glue from melting foam, use a low-temperature hot melt glue gun and apply glue sparingly. It is also a good idea to check your method on scrap pieces of foam before beginning your project.

Q: What if I use super glue on foam?

A: It will work for quick bonding but may not be safe for your kind of foam as it might dissolve or disintegrate it depending on the type of foam. In that case, stick to foam-safe adhesives.

Q: Can sprayable hot melt glue be used on foam?

A: If you use the low-temperature variety, sprayable hot melt glue can be safe for foam. It provides an even coverage and prevents hot glue from melting the foam.

Q: What to do when the foam is melting from hot glue?

A: If your foam is melting from hot glue, stop applying the glue immediately and let the foam cool. If possible, opt for a lower temperature glue or any adhesive that is safe for foam on your next attempt.

Q: Can I put wood glue on foam?

A: One would generally not recommend wood glue for foam because it often does not provide the strong hold needed and can sometimes cause warping or damage to the foam. It is best to go with adhesives designed for foam material.

References

- Guide to Bonding Foam Using Hot Melt Adhesive – A detailed guide on using hot melt adhesives for foam bonding.

- Can I use a hot glue gun to glue XPS foam together? – A discussion on Reddit about the effects of hot glue on XPS foam.

- Bonding Foams With Hot Melt: Possible Or Impossible? – Insights into using low-temperature adhesives to avoid melting foam.

- What is the best glue to use when working with foam and why – A Quora thread discussing suitable adhesives for foam and their effects.

- Shop Glues for Foam – A collection of adhesives designed for foam, with notes on heat sensitivity.