For the proper choice of glue for Styrofoam, factors such as strength, longevity, and project success must be taken into consideration. The most frequently asked question between DIYers and experts is whether hot glue is a suitable option for bonding Styrofoam surfaces. As hot glue happens to be an adhesive that is favored chiefly and fast drying and used on a variety of materials, it’s not relatively as easy when it comes to fragile materials such as Styrofoam. This guide sheds light on the science behind gluing Styrofoam, examining the nature of hot glue, the associated risks, and the optimal scenarios for its use. By the time you finish reading this article, you will know if hot glue is workable with your Styrofoam project, glean some alternatives regarding adhesion, and have some killer tips for trustworthy results when working with this unusual material.

Understanding Styrofoam and Adhesives

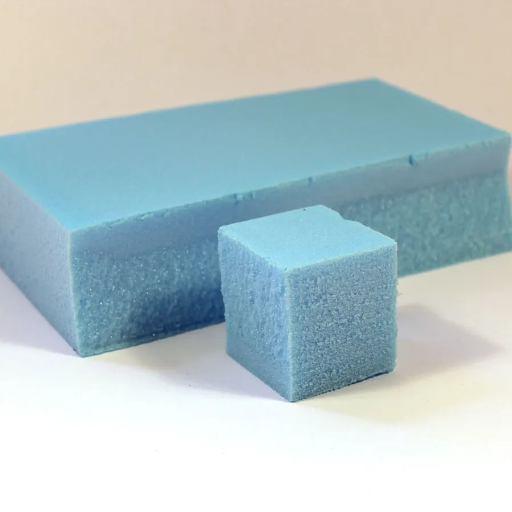

Styrofoam is a lightweight, porous material made of expanded polystyrene that tends to have a reactive surface chemistry. Thus, it is very important when working with the material concerning the choice of an adhesive. Not all glues are suitable for use with Styrofoam. Some adhesives with solvents will dissolve the Styrofoam or damage its structure. Hot glue is an adhesive used on Styrofoam but with great care. Making use of hot glue at a temperature will warp or even melt Styrofoam, seeing as the material has a very small melting point. When hot glue is utilized, it is advisable to apply it very thinly, preferably at a low temperature setting, or with glue sticks made for heat-sensitive materials. For better and stronger results, it is recommended that polyurethane glue, epoxy for Styrofoam, or double-sided tape be considered as adhesive options. In all cases, it is recommended to conduct a trial on a small piece of Styrofoam as a guarantee of the adhesive’s behavior and the material’s compatibility.

What is Styrofoam?

A handful of applications for Styrofoam, a generic name for extruded polystyrene foam, include construction, packaging, and crafts, among others. The choice of this material is due to its low weight and firmness, along with insulation from heat and moisture, making it highly desirable. Styrofoam consists primarily of polystyrene, a petroleum-based plastic polymer, being manufactured by a process that involves extrusion of molten polystyrene along with a blowing agent to produce a rigid foam-like product. Although it has numerous applications, it poses a significant downside of being non-biodegradable; therefore, landfill disposal of Styrofoam is a long-term source of hazardous pollution. Researchers and industry members alike continue to explore alternative materials and recycling solutions to address these issues.

Types of Adhesives for Styrofoam

|

Adhesive Type |

Key Features |

Suitable Applications |

Durability |

Notes |

|---|---|---|---|---|

|

Foam-Safe Cyanoacrylate |

Quick-drying, strong bond |

Crafts, prototypes |

High |

Requires proper ventilation |

|

Low-Temperature Hot Glue |

Safe for foam, easy application |

Model-making, decorations |

Medium |

Avoid high temperatures |

|

Spray Adhesives |

Even coverage, adjustable bond strength |

Large surfaces, insulation |

Medium |

Choose foam-compatible sprays |

|

Silicone-Based Adhesives |

Flexible, water-resistant |

Outdoor use, sealing edges |

High |

Longer curing time required |

|

Polystyrene Cement |

Chemical bond, very strong |

Scale models, precision work |

High |

Handle with care, flammable |

|

Acrylic-Based Adhesives |

Resistant to moisture and UV light |

Exterior insulation, signage |

High |

Excellent for harsh conditions |

|

Strong, durable adhesion |

Structural components |

High |

Prep involves mixing two parts |

|

|

Water-Based Adhesives |

Non-toxic, eco-friendly |

Arts and crafts, lightweight projects |

Low |

May lack strong bonding strength |

|

Polyurethane Adhesive |

Expands and fills gaps |

Construction foam boards |

High |

Apply sparingly to prevent excess |

How Hot Glue Interacts with Styrofoam

Hot gluing, an extremely versatile way to join numerous materials, treats Styrofoam in a unique and often tricky manner. Styrofoam, being an EPS, is pressure-sensitive to elevated temperatures due to its structural characteristics and composition. Considering that hot gluing requires temperatures of 200°F or higher from the moment beads of glue are laid, the elevated temperature of the adhesive could locally melt or deform the surface of Styrofoam, which would consequently alter the integrity of the material itself. Use of a low-temperature hot glue gun operating at a substantially reduced heat level minimizes the risk of damage. Low-temperature adhesives solidify almost immediately upon application and form a secure bond without subjecting the substrate to excessive heat. While Styrofoam is compatible with hot glue, this sort of bond strength could be questionable when the endurance of loads or prolonged stress is considered. Adhesives other than hot glue, such as epoxy resin or polyurethane, are better suited for applications that require greater durability or support.

Compatibility of Hot Glue with Styrofoam

The use of hot glue with Styrofoam is possible but only under some conditions. Low-temperature hot glue guns should be used since they prevent melting or deformation of the Styrofoam during application. The bond does hold, so it will suffice for lightweight, temporary applications, but it will not be strong enough for heavy-duty or permanent ones. When strength and durability are required in a project, epoxy resin or polyurethane adhesives present a better choice in accordance with durability and compatibility criteria.

Scientific Reasons Behind Adhesion

Molecular interaction flanked by different surfaces contributes to the occurrence of adhesion. The primary mechanism responsible for adhesion is mechanical interlocking combined with chemical bonding and intermolecular interaction, including van der Waals forces or hydrogen bonding. With mechanical interlocking, adhesive materials penetrate surface irregularities, thereby producing a physical anchoring effect. On the other hand, chemical bonding occurs when bonds form between the adhesive and the substrate; common types of bonds include covalent and ionic bonds, which provide the highest bond strength. Van der Waals forces are groups of very weak attractive forces arising from temporary dipoles in molecules that accentuate adhesion whenever chemical bonding is irrelevant.

Surface energy is also of great importance in the subject of adhesion. A material with high surface energy, such as metals, provides good adhesion because its adhesive can wet the surface properly, thereby maximizing the contact area and enhancing interaction. In contrast, a low surface energy material, such as polyethylene or polytetrafluoroethylene (PTFE), exhibits extreme adhesion difficulties and typically requires surface treatment, including plasma etching or chemical priming, to achieve compatibility. Temperature, humidity, and mechanical stress are all environmental circumstances that determine adhesion effectiveness. Stability and longevity might be affected by these factors. Therefore, having a grasp of these scientific concepts will enable one to ensure optimal performance of adhesives for various applications.

Potential Risks of Using Hot Glue

Despite its versatile uses and easy applications, hot glue presents risks that must be seriously assessed, particularly in technical or industrial applications. An incredible danger is thermal damage that can take place during application onto heat-affected materials such as thin plastics or certain fabrics, where the elevated temperature (250°F to 400°F, depending on glue formulations) may warp, melt, or degrade the surface. Furthermore, the hot glue fails if subjected to severe environmental conditions, comprising high moisture levels and significant temperature variations.

Alternative Glues for Styrofoam

When using alternative adhesives on Styrofoam, special consideration should be given to avoiding adhesives that may chemically damage the material. Conversely, water-based glues, i.e., white PVA glue, should be used to bond Styrofoam to porous surfaces like cardboard or paper. With a demand for greater strength and bonding to non-porous surfaces, silicone adhesives and other Styrofoam-safe adhesives, such as UHU Por or 3M Spray Adhesive, can also be used without the risk of chemical decomposition to the Styrofoam. These adhesives should mention Styrofoam compatibility so the adhesive can cause the least damage.

Best Glue Options for Styrofoam

Hot gluing is quite common for numerous types of craft projects, but the use of hot glue with Styrofoam still requires some considerations. The high temperature of the adhesive tends to melt sometimes and deform sometimes, standard hot glue and Styrofoam. For this reason, low-temperature hot glue guns that are meant for delicate materials may be used. These guns work at low levels of heat, which therefore reduces the chance of even slight degradation to the material while assuring reasonable bonding strength. Low-temp hot glue gives excellent results under all occasions when working with Styrofoam, especially in combination with materials like fabric, lightweight wood, or paperboard. For precise results, applying the glue to a small untreated portion first to check compatibility and adhesion is always best practice.

Specialty Adhesives Designed for Foam

Practical Tips for Working with Styrofoam

- Cutting Styrofoam Precisely

While using a styrofoam cutter or hot wire cutter for clean and precise cutting is wonderful, do not opt for dull blades—even styrofoam dislikes jagged edges and crumbling.

- Adhesion Best Practices

Select adhesives formulated explicitly for Styrofoam so as not to cause degradation of the material. Water-based adhesives, or those labeled as foam-safe, are the best choices.

- Painting Styrofoam

Water-based paints are great to coat Styrofoam; solvent-based ones are not, as they dissolve the material. Apply it in several thin coats for an even coat.

- Handling and Storage

Store the Styrofoam in a cool, dry area away from direct sunlight and heat sources to prevent evaporation and deterioration. Handle it gently to avoid dents and cracks.

- Environmental Considerations

Take the chance to recycle Styrofoam whenever you can, as it does not biodegrade. Keep track of the city recycling program for disposal alternatives.

Step-by-Step Guide to Gluing Styrofoam

- Choose the Appropriate Adhesive

Use any glue that is meant for polystyrene, namely foam-safe adhesives, polyurethane glues, or special epoxies. Solvent glues will chemically react with styrene and thus cause the melting or degradation of the styrofoam.

- Prepare the Surfaces

The styrofoam and whatever surface onto which it is to be attached must be clean and dry. Dirt, debris, or moisture can all weaken the bonding strength.

- Apply the Adhesive

Pour glue in thin, even layers on all surfaces to be fixed. For porous Styrofoam pieces, apply an initial coat of glue, allowing the glue to absorb better and cling.

- Join the Pieces

Carefully align Styrofoam pieces before pressing them together. When aligned, apply firm yet gentle pressure to affix firmly, ensuring even contact between glued surfaces.

- Allow for Curing Time

Follow the curing instructions provided by the manufacturer fully. Generally, cures require several hours to a day until adhesives reach maximum bond strength; therefore, do not disrupt glued joints before the adhesives have fully cured.

- Reinforce if Necessary

Solutions to Overcome Adhesive Issues

- Surface Preparation and Cleaning

Ensure all surfaces are free of contaminants, such as dust, grease, or moisture. Then, use a recommended cleaner, like isopropyl alcohol, suited to the materials of the substrate. In some situations, light mechanical abrasion, such as sanding, improves bonding by increasing surface roughness.

- Selection of Material-Specific Adhesives

Different materials require adhesives with properties tailored to their surface characteristics. For example, bonding non-porous surfaces, such as metals or plastics, often requires the use of epoxy-based or cyanoacrylate adhesives, whereas porous materials like wood may perform better with polyurethane or PVA adhesives. Refer to the manufacturer specifications to ensure compatibility and maximum bonding strength.

- Optimal Environmental Conditions

Temperature and humidity are more or less unwelcome guests that can interrupt curing and performance of adhesives. Whenever possible, induce adhesives within their specified temperature range; do not avoid extreme cold or high humid conditions that delay curing or weaken the bond. Controlled environments or adhesives with flexible environmental tolerances provide a good solution.

- Reinforcement Techniques

High-stress or load-bearing projects gain a great deal of structural reliability when adhesives are supported with mechanical anchors or reinforcements, screws, or rivets, or by brackets. This compromises stability if the product is under stress or undergoes any environmental changes.

- Testing and Quality Assurance

Small block tests in simulated conditions ought to be performed in advance, hence evaluating the performance of the adhesive. Expedient adjustments to subsequent procedures will result in more successful outcomes. Moreover, regular inspections over time may reveal weaknesses in bonds that could be reinforced or repaired in time.

Insights from Experts

Proper preparation of the surface before applying an adhesive is suggested as indispensable for maximum bonding strength. Contaminants like oil, dust, or moisture must never find their way on the substrate, as they tend to limit the proper functioning of adhesives. Also, with all these interventions, the adhesive selected must be the best fit for the considered materials and environmental requirements to prevent bond failure under stress or environment. manufacturer’s instructions for applied procedures and curing time must strictly be followed; otherwise, deviation would certainly compromise the bonding efficiency.

Professional Advice on Choosing the Right Glue

When selecting the appropriate glue for a project, it is essential to understand the distinct categories of adhesives and their specific use cases. For instance, cyanoacrylate adhesives, commonly known as super glues, provide rapid bonding and are ideal for non-porous materials like metal, plastic, and ceramics. Alternatively, epoxy resins stand out against their strength and durability for bonding load-bearing joints in industrial applications. PVA glues remain popular with woodworkers for bonding porous surfaces without reacting with or changing the surfaces.

Additionally, the temperature and atmosphere to which the bonded parts will be exposed must be taken into account. Structural adhesives like those based on epoxy or polyurethane are best for bonding tasks exposed to high temperatures or places with moisture, thanks to the excellent resistance the two adhesives provide to heat and water, respectively. On the contrary, hot-melt glues, though setting extremely fast, may lack the longevity needed for applications subject to high temperatures over time. The selection of adhesives is hence very important to guarantee a successful bond and initially create a verified, long-lasting product.

Real-Life Examples of Successful Projects

- Aircraft Composite Repairs Using Epoxy Adhesives

- Marine Applications with Polyurethane Adhesives

Polyurethane adhesives are used in the building and repair of boats and marine vessels. The bonds the adhesives make are durable enough to sustain resistance to water, salt, and temperature changes. One of the most iconic projects was the assembly of high-performance racing boats, wherein polyurethane sustained the joint integrity while allowing five different dynamics in a marine environment.

- Bridges and Infrastructure Reinforcement

Structural adhesives play a crucial role in modern construction work, particularly in the repair and reinforcement of aging infrastructure. For instance, some highway bridges have been rehabilitated by utilizing polymer-modified epoxies that provide adhesion under extreme load conditions and environmental stresses. This solution has, on one hand, greatly improved the operational life of important infrastructure and, on the other hand, minimized downtime during repair.

- Automotive Assembly Lines Adopting Hot-Melt Adhesives

Reference Sources

-

“Proper Insulated Materials for Temperature Accumulation in Box Technology”

- Key Findings: This study explores the use of foam-insulated boxes for heat retention in organic digestion processes. It highlights the thermal sensitivity of foam materials.

- Methodology: Experimental analysis of temperature retention in foam-insulated boxes.

- Read more

-

“The Development of CNC Hot Wire 3D Cutting Foam Tool”

- Key Findings: Focuses on cutting Styrofoam with precision using hot wire technology, addressing challenges in detailed and complex designs.

- Methodology: Development and testing of a CNC hot wire cutting tool.

- Read more

-

“Modified Mortars with the Polymers Addition for Thermal Insulation Systems of Polystyrene”

- Key Findings: Evaluates the effectiveness of Styrofoam as a thermal insulator compared to other materials like stone wool.

- Methodology: Comparative analysis of insulation materials in thermal systems.

- Read more

Frequently Asked Questions (FAQs)

Q: Will Hot Glue Work on Styrofoam?

A: Hot glue is often used for various crafting projects, including those involving styrofoam. It works great for attaching two pieces of styrofoam together due to its quick bonding capabilities. However, it’s essential to consider the temperature of the glue, as high-temperature hot glue can melt the foam, causing deformation. For a safer option, low-temp hot glue is recommended, as it can bond effectively without damaging the styrofoam. When using hot glue, ensure you apply the glue evenly and hold the pieces together for a few seconds to achieve a strong bond. If you’re unsure, always test a small area first to see how the styrofoam reacts.

Q: What Kind of Glue Works Best on Styrofoam?

A: When choosing the best kind of glue for styrofoam, it’s crucial to avoid glues that contain solvents, as these can damage the foam. Popular options include white glue, also known as school glue, and tacky glue, which provides a strong hold without melting the foam. For larger projects, you might consider using construction adhesive or a multipurpose adhesive like Weldbond or Elmer’s. If you’re looking for a quick bond, hot glue can work well, especially if you use low-temp varieties. Craft stores often carry specific styrofoam glue designed for arts and crafts, ensuring compatibility with the material.

Q: Can You Use Gorilla Glue on Styrofoam?

A: Gorilla glue is a strong adhesive that can bond various materials, but caution is needed when using it on styrofoam. While it can adhere well, it expands as it cures, which may cause the styrofoam to warp or become misshapen. If you choose to use Gorilla glue, apply it sparingly to prevent excessive expansion. For a safer alternative, consider using a glue designed specifically for styrofoam, such as contact cement or craft glue, which provides a reliable bond without damaging the material. Always read the instructions on the glue packaging to ensure it’s suitable for styrofoam use.

Q: How Do You Apply Glue to Styrofoam?

A: Applying glue to styrofoam requires a careful approach to ensure a strong bond without damaging the foam. Start by selecting the right kind of glue, such as low-temp hot glue or a dedicated styrofoam adhesive. To apply, consider using a toothpick or a small brush for precision, especially if you’re working on detailed projects. Spread an even layer of glue on both surfaces that need bonding and press them together firmly. If using hot glue, hold the pieces in place for a few seconds until the glue cools and sets. For larger pieces, you may want to use a clamp or weight to prevent movement while the glue cures.

Q: Is There Any Glue to Avoid on Styrofoam?

A: When working with styrofoam, it is crucial to avoid certain types of glue that can cause damage. Solvent-based adhesives, such as some types of epoxy, contact glue, and super glues, can melt the foam and compromise its structure. Additionally, avoid using hot glue with high-temperature settings, as it can easily melt the styrene material of styrofoam. Instead, opt for foam-safe adhesives like tacky glue, white glue, or specific styrofoam glue found in craft stores. Always test a small area if unsure about the glue’s safety on styrofoam to prevent any unwanted damage.